Cirkit Designer

Your all-in-one circuit design IDE

Home /

Project Documentation

Arduino-Controlled Robotic Vehicle with Flame Sensors and Air Pump

Circuit Documentation

Summary

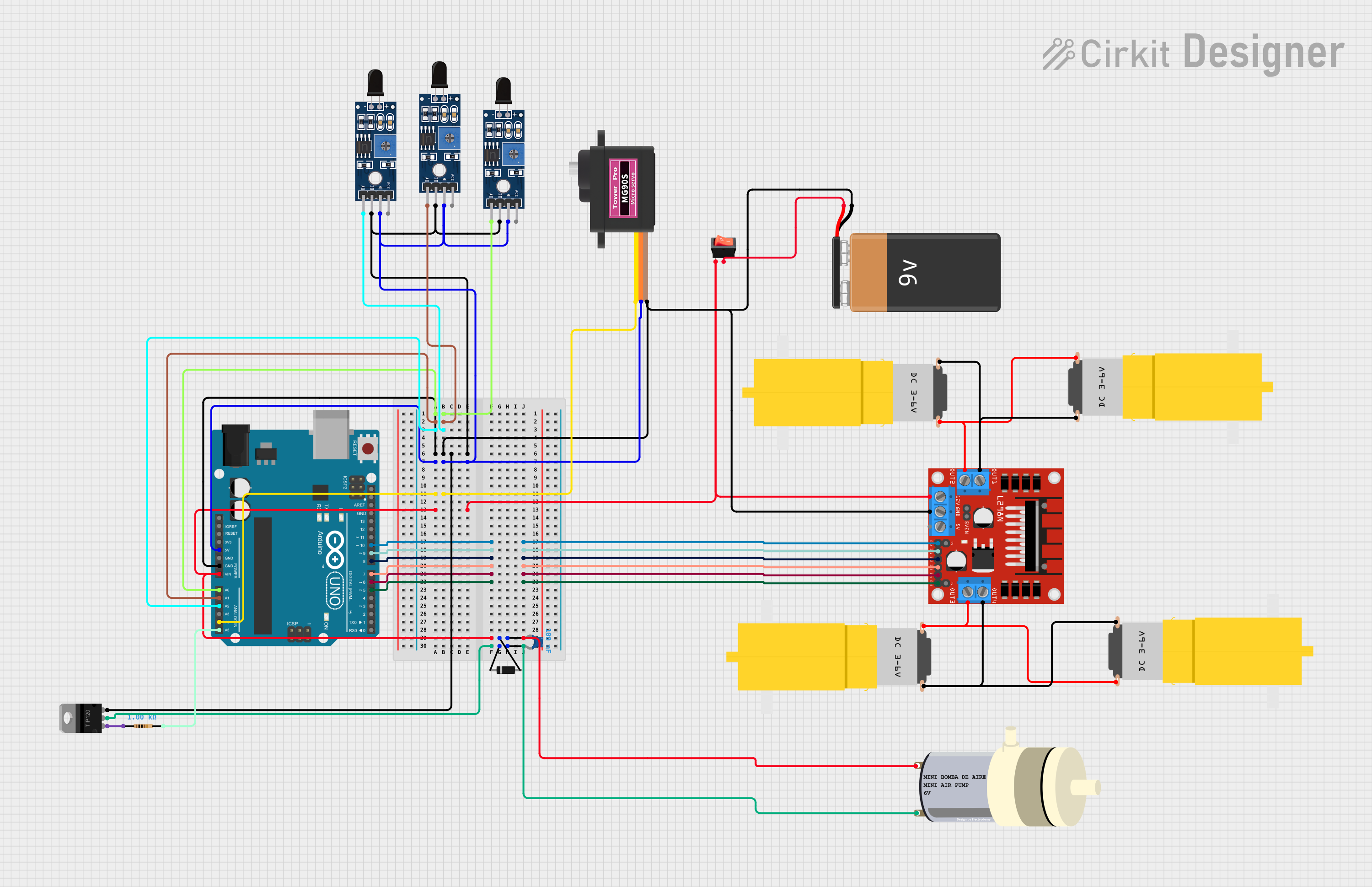

The circuit in question is designed to control a set of motors and a mini air pump, with inputs from flame sensors and a servo motor for directional control. The brain of the circuit is an Arduino UNO microcontroller, which processes sensor inputs and controls the actuators accordingly. The circuit includes a motor driver (L298N) to manage the high-current demands of the motors, and a Darlington transistor (TIP120) to control the mini air pump. Power is supplied by a 9V battery, and a rocker switch is used to turn the circuit on and off. A diode and a ceramic capacitor are included for protection and noise reduction.

Component List

- Motor Amarillo Motorreductor Hobby: A DC motor used for driving mechanisms.

- L298N DC Motor Driver: An integrated circuit used for controlling DC motors with direction and speed control.

- Mini Air Pump: A small pump used for air displacement.

- Sensor SHT113 Flame: A flame sensor used for detecting fire or flame presence.

- Arduino UNO: A microcontroller board based on the ATmega328P, used for controlling the logic of the circuit.

- 9V Battery: A standard 9V battery used as the power source for the circuit.

- Ceramic Capacitor: A capacitor used for noise reduction and voltage smoothing.

- Servomotor MG90S: A small servo motor used for precise control of angular position.

- Rocker Switch: A switch used to turn the circuit on and off.

- Diode: A component used to ensure current flows in only one direction, providing protection against reverse polarity.

- TIP120 Hi-Current Darlington Transistor: A transistor used for controlling high current loads.

- Resistor: A component used to limit current or divide voltages in the circuit.

Wiring Details

Motor Amarillo Motorreductor Hobby

- VCC: Connected to the output of the L298N motor driver.

- GND: Connected to the ground net of the circuit.

L298N DC Motor Driver

- OUT1, OUT2, OUT3, OUT4: Connected to the motors.

- 12V: Connected to the 9V battery through a rocker switch.

- GND: Connected to the ground net of the circuit.

- 5V: Not connected in this circuit.

- ENA, ENB: Connected to the Arduino UNO for speed control.

- IN1, IN2, IN3, IN4: Connected to the Arduino UNO for direction control.

Mini Air Pump

- PIN1, PIN2: Controlled by the TIP120 transistor and connected to the power supply through a diode and capacitor.

Sensor SHT113 Flame

- A0, D0: Connected to the analog pins of the Arduino UNO for flame detection.

- GND: Connected to the ground net of the circuit.

- VCC: Connected to the 5V output of the Arduino UNO.

Arduino UNO

- Digital and Analog Pins: Connected to various components for control and sensing.

- 5V, GND: Power supply for the sensors and servo motor.

- Vin: Connected to the 12V input of the L298N motor driver.

9V Battery

- +: Connected to the rocker switch.

- -: Connected to the ground net of the circuit.

Ceramic Capacitor

- Pin0, Pin1: Connected across the power supply of the mini air pump for noise reduction.

Servomotor MG90S

- SIG: Controlled by an analog pin of the Arduino UNO.

- VCC: Connected to the 5V output of the Arduino UNO.

- GND: Connected to the ground net of the circuit.

Rocker Switch

- Input: Connected to the positive terminal of the 9V battery.

- Output: Connected to the 12V input of the L298N motor driver.

Diode

- Anode: Connected to the positive terminal of the 9V battery.

- Cathode: Connected to the mini air pump and TIP120 transistor.

TIP120 Hi-Current Darlington Transistor

- BASE: Controlled by the Arduino UNO through a resistor.

- COLLECTOR: Connected to the mini air pump.

- EMITTER: Connected to the ground net of the circuit.

Resistor

- Pin1, Pin2: Connected between the Arduino UNO and the base of the TIP120 transistor to limit the base current.

Documented Code

#define enA 10 // Enable1 L298 Pin enA (Motor1 Speed Control)

#define in1 9 // Motor1 L298 Pin in1 (Motor1 Forward)

#define in2 8 // Motor1 L298 Pin in2 (Motor1 Backward)

#define in3 7 // Motor2 L298 Pin in3 (Motor2 Forward)

#define in4 6 // Motor2 L298 Pin in4 (Motor2 Backward)

#define enB 5 // Enable2 L298 Pin enB (Motor2 Speed Control)

#define ir_R A0 // Right Infrared sensor

#define ir_F A1 // Front Infrared sensor

#define ir_L A2 // Left Infrared sensor

#define servo A4 // Servo Motor pin

#define pump A5 // Pump control pin

int Speed = 160; // Duty Cycle (0 to 255) for motor speed control

int s1, s2, s3; // Variables to store sensor readings

void setup() {

Serial.begin(9600); // Start serial communication at 9600 bps

pinMode(ir_R, INPUT); // Set right sensor as input

pinMode(ir_F, INPUT); // Set front sensor as input

pinMode(ir_L, INPUT); // Set left sensor as input

pinMode(enA, OUTPUT); // Motor1 speed control

pinMode(in1, OUTPUT); // Motor1 forward

pinMode(in2, OUTPUT); // Motor1 backward

pinMode(in3, OUTPUT); // Motor2 forward

pinMode(in4, OUTPUT); // Motor2 backward

pinMode(enB, OUTPUT); // Motor2 speed control

pinMode(servo, OUTPUT); // Servo motor control

pinMode(pump, OUTPUT); // Pump control

// Initial servo movements

for (int angle = 90; angle <= 140; angle += 5) {

servoPulse(servo, angle);

}

for (int angle = 140; angle >= 40; angle -= 5) {

servoPulse(servo, angle);

}

for (int angle = 40; angle <= 95; angle += 5) {

servoPulse(servo, angle);

}

// Set initial motor speeds

analogWrite(enA, Speed); // Set Motor1 speed

analogWrite(enB, Speed); // Set Motor2 speed

delay(500);

}

void loop() {

s1 = analogRead(ir_R); // Read right sensor

s2 = analogRead(ir_F); // Read front sensor

s3 = analogRead(ir_L); // Read left sensor

// Display sensor readings on the serial monitor

Serial.print(s1); Serial.print("\t");

Serial.print(s2); Serial.print("\t");

Serial.println(s3);

delay(50);

// Automated control based on sensor input

if (s1 < 250) {

Stop();

digitalWrite(pump, 1);

for (int angle = 90; angle >= 40; angle -= 3) {

servoPulse(servo, angle);

}

for (int angle = 40; angle <= 90; angle += 3) {

servoPulse(servo, angle);

}

}

else if (s2 < 350) {

Stop();

digitalWrite(pump, 1);

for (int angle = 90; angle <= 140; angle += 3) {

servoPulse(servo, angle);

}

for (int angle = 140; angle >= 40; angle -= 3) {

servoPulse(servo, angle);

}

for (int angle = 40; angle <= 90; angle += 3) {

servoPulse(servo, angle);

}

}

else if (s3 < 250) {

Stop();

digitalWrite(pump, 1);

for (int angle = 90; angle <= 140; angle += 3) {

servoPulse(servo, angle);

}

for (int angle = 140; angle >= 90; angle -= 3) {

servoPulse(servo, angle);

}

}

else if (s1 >= 251 && s1 <= 700) {

digitalWrite(pump, 0);

backword();

delay(100);

turnRight();

delay(200);

}

else if (s2 >= 251 && s2 <= 800) {

digitalWrite(pump, 0);

forword();

}

else if (s3 >= 251 && s3 <= 700) {

digitalWrite(pump, 0);

back