Arduino Nano Controlled Gas Detection System with Servo Actuator and LCD Alert Display

Circuit Documentation

Summary

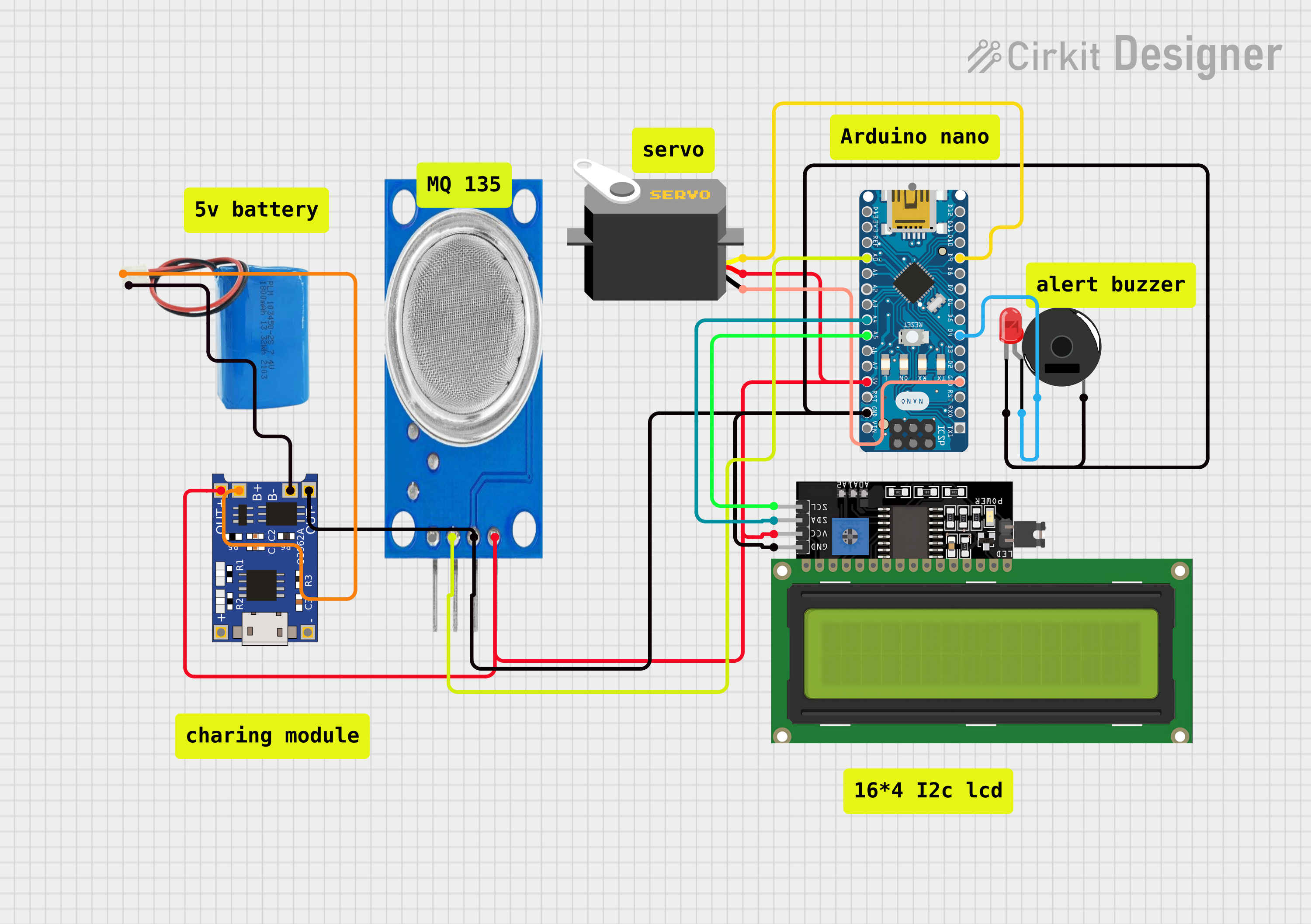

The circuit is designed to monitor gas levels using an MQ135 gas sensor and display the readings on an LCD display. If the gas level exceeds a certain threshold, a piezo buzzer is activated, and a servo motor is moved to a specific position as an alert mechanism. The system is controlled by an Arduino Nano microcontroller, which also manages the I2C communication with the LCD display. A TP4056 module is used for battery management, and a 5V battery provides the power supply.

Component List

Arduino Nano

- Microcontroller board based on the ATmega328P

- It has digital and analog I/O pins, and it is used as the central controller for the circuit.

Servo

- A motor that can be precisely controlled for angular position

- Used to perform a physical action when a certain gas level is detected.

MQ135 Gas Sensor

- A sensor for detecting a wide range of gases, including NH3, NOx, alcohol, benzene, smoke, and CO2.

- Used to monitor the gas levels in the environment.

Piezo Buzzer

- An electronic device that emits a tone when it is driven by an electrical signal.

- Used as an audible alert when a certain gas level is detected.

LED: Two Pin (red)

- A basic red light-emitting diode.

- Used as a visual indicator in the circuit.

LCD Display 16x4 I2C

- An alphanumeric liquid crystal display with an I2C interface.

- Used to display the gas level readings and alert messages.

TP4056

- A lithium battery charge management and protection module.

- Used for charging the battery and protecting the circuit from overcurrent conditions.

5v Battery

- A power source for the circuit.

- Provides the necessary voltage for the circuit operation.

Wiring Details

Arduino Nano

GNDconnected to the ground net, which includes the Servo (gnd), MQ135 (GND), Piezo Buzzer (pin 2), LED (cathode), LCD Display (GND), and TP4056 (OUT-).D4connected to the anode of the LED and pin 1 of the Piezo Buzzer.D9connected to the pulse pin of the Servo.5Vconnected to the power net, which includes the VCC of the Servo, MQ135 (VCC), and LCD Display (VCC).A5connected to the SCL pin of the LCD Display.A4connected to the SDA pin of the LCD Display.A0connected to the A0 pin of the MQ135 Gas Sensor.

Servo

gndconnected to the ground net.vccconnected to the power net.pulseconnected toD9on the Arduino Nano.

MQ135 Gas Sensor

GNDconnected to the ground net.VCCconnected to the power net.A0connected toA0on the Arduino Nano.

Piezo Buzzer

pin 1connected toD4on the Arduino Nano.pin 2connected to the ground net.

LED: Two Pin (red)

cathodeconnected to the ground net.anodeconnected toD4on the Arduino Nano.

LCD Display 16x4 I2C

GNDconnected to the ground net.VCCconnected to the power net.SCLconnected toA5on the Arduino Nano.SDAconnected toA4on the Arduino Nano.

TP4056

OUT-connected to the ground net.OUT+connected to the power net.B-connected to the negative pin of the 5v Battery.B+connected to the positive pin of the 5v Battery.

5v Battery

negativeconnected toB-on the TP4056.positiveconnected toB+on the TP4056.

Documented Code

#include <Servo.h>

#include <LiquidCrystal_I2C.h>

LiquidCrystal_I2C lcd(0x27,16,2);

const int gasSensorPin = A0; // Analog pin connected to the MQ2 gas sensor

const int buzzer = 4; // Digital pin connected to the buzzer

const int servoPin = 9; // Digital pin connected to the servo

const int gasThreshold = 400; // Threshold value for gas detection (adjust based on your testing)

Servo myServo; // Create servo object to control a servo

bool servoMoved = false; // Flag to check if the servo has already moved

void setup() {

pinMode(gasSensorPin, INPUT);

pinMode(buzzer, OUTPUT);

myServo.attach(servoPin);

myServo.write(0); // Initial position of the servo

Serial.begin(9600); // Initialize serial communication for debugging

}

void loop() {

int analogSensor = analogRead(gasSensorPin);

int gasvalue = (analogSensor - 50) / 35; // Gas module sensitivity

lcd.setCursor(0,0);

lcd.print("GAS Level:");

lcd.setCursor(10,0);

lcd.print(gasvalue);

lcd.setCursor(12,0);

lcd.print("%");

// Checks if it has reached the threshold value

if (gasvalue > gasThreshold && !servoMoved) { // Gas percentage alert

digitalWrite(buzzer, HIGH); // Turn on the buzzer

delay(2000); // Beep for 2 seconds

digitalWrite(buzzer, LOW); // Turn off the buzzer

myServo.write(75); // Rotate the servo to 90 degrees

servoMoved = true; // Set the flag to indicate the servo has moved

lcd.setCursor(0,1);

lcd.print("DANGER");

lcd.setCursor(1,1);

lcd.print("auto reg off");

tone(buzzer, 1000, 10000);

} else {

lcd.setCursor(0,1);

lcd.print("NORMAL");

noTone(buzzer);

}

delay(1000);

lcd.clear();

}

This code is responsible for reading the gas level from the MQ135 sensor, displaying the value on the LCD, and triggering the buzzer and servo motor when the gas level exceeds the threshold. The LCD displays the current gas level percentage and shows a "DANGER" message along with turning off the regulator when the threshold is crossed. The servo moves to a 75-degree position as part of the alert mechanism.