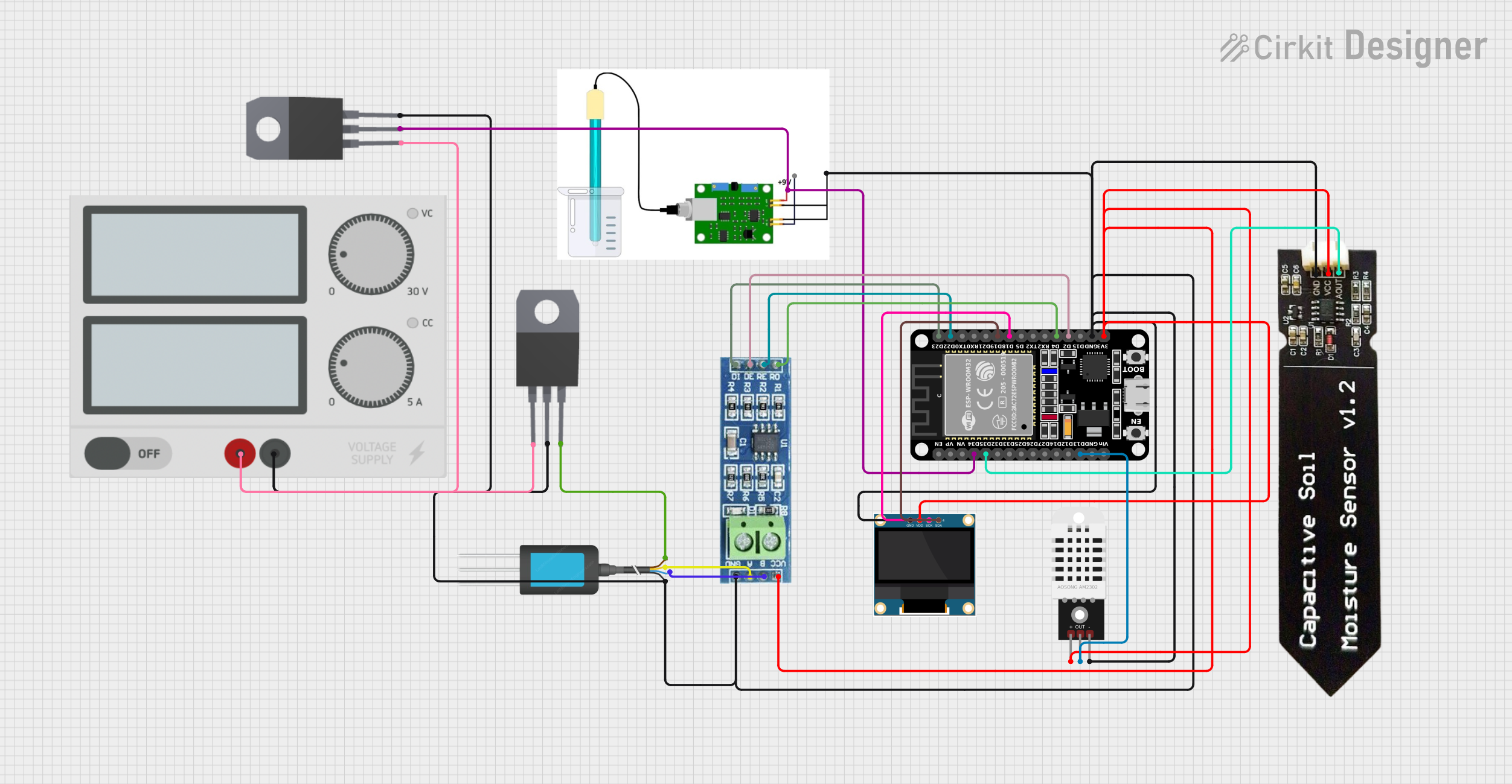

ESP32-Based Smart Agriculture Monitoring System with RS485 Communication

Circuit Documentation

Summary

The circuit in question is designed to interface various sensors and modules with an ESP32 microcontroller for the purpose of monitoring environmental parameters. The sensors include a DHT22 for temperature and humidity, a pH sensor for measuring the acidity or alkalinity of a solution, an NPK soil sensor for detecting the levels of nitrogen, phosphorus, and potassium in soil, and a capacitive soil moisture sensor. Additionally, an RS485 transceiver is used for long-distance communication, and a 0.96" OLED display is included for data visualization. The circuit is powered by a power supply unit, and voltage regulation is provided by two 7808 voltage regulators.

Component List

DHT22

- Temperature and humidity sensor

- Pins:

+,Out,-

pH Sensor

- Sensor for measuring the acidity or alkalinity of a solution

- Pins:

+9volt,output pin,GND

NPK Soil Sensor

- Sensor for detecting the levels of nitrogen, phosphorus, and potassium in soil

- Pins:

12V DC,A,B,GND

ESP32 (30 pin)

- Microcontroller with WiFi and Bluetooth capabilities

- Pins:

EN,VP,VN,D34,D35,D32,D33,D25,D26,D27,D14,D12,D13,GND,Vin,D23,D22,TX0,RX0,D21,D19,D18,D5,TX2,RX2,D4,D2,D15,3V3

Capacitive Soil Moisture Sensor V1.2

- Sensor for measuring the moisture content in soil

- Pins:

GND,VCC,AOUT

RS485 Transceiver

- Module for long-distance communication

- Pins:

VCC,RO,RE,GND,B,A,DE,DI

0.96" OLED Display

- Small display for data visualization

- Pins:

GND,VDD,SCK,SDA

7808 Voltage Regulator

- Provides regulated +8V output

- Pins:

INPUT,GND,OUTPUT

Power Supply

- Provides power to the circuit

- Pins:

+,-

Wiring Details

DHT22

+to ESP323V3Outto ESP32D13-to GND

pH Sensor

+9voltto ESP32D34output pin(not connected)GNDto GND

NPK Soil Sensor

12V DCto 7808OUTPUTAto RS485ABto RS485BGNDto GND

ESP32 (30 pin)

D34to pH Sensor+9voltD35to Capacitive Soil Moisture SensorAOUTD13to DHT22OutD23to RS485DID22to RS485RED19to OLEDSDAD18to OLEDSCKD4to RS485ROD2to RS485DE3V3to DHT22+, Capacitive Soil Moisture SensorVCC, RS485VCC, OLEDVDDGNDto GND

Capacitive Soil Moisture Sensor V1.2

AOUTto ESP32D35VCCto ESP323V3GNDto GND

RS485 Transceiver

DIto ESP32D23REto ESP32D22ROto ESP32D4DEto ESP32D2Ato NPK Soil SensorABto NPK Soil SensorBVCCto ESP323V3GNDto GND

0.96" OLED Display

GNDto GNDVDDto ESP323V3SCKto ESP32D18SDAto ESP32D19

7808 Voltage Regulator

INPUTto Power Supply+GNDto GNDOUTPUTto NPK Soil Sensor12V DC

Power Supply

+to 7808INPUT-to GND

Ground Connections

All GND pins are interconnected and connected to the Power Supply -.

Code Documentation

No code has been provided for the microcontrollers in the circuit. When code is available, it should be documented here with explanations for each function and routine, including setup and loop functions for the ESP32 microcontroller, as well as any interrupt service routines or peripheral configurations.

Please note that the above documentation is based on the provided information and assumes that the circuit is correctly designed for the intended functionality. It is recommended to review the actual circuit and test it to ensure that it operates as expected.