Cirkit Designer

Your all-in-one circuit design IDE

Home /

Project Documentation

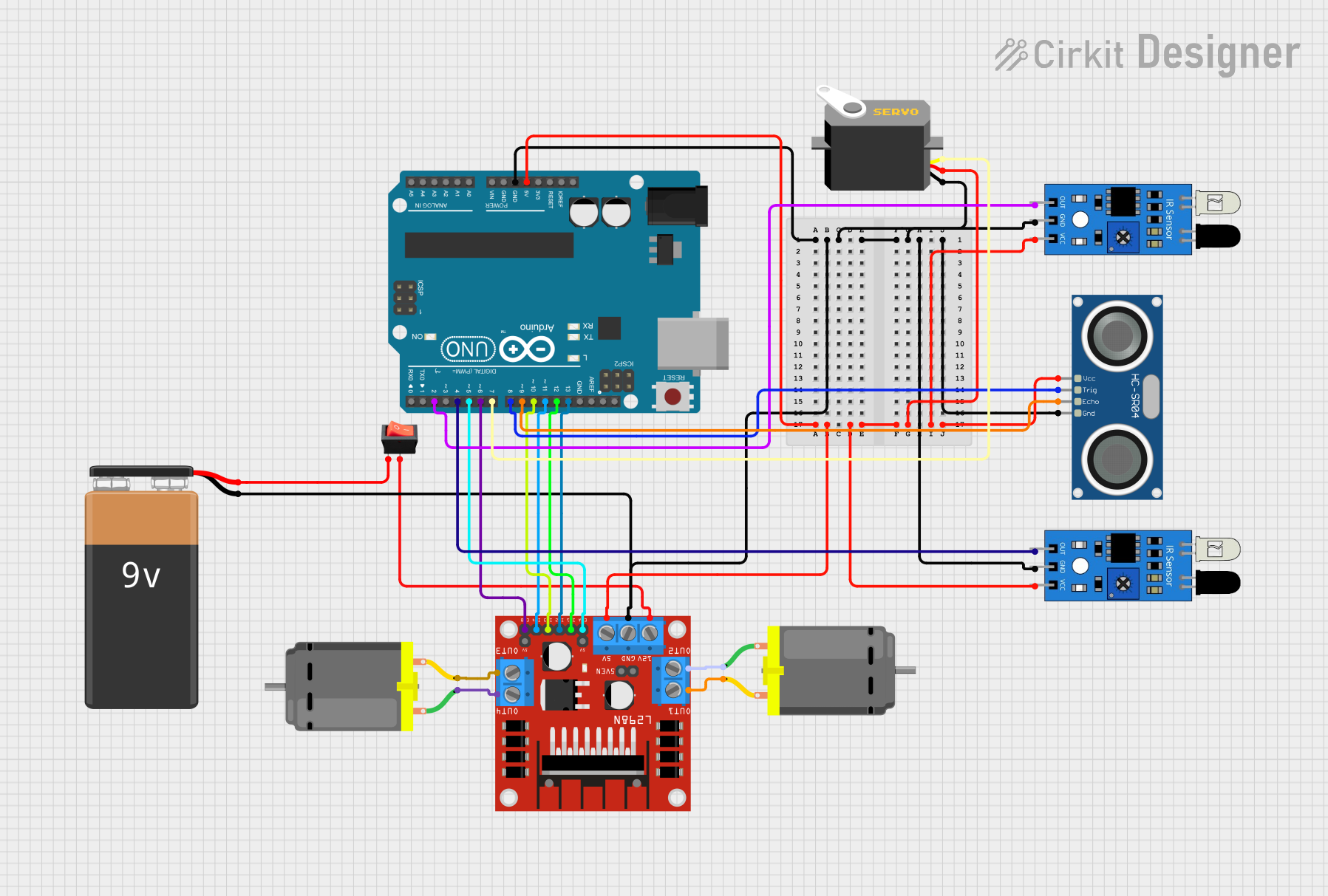

Arduino-Controlled Robotics Platform with Ultrasonic and IR Sensing

Circuit Documentation

Summary

This circuit is designed to interface an Arduino UNO with various sensors and actuators, including ultrasonic sensors (HC-SR04), infrared sensors, a servo motor, DC motors, and a motor driver (L298N). The circuit is powered by a 9V battery, which is controlled by a rocker switch. The Arduino UNO is used as the central processing unit, reading sensor inputs and controlling the actuators based on the programmed logic.

Component List

HC-SR04 Ultrasonic Sensor

- Pins: VCC, TRIG, ECHO, GND

- Description: This sensor is used to measure distance by emitting ultrasonic waves and measuring the time taken for the echo to return.

Arduino UNO

- Pins: UNUSED, IOREF, Reset, 3.3V, 5V, GND, Vin, A0-A5, SCL, SDA, AREF, D0-D13

- Description: The Arduino UNO is a microcontroller board based on the ATmega328P. It is the main controller used to process inputs and outputs in the circuit.

IR Sensor

- Pins: out, gnd, vcc

- Description: Infrared sensors are used to detect obstacles or measure distances using infrared light.

Rocker Switch

- Pins: output, input

- Description: A rocker switch is used to control the power supply to the circuit.

9V Battery

- Pins: -, +

- Description: Provides the power source for the circuit.

DC Motor

- Pins: pin 1, pin 2

- Description: Electric motors that convert electrical energy into mechanical motion.

L298N DC Motor Driver

- Pins: OUT1, OUT2, 12V, GND, 5V, OUT3, OUT4, 5V-ENA-JMP-I, 5V-ENA-JMP-O, +5V-J1, +5V-J2, ENA, IN1, IN2, IN3, IN4, ENB

- Description: A motor driver module that allows for control of the speed and direction of two DC motors.

Servo

- Pins: gnd, vcc, pulse

- Description: A rotary actuator or linear actuator that allows for precise control of angular or linear position.

Wiring Details

HC-SR04 Ultrasonic Sensor

- VCC: Connected to 5V power supply.

- TRIG: Connected to Arduino UNO pin D8.

- ECHO: Connected to Arduino UNO pin D9.

- GND: Connected to the common ground.

Arduino UNO

- 5V: Provides power to the HC-SR04 Ultrasonic Sensor, IR sensors, and L298N motor driver.

- GND: Common ground for all components.

- D8: Connected to HC-SR04 TRIG pin.

- D9: Connected to HC-SR04 ECHO pin.

- D4, D2: Connected to IR sensor output pins.

- D5, D6: Connected to L298N motor driver ENA and ENB pins for enabling motor control.

- D7: Connected to Servo pulse pin.

- D10-D13: Connected to L298N motor driver IN1-IN4 pins for motor direction control.

IR Sensor

- out: Connected to Arduino UNO pins D4 and D2 for two IR sensors.

- gnd: Connected to the common ground.

- vcc: Connected to 5V power supply.

Rocker Switch

- input: Connected to the positive terminal of the 9V Battery.

- output: Connected to the 12V input of the L298N motor driver.

9V Battery

- -: Connected to the common ground.

- +: Connected to the input of the rocker switch.

DC Motor

- pin 1, pin 2: Connected to L298N motor driver OUT1, OUT2 for one motor and OUT3, OUT4 for the other motor.

L298N DC Motor Driver

- OUT1, OUT2, OUT3, OUT4: Connected to DC motor pins.

- 12V: Connected to the output of the rocker switch.

- GND: Connected to the common ground.

- 5V: Connected to 5V power supply.

- ENA, ENB: Connected to Arduino UNO pins D5 and D6 for enabling motor control.

- IN1-IN4: Connected to Arduino UNO pins D10-D13 for motor direction control.

Servo

- gnd: Connected to the common ground.

- vcc: Connected to 5V power supply.

- pulse: Connected to Arduino UNO pin D7.

Documented Code

// Arduino UNO Code for the Circuit

// Filename: sketch.ino

// Define pin connections & motor speed variables

const int trigPin = 8;

const int echoPin = 9;

const int irSensor1 = 4;

const int irSensor2 = 2;

const int motorPin1 = 12;

const int motorPin2 = 13;

const int motorPin3 = 11;

const int motorPin4 = 10;

const int servoPin = 7;

const int motorSpeed = 255; // Max speed

// Setup function runs once at the start of the program

void setup() {

// Initialize all the motor control pins as outputs

pinMode(motorPin1, OUTPUT);

pinMode(motorPin2, OUTPUT);

pinMode(motorPin3, OUTPUT);

pinMode(motorPin4, OUTPUT);

// Initialize the servo control pin as an output

pinMode(servoPin, OUTPUT);

// Initialize the IR sensor pins as inputs

pinMode(irSensor1, INPUT);

pinMode(irSensor2, INPUT);

// Initialize the ultrasonic sensor pins

pinMode(trigPin, OUTPUT);

pinMode(echoPin, INPUT);

// Begin serial communication at a baud rate of 9600

Serial.begin(9600);

}

// Loop function runs repeatedly after setup function

void loop() {

// Implement sensor reading and motor control logic here

// ...

}

Please note that the provided code is a template and does not contain the actual logic for reading sensors or controlling motors. The user should implement the specific logic based on the requirements of their application.