Arduino UNO Controlled Line Following Robot with L298N Motor Driver and IR Sensors

Circuit Documentation

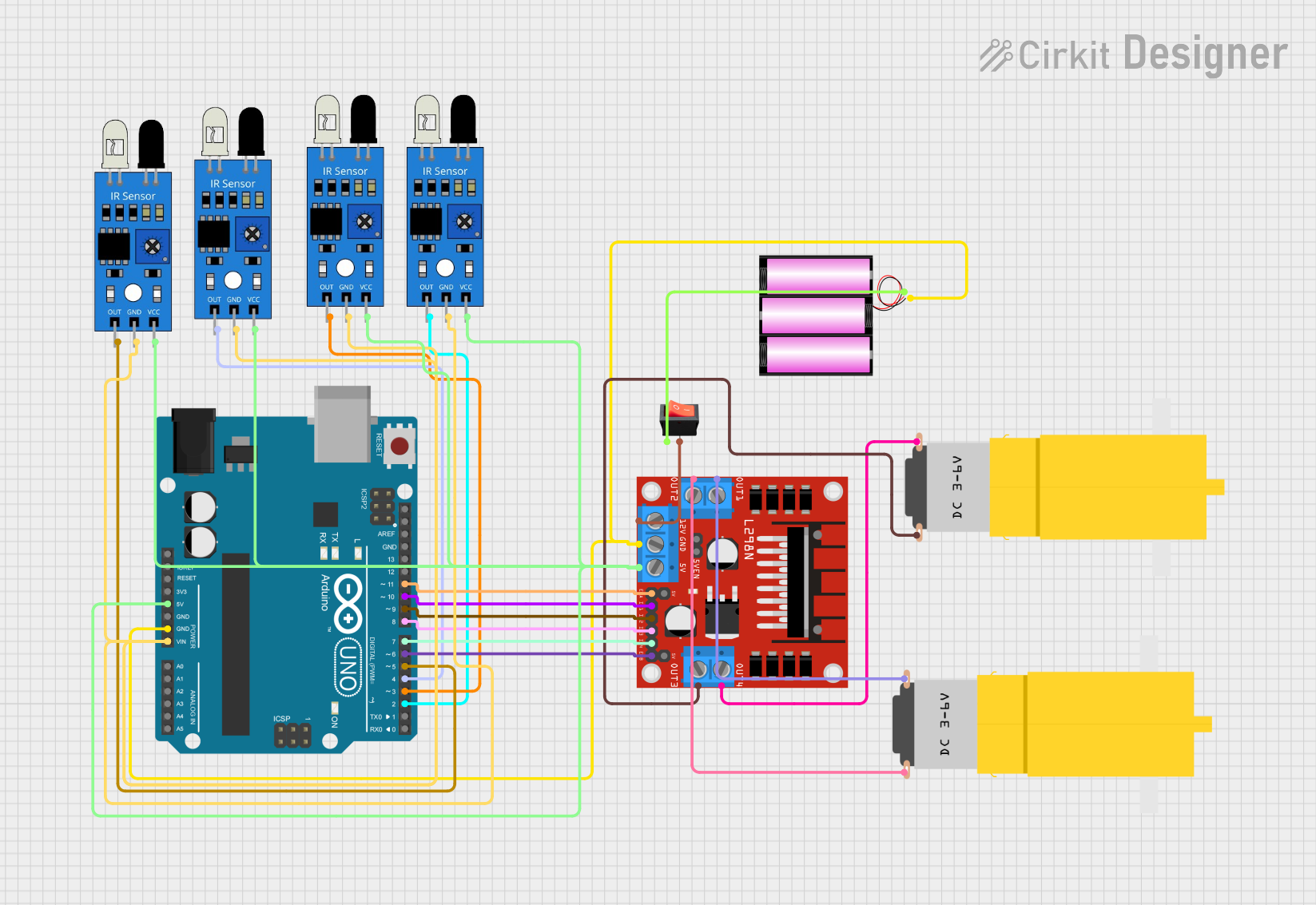

Summary of the Circuit

This circuit is designed to control a robot with two DC motors using an Arduino UNO as the main controller. The robot's path is determined by an array of four IR sensors that detect the presence of a line on the ground. The Arduino UNO reads the sensors' outputs and adjusts the motors' speeds using a PID control loop to keep the robot aligned with the line. The motors are driven by an L298N DC motor driver, which receives power from a 12V battery. A rocker switch is used to control the power supply to the motor driver.

Component List

Arduino UNO

- Microcontroller board based on the ATmega328P

- Used for reading IR sensor data and controlling the motor driver

IR Sensors (4x)

- Infrared sensors used for line detection

- Provide digital output to the Arduino UNO

L298N DC Motor Driver

- Dual H-bridge motor driver

- Controls the direction and speed of two DC motors

Battery 12V

- Provides power to the motor driver and the Arduino UNO

Motors (2x)

- DC motors used to drive the robot's wheels

Rocker Switch

- Controls the power supply from the battery to the motor driver

Wiring Details

Arduino UNO

5Vconnected to the5Vpower rail supplying the IR sensors and the L298N motor driverGNDconnected to the ground rail, which is also connected to the battery's negative terminal- Digital pins

D2toD11are used to interface with the IR sensors and the motor driver

IR Sensors

vccpins connected to the5Vpower railgndpins connected to the ground railoutpins connected to the Arduino UNO's digital pinsD2toD5

L298N DC Motor Driver

5Vconnected to the5Vpower railGNDconnected to the ground rail12Vconnected to the rocker switch's outputENAandENBconnected to Arduino UNO's digital pinsD11andD6for speed controlIN1toIN4connected to Arduino UNO's digital pinsD10toD7for direction controlOUT1toOUT4connected to the motors

Battery 12V

+connected to the rocker switch's input-connected to the ground rail

Motors

- One motor's

vccandGNDconnected toOUT1andOUT2of the motor driver - The other motor's

vccandGNDconnected toOUT3andOUT4of the motor driver

Rocker Switch

inputconnected to the battery's+terminaloutputconnected to the12Vinput of the motor driver

Documented Code

// Pin definitions for 4-channel IR sensor array

#define IR_SENSOR1 A5 // Left-most sensor

#define IR_SENSOR2 A4 // Left-middle sensor

#define IR_SENSOR3 A3 // Right-middle sensor

#define IR_SENSOR4 A2 // Right-most sensor

// Motor driver pin definitions

#define ENA 3 // Speed control for left motor

#define ENB 9 // Speed control for right motor

#define IN1 4 // Right motor backward

#define IN2 5 // Right motor forward

#define IN3 6 // Left motor backward

#define IN4 7 // Left motor forward

// Motor speed settings

int baseSpeed = 200; // Base speed for motors

int maxSpeed = 255; // Max motor speed

// PID control variables

float Kp = 65; // Proportional constant

float Ki = 0.0084; // Integral constant

float Kd = 7.9; // Derivative constant

float previousError = 0; // Store last error for derivative calculation

float integral = 0; // Integral sum

int threshold = 400; // Threshold for line detection (adjust as needed)

void setup() {

// Motor driver pins

pinMode(ENA, OUTPUT);

pinMode(ENB, OUTPUT);

pinMode(IN1, OUTPUT);

pinMode(IN2, OUTPUT);

pinMode(IN3, OUTPUT);

pinMode(IN4, OUTPUT);

// Begin serial monitor (optional for debugging)

Serial.begin(9600);

}

void botLoop() {

// Read analog values from sensors

int sensor1 = analogRead(IR_SENSOR1);

int sensor2 = analogRead(IR_SENSOR2);

int sensor3 = analogRead(IR_SENSOR3);

int sensor4 = analogRead(IR_SENSOR4);

// Calculate position based on sensor readings

int position = (sensor1 > threshold ? -3 : 0) + (sensor2 > threshold ? -1 : 0) +

(sensor3 > threshold ? 1 : 0) + (sensor4 > threshold ? 3 : 0);

// Calculate error (0 means center, negative for left, positive for right)

float error = position * -1;

// PID calculations

integral += error; // Accumulate the integral

float derivative = error - previousError; // Calculate the difference for derivative

previousError = error; // Store current error for next loop

// PID output to adjust motor speeds

float correction = Kp * error + Ki * integral + Kd * derivative;

// Calculate motor speeds with PID correction

int leftSpeed = baseSpeed + correction;

int rightSpeed = baseSpeed - correction;

// Constrain speeds to motor limits

leftSpeed = constrain(leftSpeed, (-3 * maxSpeed), maxSpeed);

rightSpeed = constrain(rightSpeed, (-3 * maxSpeed), maxSpeed);

// Print left motor speed only for Serial Plotter

Serial.println(leftSpeed);

// Move the motors

moveForward(leftSpeed, rightSpeed);

}

void loop() {

botLoop();

delay(10);

}

void moveForward(int leftSpeed, int rightSpeed) {

if (leftSpeed > 0) {

digitalWrite(IN3, HIGH); // Left motor forward

digitalWrite(IN4, LOW); // Left motor backward

} else {

digitalWrite(IN3, LOW); // Left motor forward

digitalWrite(IN4, HIGH); // Left motor backward

}

if (rightSpeed > 0) {

digitalWrite(IN1, LOW); // Right motor forward

digitalWrite(IN2, HIGH); // Right motor backward

} else {

digitalWrite(IN1, HIGH); // Right motor forward

digitalWrite(IN2, LOW); // Right motor backward

}

analogWrite(ENA, abs(rightSpeed));

analogWrite(ENB, abs(leftSpeed));

}

void stopMotors() {

digitalWrite(IN1, LOW);

digitalWrite(IN2, LOW);

digitalWrite(IN3, LOW);

digitalWrite(IN4, LOW);

analogWrite(ENA, 0);

analogWrite(ENB, 0);

}

This code is responsible for reading the IR sensor values, calculating the position of the line, and adjusting the motor speeds accordingly using a PID control loop. The moveForward function controls the direction and speed of the motors, while the stopMotors function halts all motor activity. The botLoop function is the main loop that executes the PID control and motor movement logic.