Wireless Multi-Motor Drone Control System with Video Streaming

Circuit Documentation

Summary

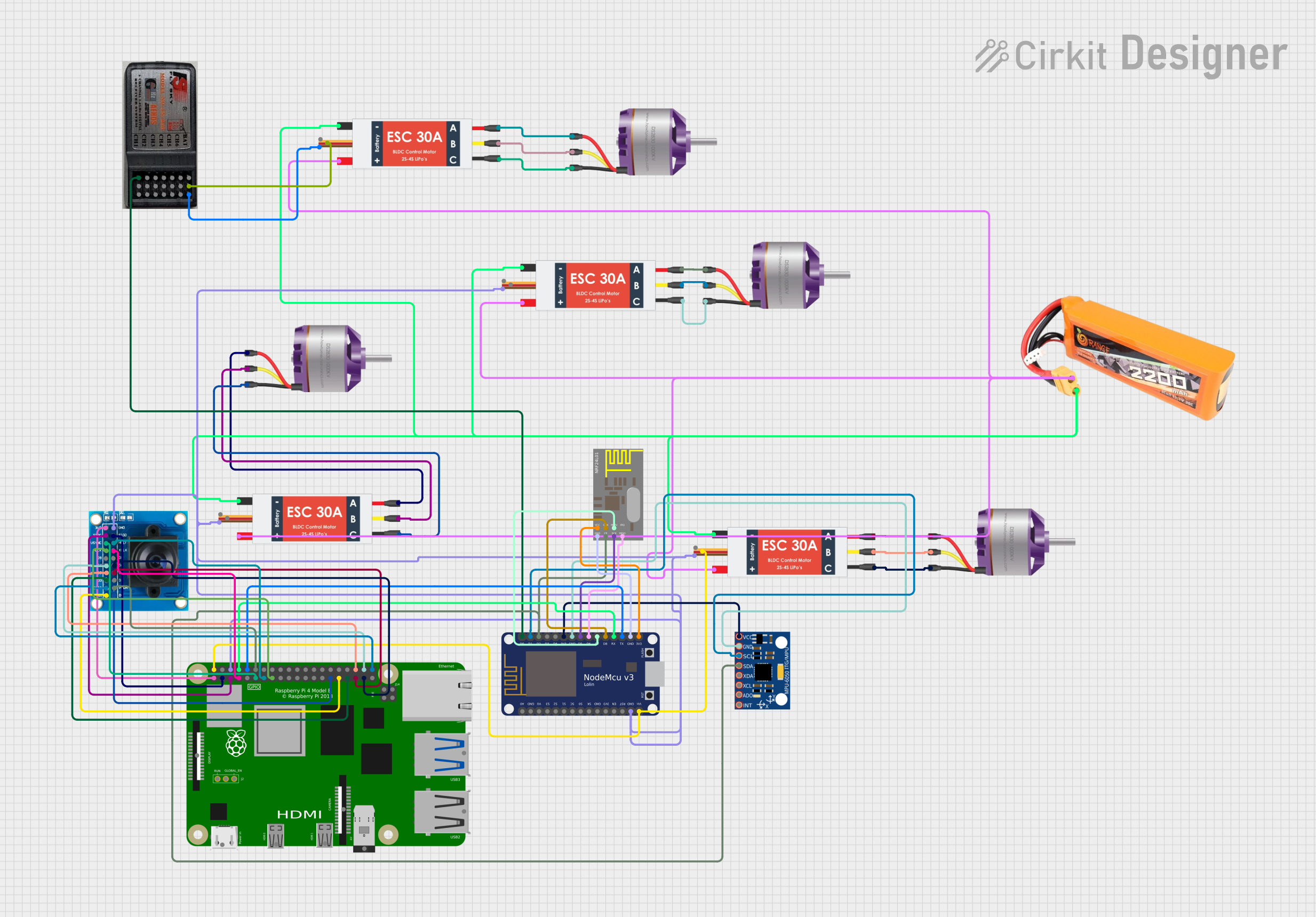

The circuit in question appears to be designed for a remote-controlled vehicle or drone, featuring brushless motors controlled by electronic speed controllers (ESCs), powered by a LiPo battery. It includes a microcontroller (NodeMCU V3 ESP8266) interfaced with an MPU-6050 sensor and an nRF24L01 wireless module for remote control capabilities. A Raspberry Pi 4B is used, possibly for higher-level control and processing, and an OV7725 camera module for vision capabilities. The RC receiver suggests the vehicle is controlled by a standard RC transmitter.

Component List

Brushless Motor

- Description: Motors that convert electrical energy into mechanical energy without brushes for commutation.

- Purpose: To provide propulsion for the vehicle.

Electronic Speed Controller (ESC)

- Description: Devices that regulate the speed and direction of the brushless motor.

- Purpose: To control the speed of the brushless motors based on input signals.

LiPo Battery 2200mAh 30C

- Description: A rechargeable battery with high energy density.

- Purpose: To provide power to the circuit.

RC Receiver 6 Channels

- Description: A receiver capable of receiving signals from an RC transmitter.

- Purpose: To receive control signals from the user's transmitter.

MPU-6050

- Description: A motion tracking device that contains a MEMS accelerometer and a MEMS gyro.

- Purpose: To provide motion sensing data such as acceleration and angular rate.

NodeMCU V3 ESP8266

- Description: A microcontroller board with Wi-Fi capabilities.

- Purpose: To process sensor data, control the ESCs, and communicate wirelessly.

nRF24L01

- Description: A wireless transceiver module that operates in the 2.4 GHz band.

- Purpose: To enable wireless communication for remote control.

Raspberry Pi 4B

- Description: A small single-board computer.

- Purpose: To perform higher-level processing and possibly control the camera module.

OV7725

- Description: A camera module capable of capturing images and video.

- Purpose: To provide vision capabilities for the vehicle.

Wiring Details

Brushless Motors

- Connected to their respective ESCs on pins L1, L2, L3.

Electronic Speed Controllers (ESCs)

- All ESCs are connected in parallel to the LiPo battery on pins Battery VCC and Battery GND.

- Each ESC's M1, M2, M3 pins are connected to a corresponding brushless motor.

- One ESC provides 5V output to the RC receiver.

- GND out pins of all ESCs are connected to the common ground net.

LiPo Battery 2200mAh 30C

- Provides power to the ESCs.

RC Receiver 6 Channels

- Powered by 5V and ground from one of the ESCs.

- CH1 is connected to the NodeMCU V3 ESP8266 for control signal input.

MPU-6050

- Powered by 3.3V from the NodeMCU V3 ESP8266.

- SCL and SDA are connected to the NodeMCU for I2C communication.

NodeMCU V3 ESP8266

- Receives power from one of the ESCs (Vin connected to 5V out).

- Interfaces with the MPU-6050, nRF24L01, and RC receiver for sensor data acquisition and wireless communication.

- Communicates with the Raspberry Pi 4B via serial connection (RX, TX).

nRF24L01

- Powered by 3.3V from the NodeMCU V3 ESP8266.

- CE, CSN, SCK, MOSI, MISO are connected to corresponding pins on the NodeMCU for SPI communication.

Raspberry Pi 4B

- Receives power from one of the ESCs (5V pin).

- Interfaced with the OV7725 camera module for vision processing.

- Communicates with the NodeMCU V3 ESP8266 via GPIO pins.

OV7725

- Powered by 3.3V from the Raspberry Pi 4B.

- Camera control and data pins are connected to corresponding GPIO pins on the Raspberry Pi 4B.

Documented Code

NodeMCU V3 ESP8266 Code (sketch.ino)

#include <SPI.h>

#include <nRF24L01.h>

#include <RF24.h>

RF24 radio(D2, D8); // CE, CSN

const byte address[5] = "00001";

struct Data_Package {

int throttle;

int yaw;

int pitch;

int roll;

};

Data_Package data;

void setup() {

Serial.begin(9600);

radio.begin();

radio.openWritingPipe(address);

radio.setPALevel(RF24_PA_MIN);

radio.stopListening();

}

void loop() {

// Read joystick values

data.throttle = analogRead(A0); // X-axis

data.yaw = analogRead(D1); // Y-axis

data.pitch = 0; // Placeholder for pitch control

data.roll = 0; // Placeholder for roll control

// Print joystick values for debugging

Serial.print("Throttle: ");

Serial.print(data.throttle);

Serial.print(" Yaw: ");

Serial.print(data.yaw);

Serial.print(" Pitch: ");

Serial.print(data.pitch);

Serial.print(" Roll: ");

Serial.println(data.roll);

// Send data package

radio.write(&data, sizeof(Data_Package));

delay(50); // Adjust delay as needed

}

This code is responsible for reading control inputs from an analog joystick connected to the NodeMCU, packaging the data into a structure, and transmitting it wirelessly via the nRF24L01 module. The Data_Package structure holds the throttle and yaw values, with placeholders for pitch and roll. The values are printed to the serial monitor for debugging purposes and sent out at a regular interval (50 ms).