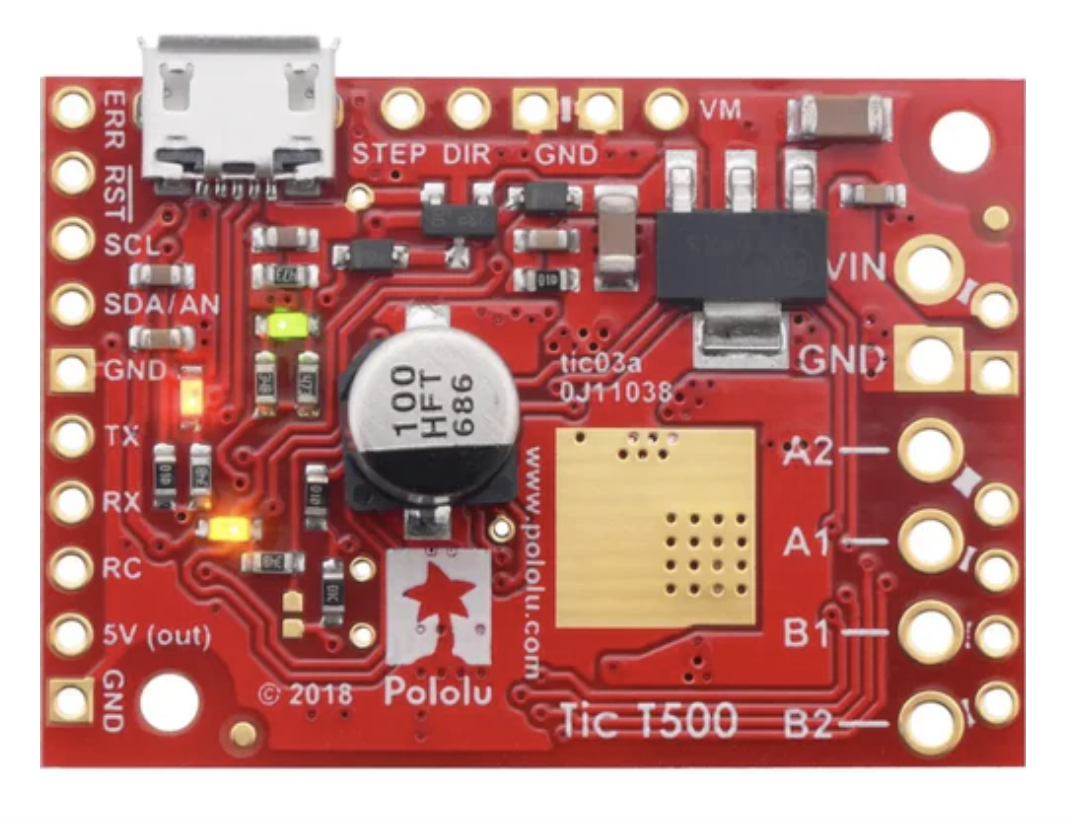

How to Use Tic T500: Examples, Pinouts, and Specs

Design with Tic T500 in Cirkit Designer

Design with Tic T500 in Cirkit DesignerIntroduction

The Tic T500, manufactured by Pololu, is a compact and high-performance stepper motor driver designed to simplify the control of stepper motors in a wide range of applications. It supports adjustable current control, microstepping, and operates over a broad voltage range, making it versatile and reliable for projects requiring precise motor control. The Tic T500 is particularly well-suited for robotics, CNC machines, 3D printers, and other motion control systems.

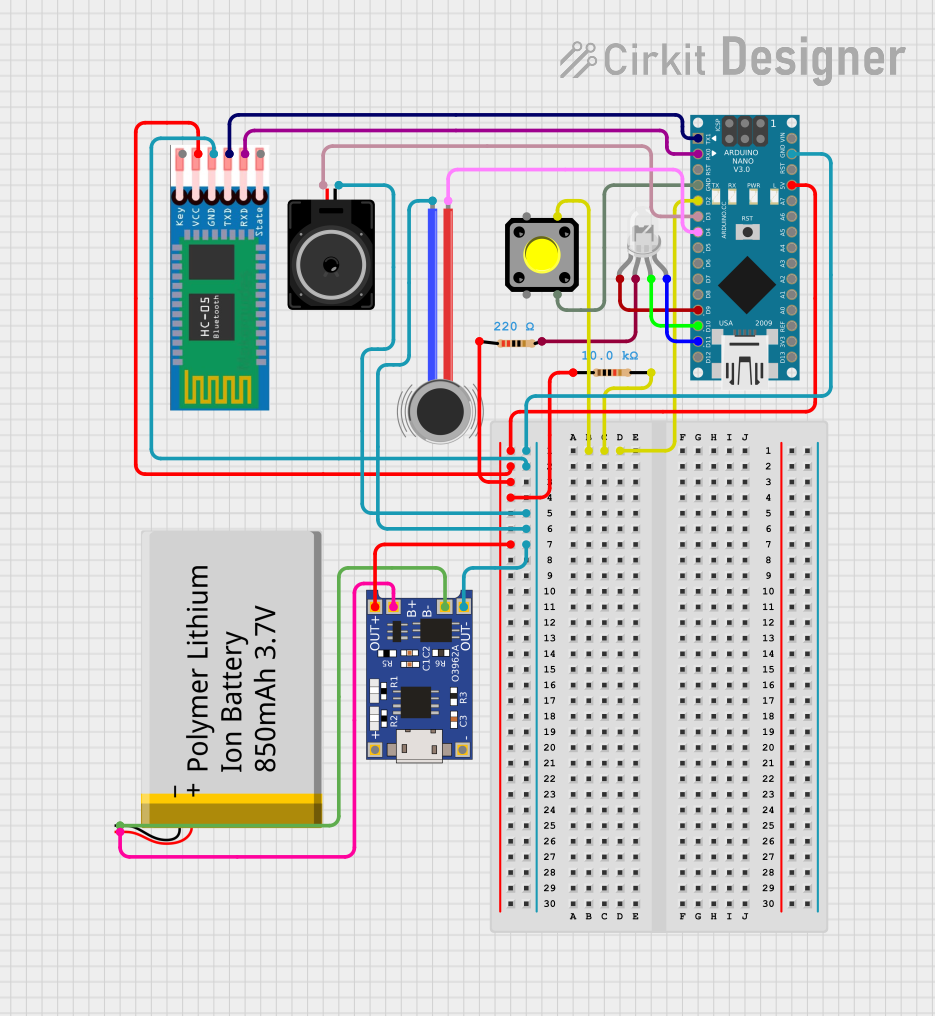

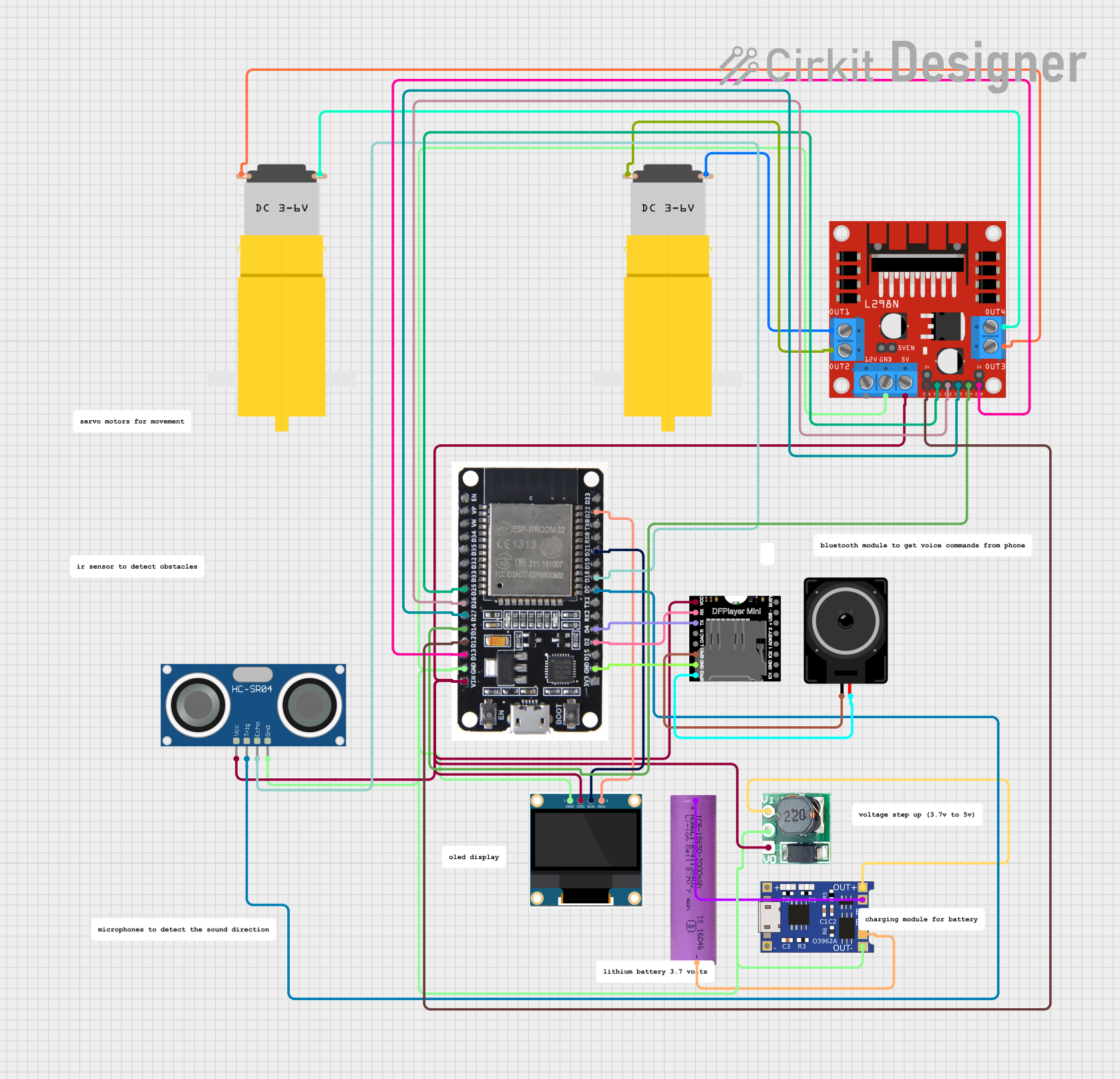

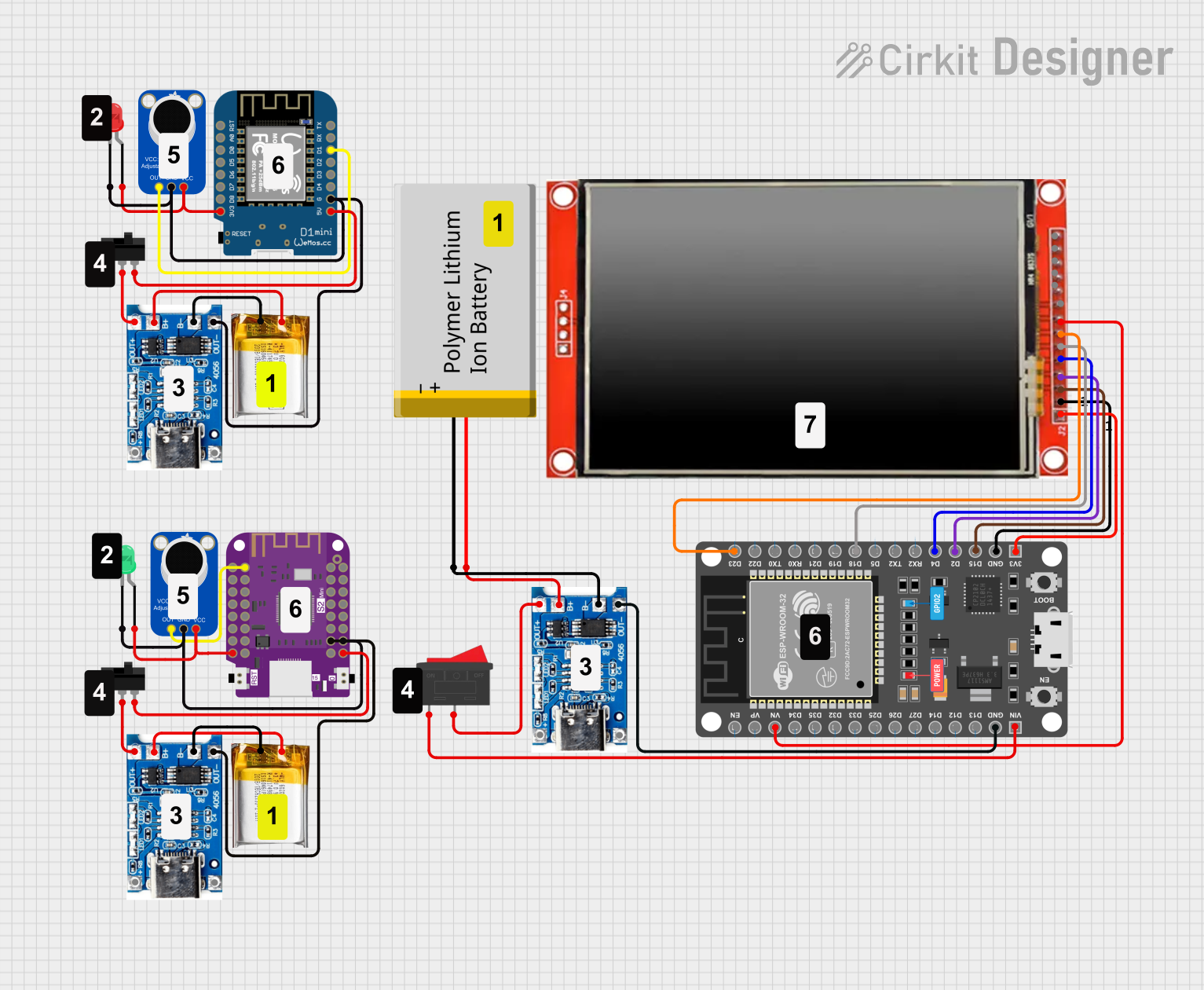

Explore Projects Built with Tic T500

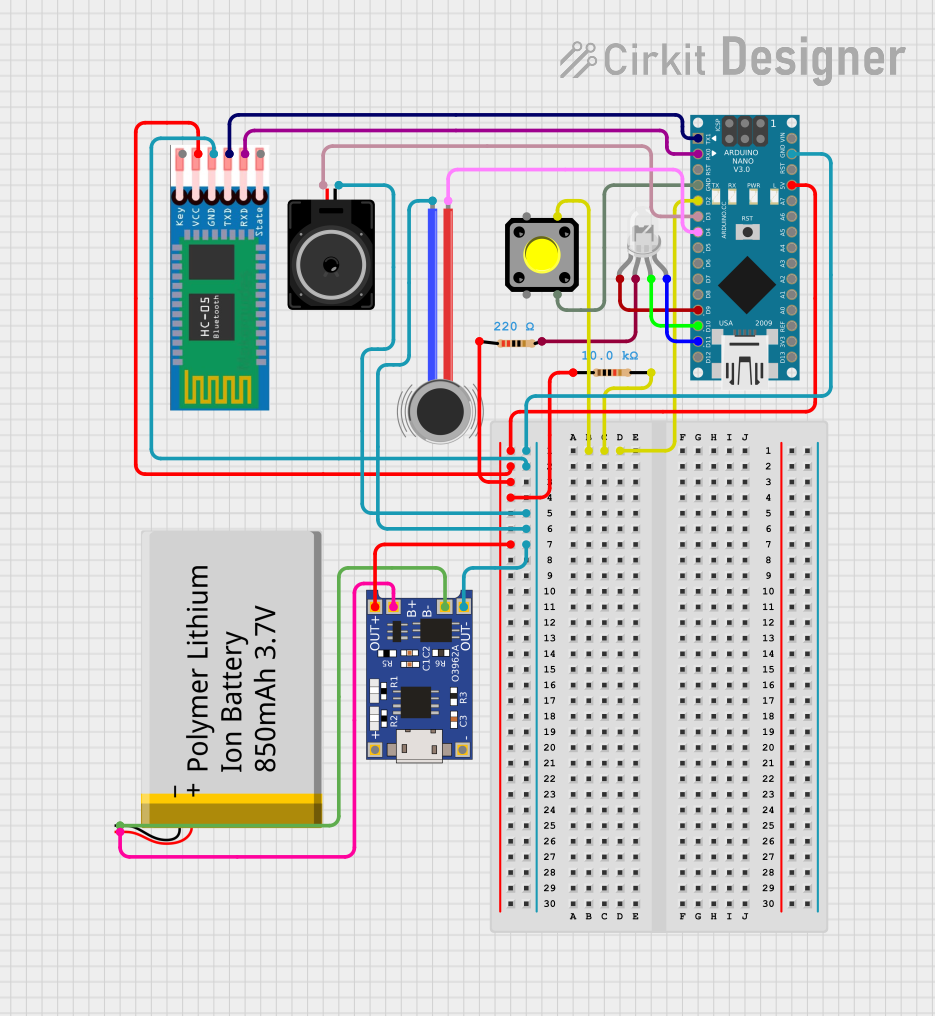

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

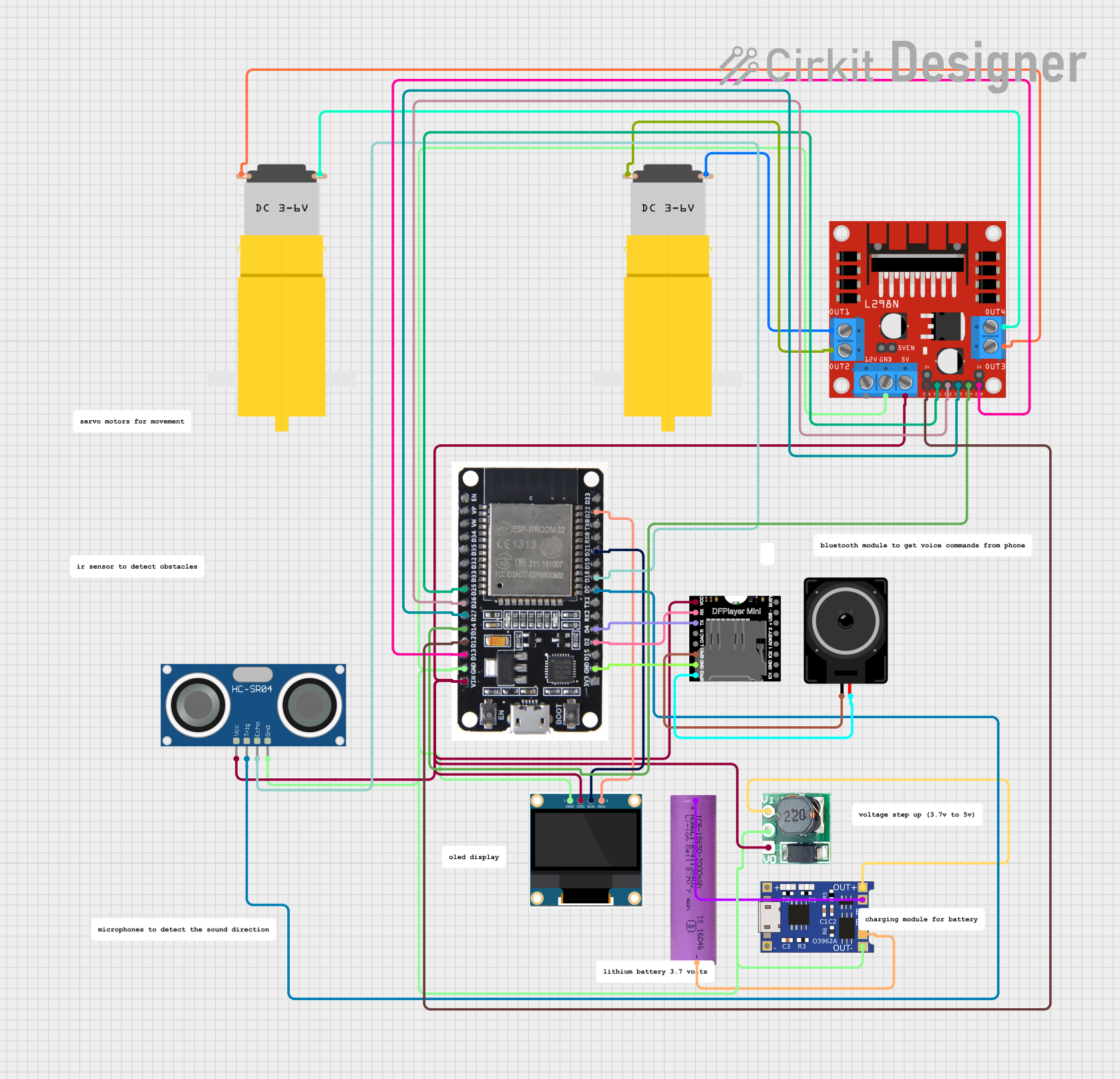

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

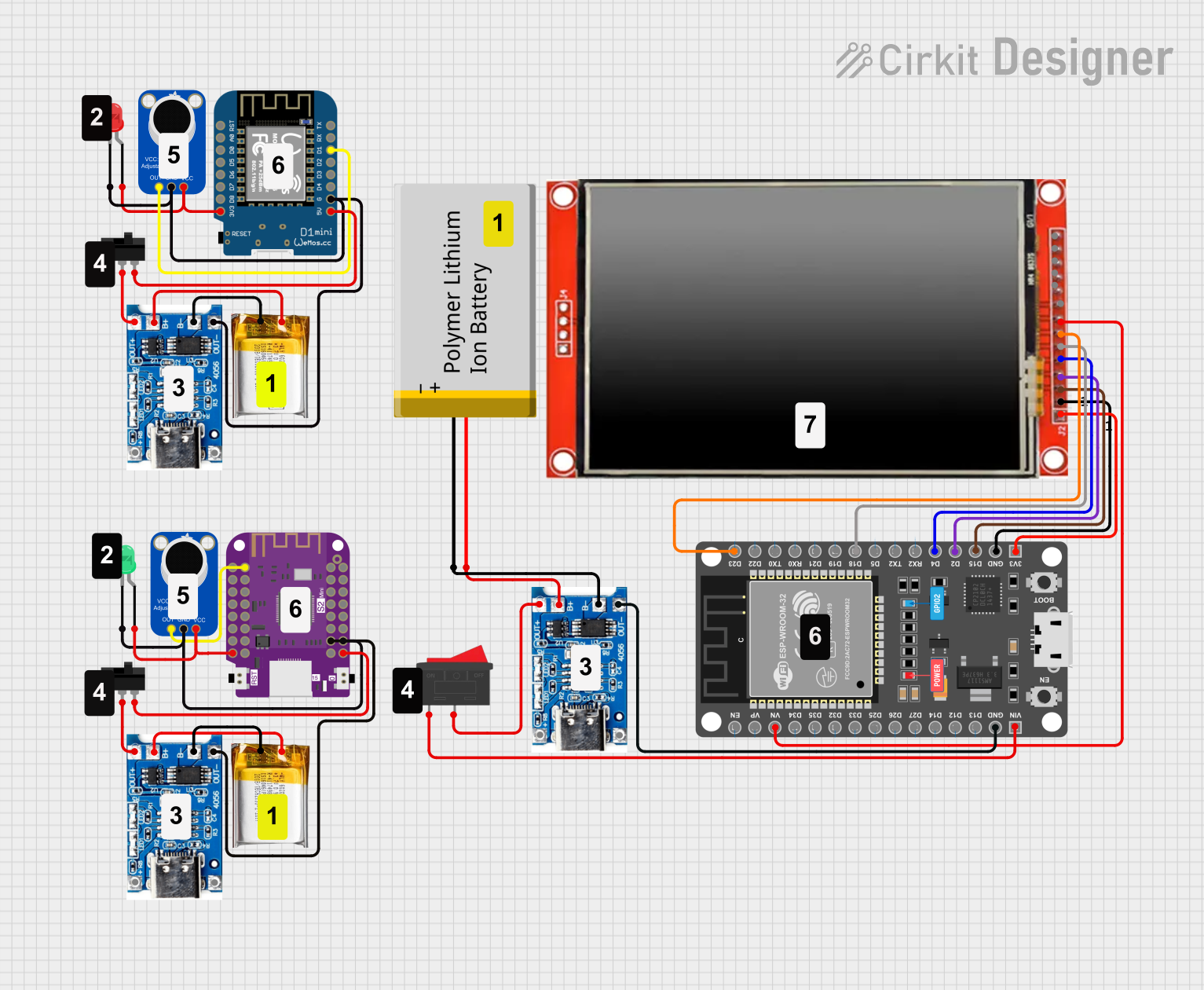

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Tic T500

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Robotics and automation systems

- CNC machines and milling equipment

- 3D printers

- Conveyor belts and industrial machinery

- Camera sliders and gimbals

Technical Specifications

The following table outlines the key technical details of the Tic T500:

| Parameter | Value |

|---|---|

| Input Voltage Range | 4.5 V to 35 V |

| Maximum Continuous Current | 1.5 A per phase (without additional cooling) |

| Microstepping Modes | Full-step, half-step, 1/4-step, 1/8-step, 1/16-step, 1/32-step |

| Control Interfaces | USB, TTL serial, I²C, analog voltage, RC hobby servo pulses |

| Logic Voltage | 3.3 V or 5 V (compatible with most microcontrollers, including Arduino) |

| Dimensions | 1.2" × 0.6" × 0.2" (30 mm × 16 mm × 5 mm) |

| Operating Temperature Range | -40°C to +85°C |

Pin Configuration and Descriptions

The Tic T500 features a variety of pins for power, motor control, and communication. The table below describes the key pins:

| Pin Name | Type | Description |

|---|---|---|

| VIN | Power Input | Main power supply input (4.5 V to 35 V). |

| GND | Power Ground | Ground connection for power and logic. |

| A1, A2 | Motor Output | Outputs for one coil of the stepper motor. |

| B1, B2 | Motor Output | Outputs for the other coil of the stepper motor. |

| TX | Serial Output | Transmit pin for TTL serial communication. |

| RX | Serial Input | Receive pin for TTL serial communication. |

| SCL | I²C Clock | Clock line for I²C communication. |

| SDA | I²C Data | Data line for I²C communication. |

| RC | Input | Input for RC hobby servo pulses. |

| AN | Input | Analog voltage input for speed or position control. |

| USB | Communication | USB interface for configuration and control. |

| RESET | Input | Resets the Tic T500 when pulled low. |

Usage Instructions

How to Use the Tic T500 in a Circuit

- Power Supply: Connect a power source (4.5 V to 35 V) to the VIN and GND pins. Ensure the power supply can provide sufficient current for your stepper motor.

- Motor Connection: Connect the stepper motor's coils to the A1, A2, B1, and B2 pins. Refer to your motor's datasheet to identify the correct wiring.

- Control Interface: Choose a control method (e.g., USB, TTL serial, I²C, analog, or RC). Connect the appropriate pins to your microcontroller or control device.

- Configuration: Use the Pololu Tic Control Center software to configure the Tic T500. This software allows you to set parameters such as current limits, microstepping mode, and control interface.

- Testing: Test the setup by sending commands through your chosen interface. Monitor the motor's behavior and adjust settings as needed.

Important Considerations and Best Practices

- Cooling: If operating near the maximum current limit, consider adding a heatsink or active cooling to prevent overheating.

- Power Supply: Use a power supply with sufficient current capacity to avoid voltage drops or instability.

- Wiring: Keep motor and power wires as short as possible to minimize noise and voltage loss.

- Microstepping: Use higher microstepping modes for smoother motion but be aware that torque may decrease at higher resolutions.

- Safety: Always disconnect power before making changes to the wiring or configuration.

Example: Using the Tic T500 with an Arduino UNO

The following example demonstrates how to control the Tic T500 using an Arduino UNO via TTL serial communication.

Wiring

- Connect the Tic T500's RX pin to the Arduino's TX pin (pin 1).

- Connect the Tic T500's TX pin to the Arduino's RX pin (pin 0).

- Connect the Tic T500's GND pin to the Arduino's GND.

- Connect the stepper motor and power supply as described above.

Code

#include <SoftwareSerial.h>

// Define the Arduino pins connected to the Tic T500

#define TIC_RX_PIN 10 // Arduino pin connected to Tic TX

#define TIC_TX_PIN 11 // Arduino pin connected to Tic RX

// Create a SoftwareSerial object for communication with the Tic T500

SoftwareSerial ticSerial(TIC_RX_PIN, TIC_TX_PIN);

void setup() {

// Start serial communication with the Tic T500

ticSerial.begin(9600);

// Set the stepper motor target position

setTargetPosition(2000); // Move to position 2000

}

void loop() {

// Add your main code here (e.g., update position or speed dynamically)

}

// Function to send a "Set Target Position" command to the Tic T500

void setTargetPosition(int32_t targetPosition) {

ticSerial.write(0xE0); // Command byte for "Set Target Position"

ticSerial.write((uint8_t)(targetPosition & 0xFF)); // Lowest byte

ticSerial.write((uint8_t)((targetPosition >> 8) & 0xFF)); // Second byte

ticSerial.write((uint8_t)((targetPosition >> 16) & 0xFF)); // Third byte

ticSerial.write((uint8_t)((targetPosition >> 24) & 0xFF)); // Highest byte

}

Troubleshooting and FAQs

Common Issues

Motor Not Moving:

- Ensure the motor is properly connected to the A1, A2, B1, and B2 pins.

- Verify that the power supply voltage and current meet the motor's requirements.

- Check the control interface configuration in the Tic Control Center.

Overheating:

- Reduce the current limit in the Tic Control Center.

- Add a heatsink or active cooling to the Tic T500.

Communication Errors:

- Verify the wiring between the Tic T500 and the control device.

- Ensure the baud rate and other communication settings match.

Motor Vibrates but Does Not Rotate:

- Check the wiring of the stepper motor coils. Incorrect wiring can cause this issue.

- Reduce the microstepping mode to increase torque.

FAQs

Q: Can I use the Tic T500 with a 12 V power supply?

A: Yes, the Tic T500 supports input voltages from 4.5 V to 35 V, so a 12 V power supply is suitable.

Q: How do I reset the Tic T500?

A: Pull the RESET pin low to reset the Tic T500. Alternatively, you can use the reset option in the Tic Control Center software.

Q: What is the maximum step rate supported by the Tic T500?

A: The Tic T500 supports step rates up to 50,000 steps per second, depending on the microstepping mode and motor.

Q: Can I control multiple Tic T500s with one Arduino?

A: Yes, you can control multiple Tic T500s using unique addresses for I²C or separate serial connections.