How to Use 12 V 50 W PTC Ceramic Heater: Examples, Pinouts, and Specs

Design with 12 V 50 W PTC Ceramic Heater in Cirkit Designer

Design with 12 V 50 W PTC Ceramic Heater in Cirkit DesignerIntroduction

The 12 V 50 W PTC Ceramic Heater is a self-regulating heating element that utilizes Positive Temperature Coefficient (PTC) technology. This heater operates at 12 volts and delivers a power output of 50 watts, making it an efficient and reliable solution for various heating applications. The PTC ceramic material ensures that the heater automatically adjusts its temperature, preventing overheating and maintaining consistent performance.

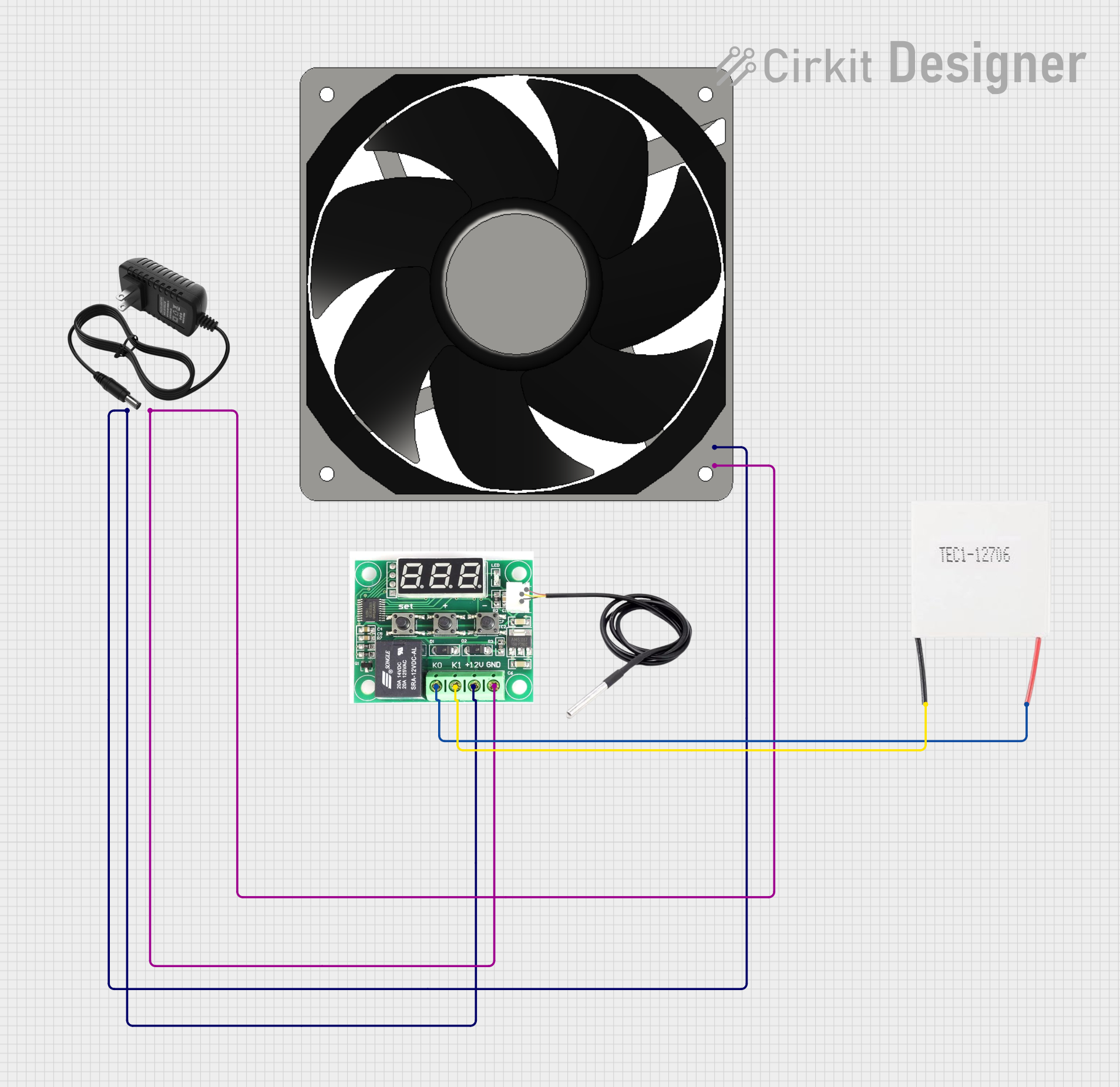

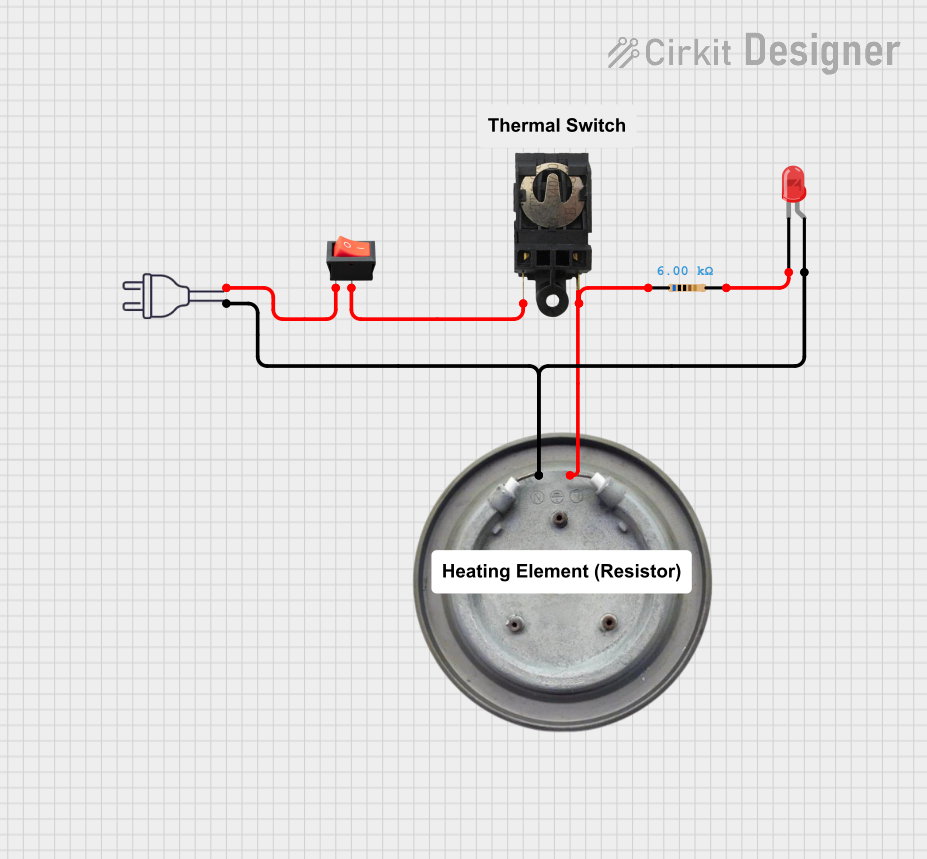

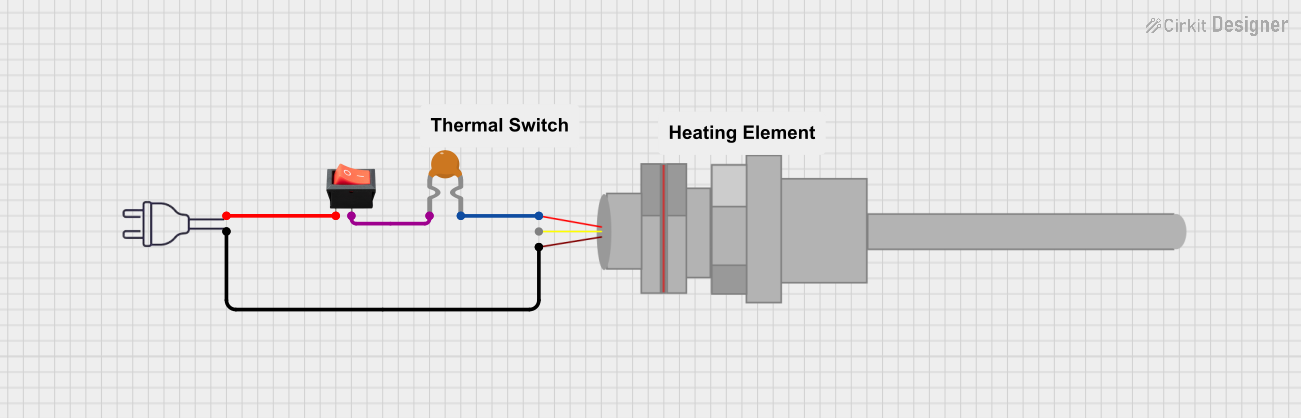

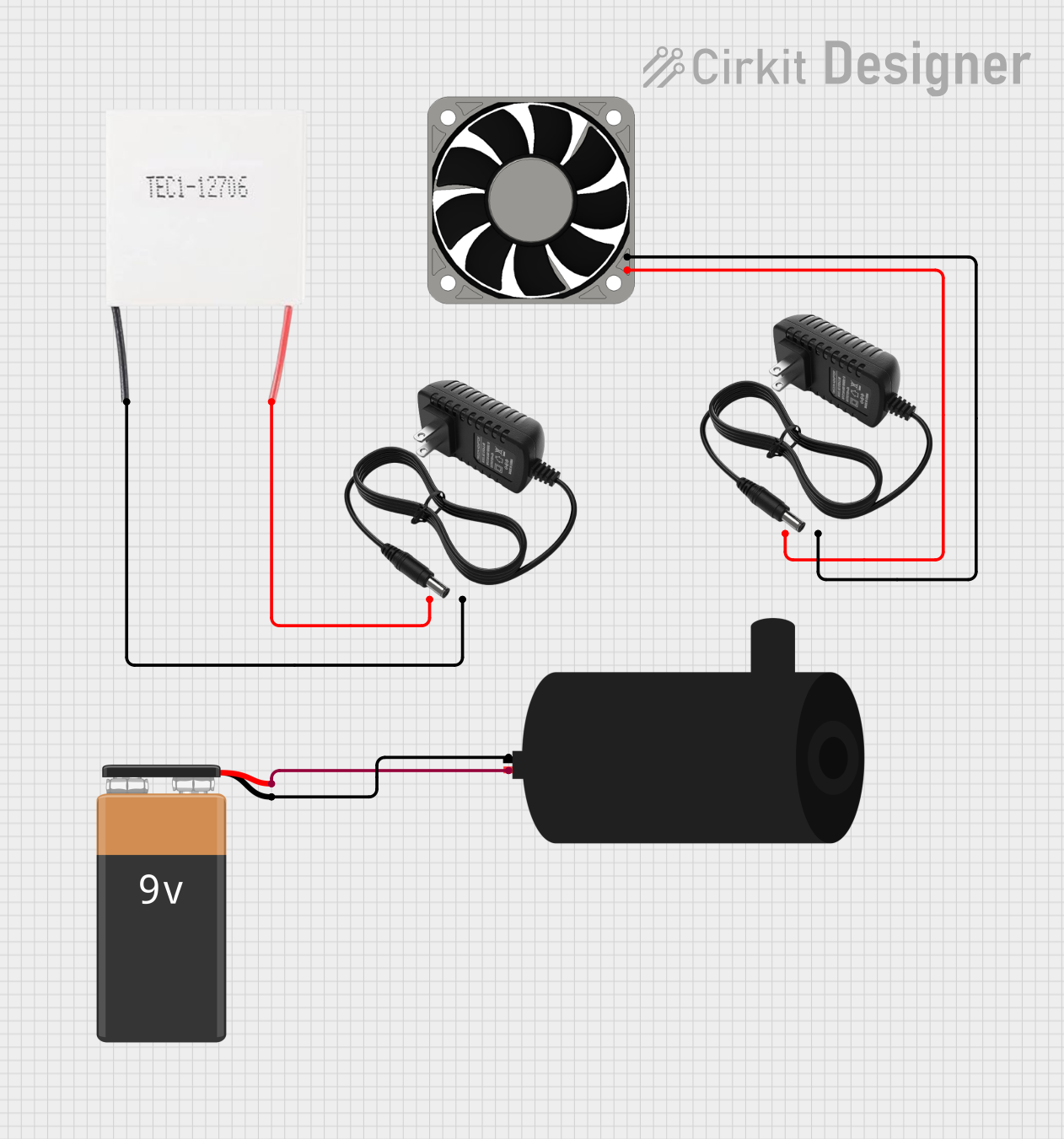

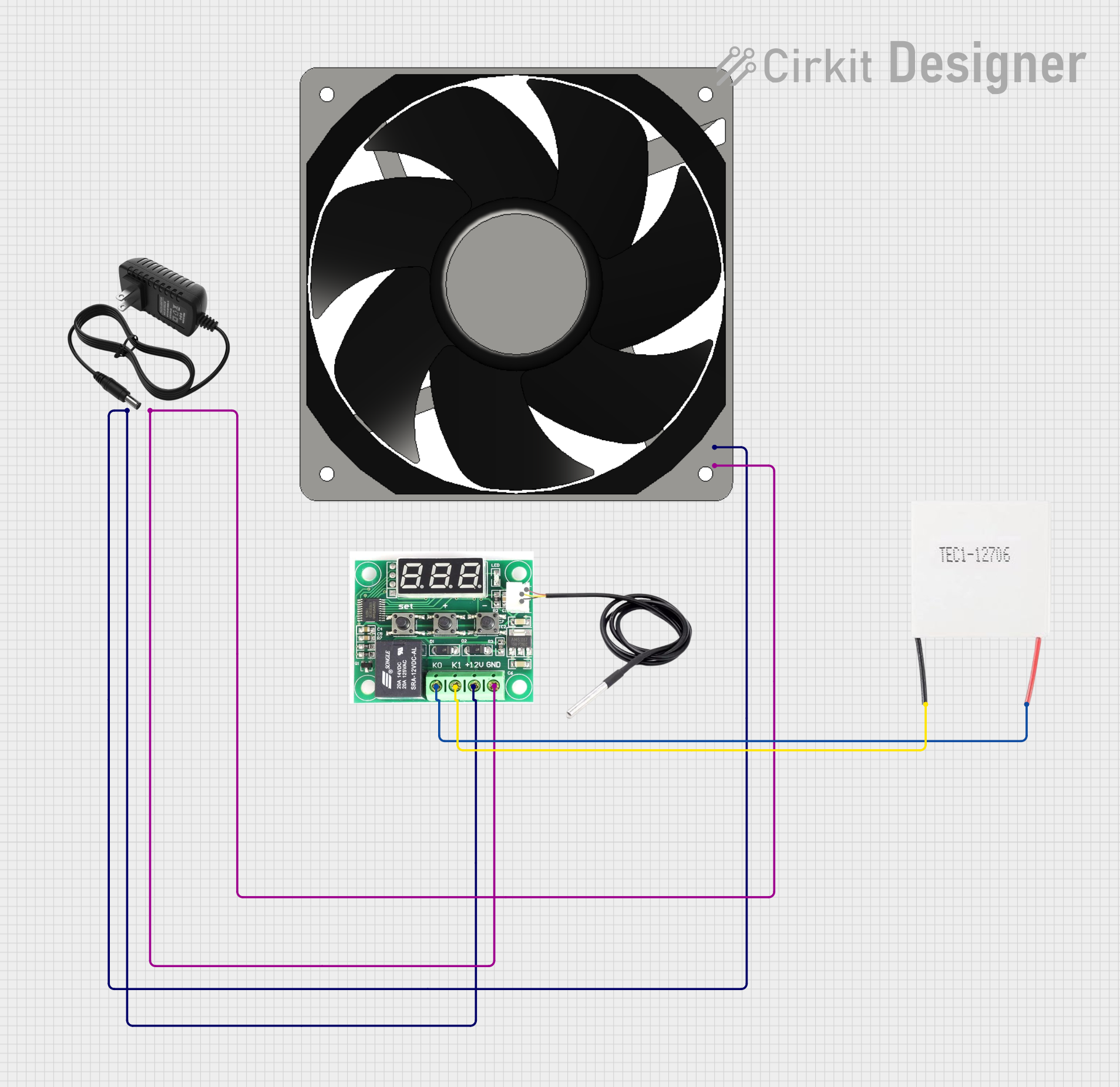

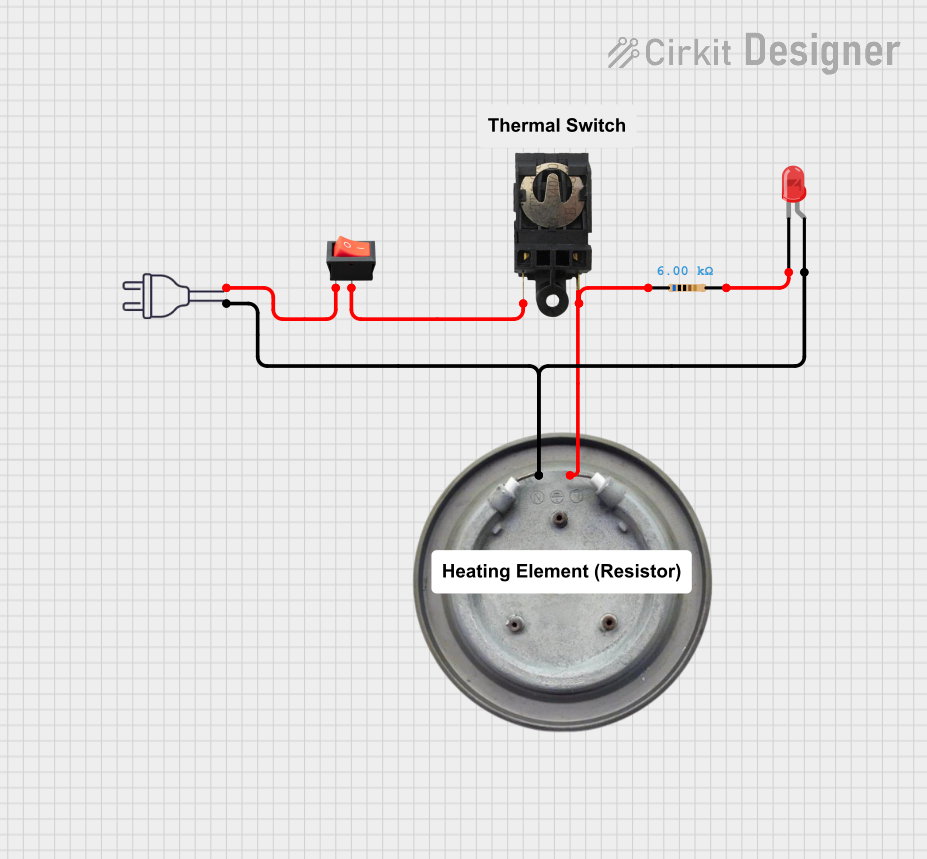

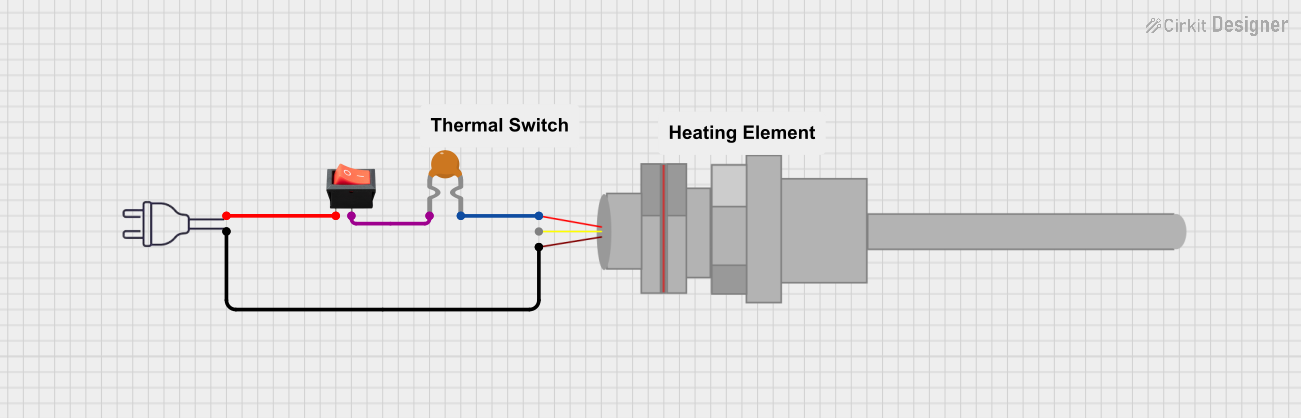

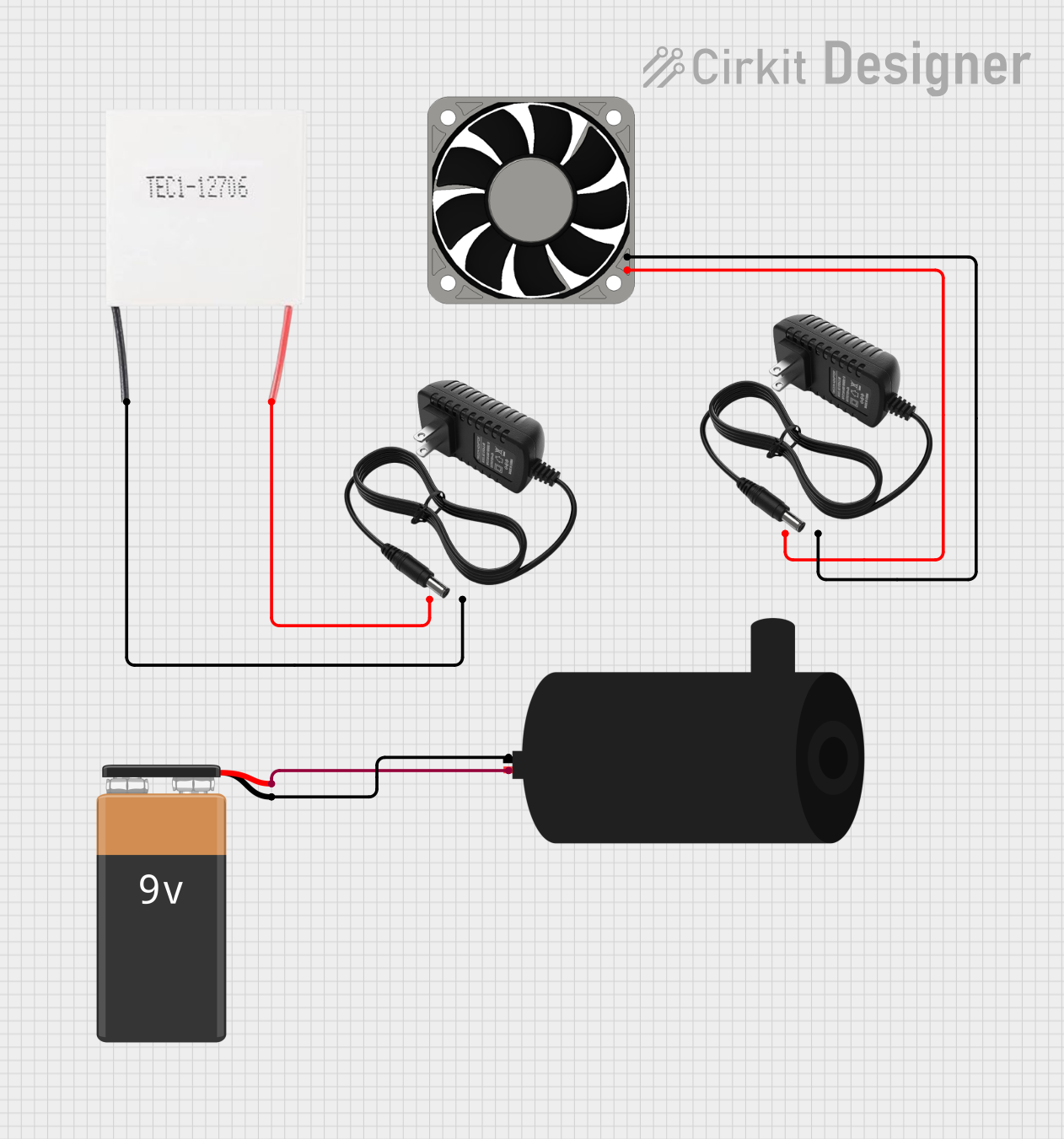

Explore Projects Built with 12 V 50 W PTC Ceramic Heater

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 12 V 50 W PTC Ceramic Heater

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Automotive: Seat warmers, defoggers, and cabin heating systems.

- Electronics: Temperature control for enclosures and devices.

- Industrial: Preheating fluids, adhesives, or small components.

- Home Appliances: Hair dryers, space heaters, and humidifiers.

- DIY Projects: Custom heating solutions for hobbyists and makers.

Technical Specifications

The following table outlines the key technical details of the 12 V 50 W PTC Ceramic Heater:

| Parameter | Value |

|---|---|

| Operating Voltage | 12 V DC |

| Power Rating | 50 W |

| Heating Element Type | PTC Ceramic |

| Temperature Regulation | Self-regulating (PTC effect) |

| Maximum Surface Temp. | ~200°C (varies by airflow) |

| Dimensions | Varies by model (e.g., 50x20 mm) |

| Lead Wire Length | Typically 100-150 mm |

| Insulation Resistance | ≥100 MΩ |

Pin Configuration and Descriptions

The PTC ceramic heater typically has two lead wires for electrical connections. The table below describes the connections:

| Pin/Lead | Description |

|---|---|

| Red Wire | Positive terminal (+12 V DC input) |

| Black Wire | Negative terminal (Ground) |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect the heater to a stable 12 V DC power source capable of supplying at least 4.2 A (to account for the 50 W power rating).

- Polarity: Ensure correct polarity by connecting the red wire to the positive terminal and the black wire to the ground.

- Mounting: Secure the heater in place using a heat-resistant adhesive or mounting bracket. Ensure proper ventilation to avoid heat buildup.

- Safety: Avoid direct contact with the heater during operation, as the surface can reach high temperatures.

Important Considerations and Best Practices

- Airflow: The heater's surface temperature depends on the surrounding airflow. Ensure adequate ventilation for consistent performance.

- Power Supply: Use a regulated DC power supply to prevent voltage fluctuations that could affect the heater's performance.

- Heat Dissipation: Avoid enclosing the heater in a sealed space without proper heat dissipation, as this may lead to overheating.

- Wiring: Use wires with appropriate insulation and current ratings to handle the power requirements safely.

Example: Using the Heater with an Arduino UNO

While the PTC ceramic heater cannot be directly powered by an Arduino UNO due to its high current requirements, you can control it using a relay module. Below is an example circuit and code to toggle the heater on and off using an Arduino:

Circuit Setup

- Connect the heater's red wire to the relay's NO (Normally Open) terminal.

- Connect the heater's black wire to the relay's COM (Common) terminal.

- Connect the relay module's VCC, GND, and IN pins to the Arduino's 5V, GND, and a digital pin (e.g., D7), respectively.

- Use an external 12 V DC power supply to power the heater.

Arduino Code

// Define the relay control pin

const int relayPin = 7;

void setup() {

// Set the relay pin as an output

pinMode(relayPin, OUTPUT);

// Start with the relay off

digitalWrite(relayPin, LOW);

}

void loop() {

// Turn the heater on for 10 seconds

digitalWrite(relayPin, HIGH);

delay(10000); // 10-second delay

// Turn the heater off for 10 seconds

digitalWrite(relayPin, LOW);

delay(10000); // 10-second delay

}

Note: Ensure the relay module can handle the heater's current and voltage requirements.

Troubleshooting and FAQs

Common Issues and Solutions

Heater Not Heating:

- Cause: Insufficient power supply.

- Solution: Verify that the power supply provides 12 V DC and at least 4.2 A.

Overheating or Burnt Smell:

- Cause: Poor ventilation or incorrect mounting.

- Solution: Ensure proper airflow and avoid enclosing the heater in a sealed space.

Relay Not Switching:

- Cause: Incorrect wiring or insufficient current to the relay.

- Solution: Double-check the relay connections and ensure the Arduino pin is configured correctly.

Heater Surface Temperature Too Low:

- Cause: Excessive airflow or low ambient temperature.

- Solution: Reduce airflow or use insulation to retain heat.

FAQs

Q: Can I use this heater with an AC power source?

A: No, this heater is designed for DC operation only. Using AC power may damage the component.Q: Is the heater waterproof?

A: Most PTC ceramic heaters are not waterproof. Avoid exposing the heater to moisture or liquids.Q: Can I control the temperature of the heater?

A: The heater's temperature is self-regulating due to the PTC effect. However, you can control the on/off state using a relay or MOSFET.Q: What is the lifespan of the heater?

A: PTC ceramic heaters are highly durable and can last for thousands of hours under normal operating conditions.

By following this documentation, you can safely and effectively integrate the 12 V 50 W PTC Ceramic Heater into your projects.