How to Use MQ-138: Examples, Pinouts, and Specs

Design with MQ-138 in Cirkit Designer

Design with MQ-138 in Cirkit DesignerIntroduction

The MQ-138 is a gas sensor manufactured by Flying Fish, designed to detect various gases, particularly volatile organic compounds (VOCs) and other harmful gases in the environment. It operates on the principle of resistive change in the presence of target gases, providing an analog output that can be easily interfaced with microcontrollers and other electronic systems.

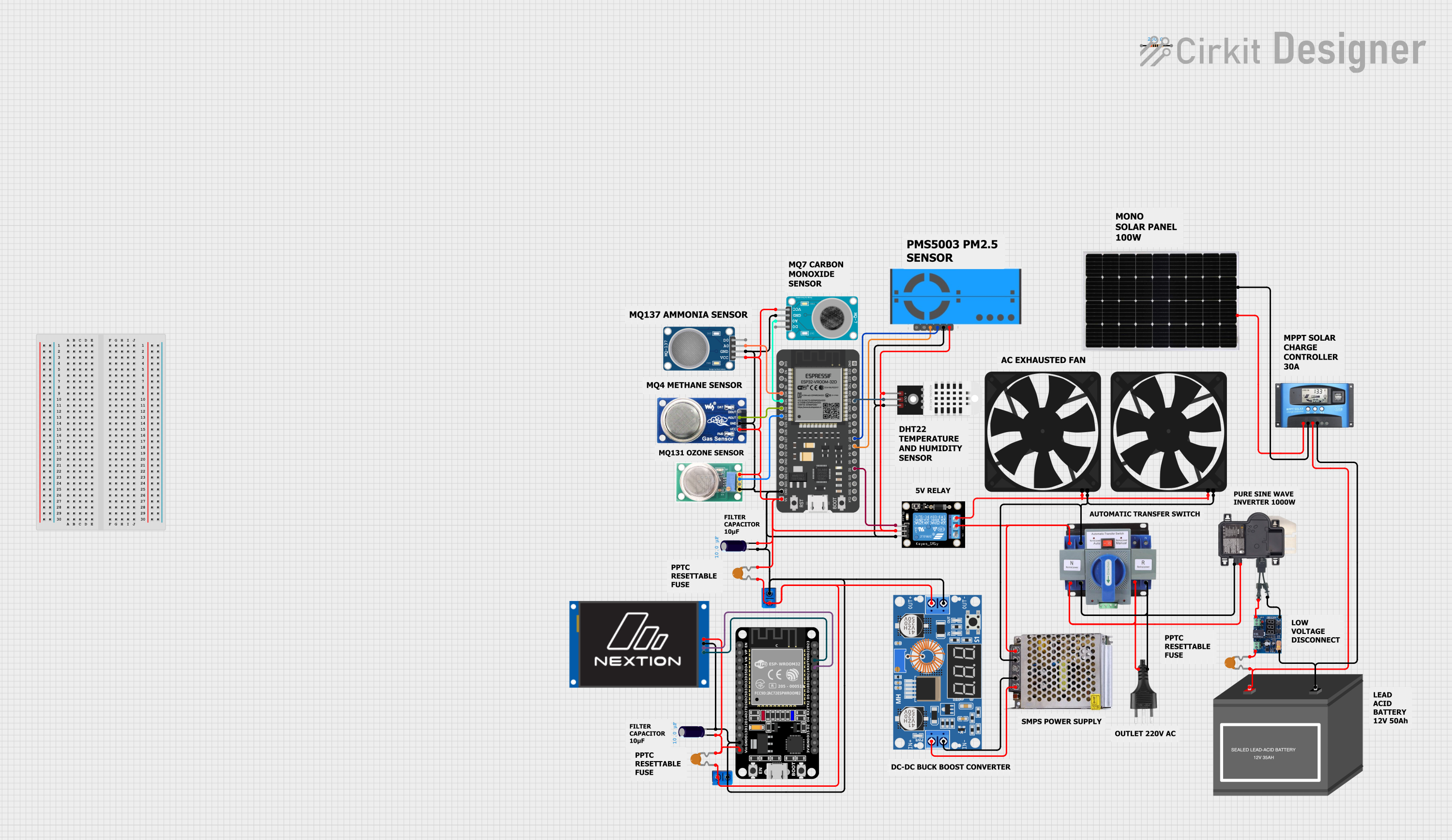

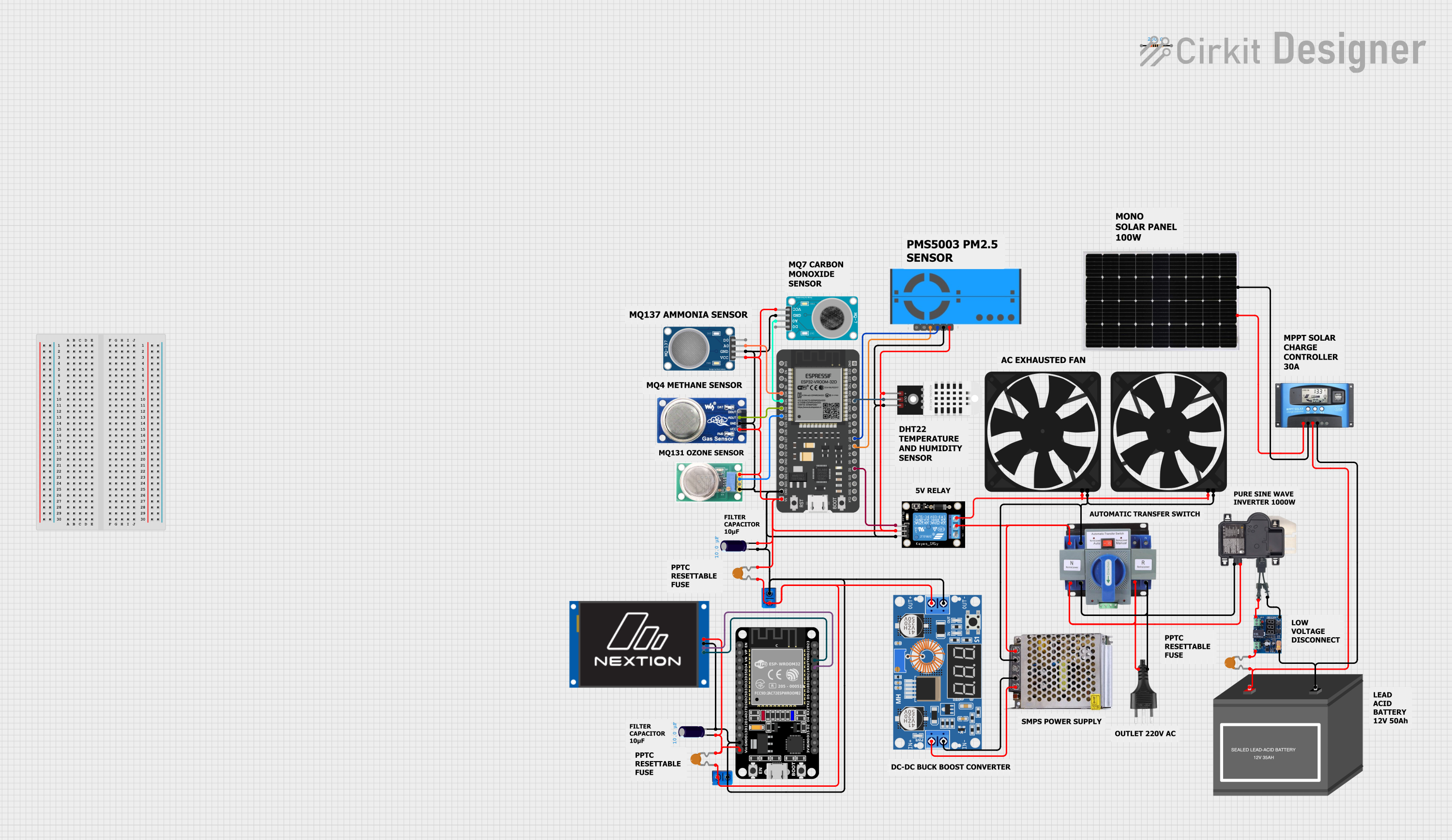

Explore Projects Built with MQ-138

Open Project in Cirkit Designer

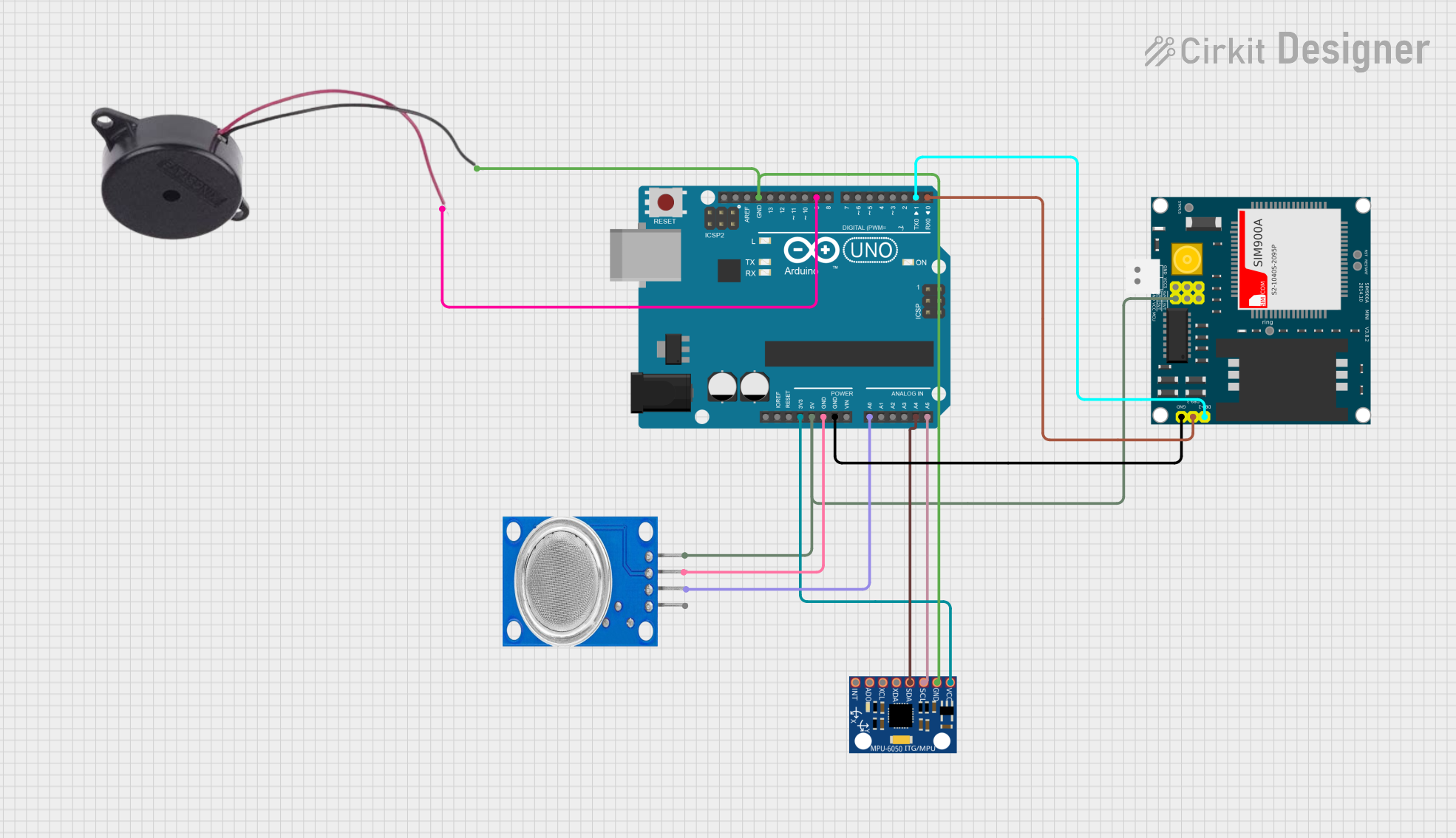

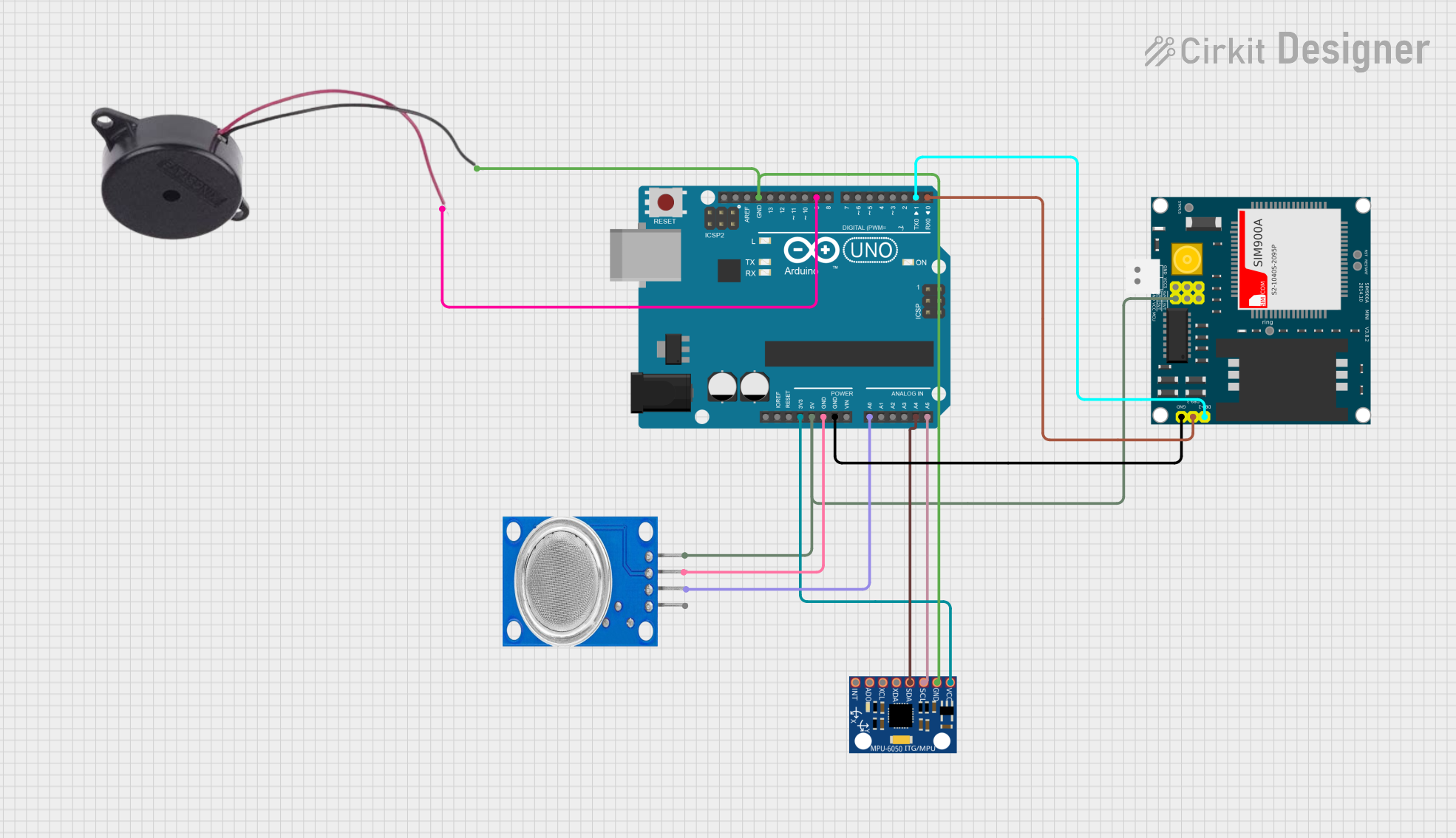

Open Project in Cirkit Designer

Open Project in Cirkit Designer

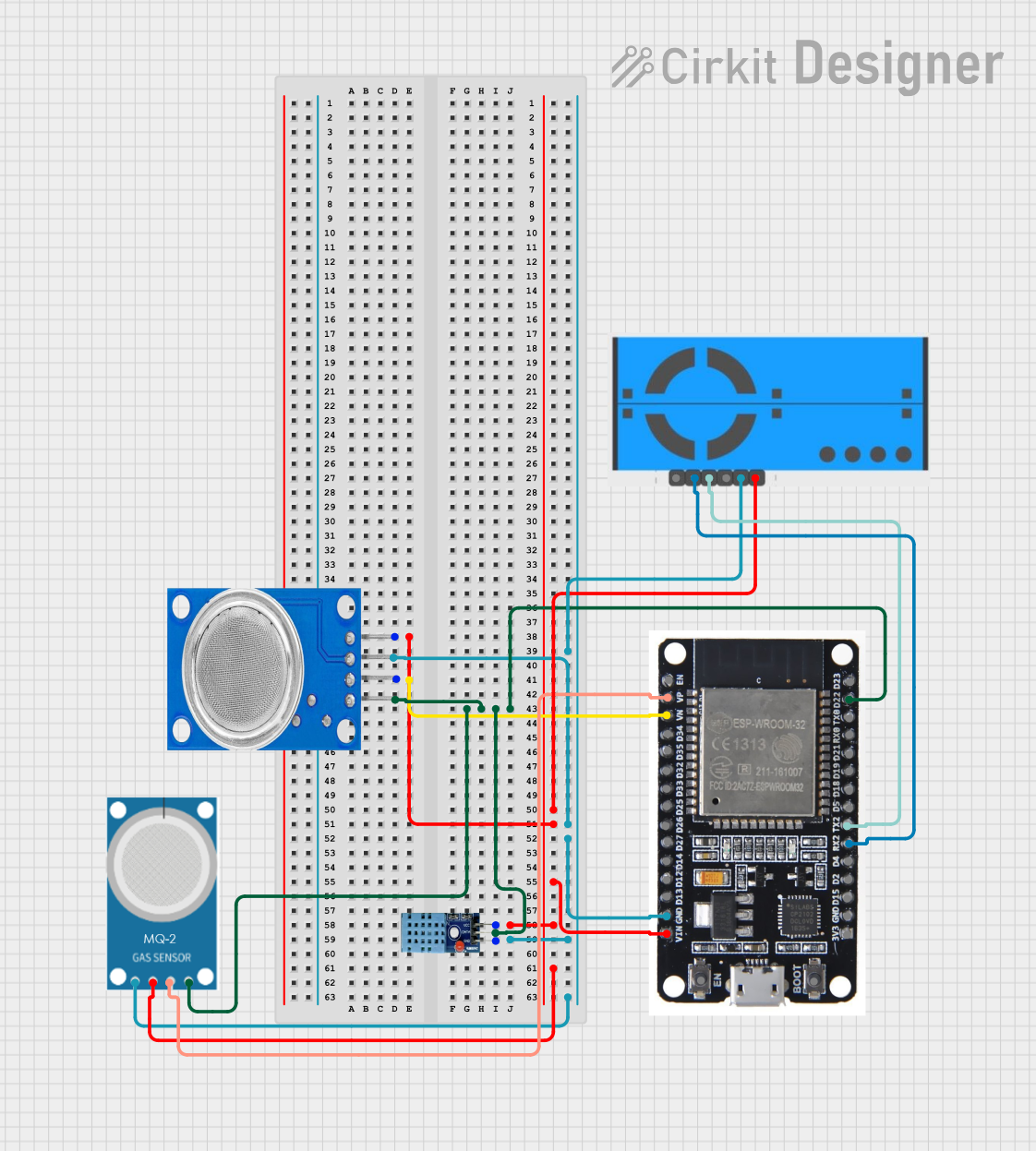

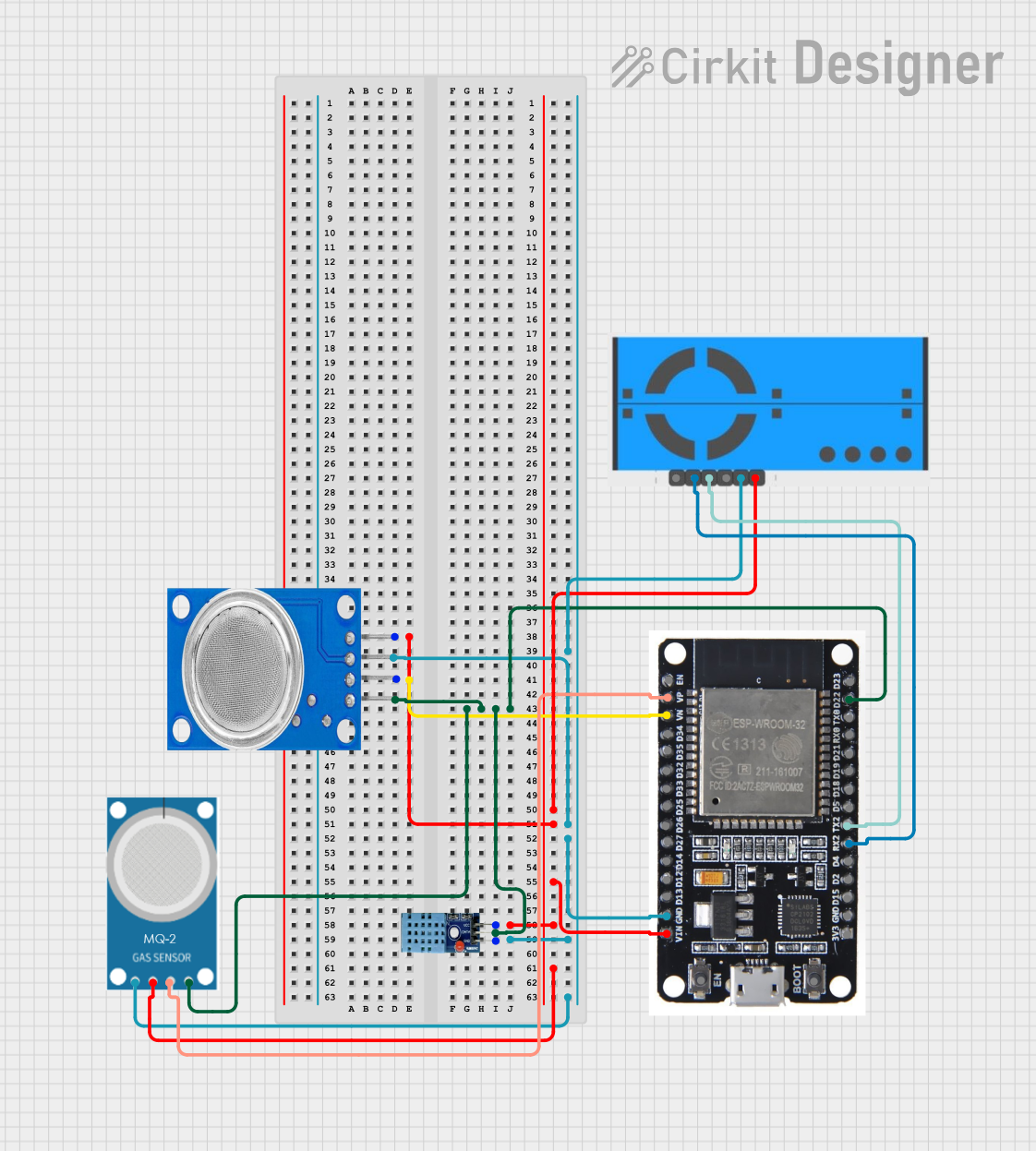

Open Project in Cirkit Designer

Open Project in Cirkit Designer

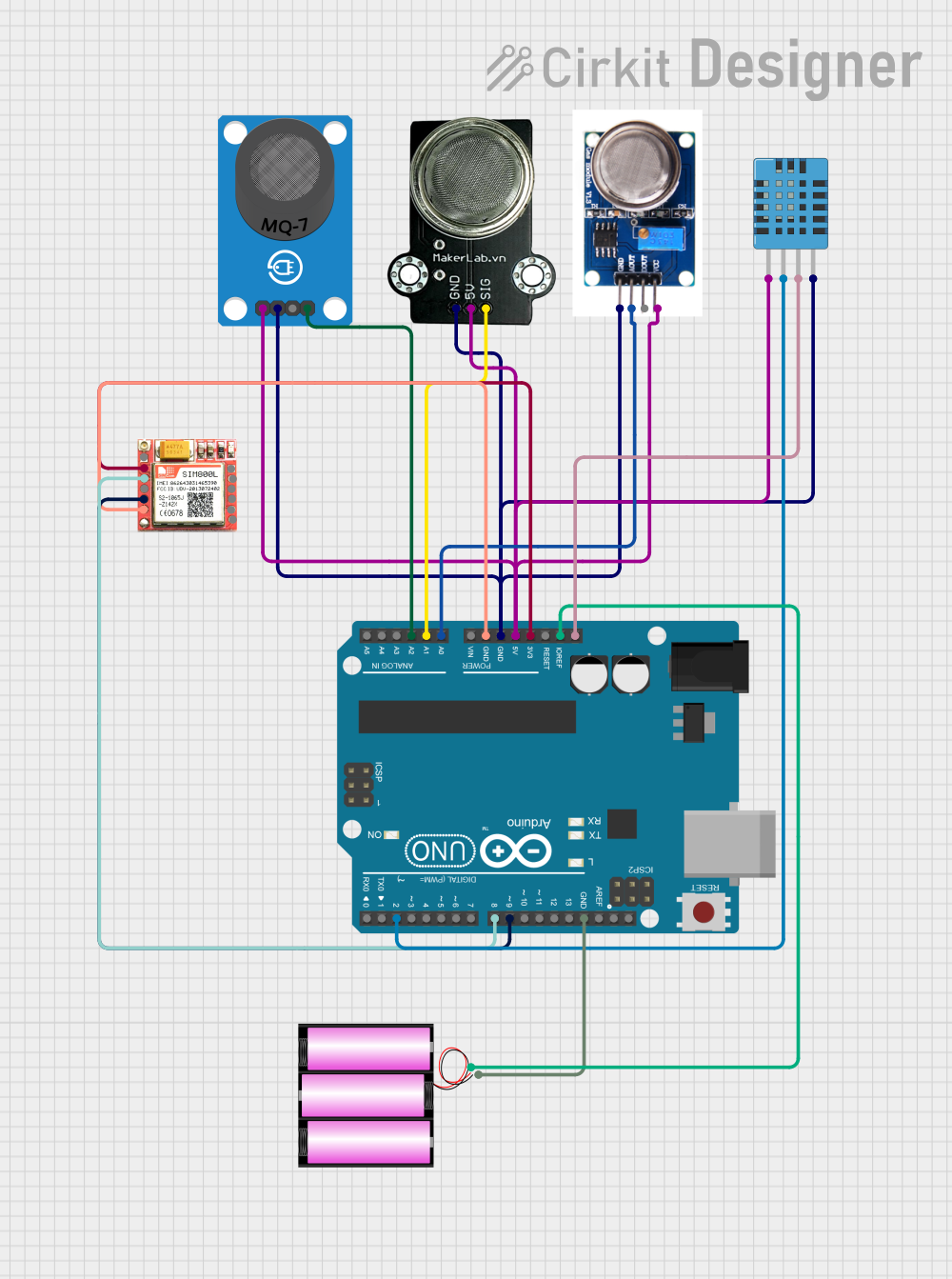

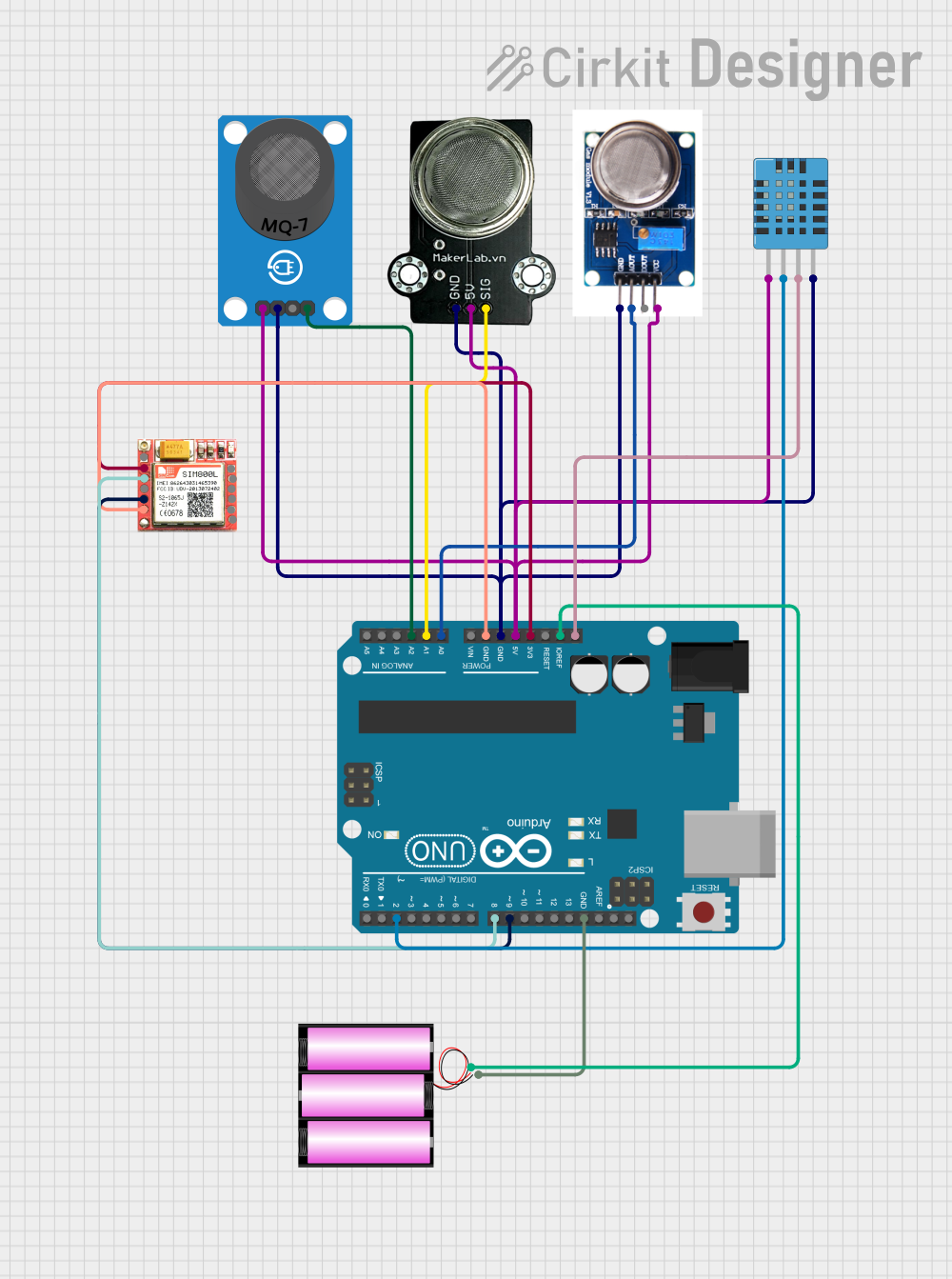

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with MQ-138

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Air quality monitoring systems

- Industrial safety and hazardous gas detection

- Smart home automation for environmental monitoring

- Laboratory and research applications

- Portable gas detection devices

Technical Specifications

The MQ-138 sensor is a versatile and reliable component for gas detection. Below are its key technical details:

| Parameter | Value |

|---|---|

| Operating Voltage | 5V DC |

| Load Resistance (RL) | Adjustable (typically 10 kΩ) |

| Heater Voltage (VH) | 5V ± 0.2V |

| Heater Power Consumption | ≤ 800 mW |

| Detection Range | 1 ppm to 1000 ppm (varies by gas) |

| Preheat Time | ≥ 24 hours for stable operation |

| Output Signal | Analog voltage |

| Operating Temperature | -20°C to 50°C |

| Humidity Range | ≤ 95% RH |

| Dimensions | 32mm x 20mm x 22mm (approx.) |

Pin Configuration and Descriptions

The MQ-138 module typically comes with a 4-pin interface. Below is the pinout description:

| Pin | Name | Description |

|---|---|---|

| 1 | VCC | Power supply pin. Connect to 5V DC. |

| 2 | GND | Ground pin. Connect to the ground of the circuit. |

| 3 | AOUT | Analog output pin. Provides a voltage proportional to the gas concentration. |

| 4 | DOUT | Digital output pin. Outputs HIGH or LOW based on the gas concentration threshold. |

Usage Instructions

How to Use the MQ-138 in a Circuit

- Powering the Sensor: Connect the VCC pin to a 5V DC power supply and the GND pin to the ground.

- Reading the Output:

- Use the AOUT pin to read the analog voltage corresponding to the gas concentration.

- Optionally, use the DOUT pin for a digital HIGH/LOW signal if a threshold is set using the onboard potentiometer.

- Preheating the Sensor: Allow the sensor to preheat for at least 24 hours before taking accurate measurements. This stabilizes the internal heater and sensing element.

- Interfacing with a Microcontroller:

- Connect the AOUT pin to an analog input pin of a microcontroller (e.g., Arduino UNO).

- If using the DOUT pin, connect it to a digital input pin.

Important Considerations and Best Practices

- Calibration: The sensor requires calibration for the specific gas you intend to detect. Use a known concentration of the target gas to determine the relationship between the analog output and gas concentration.

- Ventilation: Ensure proper ventilation around the sensor to avoid saturation and improve response time.

- Power Supply: Use a stable 5V power supply to avoid fluctuations in the sensor's output.

- Avoid Contaminants: Keep the sensor away from water, oil, and other contaminants that may damage the sensing element.

Example Code for Arduino UNO

Below is an example of how to interface the MQ-138 with an Arduino UNO to read the analog output:

// MQ-138 Gas Sensor Example Code

// This code reads the analog output of the MQ-138 sensor and prints the value

// to the Serial Monitor. Ensure the sensor is properly connected to the Arduino.

const int analogPin = A0; // Connect AOUT pin of MQ-138 to A0 on Arduino

void setup() {

Serial.begin(9600); // Initialize serial communication at 9600 baud

pinMode(analogPin, INPUT); // Set the analog pin as input

}

void loop() {

int sensorValue = analogRead(analogPin); // Read the analog value from the sensor

float voltage = sensorValue * (5.0 / 1023.0); // Convert to voltage (0-5V range)

// Print the sensor value and voltage to the Serial Monitor

Serial.print("Sensor Value: ");

Serial.print(sensorValue);

Serial.print(" | Voltage: ");

Serial.print(voltage);

Serial.println(" V");

delay(1000); // Wait for 1 second before the next reading

}

Troubleshooting and FAQs

Common Issues and Solutions

No Output or Incorrect Readings:

- Ensure the sensor is properly powered (5V to VCC and GND connected).

- Verify that the sensor has been preheated for at least 24 hours.

- Check the connections to the microcontroller or ADC.

Fluctuating Readings:

- Use a stable power supply to avoid noise in the output.

- Ensure the sensor is in a well-ventilated area to prevent gas accumulation.

Digital Output Not Triggering:

- Adjust the onboard potentiometer to set the desired gas concentration threshold.

- Verify the DOUT pin connection to the microcontroller.

Sensor Not Responding to Target Gas:

- Confirm that the gas concentration is within the sensor's detection range.

- Calibrate the sensor for the specific gas being detected.

FAQs

Q: Can the MQ-138 detect multiple gases simultaneously?

A: The MQ-138 is sensitive to a range of gases, but it does not differentiate between them. Calibration for a specific gas is recommended for accurate detection.

Q: How long does the sensor last?

A: The sensor has a typical lifespan of 2-3 years under normal operating conditions. Prolonged exposure to high concentrations of gases or contaminants may reduce its lifespan.

Q: Can I use the MQ-138 with a 3.3V system?

A: The MQ-138 requires a 5V power supply for proper operation. However, the analog output can be read by a 3.3V ADC if the voltage levels are within range.

Q: Is the sensor affected by temperature or humidity?

A: Yes, extreme temperatures and high humidity can affect the sensor's performance. Use it within the specified operating range for best results.