How to Use stepper motor one: Examples, Pinouts, and Specs

Design with stepper motor one in Cirkit Designer

Design with stepper motor one in Cirkit DesignerIntroduction

A stepper motor is an electromechanical device that converts electrical pulses into discrete mechanical movements. It rotates in fixed angular steps or increments, making it suitable for applications that require precise position control. Common applications include robotics, CNC machines, and 3D printers.

Explore Projects Built with stepper motor one

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with stepper motor one

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

General Characteristics

- Step Angle: Typically 1.8 degrees per step (200 steps per revolution)

- Voltage Rating: Varies by model (commonly 12V)

- Current Rating: Varies by model (commonly 1-2A per phase)

- Phase: Bipolar or Unipolar (depending on model)

Pin Configuration and Descriptions

| Pin Number | Description | Notes |

|---|---|---|

| 1 | Coil 1A | Connect to a driver output |

| 2 | Coil 1B | Connect to a driver output |

| 3 | Coil 2A | Connect to a driver output |

| 4 | Coil 2B | Connect to a driver output |

| 5 | (Optional) Center tap | For unipolar configurations |

Usage Instructions

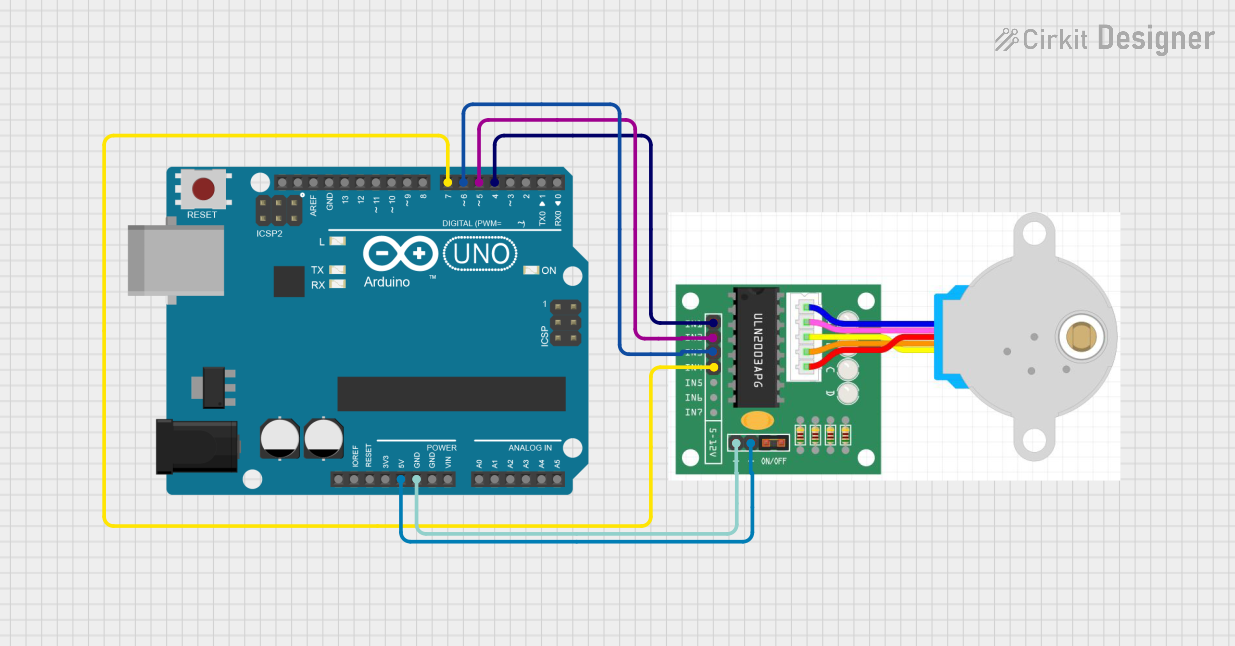

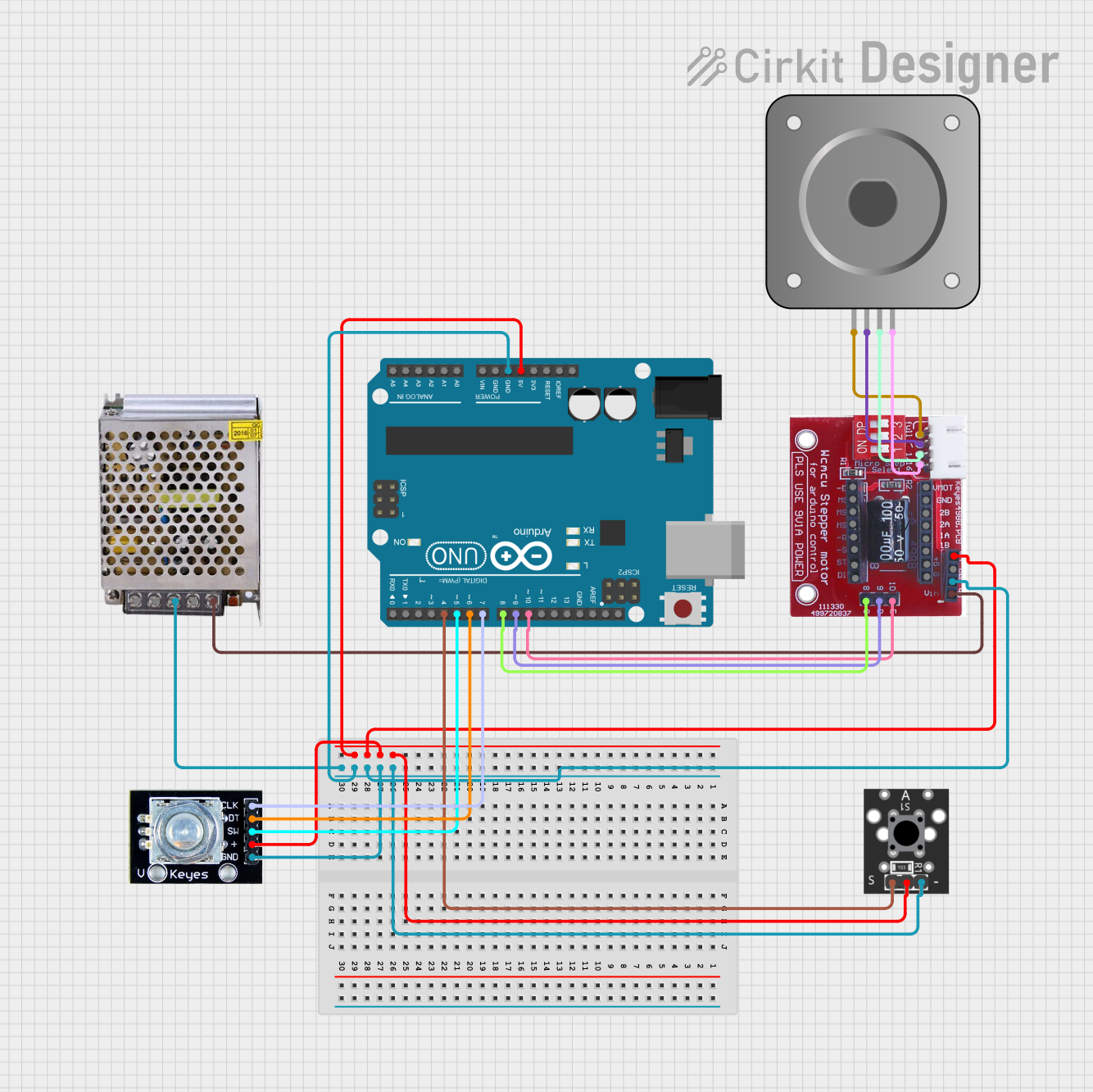

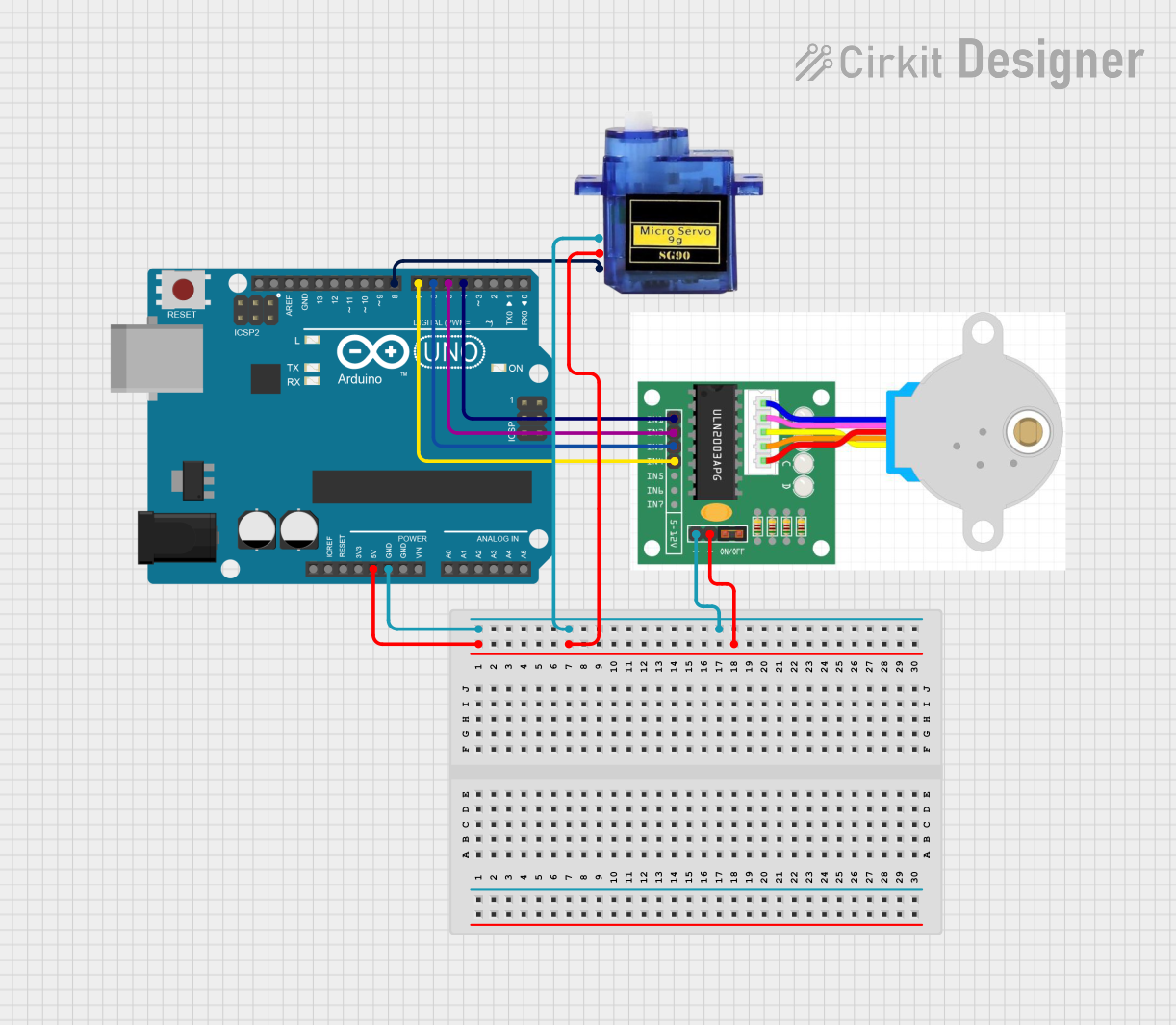

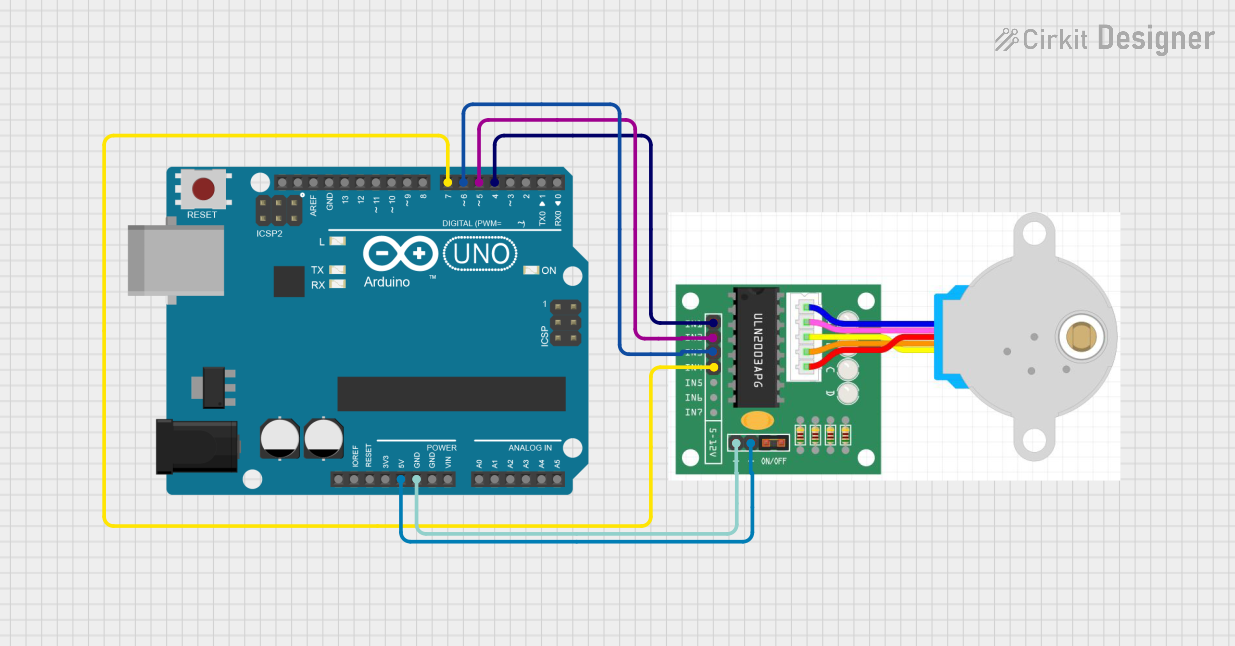

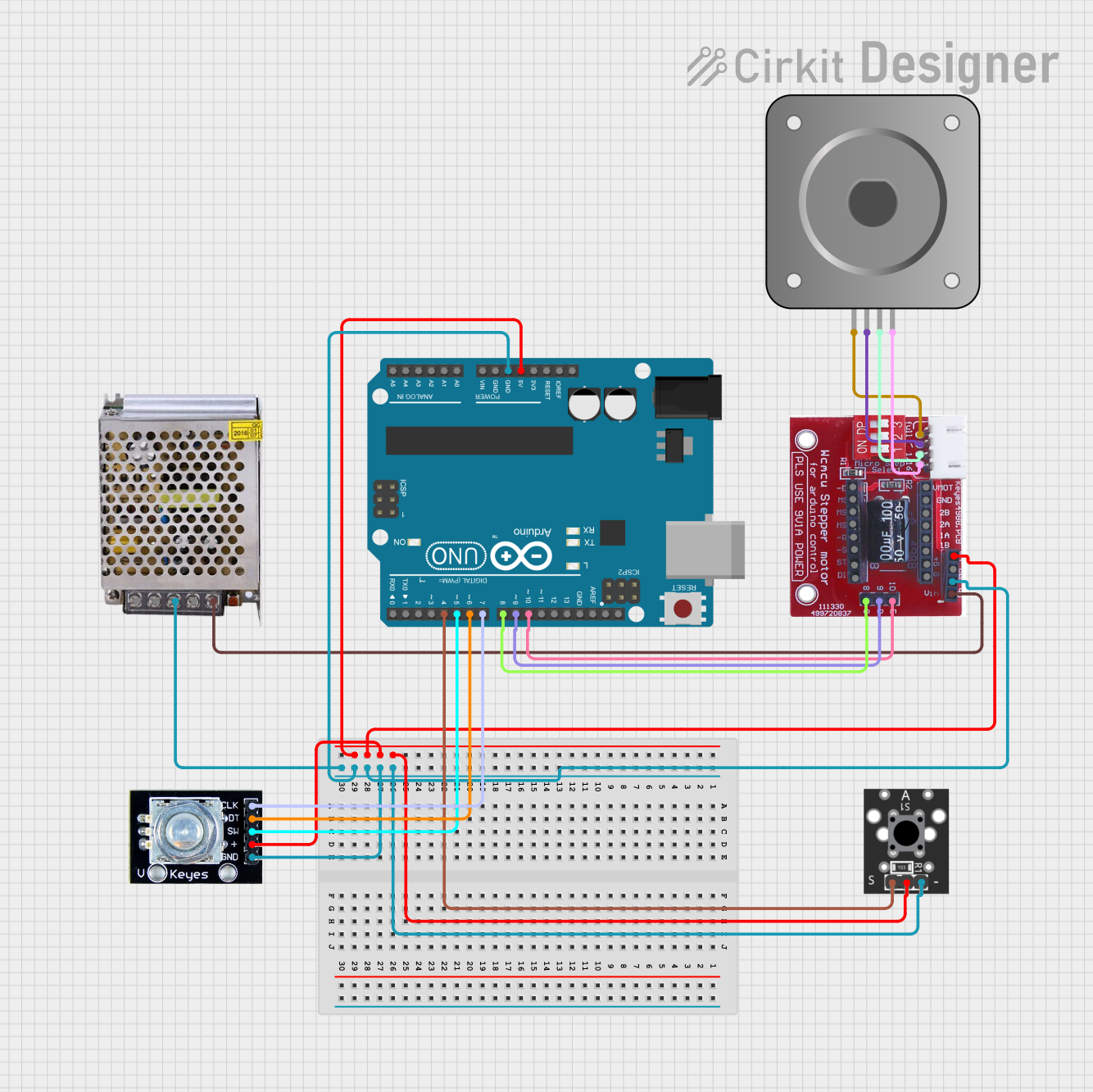

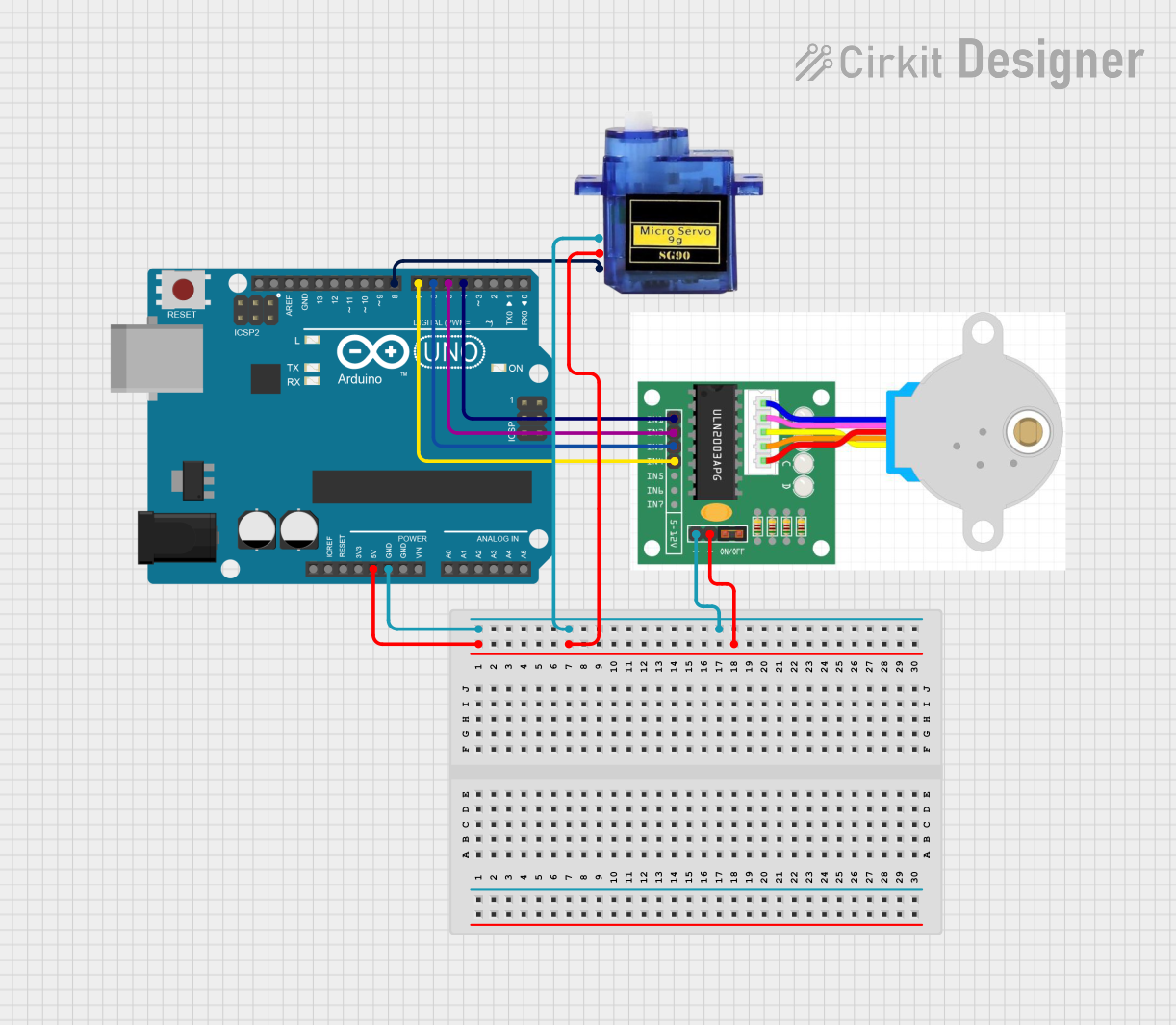

Connecting to an Arduino UNO

To use the stepper motor with an Arduino UNO, you will need a stepper motor driver, such as the A4988 or the ULN2003, depending on the motor's voltage and current specifications.

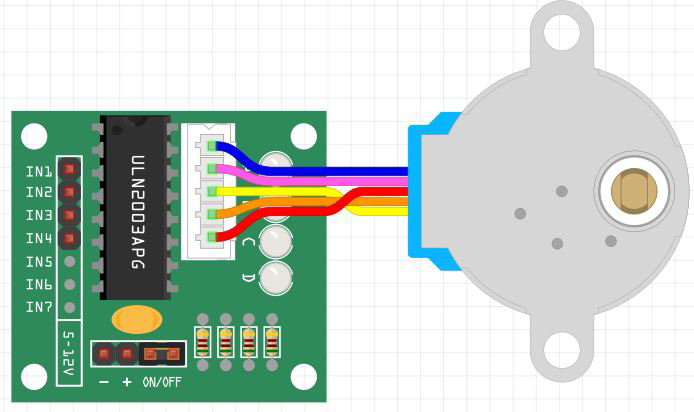

Wiring Diagram

- Connect the motor's coils to the driver's output pins.

- Connect the driver's input pins to the Arduino's digital output pins.

- Connect the driver's power supply pins to an appropriate power source.

- Ground the driver and the Arduino to a common ground.

Example Code

#include <Stepper.h>

// Change these values based on your motor's specifications

const int stepsPerRevolution = 200; // typically 200 steps for a 1.8 degree stepper

// Wiring: Arduino pins are connected to stepper driver inputs

Stepper myStepper(stepsPerRevolution, 8, 9, 10, 11);

void setup() {

myStepper.setSpeed(60); // Set the speed to 60 RPM

}

void loop() {

// Step one revolution in one direction:

myStepper.step(stepsPerRevolution);

delay(500);

// Step one revolution in the other direction:

myStepper.step(-stepsPerRevolution);

delay(500);

}

Important Considerations and Best Practices

- Always use a stepper motor driver; do not connect a stepper motor directly to the Arduino.

- Ensure the power supply matches the motor's requirements.

- Avoid running the stepper motor at its maximum ratings for extended periods to prevent overheating.

- Use a decoupling capacitor across the power supply to minimize voltage spikes.

Troubleshooting and FAQs

Common Issues

- Motor does not turn: Check wiring, ensure the power supply is adequate, and verify that the driver is functioning.

- Motor skips steps or stalls: This may be due to excessive speed, high load, or insufficient current. Adjust the driver settings accordingly.

- Motor overheats: Reduce the current, improve cooling, or reduce the duty cycle.

FAQs

Q: Can I run a stepper motor without a driver? A: No, a driver is necessary to control the current and to protect the Arduino from damage.

Q: How do I know if my stepper motor is bipolar or unipolar? A: Bipolar motors have two coils with no center taps, while unipolar motors have center taps that can be used to change the winding configuration.

Q: What is the maximum speed of a stepper motor? A: The maximum speed depends on the motor and driver capabilities, as well as the load and voltage applied. It is important to refer to the motor's datasheet for specific details.

For further assistance, consult the manufacturer's datasheet or contact technical support.