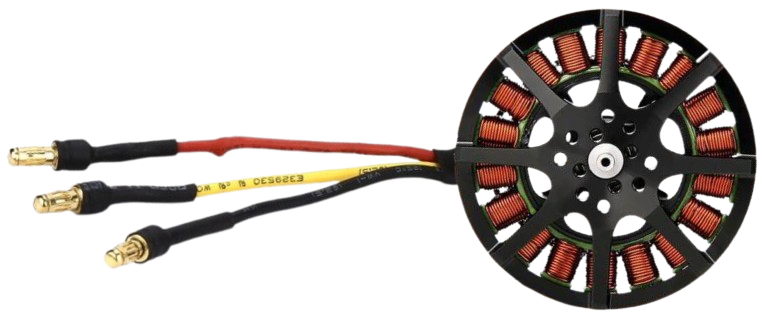

How to Use BLDC Motor: Examples, Pinouts, and Specs

Design with BLDC Motor in Cirkit Designer

Design with BLDC Motor in Cirkit DesignerIntroduction

A Brushless DC (BLDC) Motor is an electric motor that operates without brushes, using electronic commutation instead. Unlike traditional brushed motors, BLDC motors rely on electronic controllers to switch the current in the motor windings, which generates a rotating magnetic field. This design eliminates the need for physical brushes, resulting in higher efficiency, reduced wear and tear, and lower maintenance requirements.

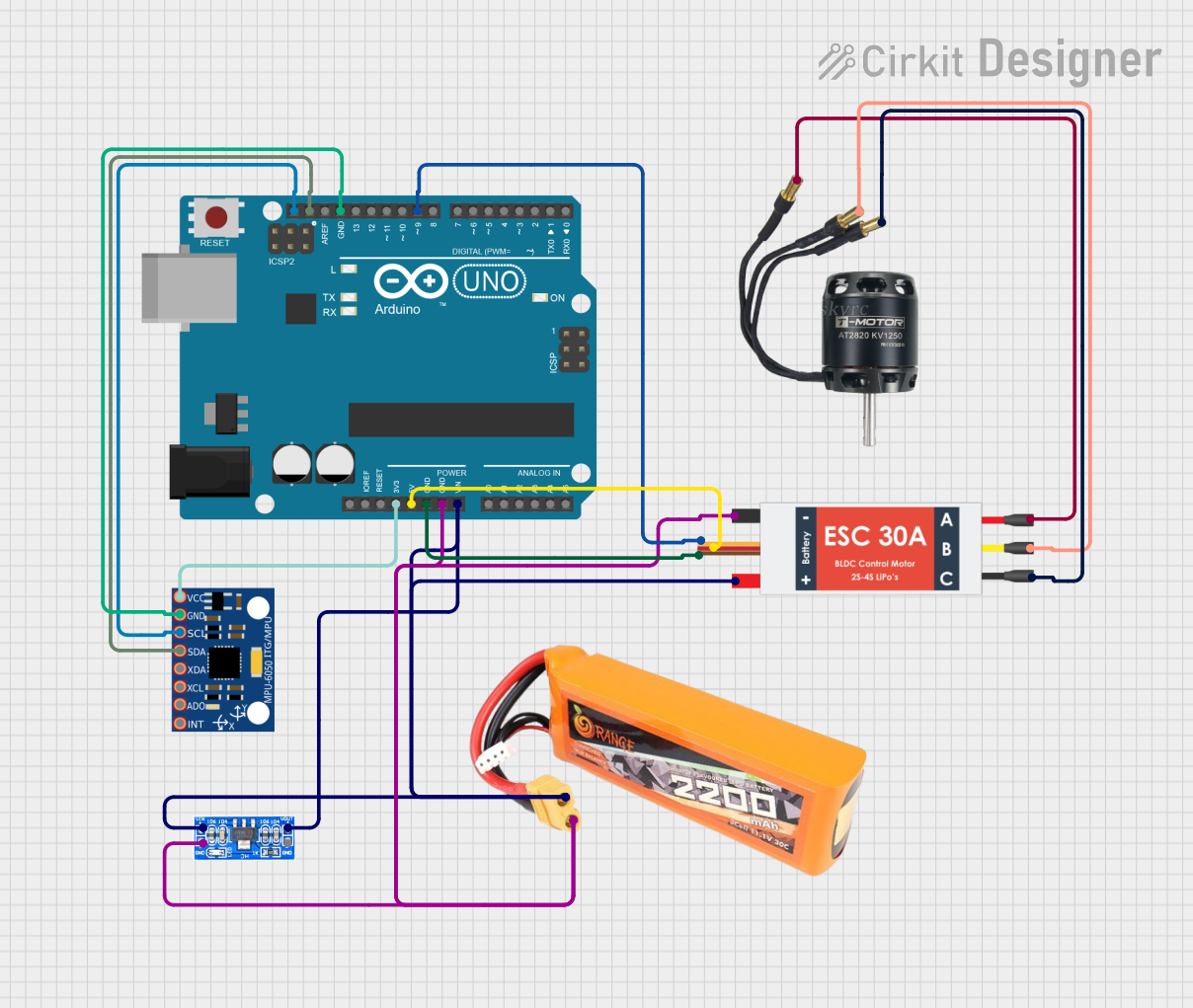

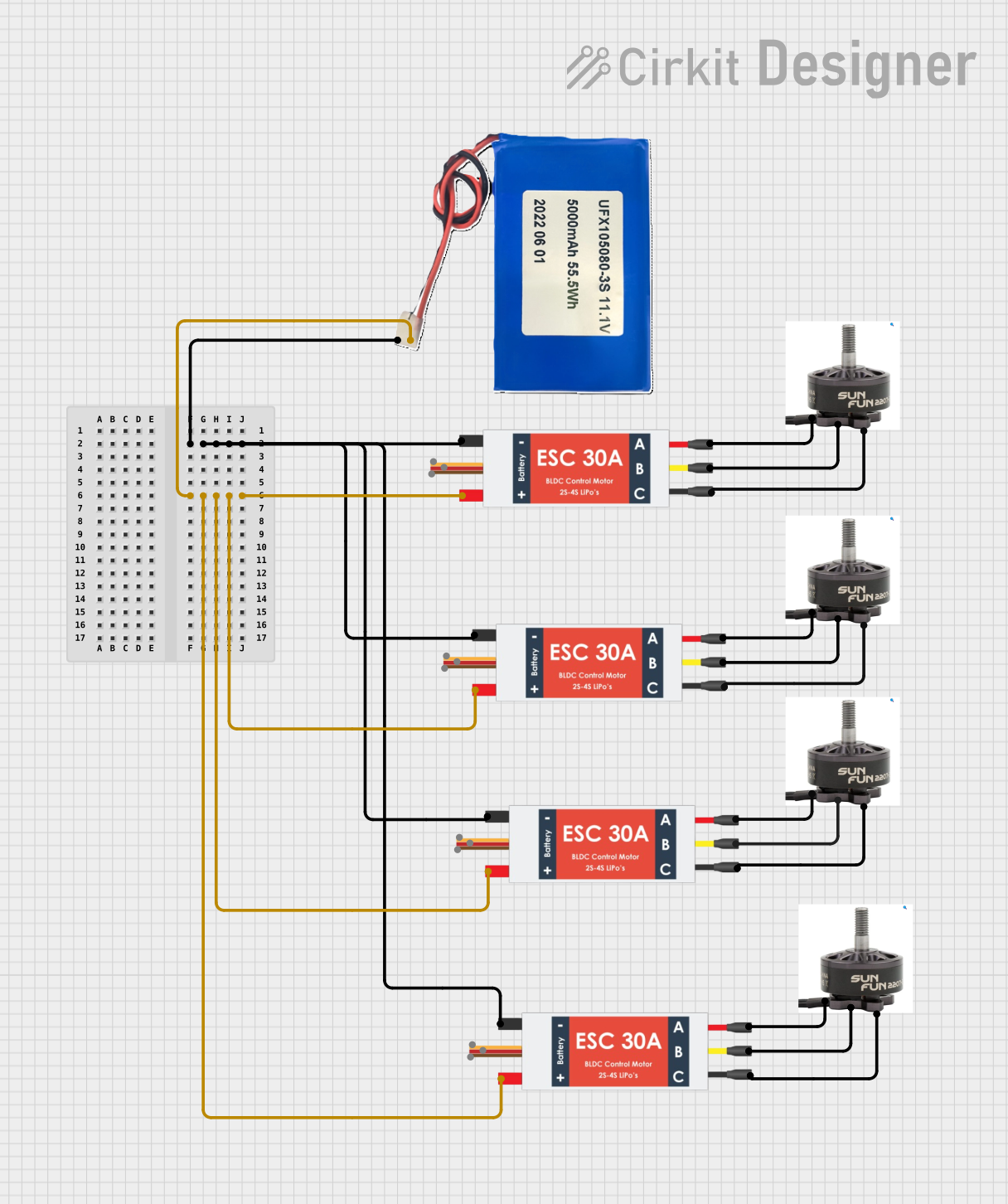

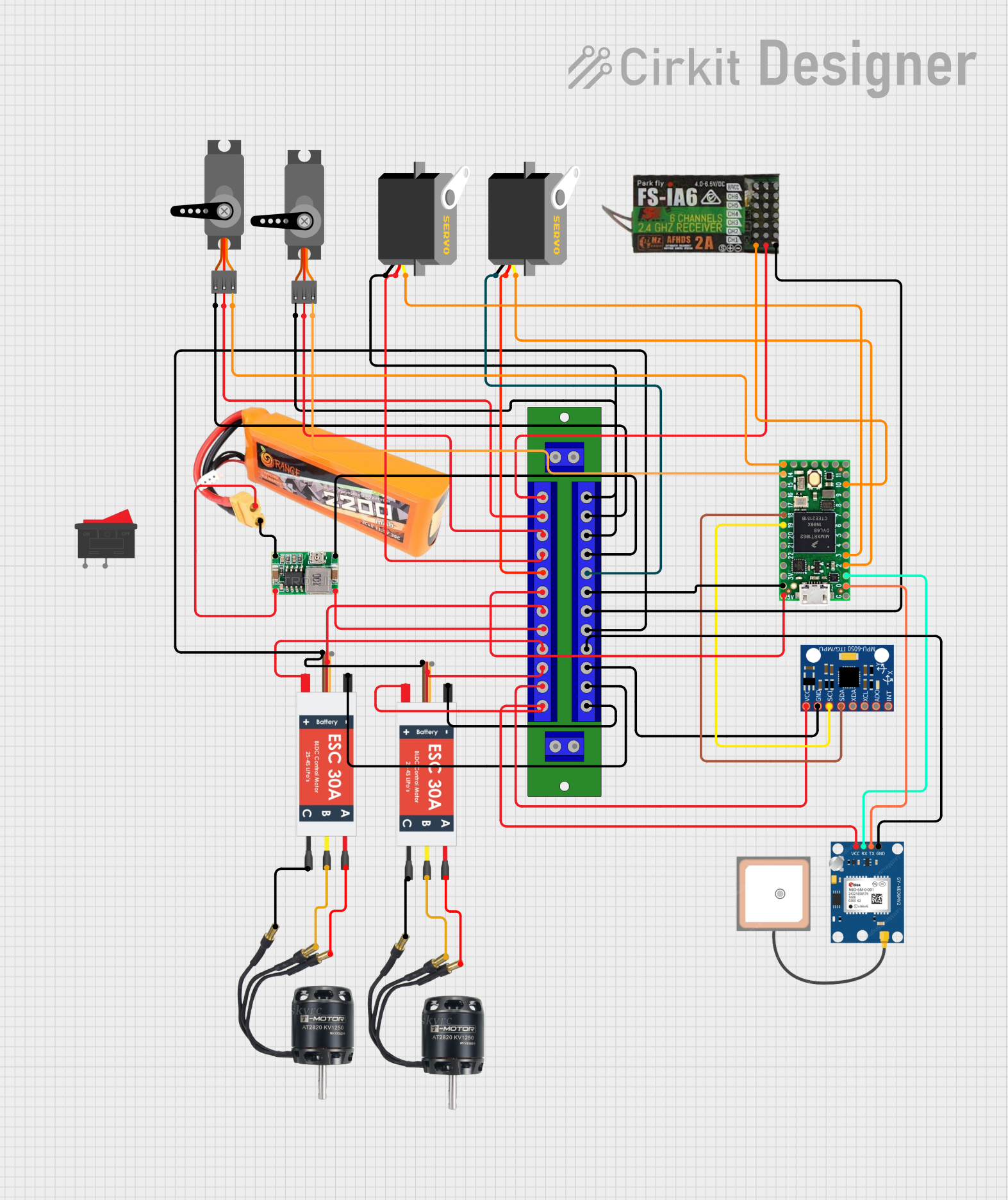

Explore Projects Built with BLDC Motor

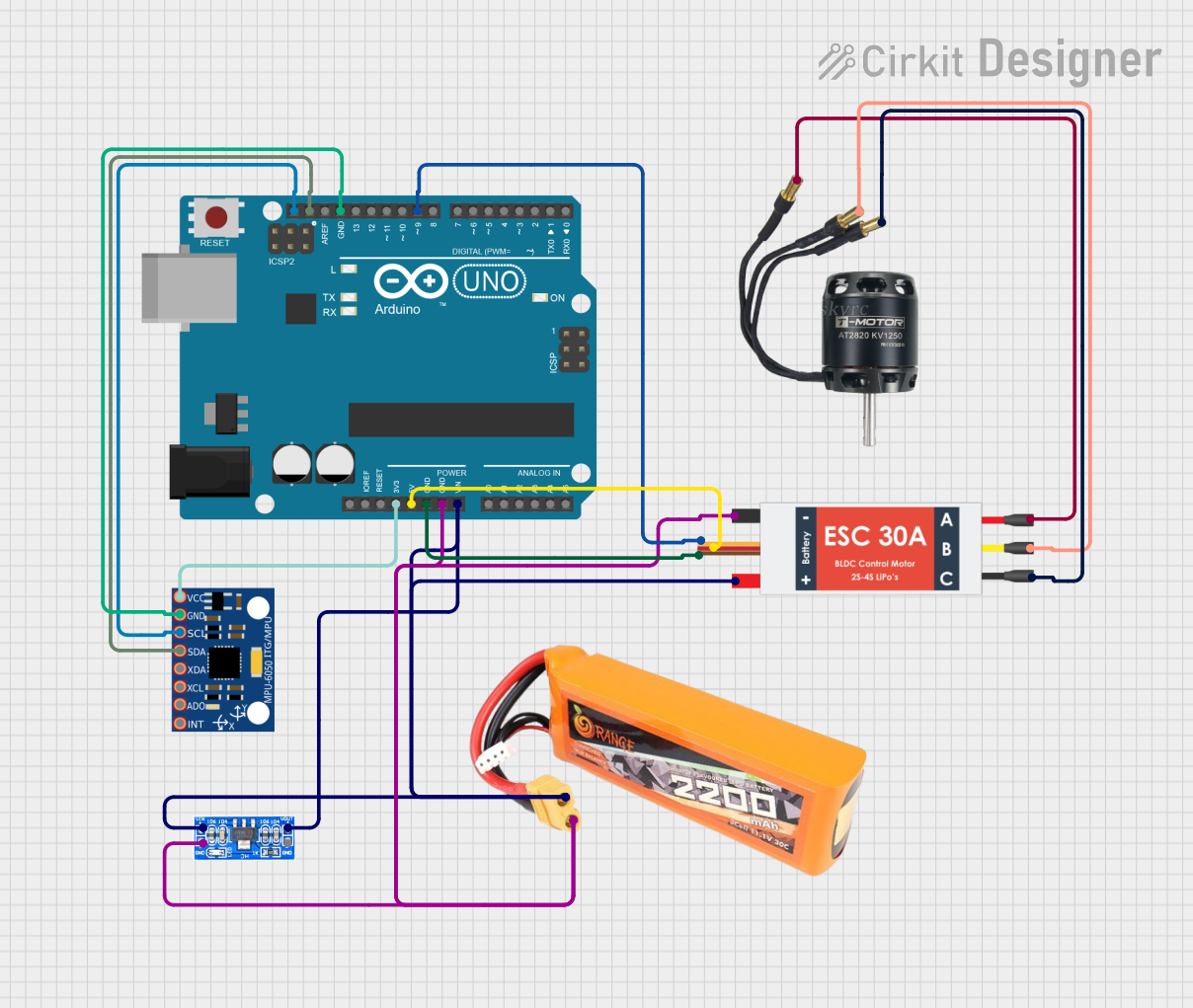

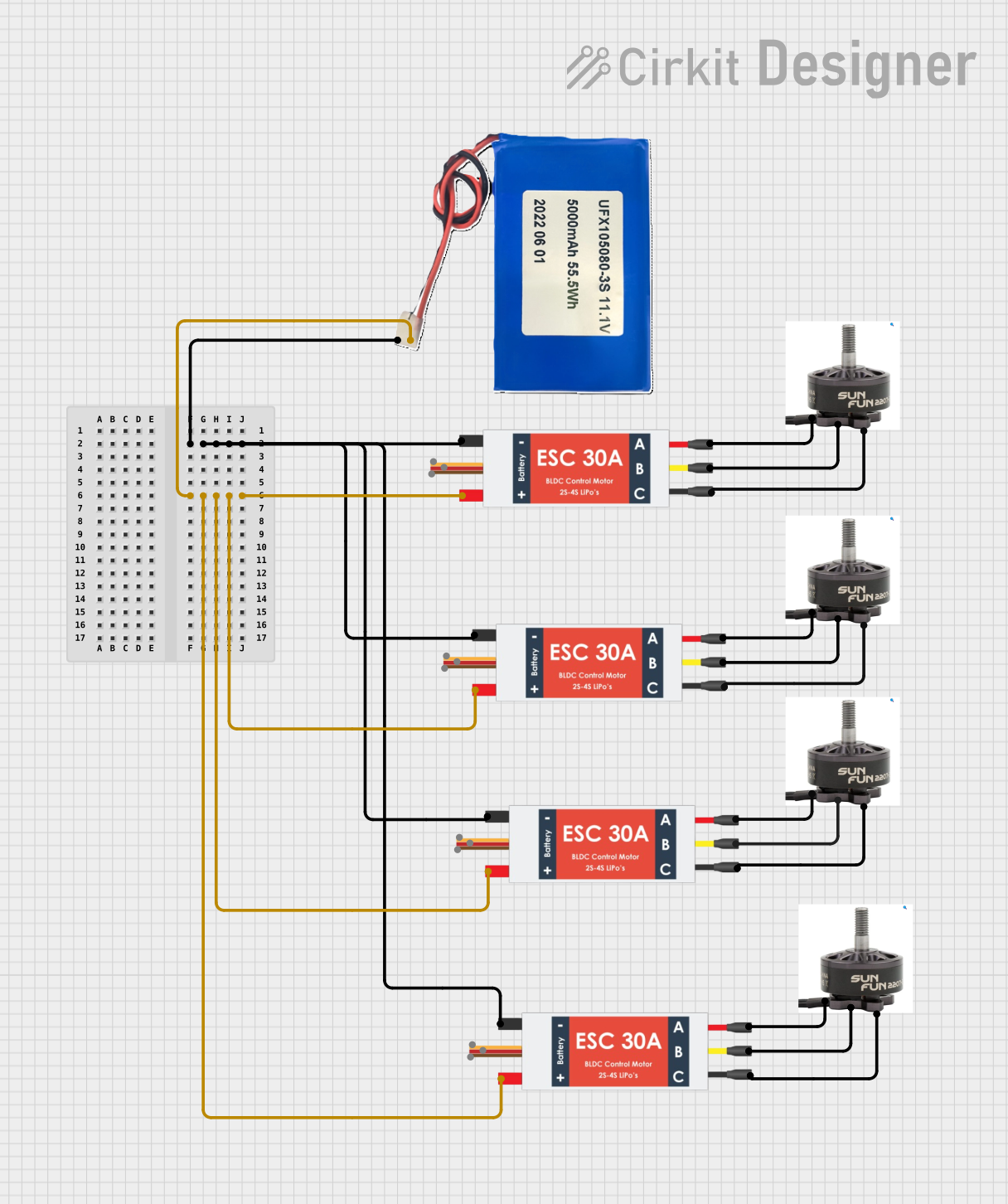

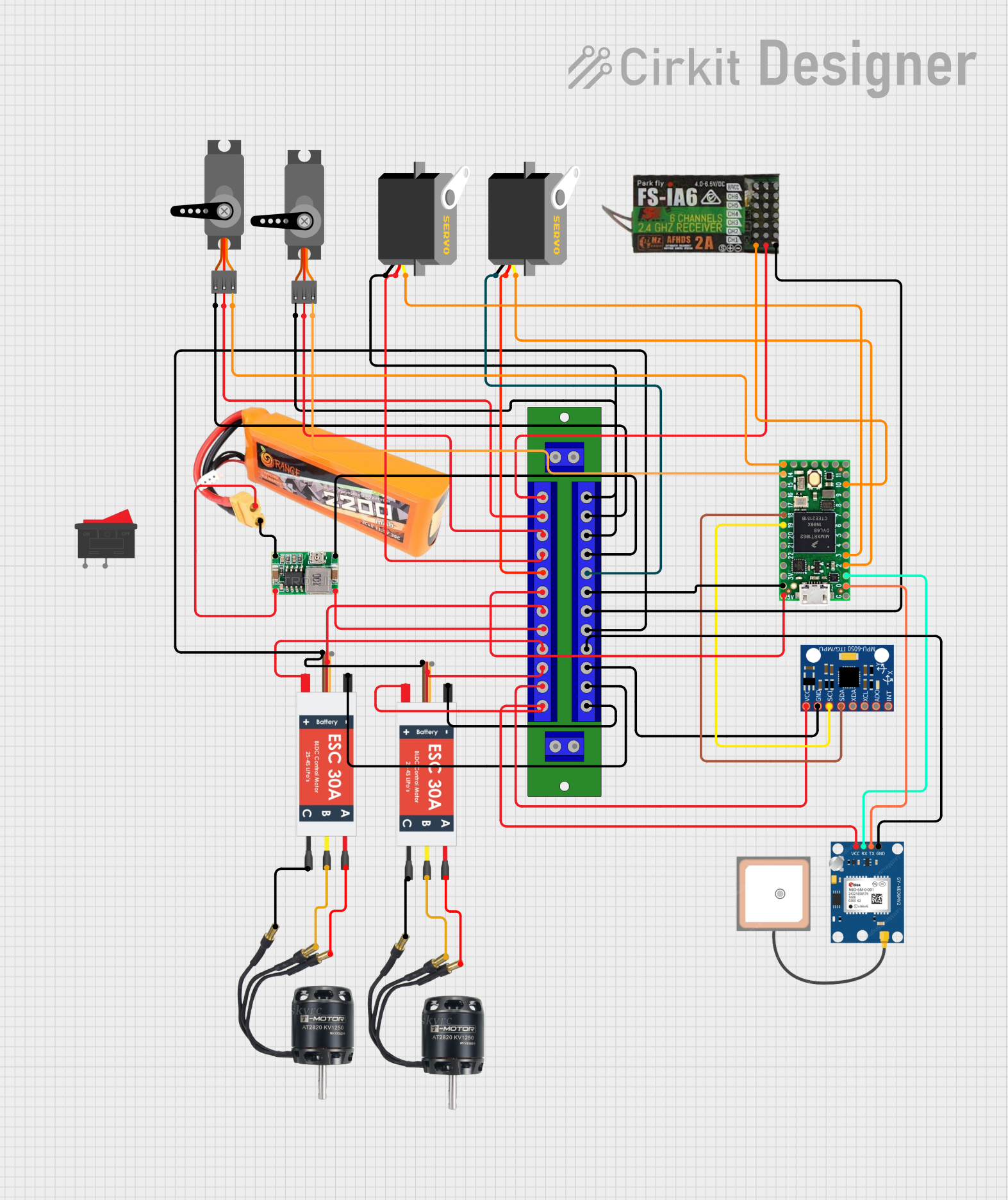

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with BLDC Motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Used for precise motion control and high torque applications.

- Electric Vehicles (EVs): Powers the drivetrain for efficient and quiet operation.

- Drones and UAVs: Provides lightweight, high-speed propulsion.

- Industrial Machines: Drives conveyor belts, pumps, and fans.

- Home Appliances: Found in washing machines, air conditioners, and vacuum cleaners.

Technical Specifications

Below are the general technical specifications for a typical BLDC motor. Note that specific values may vary depending on the model and manufacturer.

Key Technical Details

- Operating Voltage: 12V to 48V (common range; some models may vary)

- Rated Current: 1A to 50A (depending on motor size and application)

- Power Output: 10W to several kW

- Speed Range: 1,000 to 20,000 RPM

- Torque: 0.1 Nm to 10 Nm

- Efficiency: Typically 85% to 95%

- Number of Poles: 2 to 14 (varies by design)

- Commutation: Electronic (requires an external controller)

Pin Configuration and Descriptions

BLDC motors typically have three main wires for the motor windings and additional wires for sensors (if equipped). Below is a table describing the common pin configuration:

| Pin Name | Description |

|---|---|

| Phase A | First motor winding connection (connects to the controller). |

| Phase B | Second motor winding connection (connects to the controller). |

| Phase C | Third motor winding connection (connects to the controller). |

| Hall Sensor VCC | Power supply for the Hall effect sensors (commonly 5V). |

| Hall Sensor GND | Ground connection for the Hall effect sensors. |

| Hall Sensor A | Output signal from Hall sensor A (used for position feedback). |

| Hall Sensor B | Output signal from Hall sensor B (used for position feedback). |

| Hall Sensor C | Output signal from Hall sensor C (used for position feedback). |

Usage Instructions

How to Use the Component in a Circuit

Connect the Motor to a Controller:

- BLDC motors require an external electronic speed controller (ESC) to operate. The ESC manages the commutation and speed control.

- Connect the motor's three-phase wires (Phase A, B, and C) to the corresponding outputs on the ESC.

Power the ESC:

- Provide the ESC with the appropriate voltage and current as specified by the motor and ESC ratings.

- Ensure the power supply can handle the peak current requirements of the motor.

Connect Hall Sensors (if applicable):

- If the motor is equipped with Hall effect sensors, connect the sensor wires (VCC, GND, A, B, C) to the ESC or microcontroller for position feedback.

Control the Motor:

- Use a microcontroller (e.g., Arduino UNO) or a remote control system to send PWM signals to the ESC for speed and direction control.

Important Considerations and Best Practices

- Match the ESC to the Motor: Ensure the ESC is compatible with the motor's voltage, current, and power ratings.

- Cooling: High-power BLDC motors may require additional cooling (e.g., heatsinks or fans) to prevent overheating.

- Avoid Overloading: Do not exceed the motor's rated current or torque to avoid damage.

- Secure Mounting: Properly mount the motor to prevent vibrations and ensure stable operation.

- Check Wiring: Double-check all connections to avoid short circuits or incorrect wiring.

Example Code for Arduino UNO

Below is an example of how to control a BLDC motor using an ESC and an Arduino UNO:

// Example code to control a BLDC motor using an ESC and Arduino UNO

// The ESC is controlled via a PWM signal on pin 9

#include <Servo.h> // Include the Servo library to generate PWM signals

Servo esc; // Create a Servo object to control the ESC

void setup() {

esc.attach(9); // Attach the ESC to pin 9

esc.writeMicroseconds(1000); // Send minimum throttle signal (1000 µs)

delay(2000); // Wait for 2 seconds to allow the ESC to initialize

}

void loop() {

esc.writeMicroseconds(1500); // Set throttle to 50% (1500 µs)

delay(5000); // Run the motor at 50% speed for 5 seconds

esc.writeMicroseconds(2000); // Set throttle to 100% (2000 µs)

delay(5000); // Run the motor at full speed for 5 seconds

esc.writeMicroseconds(1000); // Stop the motor (1000 µs)

delay(5000); // Wait for 5 seconds before repeating

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Does Not Spin:

- Cause: Incorrect wiring or insufficient power supply.

- Solution: Verify all connections and ensure the power supply meets the motor's requirements.

Motor Vibrates but Does Not Rotate:

- Cause: Incorrect phase wiring or damaged ESC.

- Solution: Check the phase connections and replace the ESC if necessary.

Overheating:

- Cause: Overloading or insufficient cooling.

- Solution: Reduce the load on the motor and add cooling mechanisms.

Inconsistent Speed or Stalling:

- Cause: Faulty Hall sensors or poor signal quality.

- Solution: Inspect the Hall sensor connections and replace any damaged sensors.

FAQs

Q: Can I run a BLDC motor without an ESC?

- A: No, a BLDC motor requires an ESC for electronic commutation and speed control.

Q: How do I reverse the motor's direction?

- A: Swap any two of the three-phase wires (Phase A, B, or C) to reverse the direction.

Q: What is the advantage of using Hall sensors?

- A: Hall sensors provide precise position feedback, enabling smoother operation and better control at low speeds.

Q: Can I use a BLDC motor with a battery?

- A: Yes, as long as the battery voltage and current ratings match the motor and ESC requirements.