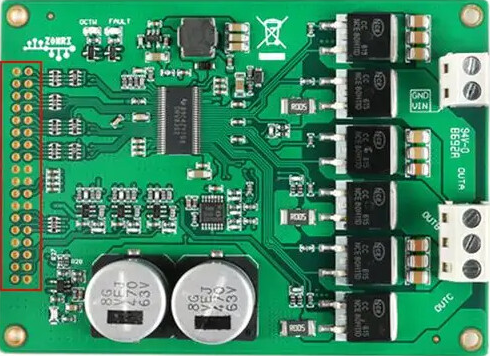

How to Use DRV8302: Examples, Pinouts, and Specs

Design with DRV8302 in Cirkit Designer

Design with DRV8302 in Cirkit DesignerIntroduction

The DRV8302 is a three-phase motor driver IC designed for driving brushless DC (BLDC) motors. It integrates a gate driver, current sensing, and protection features, enabling efficient control of motor operation with minimal external components. This component is ideal for applications requiring high-performance motor control, such as robotics, drones, electric vehicles, and industrial automation.

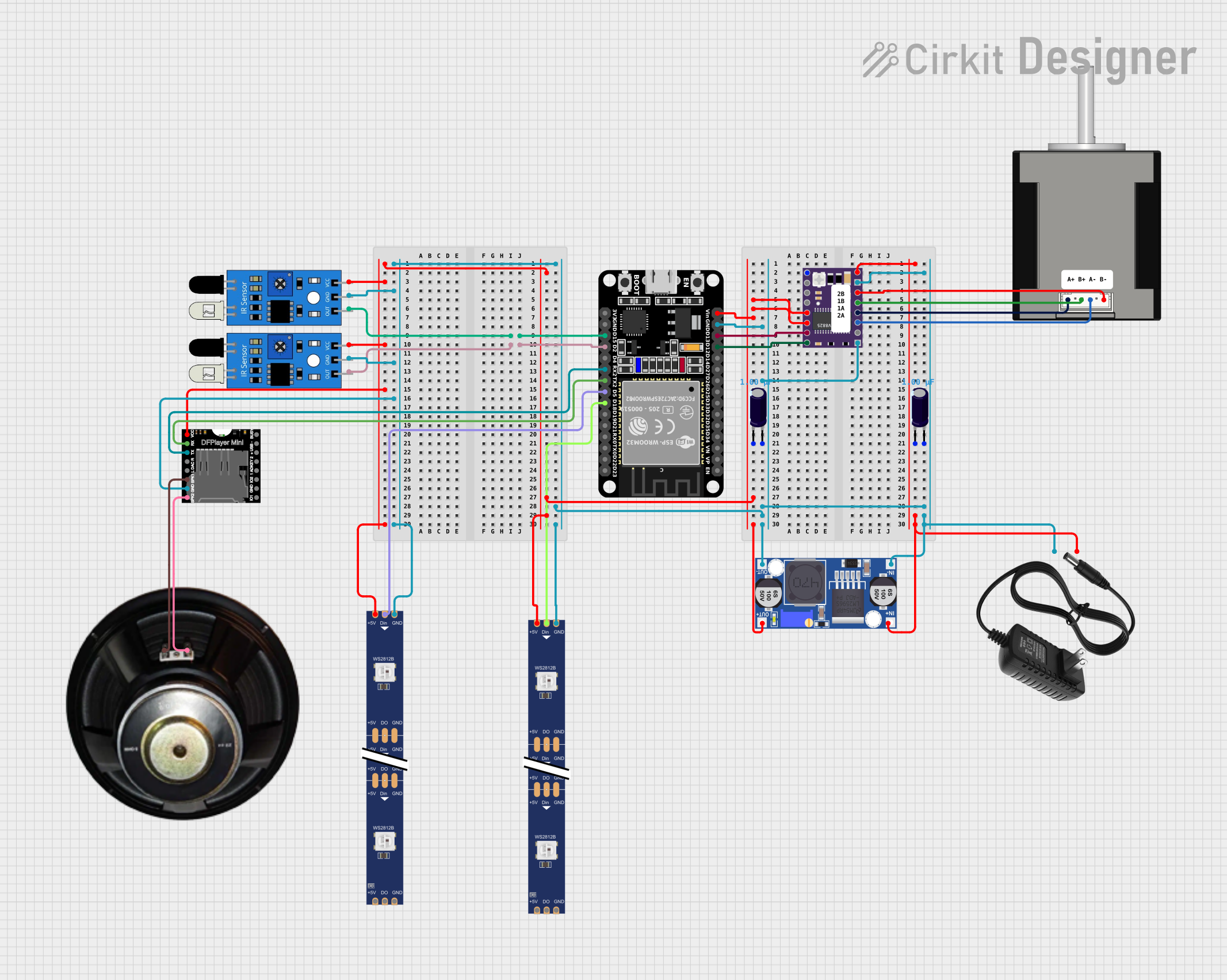

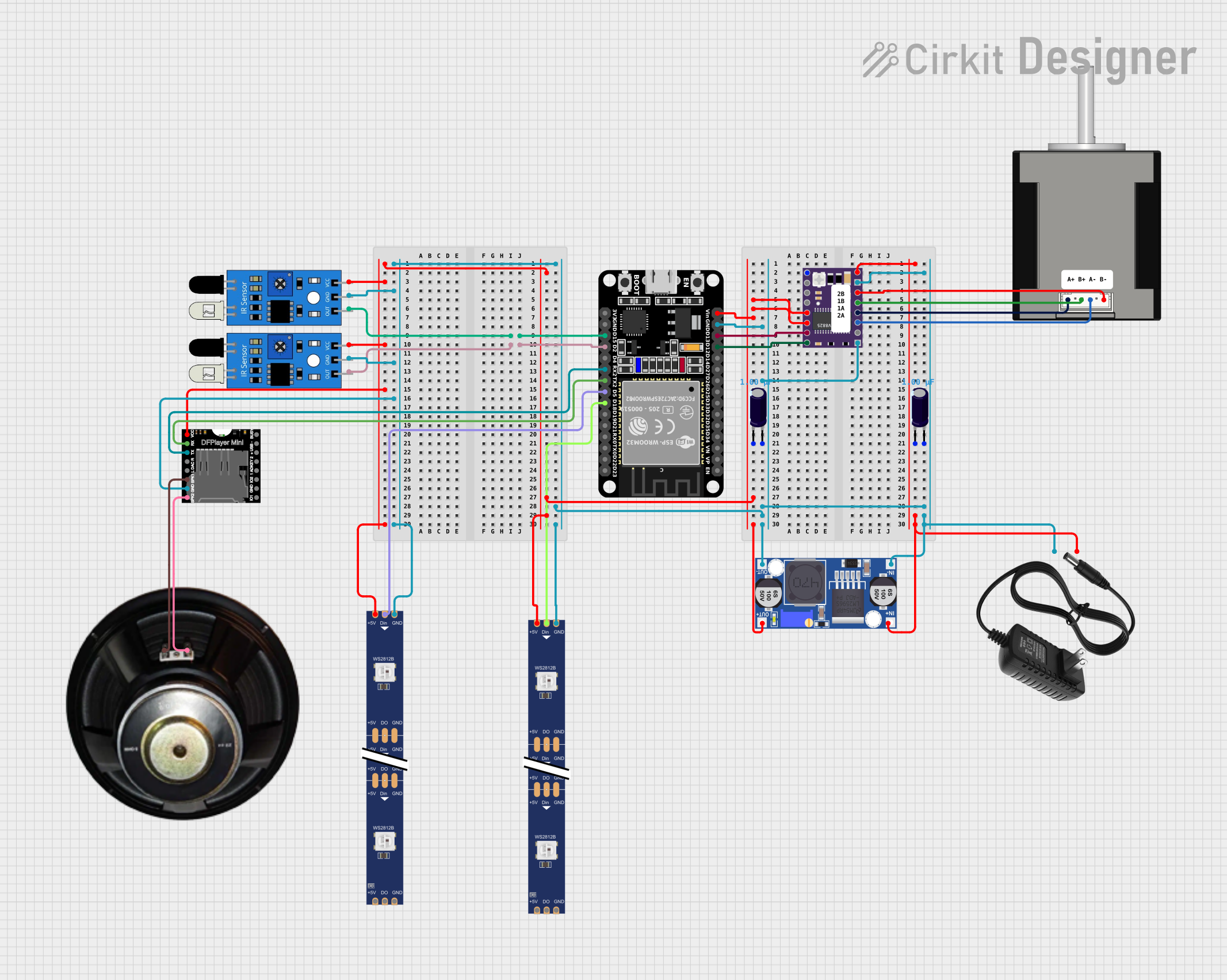

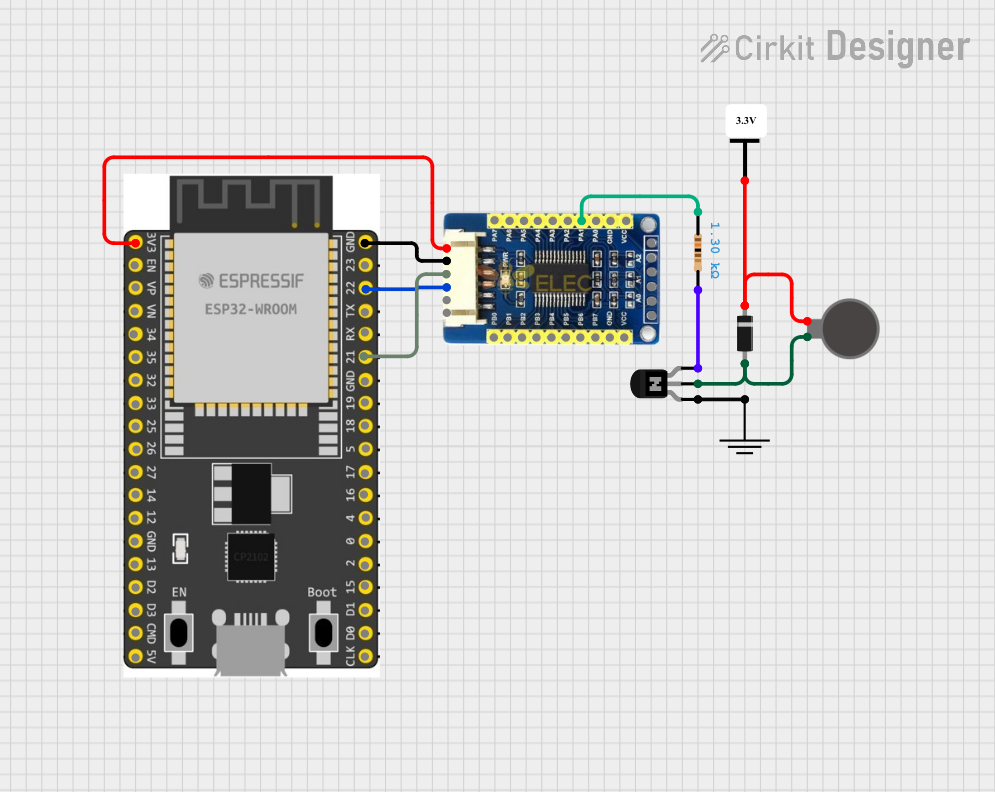

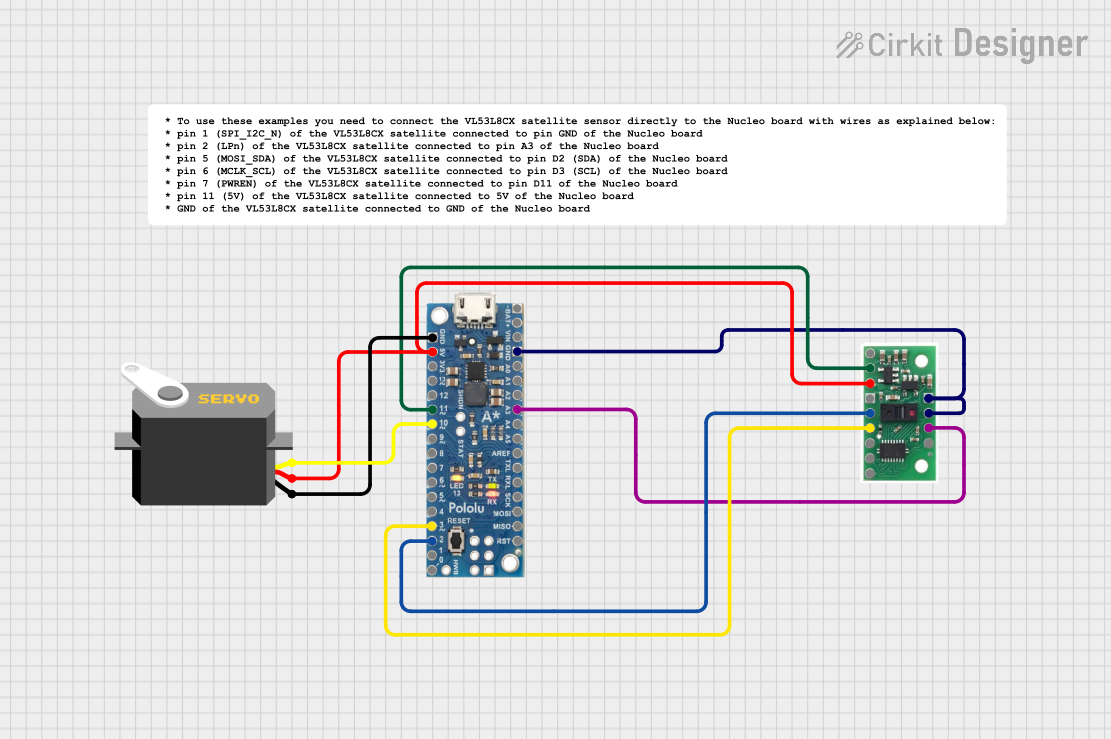

Explore Projects Built with DRV8302

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with DRV8302

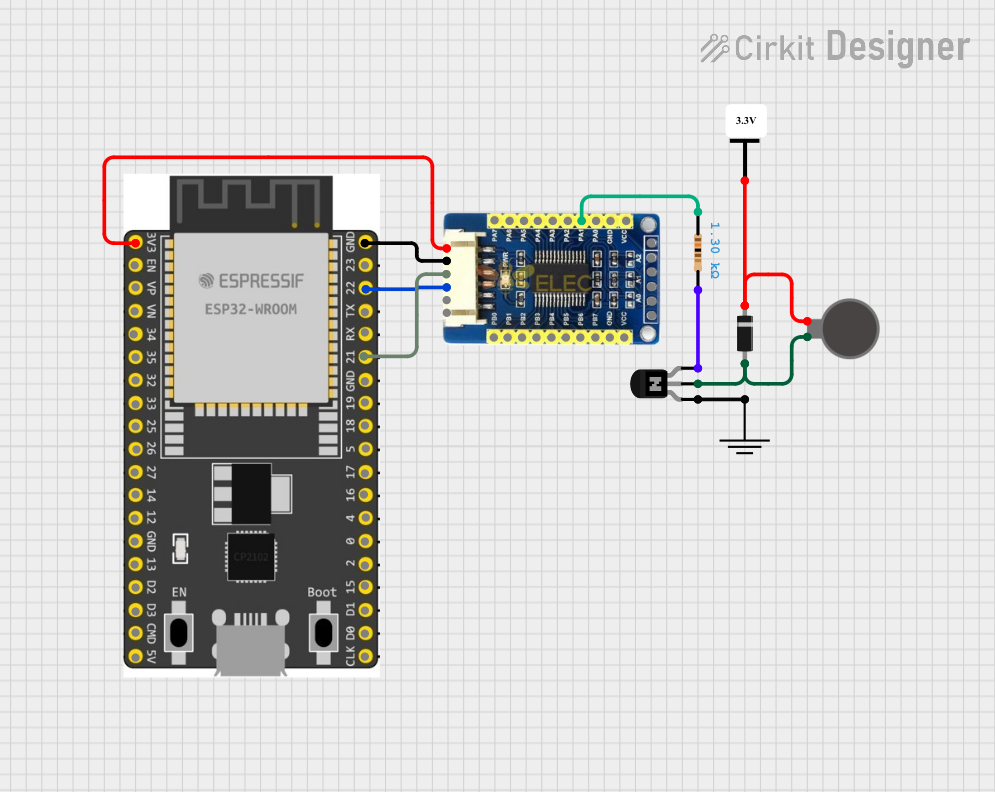

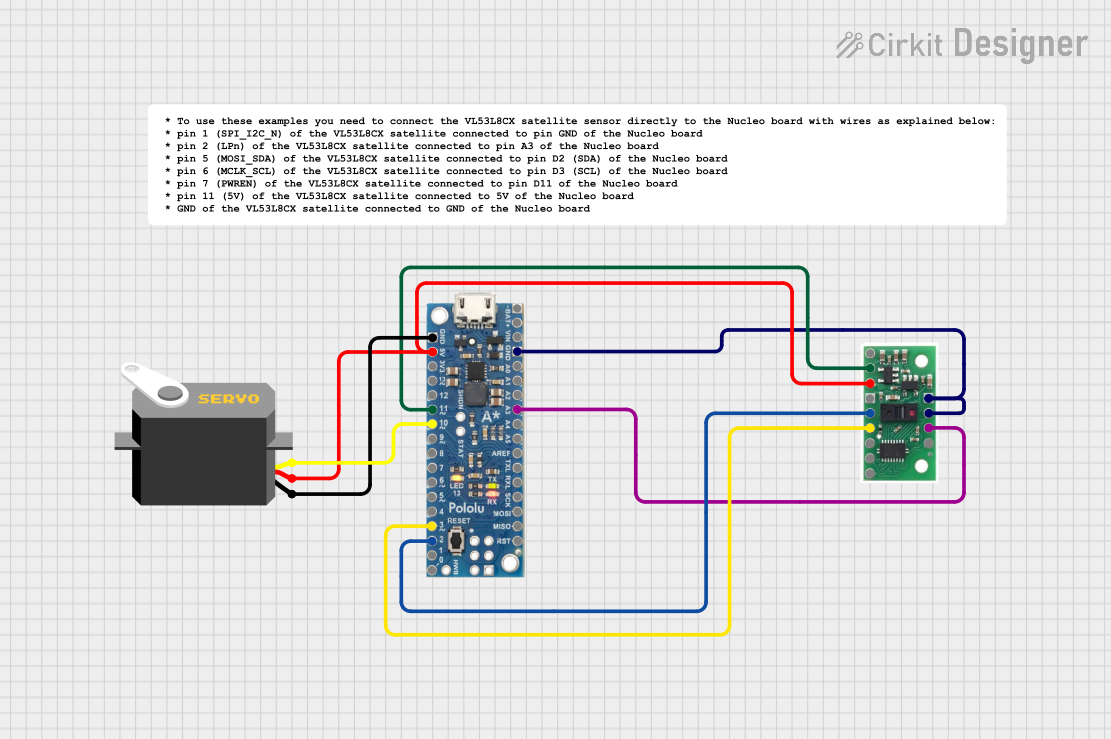

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Brushless DC motor control in robotics and drones

- Electric vehicle motor drivers

- Industrial automation systems

- HVAC systems

- Power tools and appliances

Technical Specifications

Key Technical Details

- Operating Voltage Range: 8 V to 60 V

- Gate Drive Current: 1.7 A source, 2.3 A sink

- Integrated Buck Converter: Adjustable output voltage (up to 60 V input, 7.5 V output)

- Current Sensing: Integrated shunt amplifier with adjustable gain

- PWM Input Frequency: Up to 200 kHz

- Protection Features: Overcurrent, overtemperature, and undervoltage lockout

- Package: HTSSOP-48 with PowerPAD for thermal management

Pin Configuration and Descriptions

The DRV8302 comes in a 48-pin HTSSOP package. Below is a summary of key pins:

| Pin Name | Type | Description |

|---|---|---|

| PVDD | Power | Main power supply input for the motor driver (8 V to 60 V). |

| GND | Ground | Ground connection for the IC. |

| GHx, GLx | Output | High-side (GHx) and low-side (GLx) gate drive outputs for the three motor phases. |

| SHx | Input/Output | Source connection for high-side FETs. |

| SP/SM | Input | Current sense amplifier inputs for phase current measurement. |

| EN_GATE | Input | Enables the gate driver when set high. |

| PWM_A, PWM_B | Input | PWM inputs for controlling motor phases. |

| VREG | Output | Regulated voltage output from the internal buck converter. |

| OC_ADJ | Input | Adjusts the overcurrent protection threshold. |

| FAULT | Output | Fault indicator pin (active low). |

For a complete pinout, refer to the DRV8302 datasheet.

Usage Instructions

How to Use the DRV8302 in a Circuit

- Power Supply: Connect the PVDD pin to a power supply within the range of 8 V to 60 V. Ensure proper decoupling capacitors are placed close to the IC to minimize noise.

- Gate Drive: Connect the GHx and GLx pins to the gates of external MOSFETs for each motor phase. Use low-resistance, high-speed MOSFETs for optimal performance.

- Current Sensing: Connect shunt resistors to the SP and SM pins for phase current measurement. Adjust the gain of the current sense amplifier as needed.

- PWM Control: Provide PWM signals to the PWM_A and PWM_B pins to control motor speed and direction.

- Enable Gate Driver: Set the EN_GATE pin high to enable the gate driver. Use a pull-down resistor to ensure the pin is low during power-up.

- Fault Monitoring: Monitor the FAULT pin for any error conditions, such as overcurrent or overtemperature.

Important Considerations and Best Practices

- Thermal Management: Use a proper heatsink or ensure good PCB thermal design to dissipate heat from the PowerPAD.

- Decoupling: Place high-quality ceramic capacitors (e.g., 0.1 µF and 10 µF) close to the PVDD and VREG pins to reduce noise and stabilize the power supply.

- Protection: Configure the OC_ADJ pin to set the overcurrent protection threshold based on your application requirements.

- Startup Sequence: Ensure the EN_GATE pin is low during power-up to prevent unintended motor operation.

Example Code for Arduino UNO

Below is an example of how to control the DRV8302 using an Arduino UNO:

// Define PWM pins for motor control

const int pwmA = 9; // Connect to PWM_A pin of DRV8302

const int pwmB = 10; // Connect to PWM_B pin of DRV8302

const int enablePin = 8; // Connect to EN_GATE pin of DRV8302

void setup() {

// Set up pins as outputs

pinMode(pwmA, OUTPUT);

pinMode(pwmB, OUTPUT);

pinMode(enablePin, OUTPUT);

// Enable the gate driver

digitalWrite(enablePin, HIGH);

// Initialize PWM signals

analogWrite(pwmA, 128); // 50% duty cycle

analogWrite(pwmB, 0); // 0% duty cycle (motor stopped)

}

void loop() {

// Example: Ramp up motor speed

for (int speed = 0; speed <= 255; speed++) {

analogWrite(pwmA, speed); // Increase duty cycle on PWM_A

delay(10); // Small delay for smooth ramp-up

}

// Example: Ramp down motor speed

for (int speed = 255; speed >= 0; speed--) {

analogWrite(pwmA, speed); // Decrease duty cycle on PWM_A

delay(10); // Small delay for smooth ramp-down

}

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Does Not Spin:

- Ensure the EN_GATE pin is set high to enable the gate driver.

- Verify that the PWM signals are being generated correctly.

- Check the connections to the external MOSFETs and motor phases.

Overcurrent Fault:

- Verify the shunt resistor values and ensure they are appropriate for the motor current.

- Adjust the OC_ADJ pin to increase the overcurrent protection threshold if necessary.

Overheating:

- Ensure proper thermal management by using a heatsink or optimizing PCB layout.

- Check for excessive current draw from the motor.

Fault Pin Active (Low):

- Check for fault conditions such as overcurrent, undervoltage, or overtemperature.

- Reset the fault by toggling the EN_GATE pin low and then high.

FAQs

Can the DRV8302 drive a brushed DC motor? No, the DRV8302 is specifically designed for three-phase brushless DC motors.

What type of MOSFETs should I use with the DRV8302? Use low-resistance, high-speed N-channel MOSFETs rated for the motor's voltage and current.

How do I adjust the current sense amplifier gain? The gain can be adjusted using external resistors connected to the SP and SM pins. Refer to the datasheet for detailed calculations.

What is the maximum PWM frequency supported? The DRV8302 supports PWM frequencies up to 200 kHz. Ensure your microcontroller can generate PWM signals within this range.