How to Use DRV8838 Single Brushed DC Motor Driver: Examples, Pinouts, and Specs

Design with DRV8838 Single Brushed DC Motor Driver in Cirkit Designer

Design with DRV8838 Single Brushed DC Motor Driver in Cirkit DesignerIntroduction

The DRV8838 is a single brushed DC motor driver designed to provide efficient and reliable control of a single brushed DC motor. It features a compact design, making it ideal for space-constrained applications. The DRV8838 supports adjustable speed and direction control, and it includes built-in protection mechanisms such as overcurrent protection, thermal shutdown, and undervoltage lockout. This makes it a robust choice for motor control in a variety of applications.

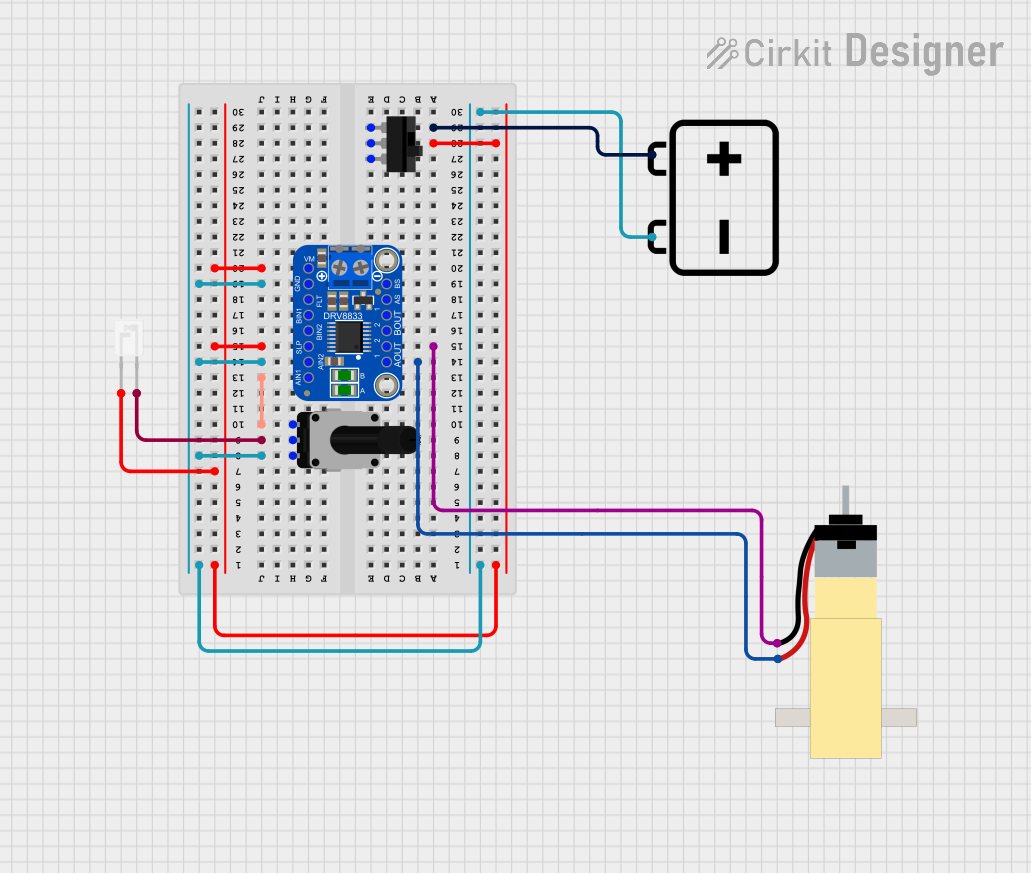

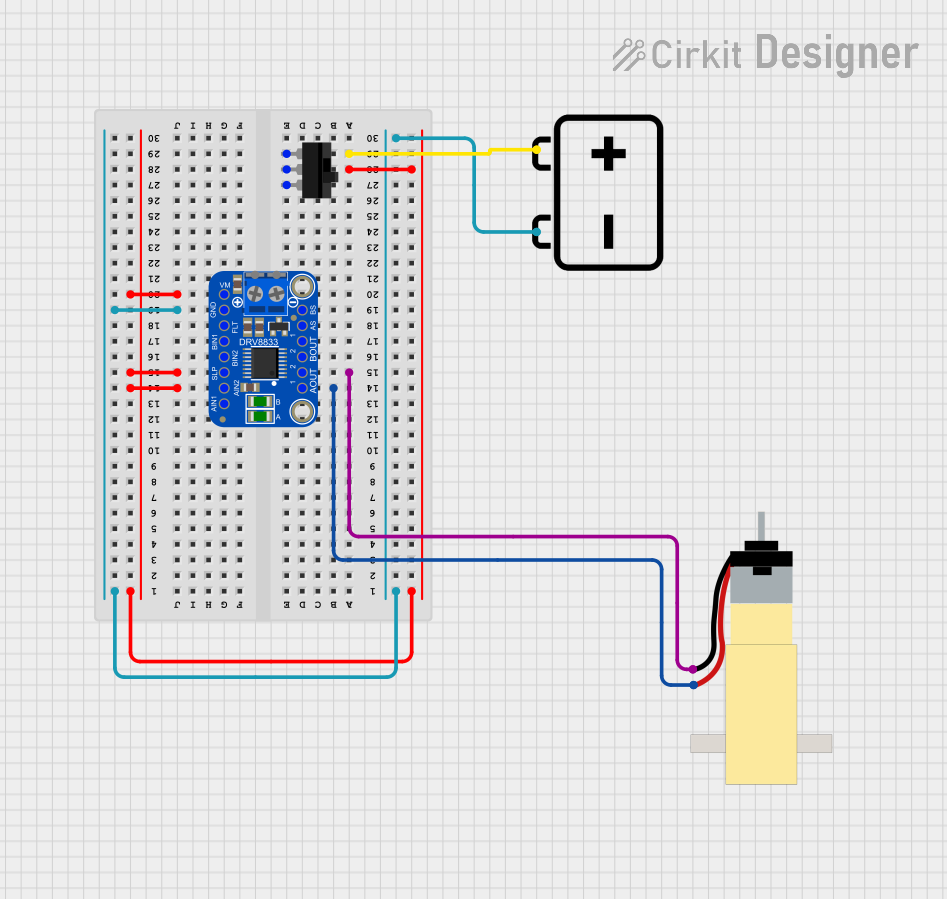

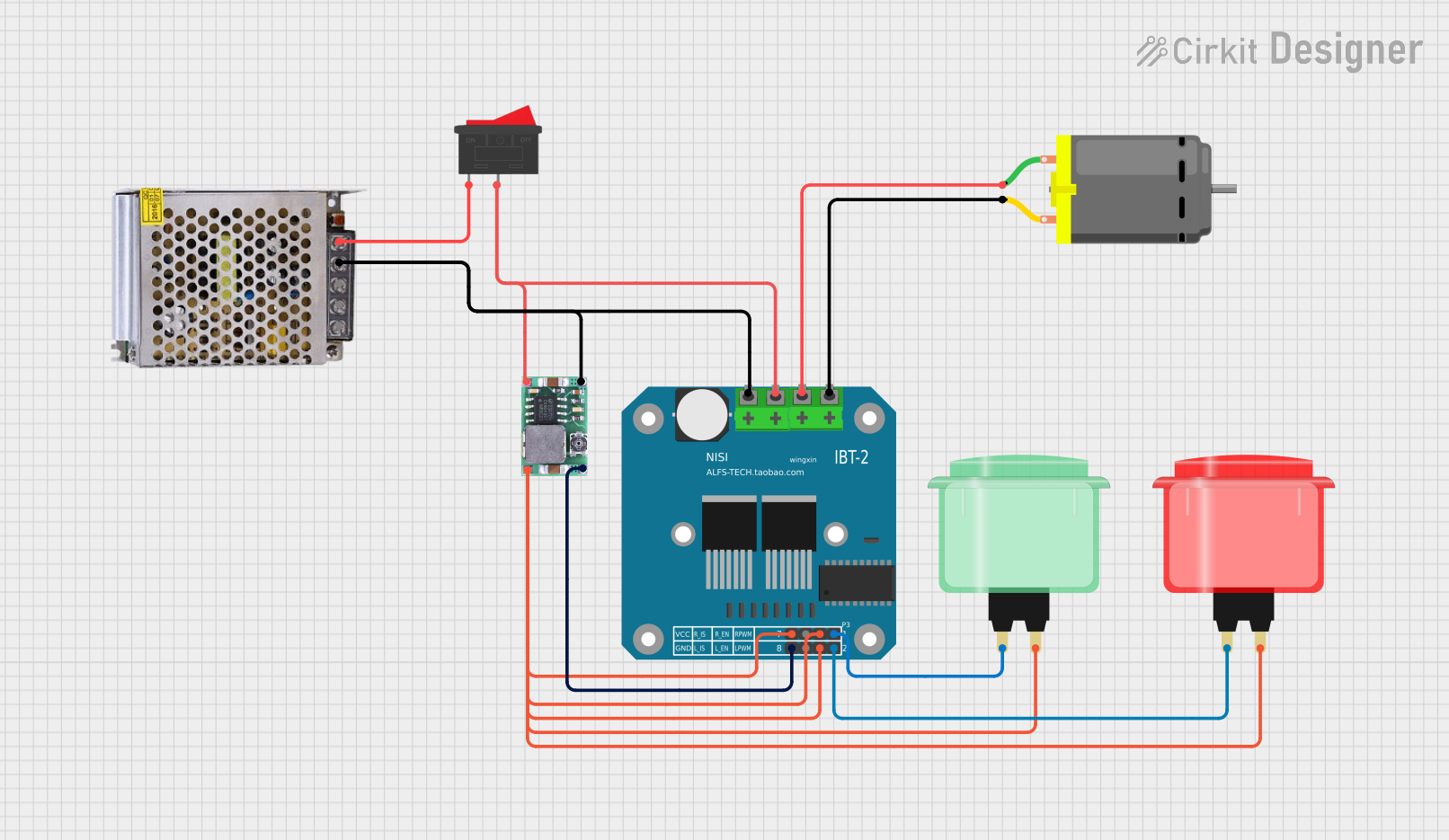

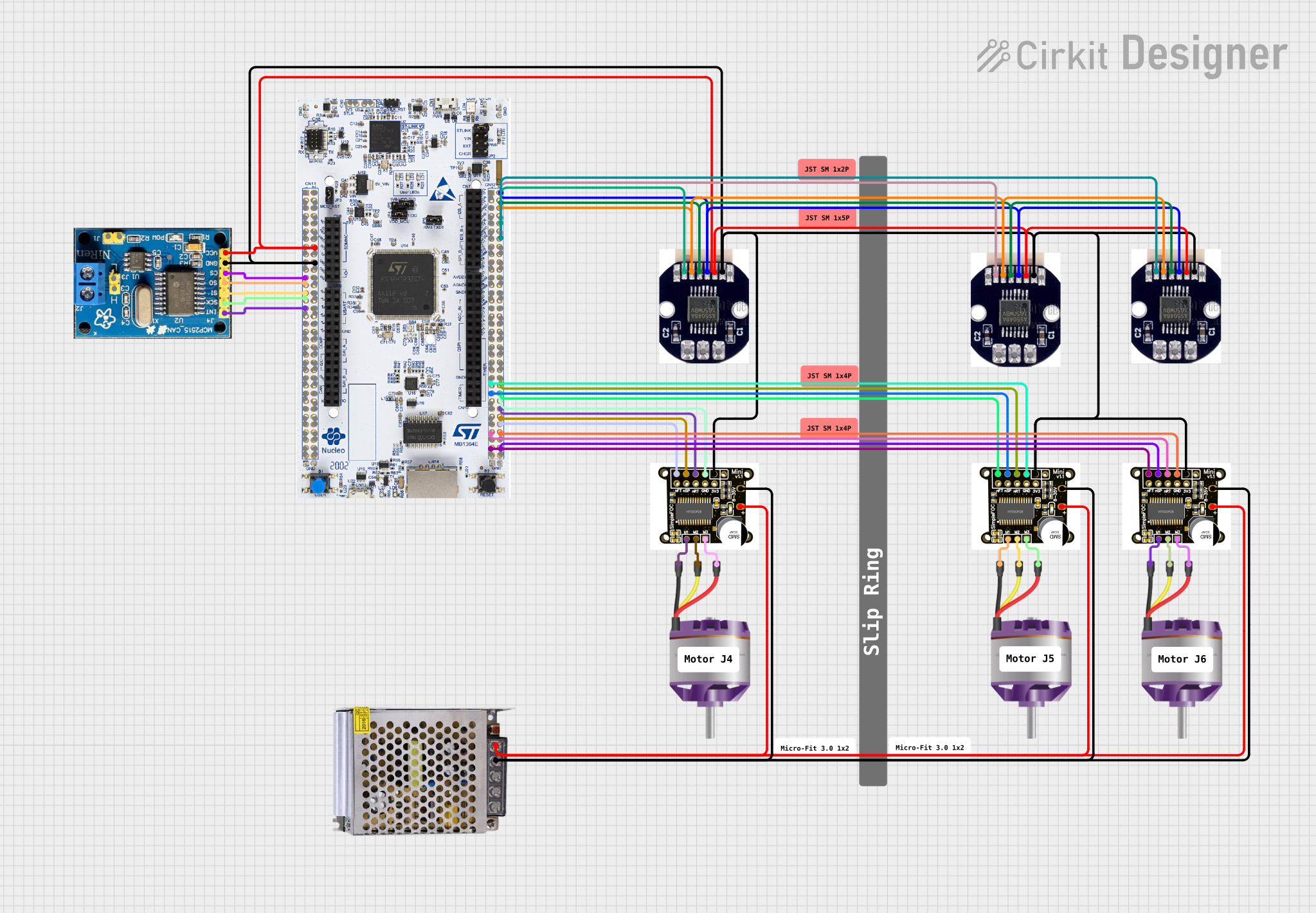

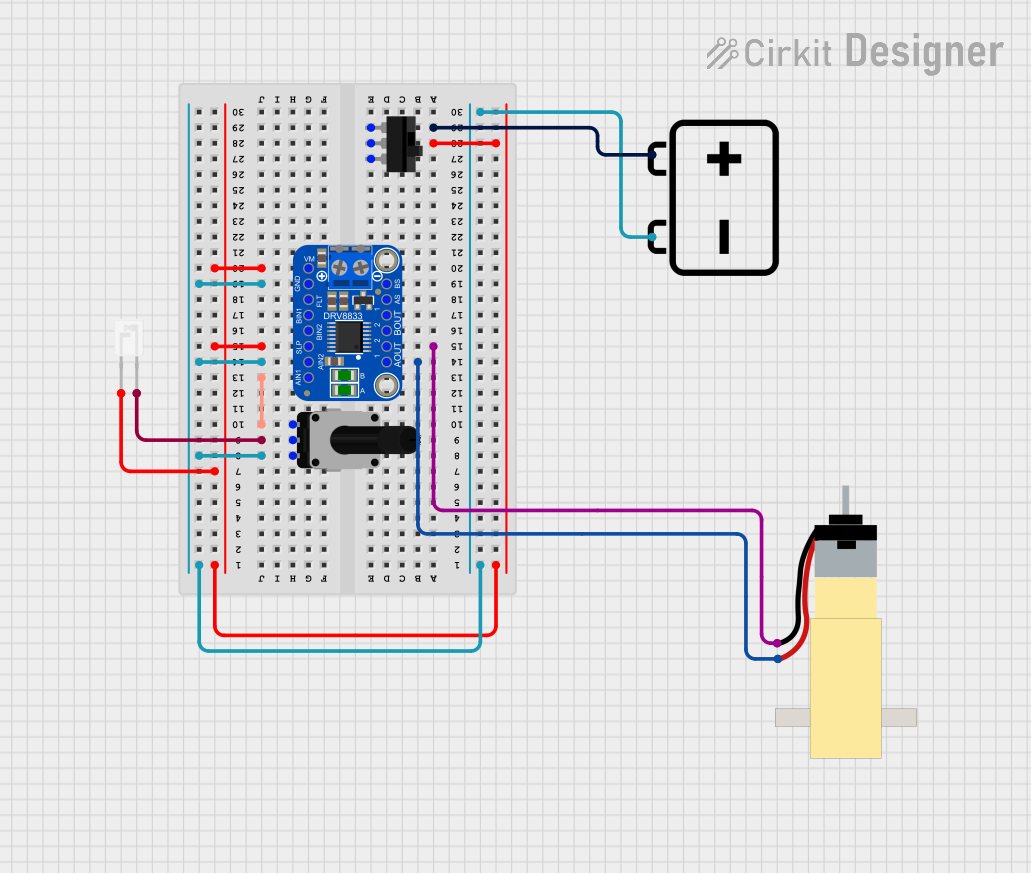

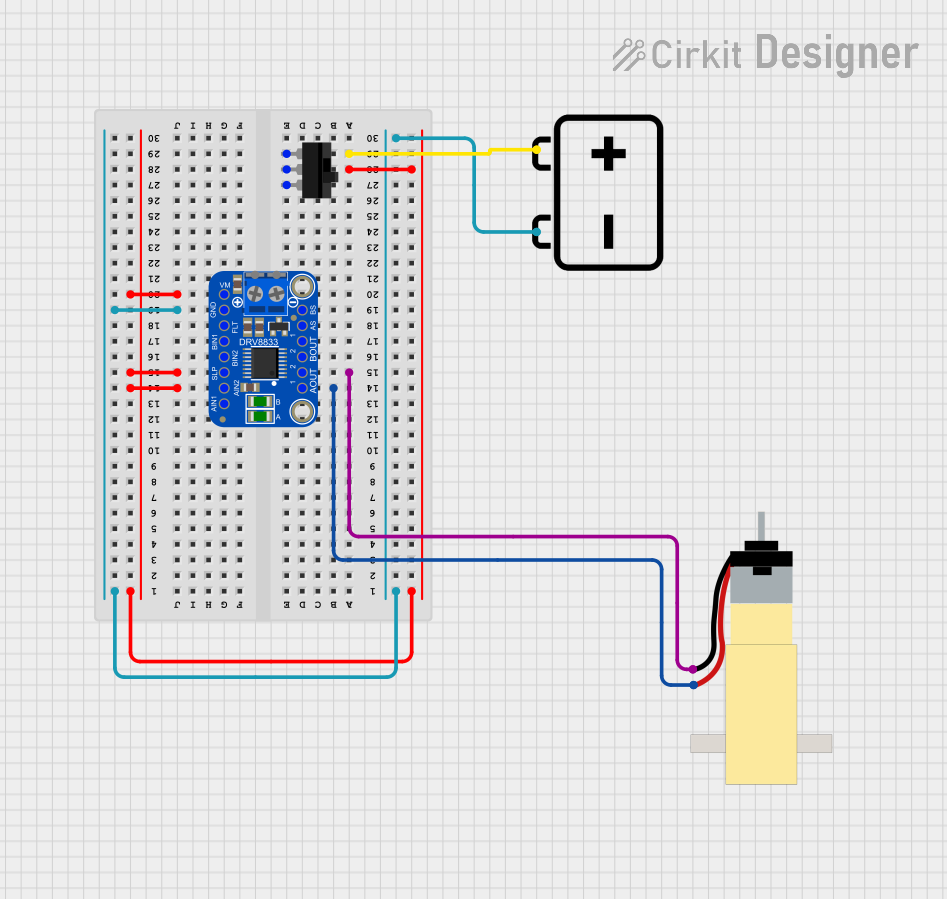

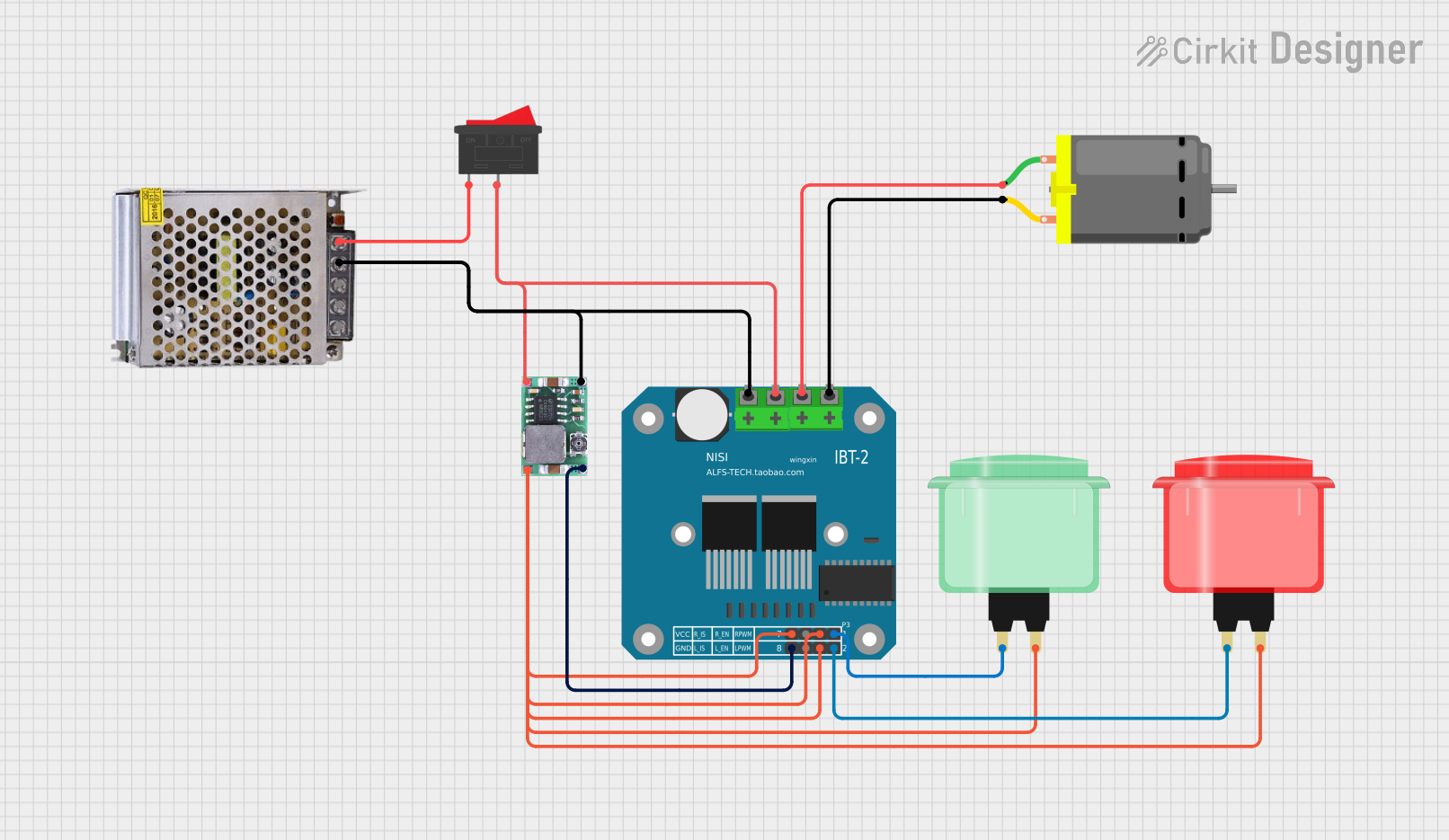

Explore Projects Built with DRV8838 Single Brushed DC Motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with DRV8838 Single Brushed DC Motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics and automation systems

- Small electric vehicles

- Industrial equipment

- Consumer electronics

- Educational projects and prototyping

Technical Specifications

Key Technical Details

- Operating Voltage Range: 0 V to 11 V

- Output Current: Up to 1.7 A (continuous), 1.8 A (peak)

- Control Interface: PWM (Pulse Width Modulation) and direction control

- Logic Voltage Range: 1.8 V to 7 V

- Built-in Protections:

- Overcurrent protection

- Thermal shutdown

- Undervoltage lockout

- Operating Temperature Range: -40°C to 150°C

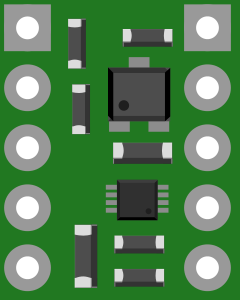

- Package Type: 8-pin WSON (3 mm × 3 mm)

Pin Configuration and Descriptions

The DRV8838 comes in an 8-pin WSON package. Below is the pinout and description:

| Pin | Name | Type | Description |

|---|---|---|---|

| 1 | IN1 | Input | Logic input to control motor direction and speed (PWM capable). |

| 2 | IN2 | Input | Logic input to control motor direction and speed (PWM capable). |

| 3 | nSLEEP | Input | Active-low sleep mode input. Pull high to enable the driver. |

| 4 | GND | Ground | Ground connection for the device. |

| 5 | OUT2 | Output | Motor output terminal 2. |

| 6 | VM | Power Supply | Motor power supply input (0 V to 11 V). |

| 7 | OUT1 | Output | Motor output terminal 1. |

| 8 | nFAULT | Output (Open-Drain) | Fault indicator. Pulled low during fault conditions (e.g., overcurrent). |

Usage Instructions

How to Use the DRV8838 in a Circuit

- Power Supply: Connect the motor power supply (VM) to the VM pin. Ensure the voltage is within the range of 0 V to 11 V.

- Logic Inputs: Use the IN1 and IN2 pins to control the motor's speed and direction:

- Apply a PWM signal to either IN1 or IN2 to control speed.

- Set IN1 high and IN2 low to rotate the motor in one direction.

- Set IN1 low and IN2 high to rotate the motor in the opposite direction.

- Set both IN1 and IN2 low to brake the motor.

- Sleep Mode: Pull the nSLEEP pin high to enable the driver. Pull it low to put the driver into low-power sleep mode.

- Fault Monitoring: Monitor the nFAULT pin for fault conditions. If it is pulled low, check for overcurrent, thermal shutdown, or undervoltage issues.

- Motor Connections: Connect the motor terminals to OUT1 and OUT2.

Important Considerations and Best Practices

- Use a decoupling capacitor (e.g., 10 µF) close to the VM pin to stabilize the power supply.

- Avoid exceeding the maximum current rating to prevent damage to the driver.

- Ensure proper heat dissipation, especially in high-current applications.

- Use pull-up resistors on the nFAULT pin if you need to monitor fault conditions.

- For Arduino or microcontroller-based projects, ensure the logic voltage levels are compatible with the DRV8838's input range (1.8 V to 7 V).

Example Arduino Code

Below is an example of how to control a motor using the DRV8838 with an Arduino UNO:

// Define pin connections

const int IN1 = 9; // PWM pin for motor control

const int IN2 = 10; // Direction control pin

const int nSLEEP = 8; // Sleep mode pin

void setup() {

// Set pin modes

pinMode(IN1, OUTPUT);

pinMode(IN2, OUTPUT);

pinMode(nSLEEP, OUTPUT);

// Enable the motor driver

digitalWrite(nSLEEP, HIGH);

}

void loop() {

// Rotate motor in one direction at 50% speed

analogWrite(IN1, 128); // 50% duty cycle (0-255 scale)

digitalWrite(IN2, LOW);

delay(2000); // Run for 2 seconds

// Rotate motor in the opposite direction at 75% speed

analogWrite(IN1, 0); // Stop IN1

analogWrite(IN2, 192); // 75% duty cycle

delay(2000); // Run for 2 seconds

// Brake the motor

digitalWrite(IN1, LOW);

digitalWrite(IN2, LOW);

delay(2000); // Brake for 2 seconds

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Does Not Spin:

- Ensure the nSLEEP pin is pulled high to enable the driver.

- Verify that the power supply voltage is within the specified range (0 V to 11 V).

- Check the connections to the motor and ensure they are secure.

nFAULT Pin Pulled Low:

- Check for overcurrent conditions. Reduce the motor load if necessary.

- Ensure the driver is not overheating. Improve heat dissipation if needed.

- Verify that the power supply voltage is stable and within range.

Motor Spins in the Wrong Direction:

- Swap the logic levels on the IN1 and IN2 pins to reverse the motor direction.

Driver Overheats:

- Ensure the current draw does not exceed the maximum rating.

- Use a heatsink or improve ventilation around the driver.

FAQs

Can I use the DRV8838 with a 3.3 V microcontroller? Yes, the DRV8838 supports logic voltage levels as low as 1.8 V, making it compatible with 3.3 V systems.

What happens if both IN1 and IN2 are high? The motor will enter a high-impedance state (coast mode), and it will not actively brake.

Is the DRV8838 suitable for battery-powered applications? Yes, its low operating voltage and sleep mode make it ideal for battery-powered systems.

Can I control the speed of the motor? Yes, you can use a PWM signal on the IN1 or IN2 pin to adjust the motor speed.