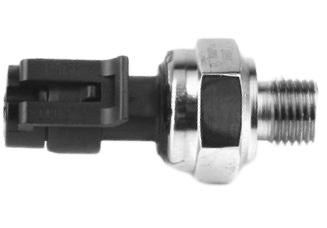

How to Use Industrial Pressure Sensor: Examples, Pinouts, and Specs

Design with Industrial Pressure Sensor in Cirkit Designer

Design with Industrial Pressure Sensor in Cirkit DesignerIntroduction

An Industrial Pressure Sensor is a critical component used to measure the pressure of gases or liquids in industrial settings. These sensors are engineered to endure the rigors of harsh environments, including extreme temperatures, vibrations, and corrosive materials. They are commonly used in applications such as hydraulic systems, pneumatic systems, process control, and automation.

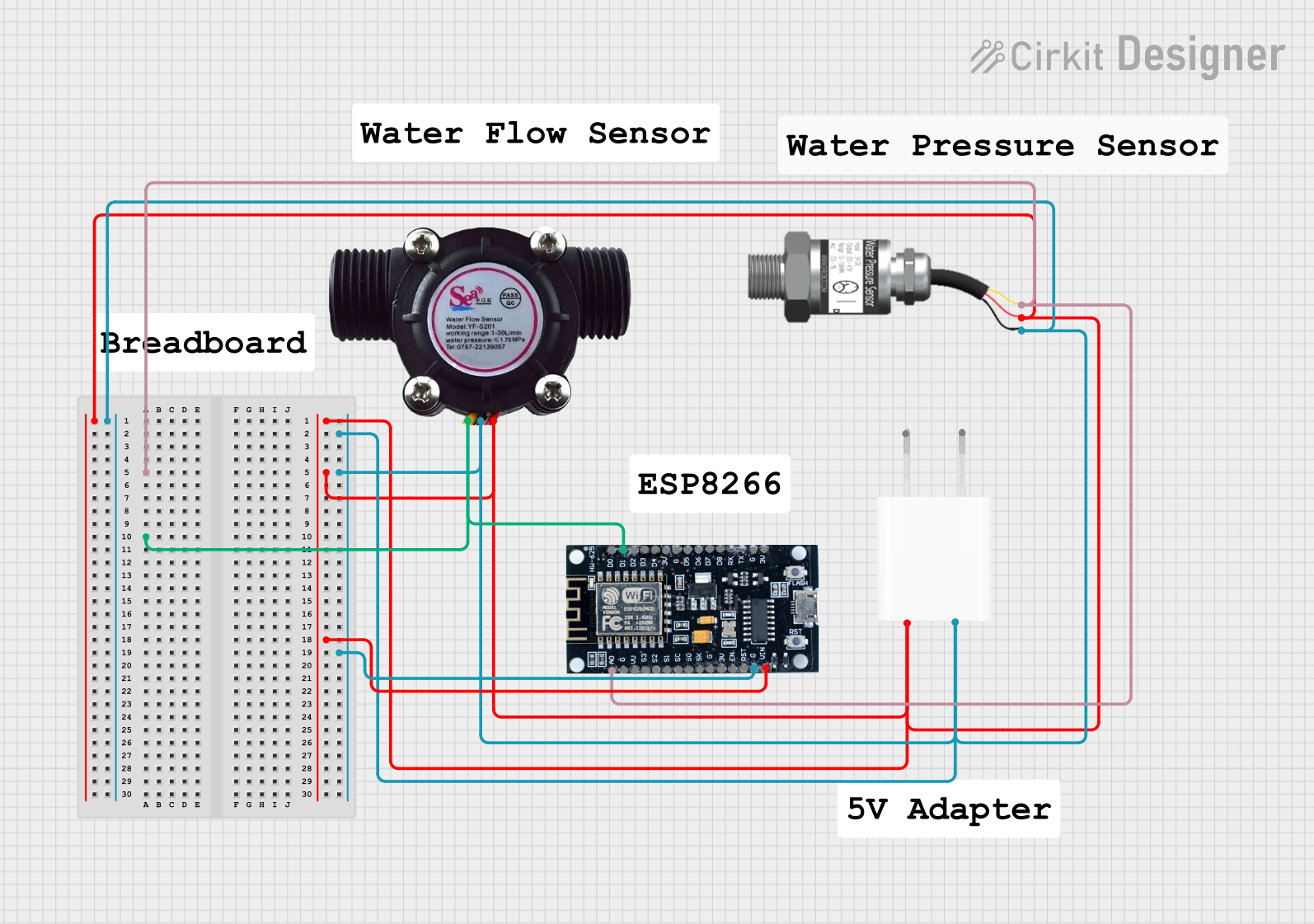

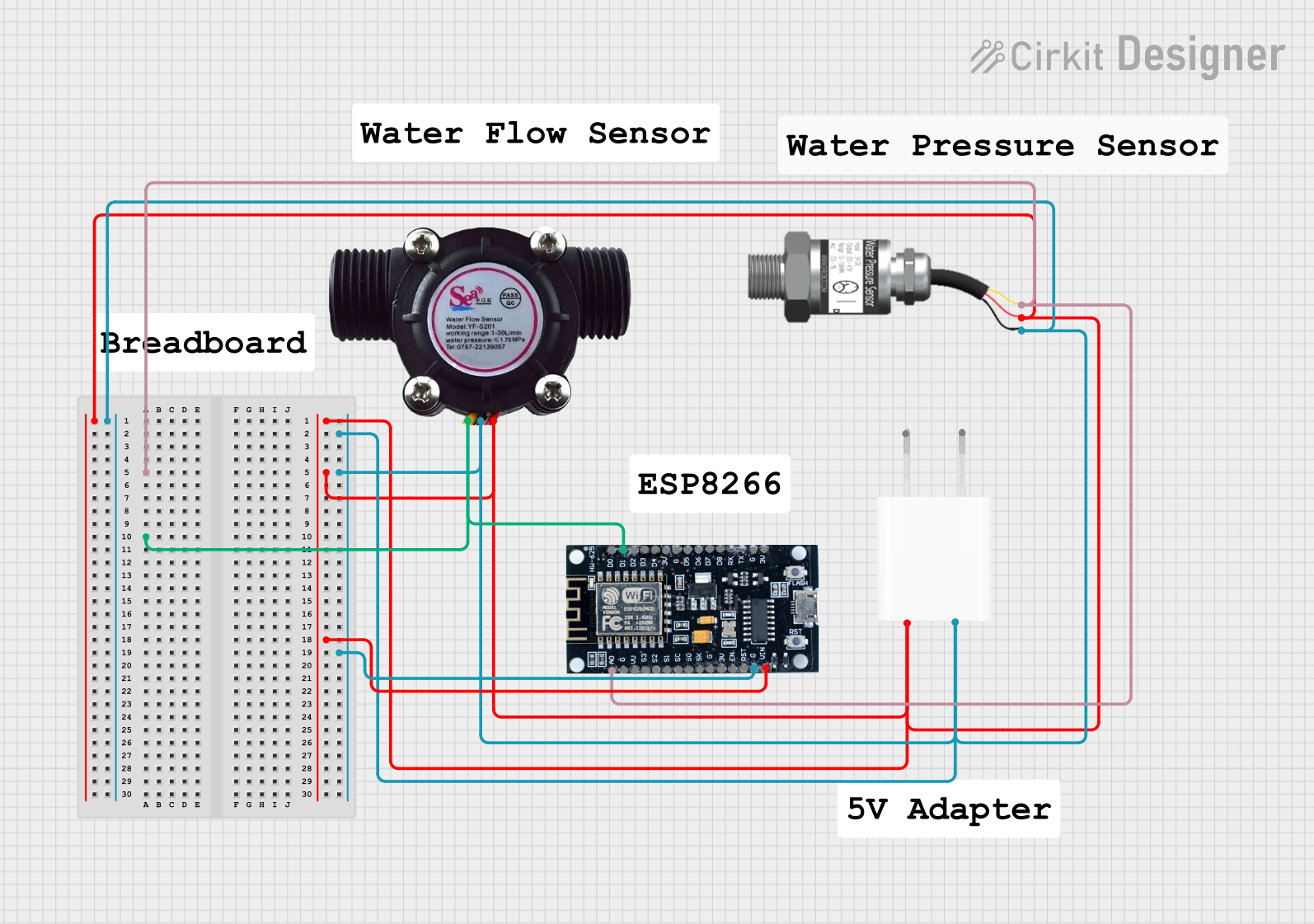

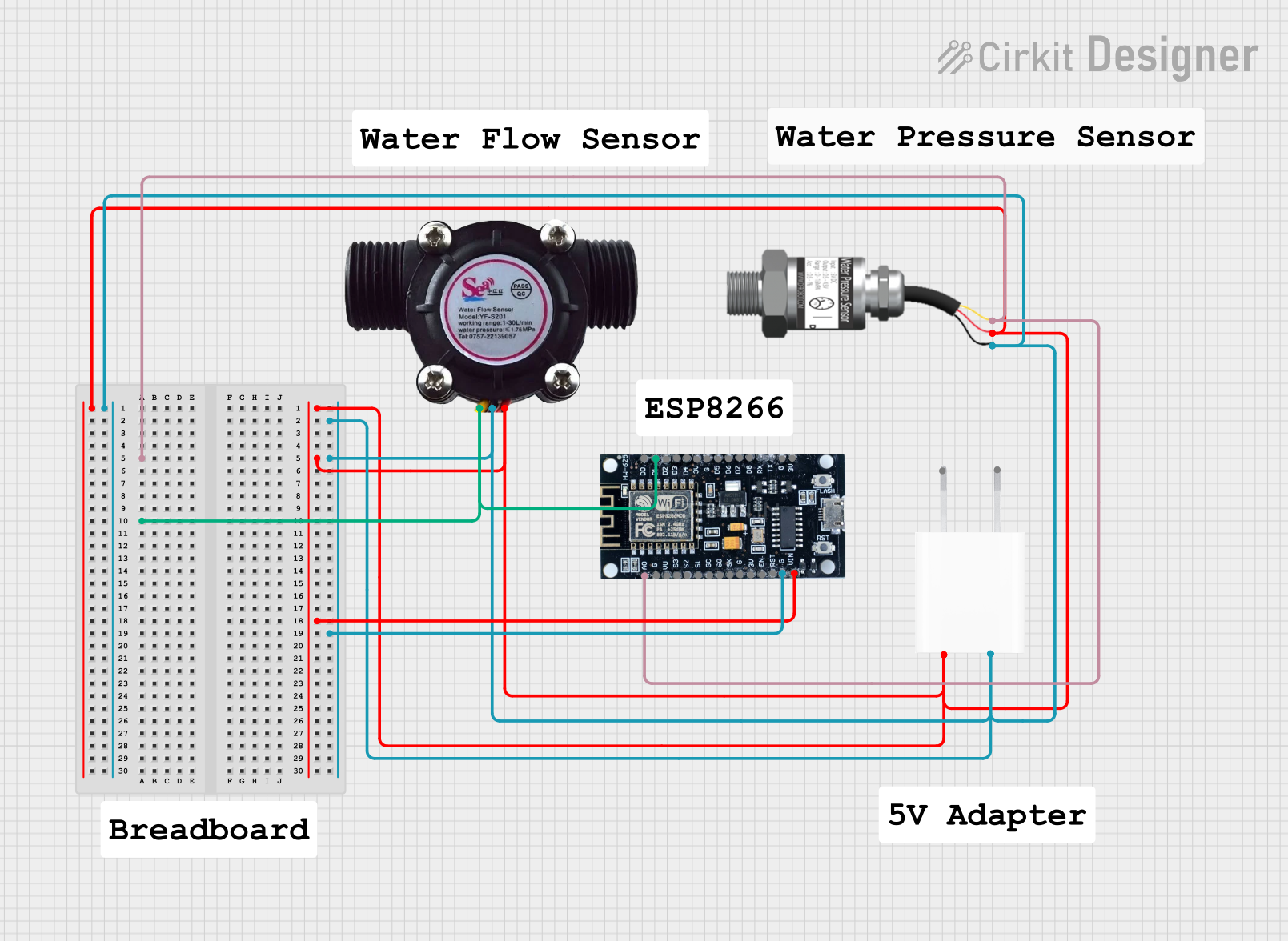

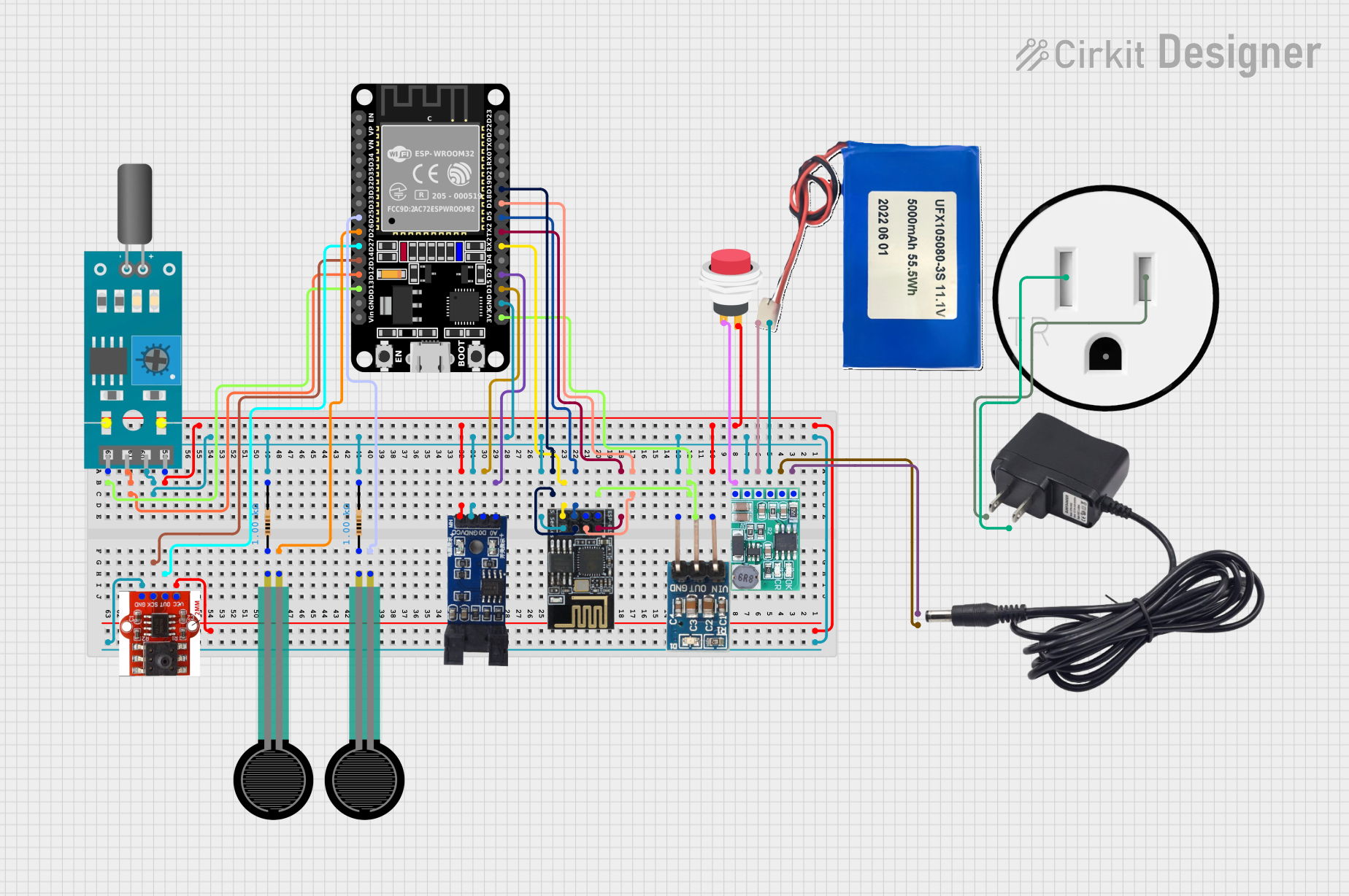

Explore Projects Built with Industrial Pressure Sensor

Open Project in Cirkit Designer

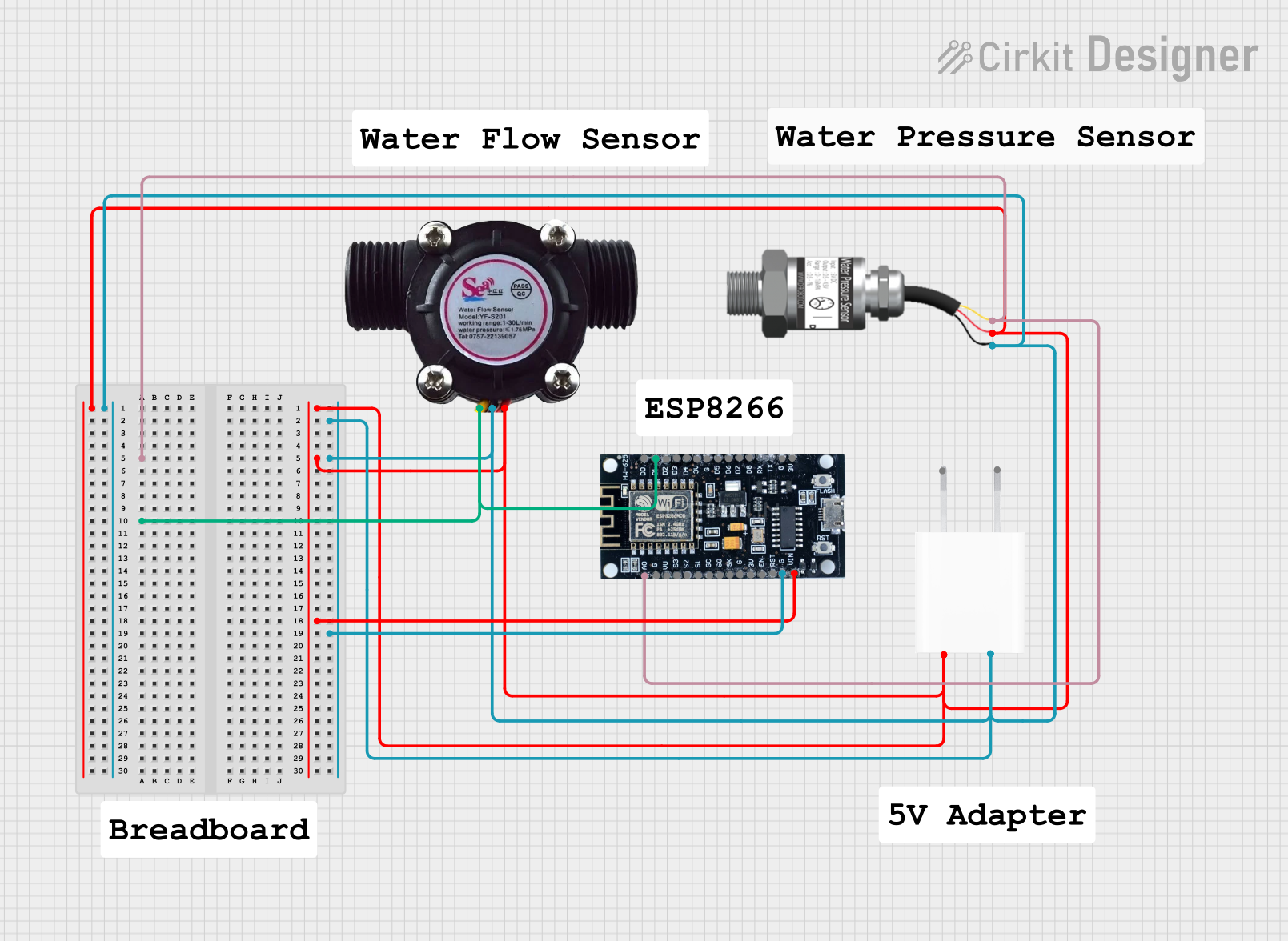

Open Project in Cirkit Designer

Open Project in Cirkit Designer

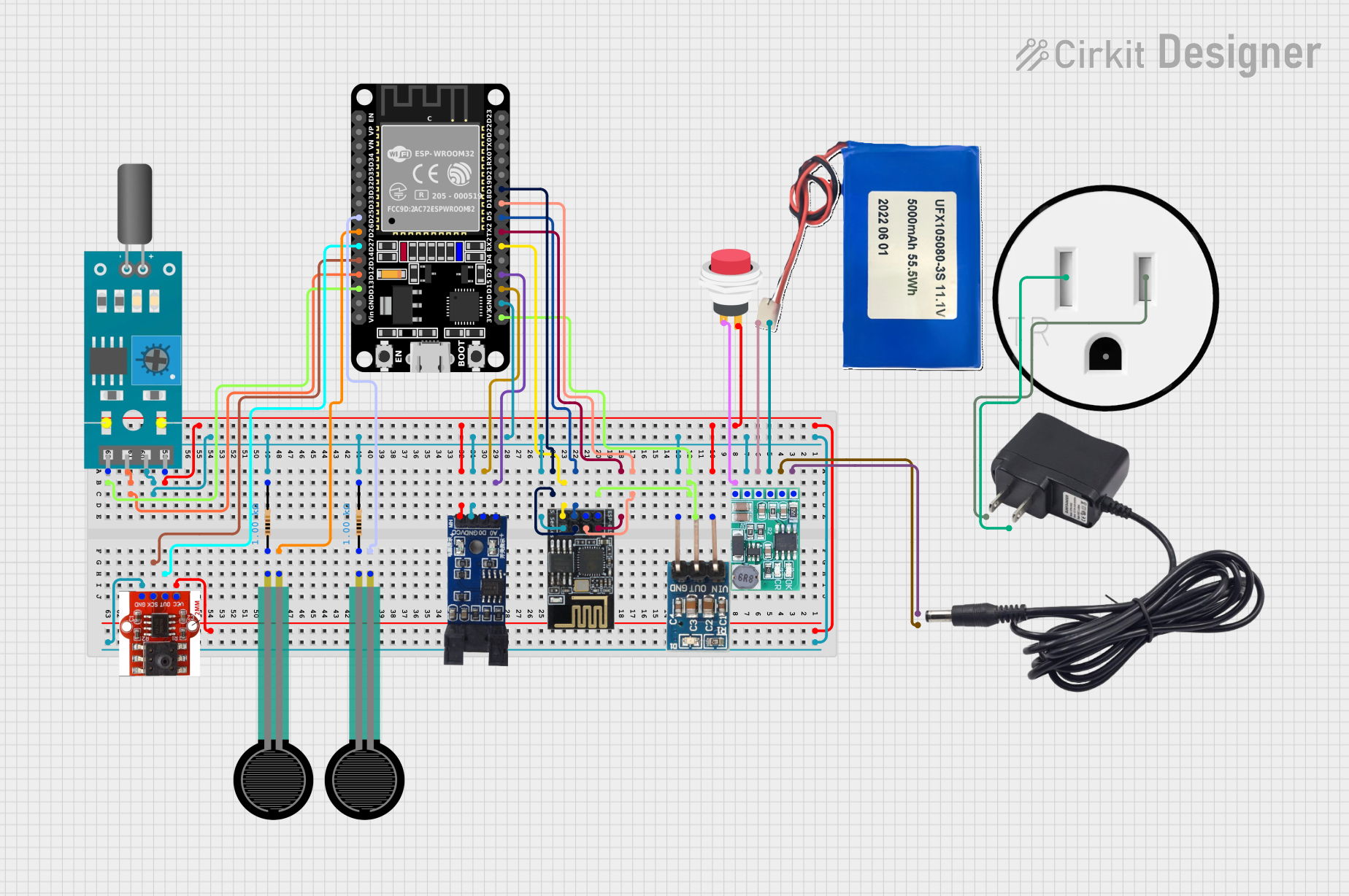

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Industrial Pressure Sensor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

General Specifications

- Pressure Range: 0 to 1.6 MPa

- Output Signal: 4-20 mA (current loop)

- Supply Voltage: 12 to 36 VDC

- Accuracy: ±0.5% FS (Full Scale)

- Operating Temperature: -40°C to 85°C

- Process Connection: 1/4" NPT Male

- Electrical Connection: DIN 43650 Connector

- Protection Rating: IP67

Pin Configuration and Descriptions

| Pin Number | Description | Notes |

|---|---|---|

| 1 | +V (Power Supply) | Connect to 12-36 VDC |

| 2 | Output (4-20 mA) | Connect to current loop input |

| 3 | Common (Ground) | Connect to system ground |

Usage Instructions

Integration into a Circuit

- Power Supply Connection: Connect the sensor's power supply pin to a stable DC voltage source between 12 and 36 volts.

- Output Connection: Connect the sensor's output pin to the current loop input of your monitoring or control device.

- Grounding: Connect the sensor's ground pin to the common ground in your system to complete the circuit.

Best Practices

- Calibration: Before use, calibrate the sensor according to the manufacturer's instructions to ensure accurate readings.

- Installation: Ensure the sensor is installed with the correct orientation and securely tightened to the process connection.

- Cabling: Use shielded cables for the connections to minimize electrical noise and interference.

- Environmental Protection: Although the sensor is rated IP67, avoid submerging the sensor unless it is specified for submersion.

Troubleshooting and FAQs

Common Issues and Solutions

- Inaccurate Readings: Check for proper calibration. Ensure that the sensor is not exposed to pressures beyond its specified range.

- No Output Signal: Verify the power supply voltage and connections. Check for any damage to the sensor or wiring.

- Fluctuating Readings: Ensure there is no air in the system for liquid pressure measurements. Check for electrical interference and proper grounding.

FAQs

Q: Can the sensor be used with any type of liquid or gas? A: The sensor is designed for use with a variety of media, but always check the compatibility with specific chemicals and conditions.

Q: What is the significance of the 4-20 mA output signal? A: The 4-20 mA current loop is a standard for transmitting sensor data over long distances with high immunity to electrical noise.

Q: How often should the sensor be calibrated? A: Calibration frequency depends on the usage and environmental conditions. Refer to the manufacturer's recommendations for guidance.

Example Arduino UNO Code

// This example demonstrates how to read a 4-20 mA pressure sensor using an Arduino UNO.

const int sensorPin = A0; // Analog input pin connected to the sensor output

void setup() {

Serial.begin(9600); // Start serial communication at 9600 baud

}

void loop() {

int sensorValue = analogRead(sensorPin); // Read the sensor output

float current = map(sensorValue, 0, 1023, 4, 20); // Map the analog value to 4-20 mA

float pressure = (current - 4) * (1.6 / 16); // Convert current to pressure in MPa

Serial.print("Pressure: ");

Serial.print(pressure);

Serial.println(" MPa");

delay(1000); // Wait for a second before reading again

}

Note: The map function in the code is a simple linear approximation. For more accurate results, use a calibrated conversion method.

This documentation provides a comprehensive guide to using a generic Industrial Pressure Sensor with a 1.6 MPa range. For further assistance, consult the manufacturer's datasheet and technical support resources.