How to Use 12V DC AIR PUMP: Examples, Pinouts, and Specs

Design with 12V DC AIR PUMP in Cirkit Designer

Design with 12V DC AIR PUMP in Cirkit DesignerIntroduction

A 12V DC air pump is an electric pump designed to operate on a 12-volt direct current power supply. It is commonly used for inflating or deflating air-filled items such as tires, balloons, air mattresses, or inflatable structures. Due to its compact and portable design, it is widely utilized in automotive, camping, and recreational applications. The pump is efficient, easy to use, and often comes with various nozzle attachments to accommodate different inflation needs.

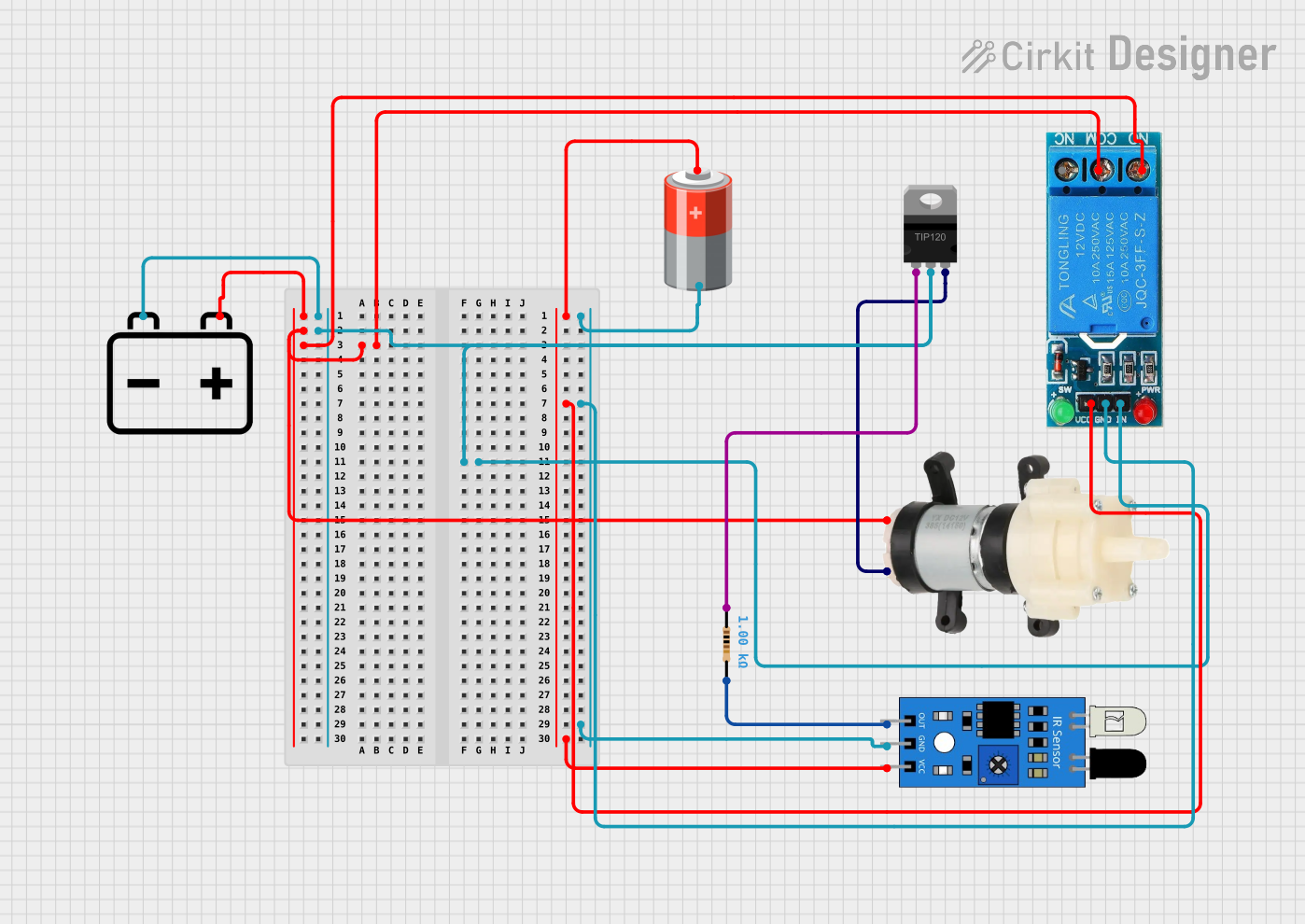

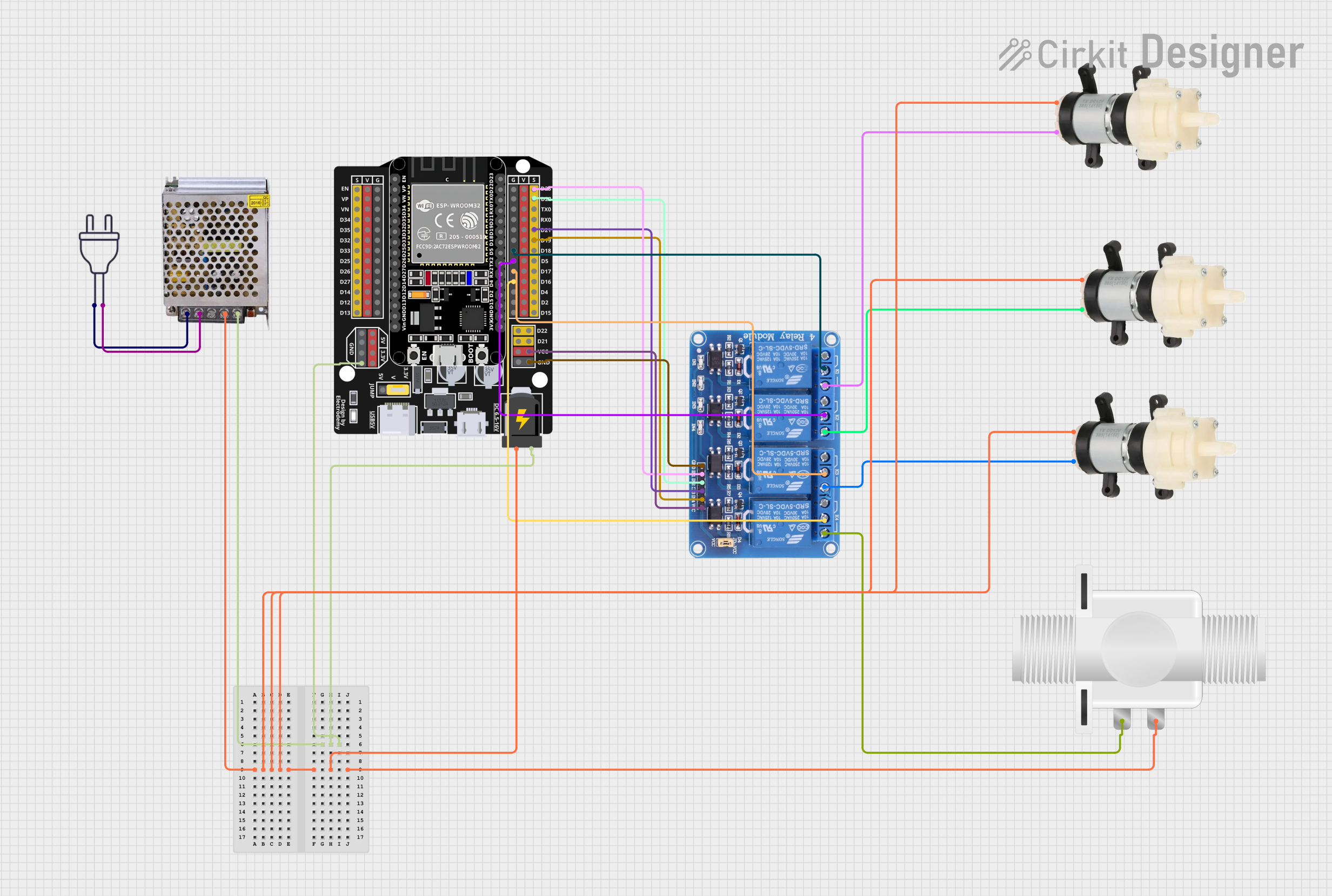

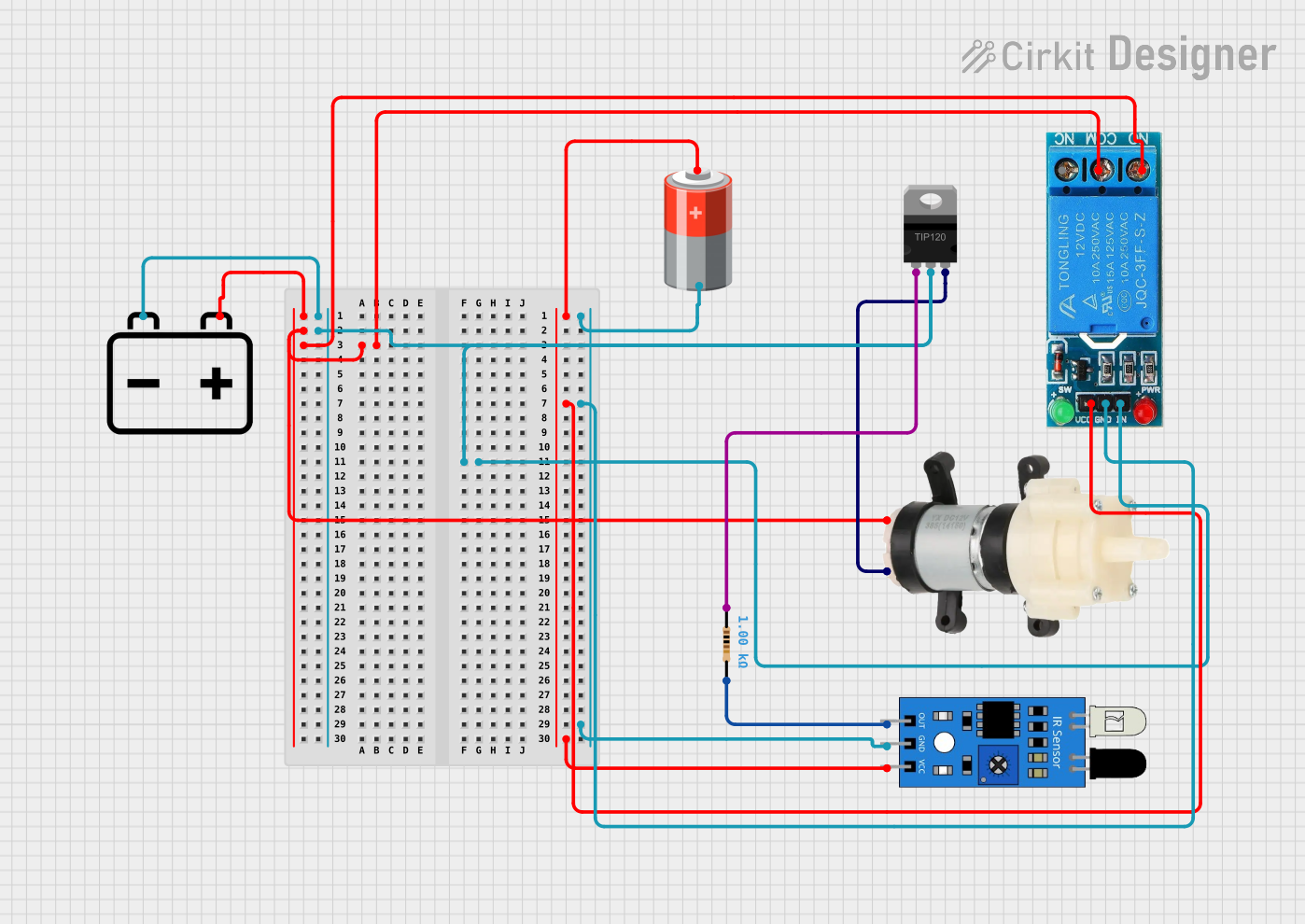

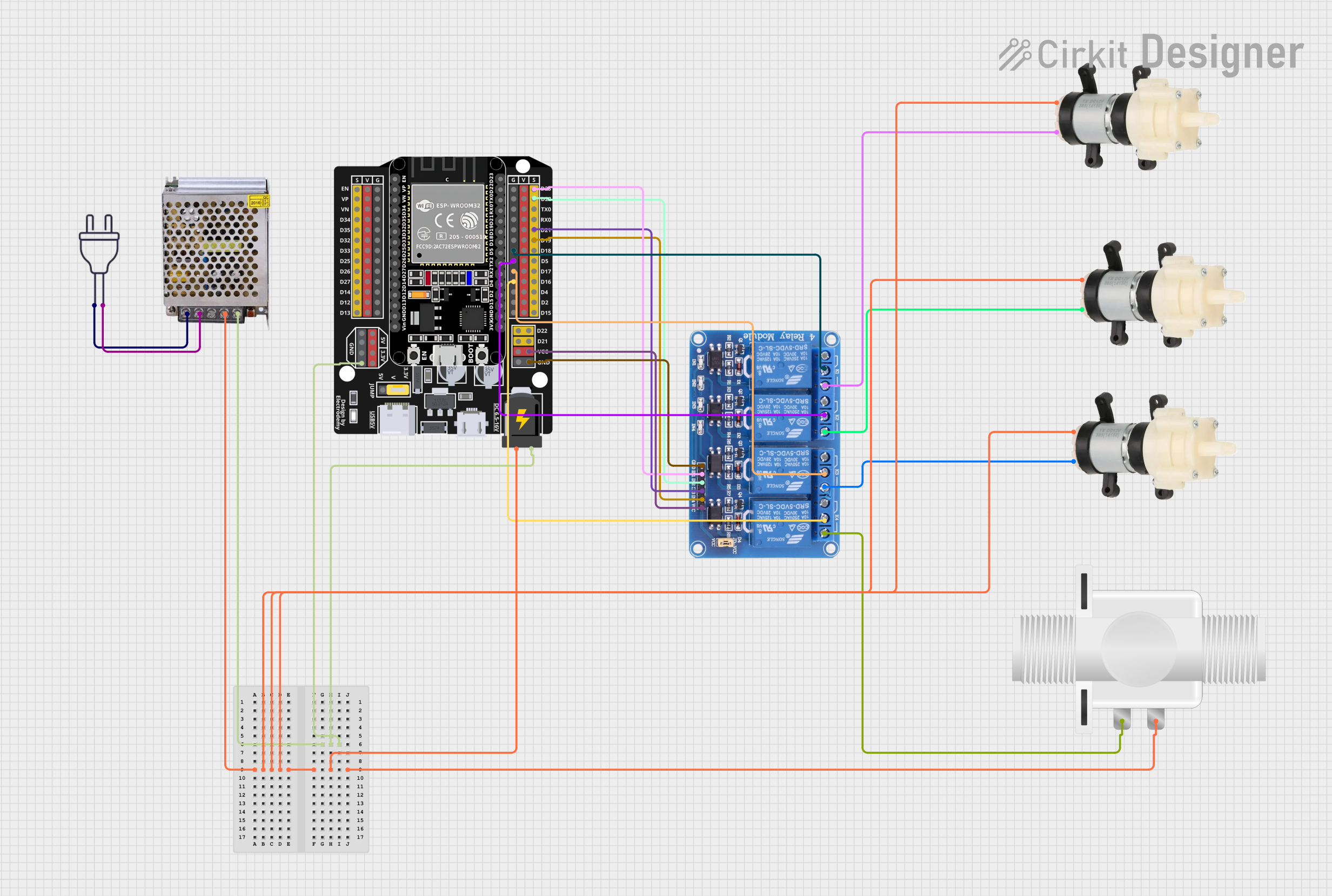

Explore Projects Built with 12V DC AIR PUMP

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 12V DC AIR PUMP

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Below are the key technical details of the 12V DC air pump:

| Parameter | Value |

|---|---|

| Operating Voltage | 12V DC |

| Current Consumption | 3A to 5A (depending on load) |

| Power Rating | 36W to 60W |

| Maximum Pressure | 100 PSI (varies by model) |

| Airflow Rate | 15-30 L/min (varies by model) |

| Dimensions | Compact (varies by manufacturer) |

| Weight | ~0.5 to 1.5 kg |

| Noise Level | ~60-75 dB |

| Operating Temperature | -10°C to 50°C |

Pin Configuration and Descriptions

The 12V DC air pump typically has two electrical connections:

| Pin/Connection | Description |

|---|---|

| Positive (+) | Connects to the positive terminal of the 12V power supply. |

| Negative (-) | Connects to the negative terminal (ground) of the 12V power supply. |

Some models may include an additional switch or control pin for advanced functionality, but the basic configuration involves only the positive and negative terminals.

Usage Instructions

How to Use the 12V DC Air Pump in a Circuit

- Power Supply: Ensure you have a stable 12V DC power source capable of supplying sufficient current (3A to 5A). This can be a car battery, a 12V DC adapter, or a portable power bank designed for automotive use.

- Connections:

- Connect the positive terminal of the pump to the positive terminal of the power supply.

- Connect the negative terminal of the pump to the ground (negative terminal) of the power supply.

- Switch Control (if applicable): If the pump includes a built-in switch, ensure it is in the "off" position before connecting the power supply.

- Operation:

- Turn on the power supply or activate the switch to start the pump.

- Attach the appropriate nozzle to the pump's outlet and connect it to the item you wish to inflate or deflate.

- Monitoring: Monitor the pressure (if the pump has a built-in pressure gauge) to avoid over-inflation.

Important Considerations and Best Practices

- Power Source: Always use a power source that matches the pump's voltage and current requirements to avoid damage.

- Polarity: Double-check the polarity of the connections to prevent short circuits or damage to the pump.

- Duty Cycle: Many 12V DC air pumps are not designed for continuous operation. Follow the manufacturer's recommended duty cycle (e.g., 10 minutes on, 10 minutes off) to prevent overheating.

- Environment: Avoid using the pump in wet or dusty environments unless it is specifically rated for such conditions.

- Safety: Do not leave the pump unattended while in use, especially when inflating high-pressure items.

Example: Using the Pump with an Arduino UNO

If you want to control the 12V DC air pump using an Arduino UNO, you can use a relay module to switch the pump on and off. Below is an example code:

// Example code to control a 12V DC air pump using an Arduino UNO and a relay module

const int relayPin = 7; // Pin connected to the relay module

void setup() {

pinMode(relayPin, OUTPUT); // Set the relay pin as an output

digitalWrite(relayPin, LOW); // Ensure the relay is off at startup

}

void loop() {

digitalWrite(relayPin, HIGH); // Turn on the pump

delay(5000); // Keep the pump on for 5 seconds

digitalWrite(relayPin, LOW); // Turn off the pump

delay(5000); // Wait for 5 seconds before turning it on again

}

Note: Ensure the relay module is rated for the pump's current and voltage. Use an external power source to power the pump, as the Arduino cannot supply sufficient current.

Troubleshooting and FAQs

Common Issues and Solutions

Pump Does Not Start:

- Cause: Insufficient power supply or incorrect wiring.

- Solution: Verify the power source provides 12V DC and sufficient current. Check the wiring for proper polarity and secure connections.

Pump Overheats:

- Cause: Exceeding the recommended duty cycle.

- Solution: Allow the pump to cool down between usage cycles. Follow the manufacturer's duty cycle guidelines.

Low Airflow or Pressure:

- Cause: Blocked or damaged nozzle, or insufficient power.

- Solution: Inspect the nozzle for blockages or damage. Ensure the power source is adequate.

Excessive Noise:

- Cause: Loose components or worn-out motor.

- Solution: Tighten any loose screws or fittings. If the issue persists, the pump may require servicing or replacement.

FAQs

Q: Can I use the pump with a 24V power supply?

A: No, the pump is designed for 12V DC operation. Using a higher voltage may damage the pump.Q: Is the pump waterproof?

A: Most 12V DC air pumps are not waterproof. Check the manufacturer's specifications before using the pump in wet conditions.Q: Can I use the pump continuously for long periods?

A: No, most pumps have a duty cycle (e.g., 10 minutes on, 10 minutes off). Continuous use may cause overheating and damage.Q: How do I clean the pump?

A: Disconnect the pump from the power source and use a dry cloth to clean the exterior. Avoid using water or solvents unless specified by the manufacturer.