Cirkit Designer

Your all-in-one circuit design IDE

Home /

Component Documentation

How to Use motor and wheels: Examples, Pinouts, and Specs

Design with motor and wheels in Cirkit Designer

Design with motor and wheels in Cirkit DesignerIntroduction

- The motor and wheels assembly is a fundamental component for building mobile robotic systems. It typically consists of a DC motor or stepper motor attached to wheels, enabling movement and navigation. This setup is widely used in robotics, remote-controlled vehicles, and automation projects.

- Common applications include robotic cars, conveyor systems, automated guided vehicles (AGVs), and educational robotics kits.

Explore Projects Built with motor and wheels

Battery-Powered Dual Gearmotor Drive System

This circuit consists of a 6V battery pack connected in parallel to two DC gearmotors, one for the left wheel and one for the right wheel of a vehicle. The battery provides power directly to both motors, enabling them to run simultaneously. As there is no control circuitry or microcontroller code provided, the motors will run continuously when the circuit is powered.

Open Project in Cirkit Designer

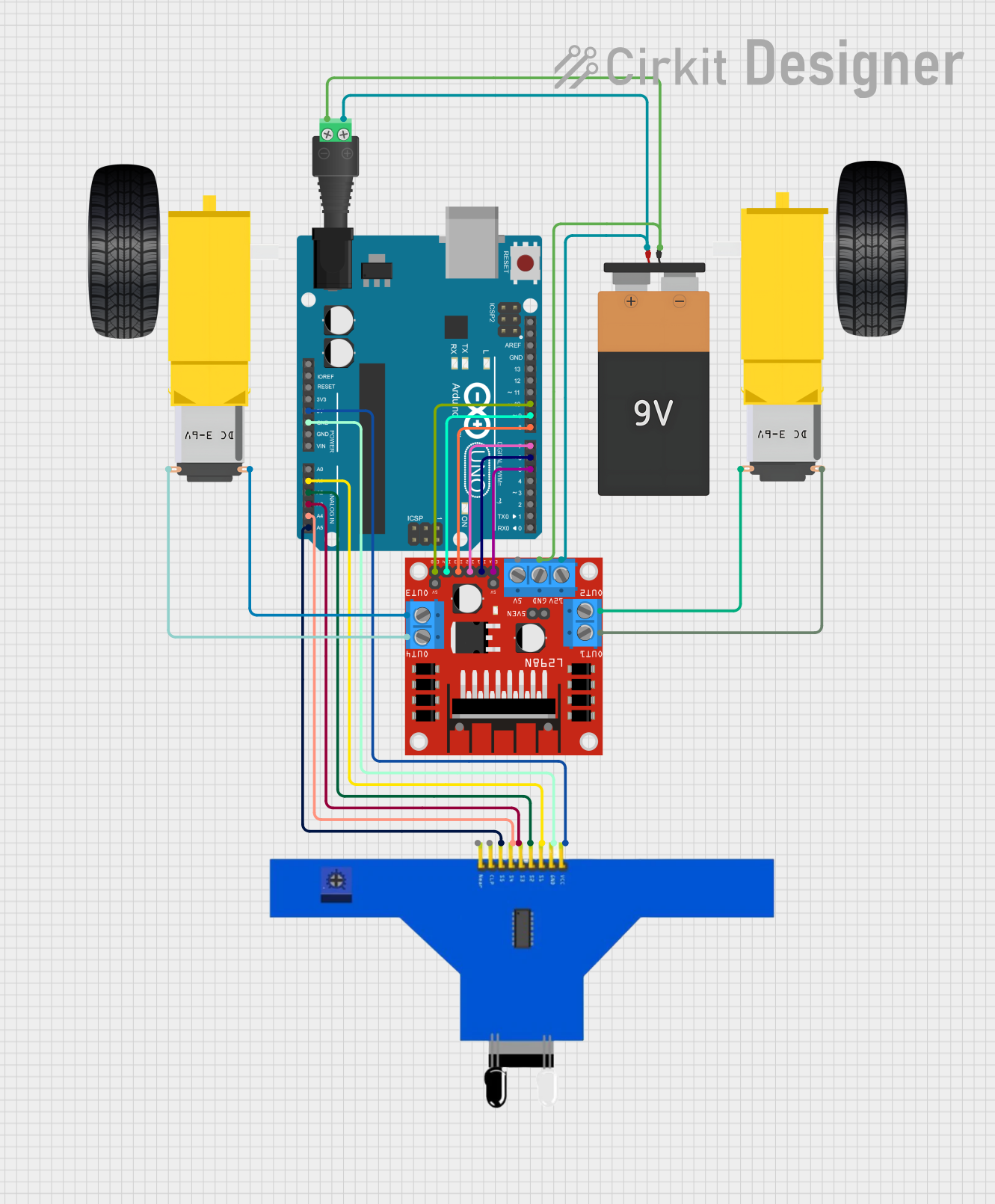

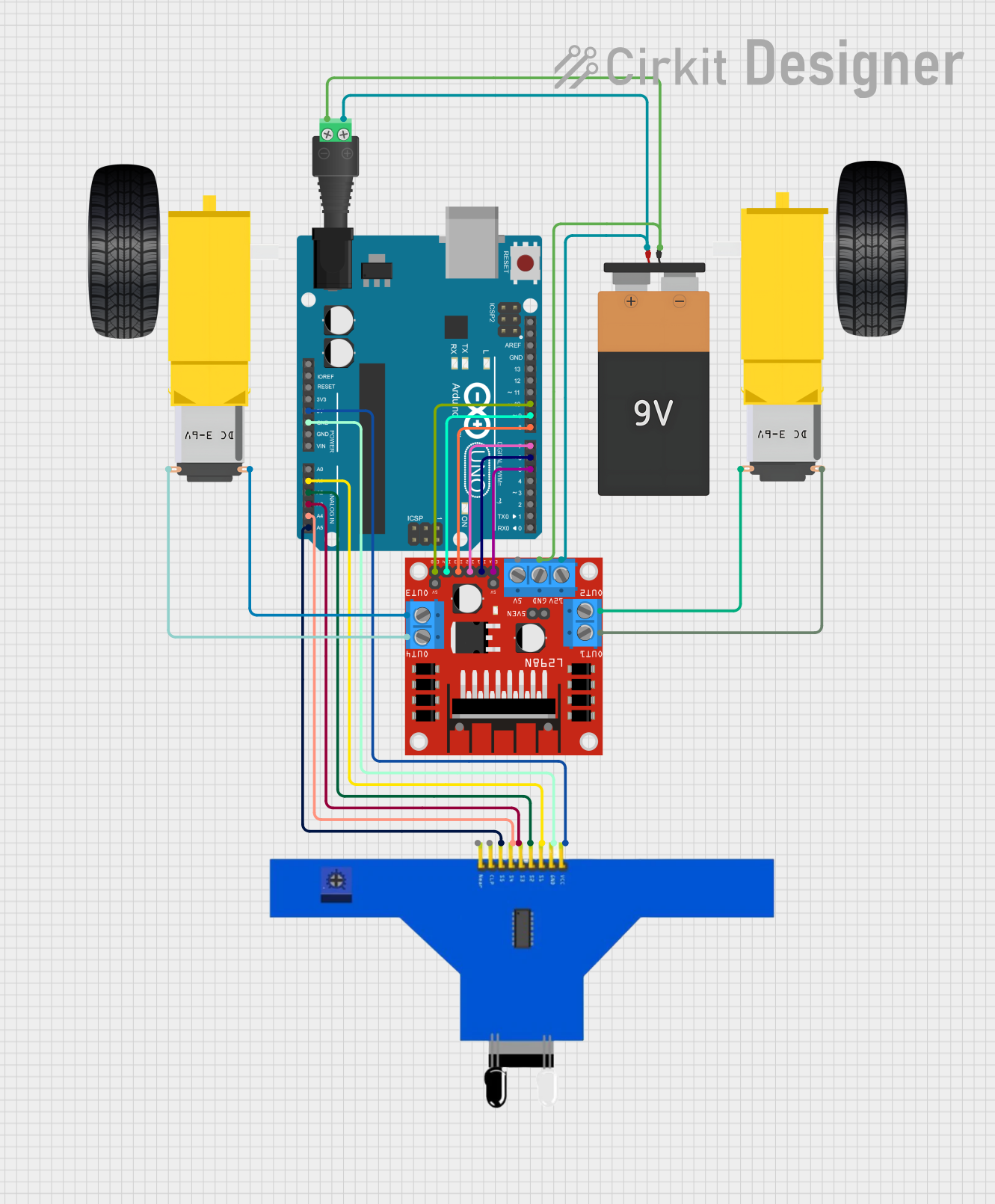

Open Project in Cirkit DesignerArduino-Controlled Robotic Vehicle with IR Sensors and L298N Motor Driver

This circuit is designed to control a pair of DC gearmotors using an L298N motor driver module, which is interfaced with an Arduino UNO microcontroller. The Arduino is also connected to a 5-channel IR sensor for input, which may be used for line tracking or obstacle detection. Power is supplied by a 9V battery connected through a 2.1mm barrel jack, and the motor driver module regulates this power to drive the left and right gearmotors for a mobile robot platform.

Open Project in Cirkit Designer

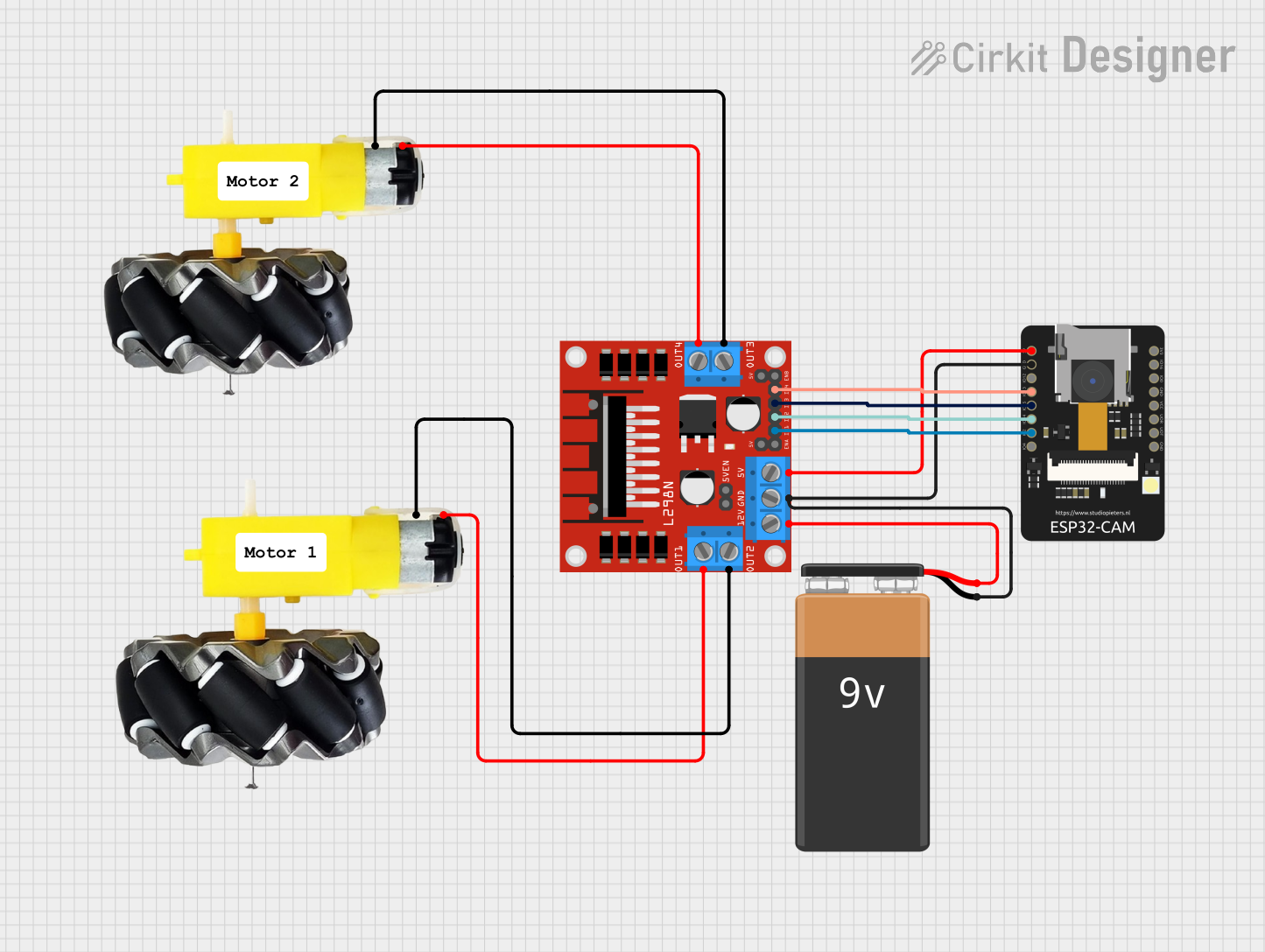

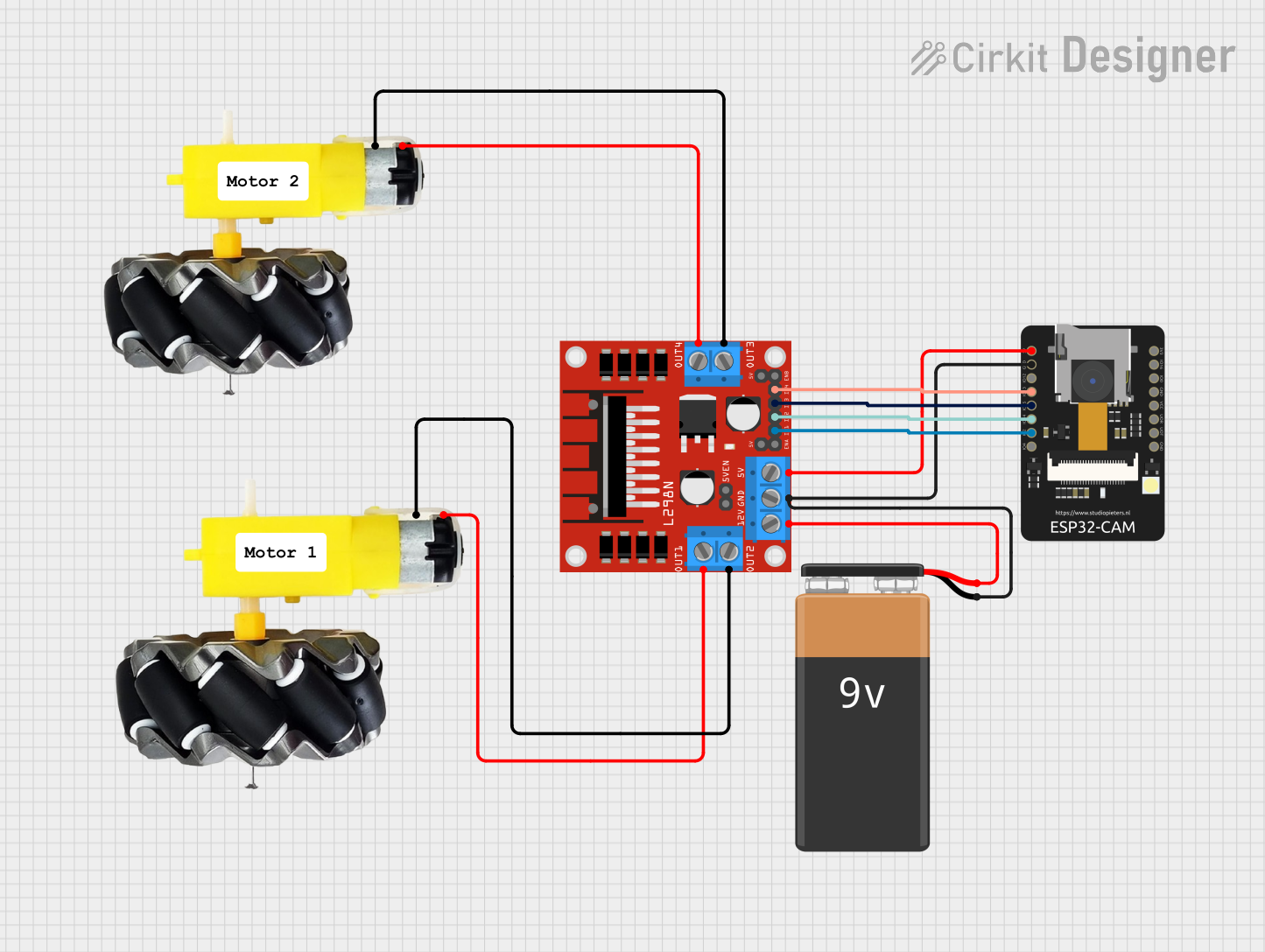

Open Project in Cirkit DesignerESP32-CAM Controlled Wi-Fi Robot Car

This circuit is designed to control a two-wheel motorized vehicle using an ESP32-CAM microcontroller. The ESP32-CAM is interfaced with an L298N DC motor driver to control the direction and speed of the motors attached to the wheels. Additionally, the ESP32-CAM is configured to capture images and provide WiFi connectivity for remote control via a web server with a user interface for driving commands.

Open Project in Cirkit Designer

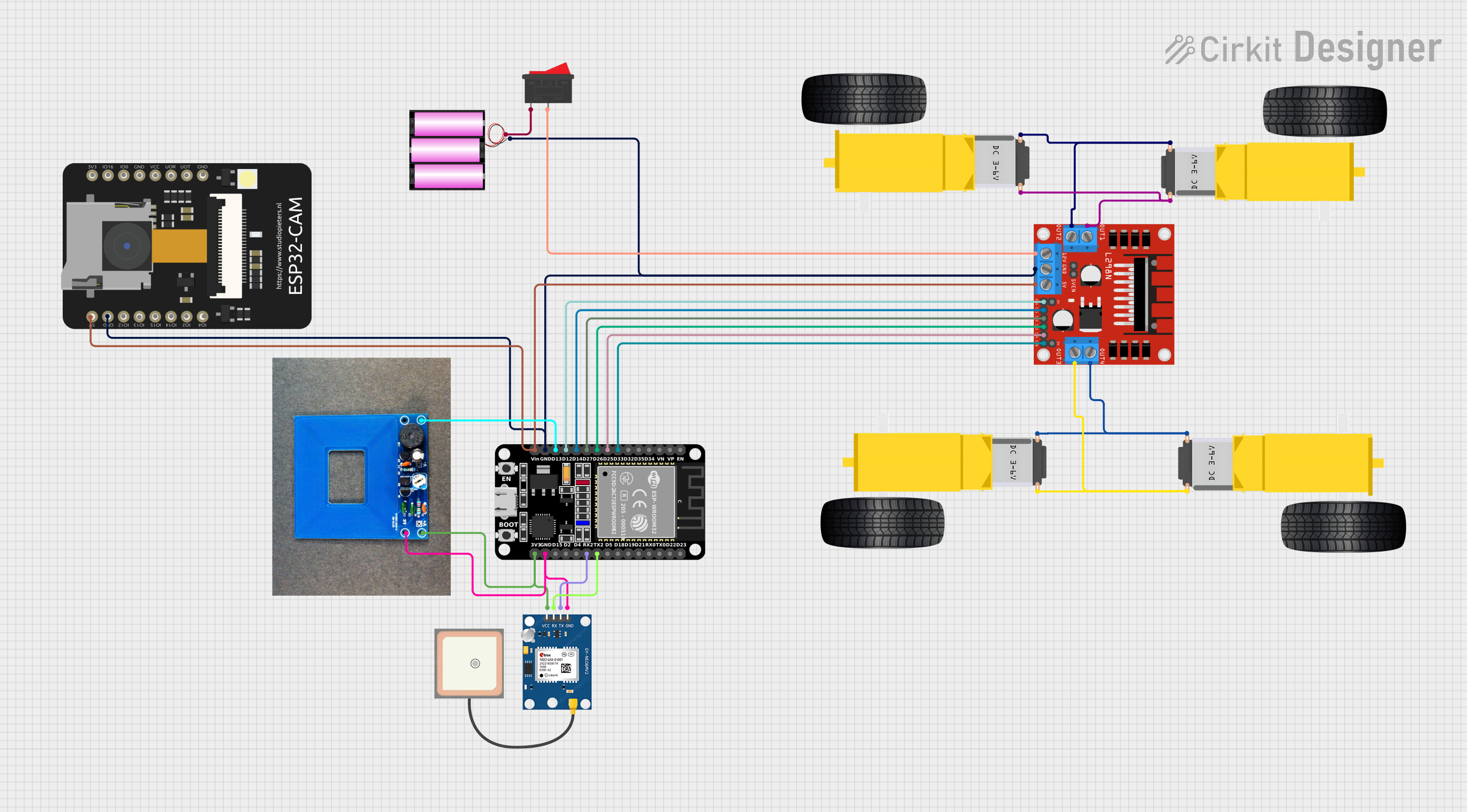

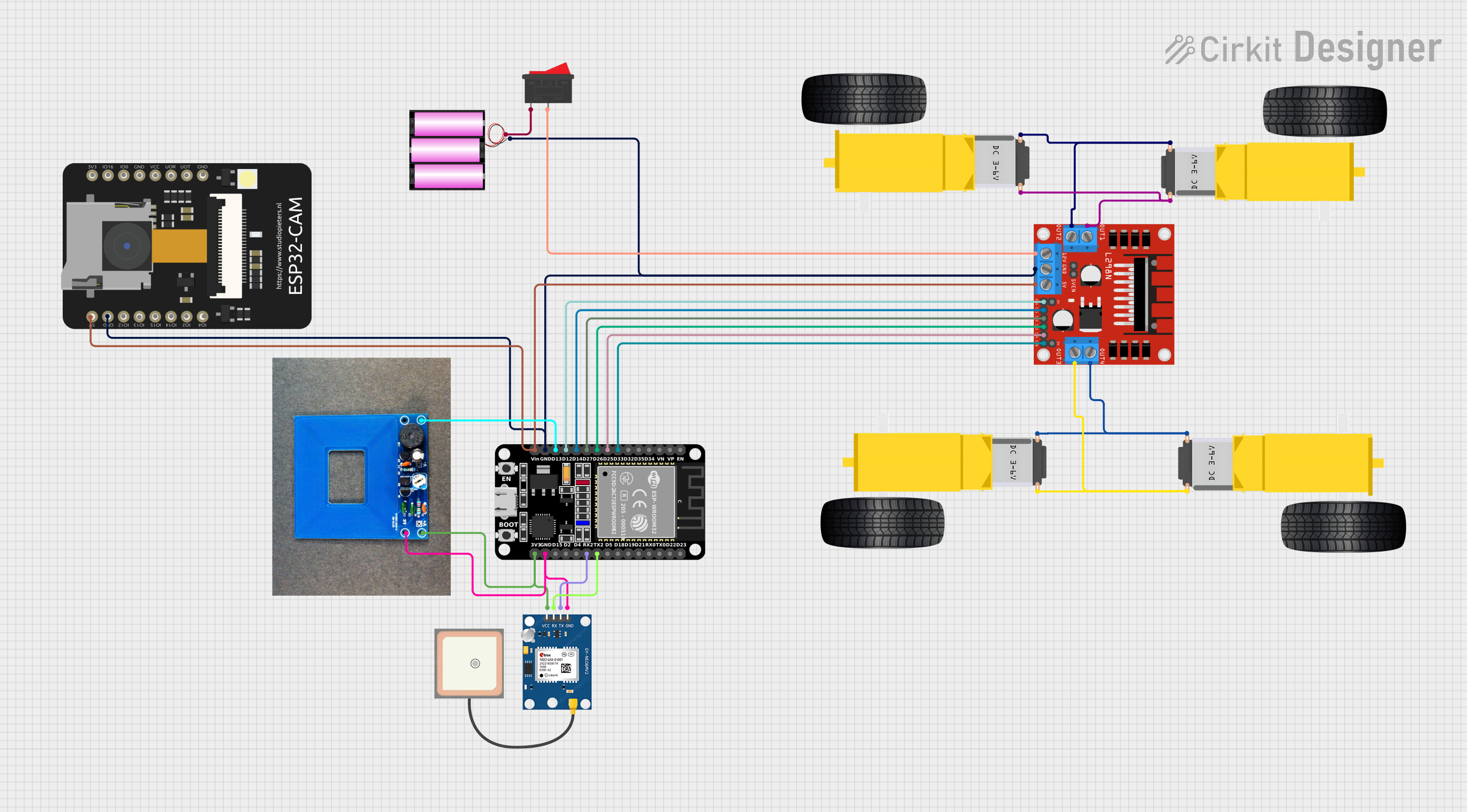

Open Project in Cirkit DesignerESP32 and L298N Motor Driver-Based Wi-Fi Controlled Robotic Vehicle with GPS and Metal Detection

This circuit is a robotic vehicle control system that uses an ESP32 microcontroller to drive four DC gear motors via an L298N motor driver. It also includes a GPS module for location tracking, a metal detector for object detection, and an ESP32 CAM for capturing images or video, all powered by a 12V battery.

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with motor and wheels

Battery-Powered Dual Gearmotor Drive System

This circuit consists of a 6V battery pack connected in parallel to two DC gearmotors, one for the left wheel and one for the right wheel of a vehicle. The battery provides power directly to both motors, enabling them to run simultaneously. As there is no control circuitry or microcontroller code provided, the motors will run continuously when the circuit is powered.

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Arduino-Controlled Robotic Vehicle with IR Sensors and L298N Motor Driver

This circuit is designed to control a pair of DC gearmotors using an L298N motor driver module, which is interfaced with an Arduino UNO microcontroller. The Arduino is also connected to a 5-channel IR sensor for input, which may be used for line tracking or obstacle detection. Power is supplied by a 9V battery connected through a 2.1mm barrel jack, and the motor driver module regulates this power to drive the left and right gearmotors for a mobile robot platform.

Open Project in Cirkit Designer

Open Project in Cirkit Designer

ESP32-CAM Controlled Wi-Fi Robot Car

This circuit is designed to control a two-wheel motorized vehicle using an ESP32-CAM microcontroller. The ESP32-CAM is interfaced with an L298N DC motor driver to control the direction and speed of the motors attached to the wheels. Additionally, the ESP32-CAM is configured to capture images and provide WiFi connectivity for remote control via a web server with a user interface for driving commands.

Open Project in Cirkit Designer

Open Project in Cirkit Designer

ESP32 and L298N Motor Driver-Based Wi-Fi Controlled Robotic Vehicle with GPS and Metal Detection

This circuit is a robotic vehicle control system that uses an ESP32 microcontroller to drive four DC gear motors via an L298N motor driver. It also includes a GPS module for location tracking, a metal detector for object detection, and an ESP32 CAM for capturing images or video, all powered by a 12V battery.

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Motor Specifications

| Parameter | Value |

|---|---|

| Motor Type | DC Motor or Stepper Motor |

| Operating Voltage | 3V to 12V (varies by model) |

| Current Rating | 100mA to 2A (depending on load) |

| Speed | 100 RPM to 300 RPM |

| Torque | 0.5 kg-cm to 5 kg-cm |

Wheel Specifications

| Parameter | Value |

|---|---|

| Wheel Diameter | 65mm to 100mm (varies by model) |

| Material | Rubber or Plastic |

| Mounting Type | Direct or Coupled to Motor |

Pin Configuration (for DC Motor)

| Pin Name | Description |

|---|---|

| V+ | Positive terminal for power |

| V- | Negative terminal for power |

Pin Configuration (for Stepper Motor)

| Pin Name | Description |

|---|---|

| A+ | Coil A positive terminal |

| A- | Coil A negative terminal |

| B+ | Coil B positive terminal |

| B- | Coil B negative terminal |

Usage Instructions

Connecting the Motor and Wheels:

- Attach the wheels securely to the motor shaft using the provided coupler or mounting mechanism.

- Ensure the wheels are balanced and aligned to avoid wobbling during operation.

Wiring the Motor:

- For a DC motor, connect the V+ and V- terminals to a motor driver or directly to a power source (if no driver is used).

- For a stepper motor, connect the A+, A-, B+, and B- terminals to a stepper motor driver.

Using with an Arduino UNO:

- For DC motors, use an H-bridge motor driver (e.g., L298N) to control speed and direction.

- For stepper motors, use a stepper motor driver (e.g., ULN2003 or A4988) for precise control.

Example Code for DC Motor with Arduino UNO

// Include the motor driver library (if required for your driver)

// Define motor control pins

const int motorPin1 = 9; // Pin connected to motor driver IN1

const int motorPin2 = 10; // Pin connected to motor driver IN2

const int enablePin = 11; // Pin connected to motor driver ENA

void setup() {

// Set motor pins as outputs

pinMode(motorPin1, OUTPUT);

pinMode(motorPin2, OUTPUT);

pinMode(enablePin, OUTPUT);

// Start the motor at full speed

analogWrite(enablePin, 255); // Set speed (0-255)

digitalWrite(motorPin1, HIGH); // Set direction

digitalWrite(motorPin2, LOW);

}

void loop() {

// Motor runs continuously in setup; add logic here for control

}

Important Considerations:

- Always use a motor driver to protect the Arduino from high current draw.

- Ensure the power supply matches the motor's voltage and current requirements.

- Use a heat sink or cooling mechanism for the motor driver if operating at high currents.

Troubleshooting and FAQs

Common Issues

Motor not spinning:

- Check the power supply and ensure it matches the motor's voltage requirements.

- Verify the wiring connections to the motor driver or power source.

Motor spins in the wrong direction:

- Reverse the polarity of the motor terminals (for DC motors).

- Adjust the control signals for stepper motors.

Motor overheats:

- Ensure the motor is not overloaded beyond its torque rating.

- Use a proper heat dissipation mechanism for the motor driver.

Wheels wobble or detach:

- Check the mounting mechanism and ensure the wheels are securely attached.

- Use thread-locking adhesive if necessary.

FAQs

Can I use a single power source for both the motor and Arduino?

- Yes, but ensure the power source can handle the combined current draw. Use a voltage regulator if needed.

What is the best motor type for precise control?

- Stepper motors are ideal for precise control, while DC motors are better for high-speed applications.

How do I calculate the required torque for my application?

- Use the formula: Torque = Force × Radius. Consider the weight of the load and the wheel radius.

By following this documentation, you can effectively integrate motor and wheels into your projects for reliable and efficient operation.