How to Use throttle: Examples, Pinouts, and Specs

Design with throttle in Cirkit Designer

Design with throttle in Cirkit DesignerIntroduction

A throttle is a device used to regulate the flow of fuel or air into an engine, thereby controlling its power output and speed. It is a critical component in internal combustion engines, enabling precise control over engine performance. Throttles are commonly found in vehicles, motorcycles, and other machinery that relies on engines for operation. In electronic systems, throttle sensors are often used to monitor and adjust throttle position, ensuring optimal performance and efficiency.

Explore Projects Built with throttle

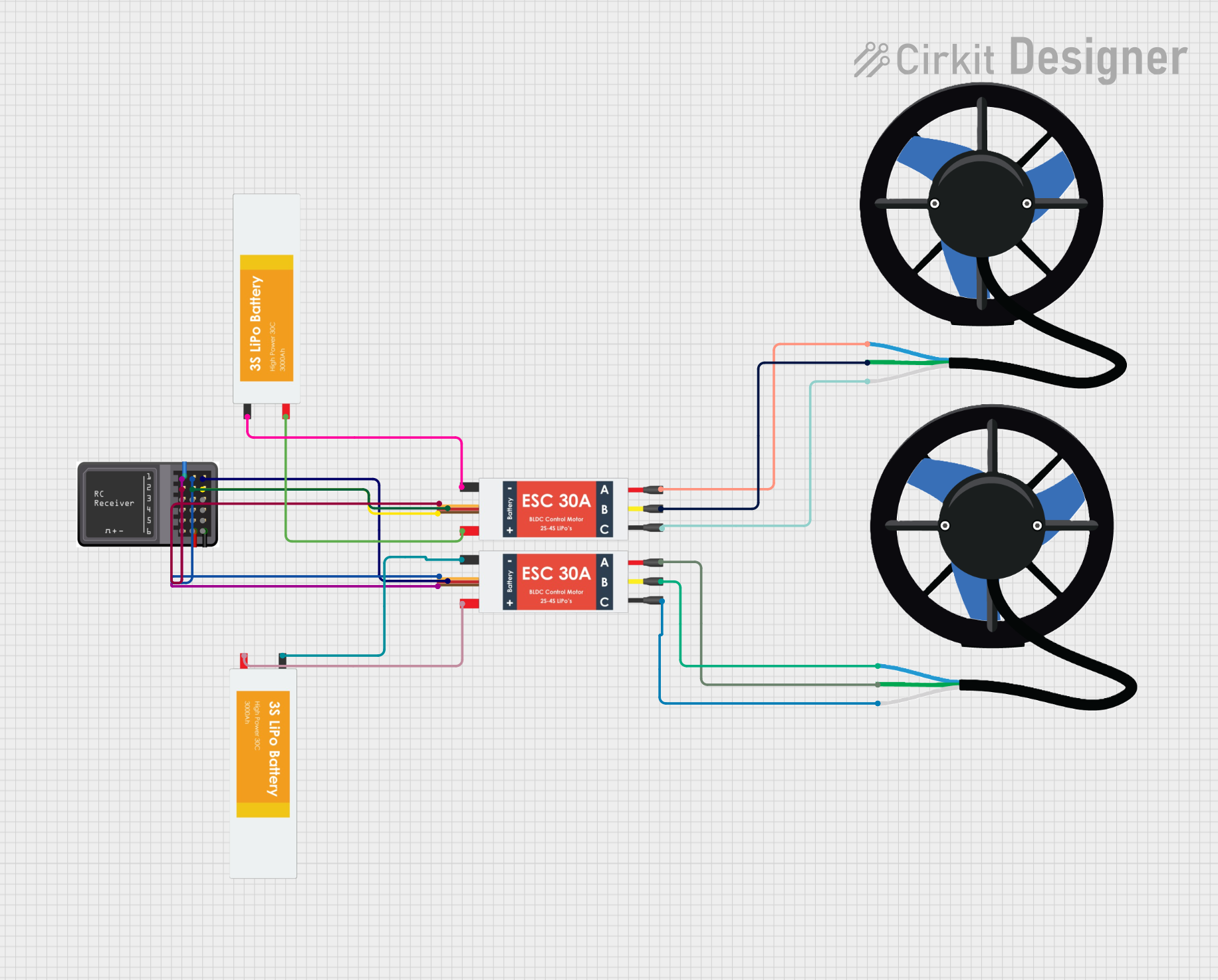

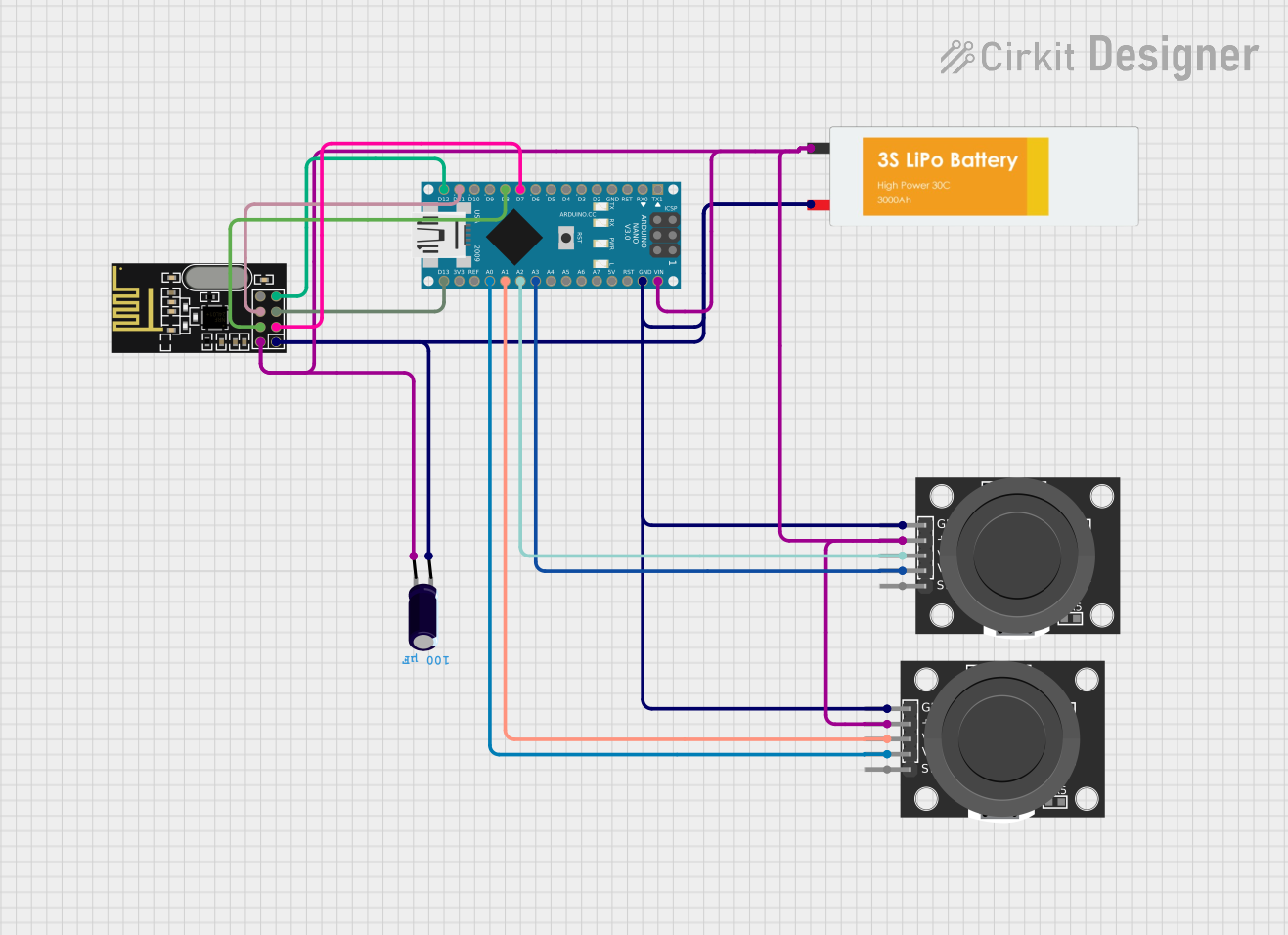

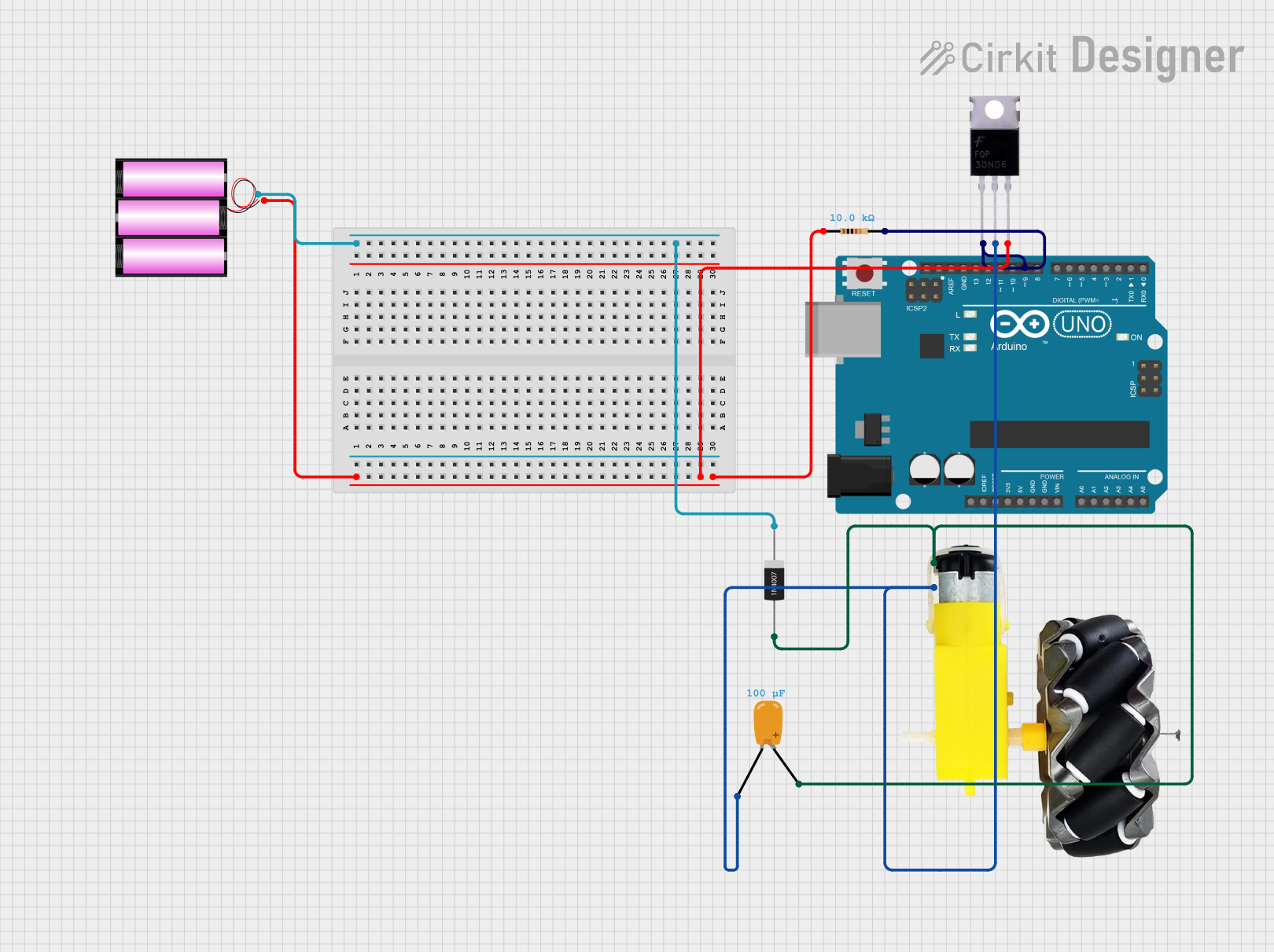

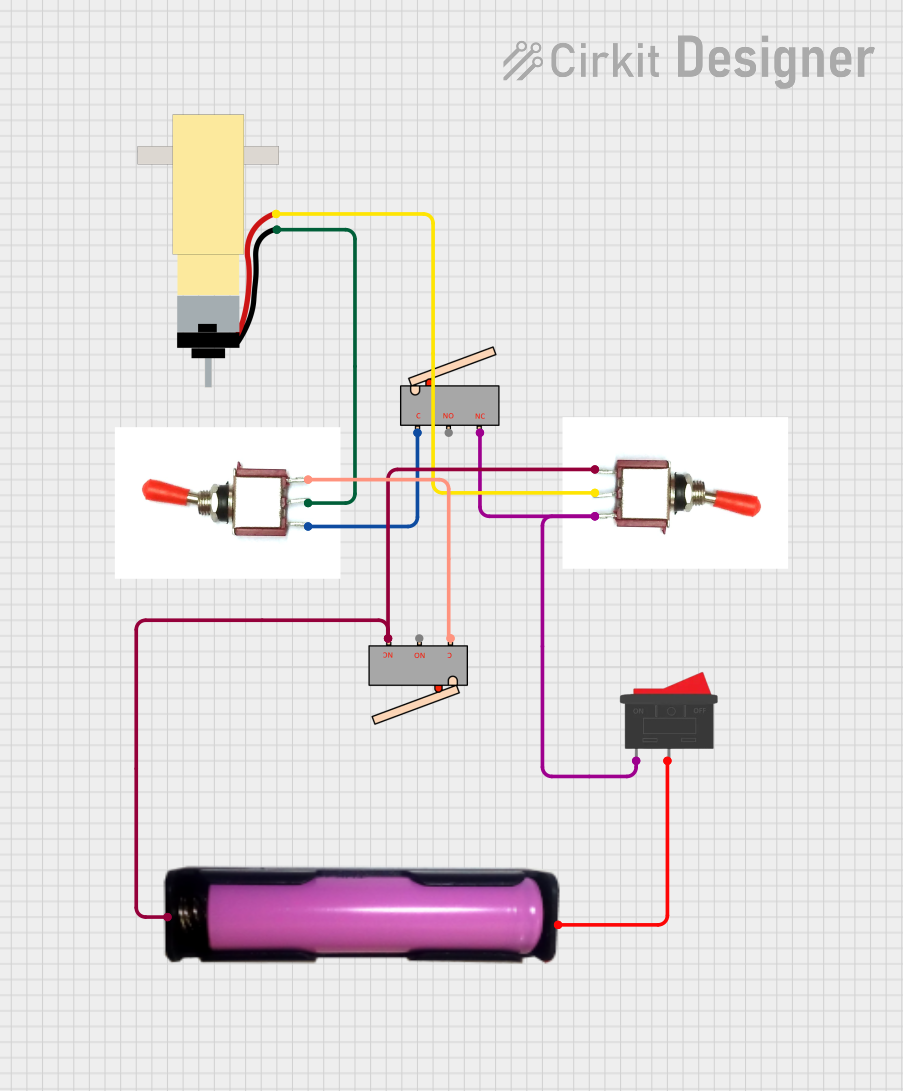

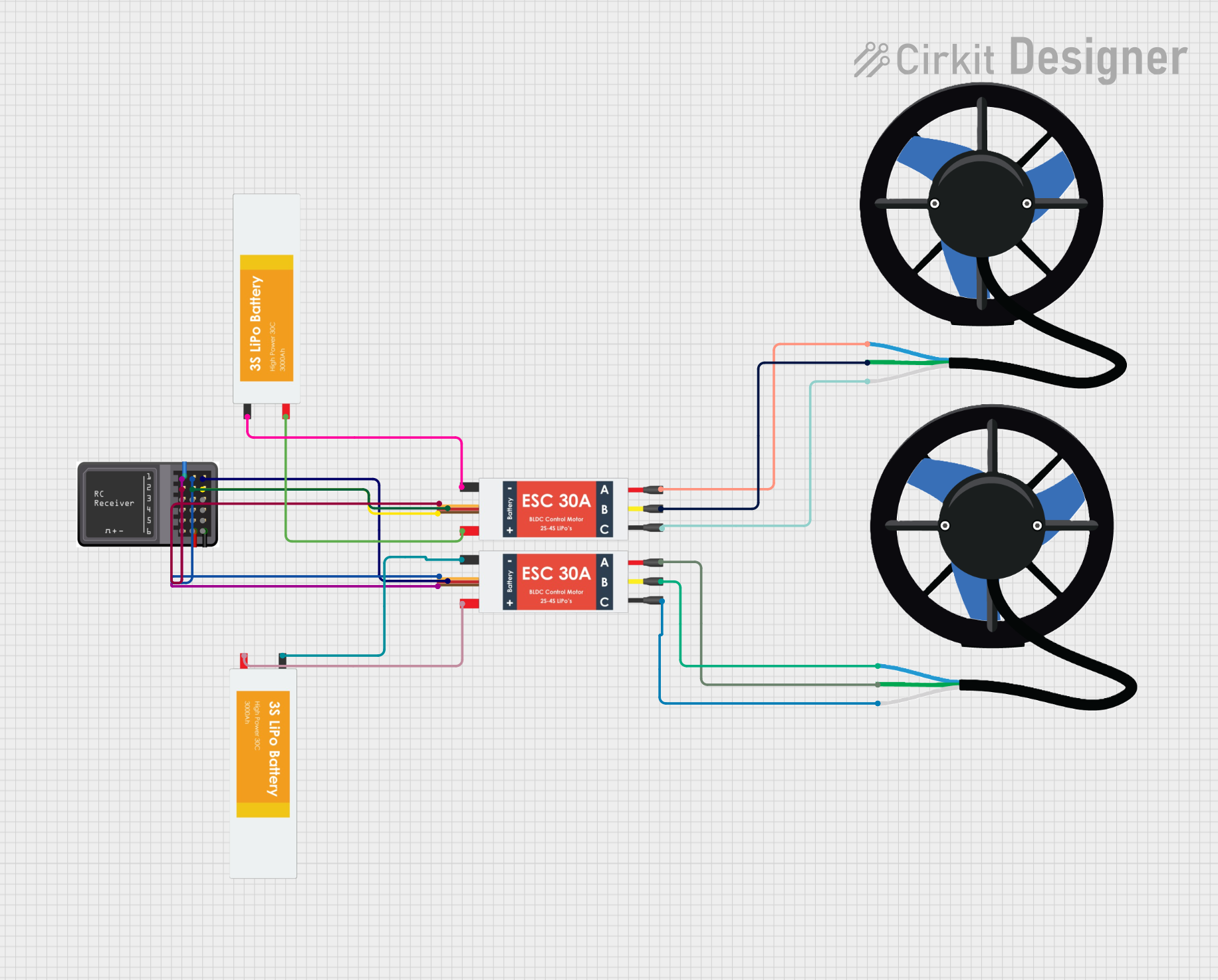

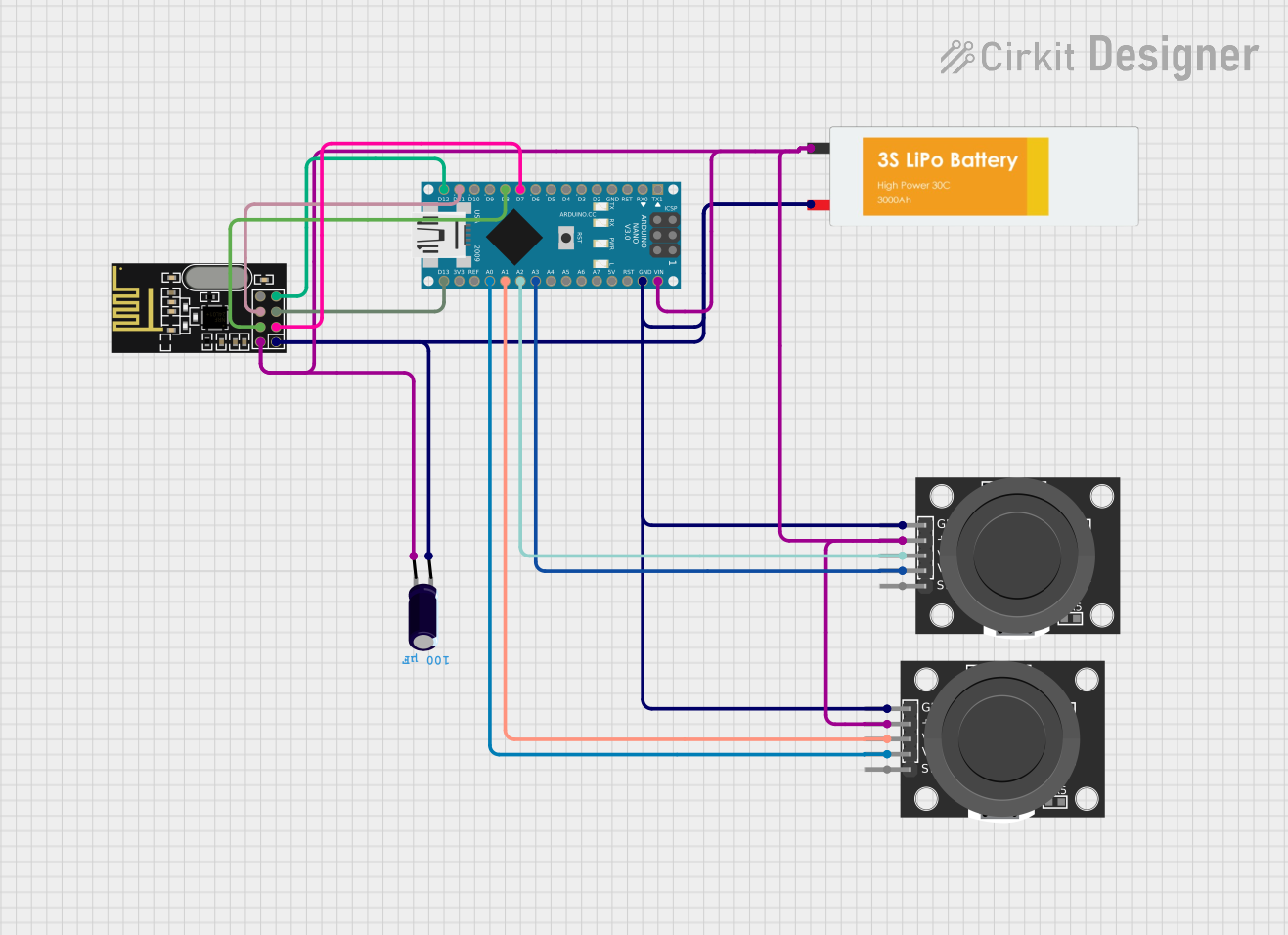

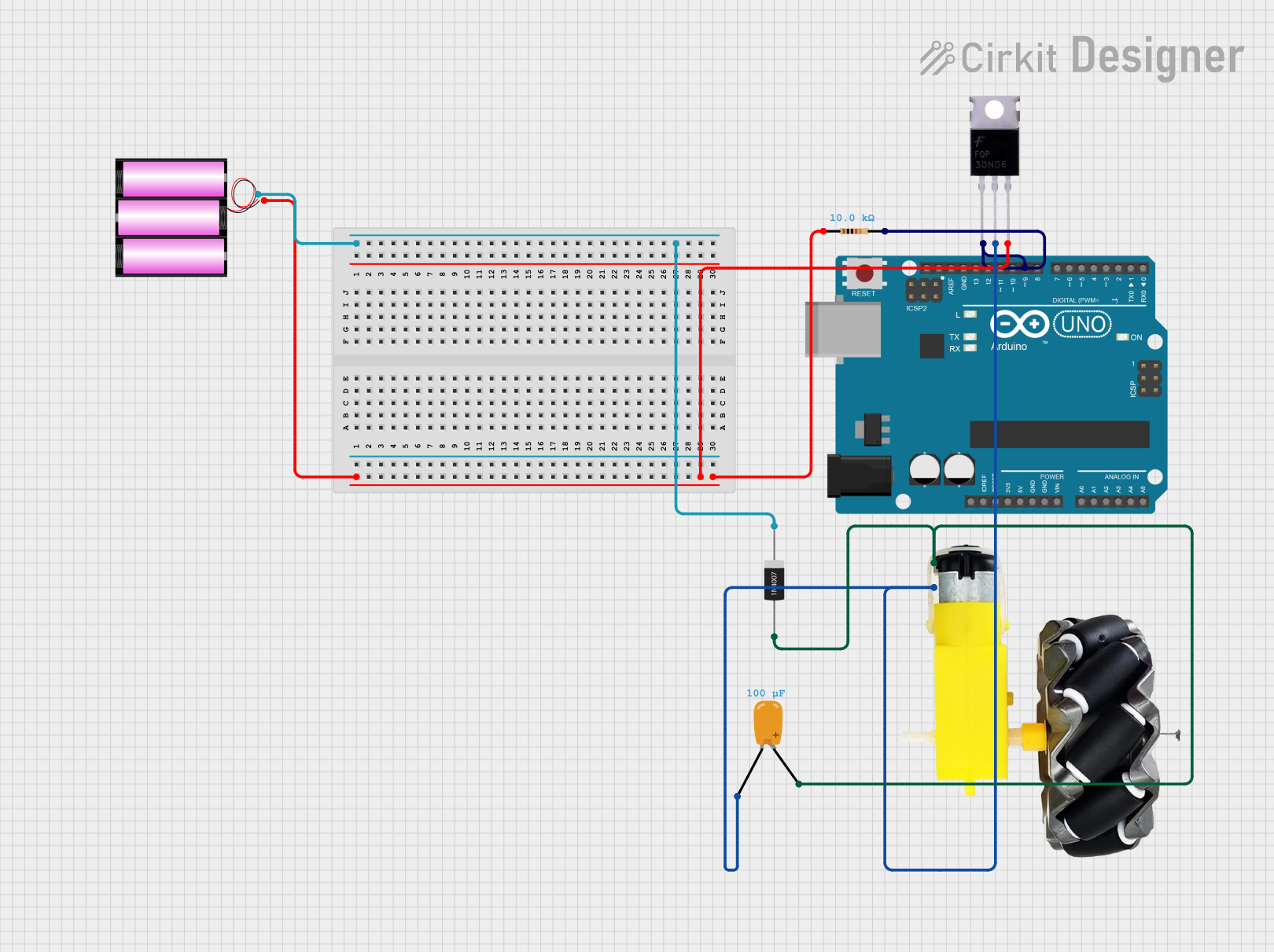

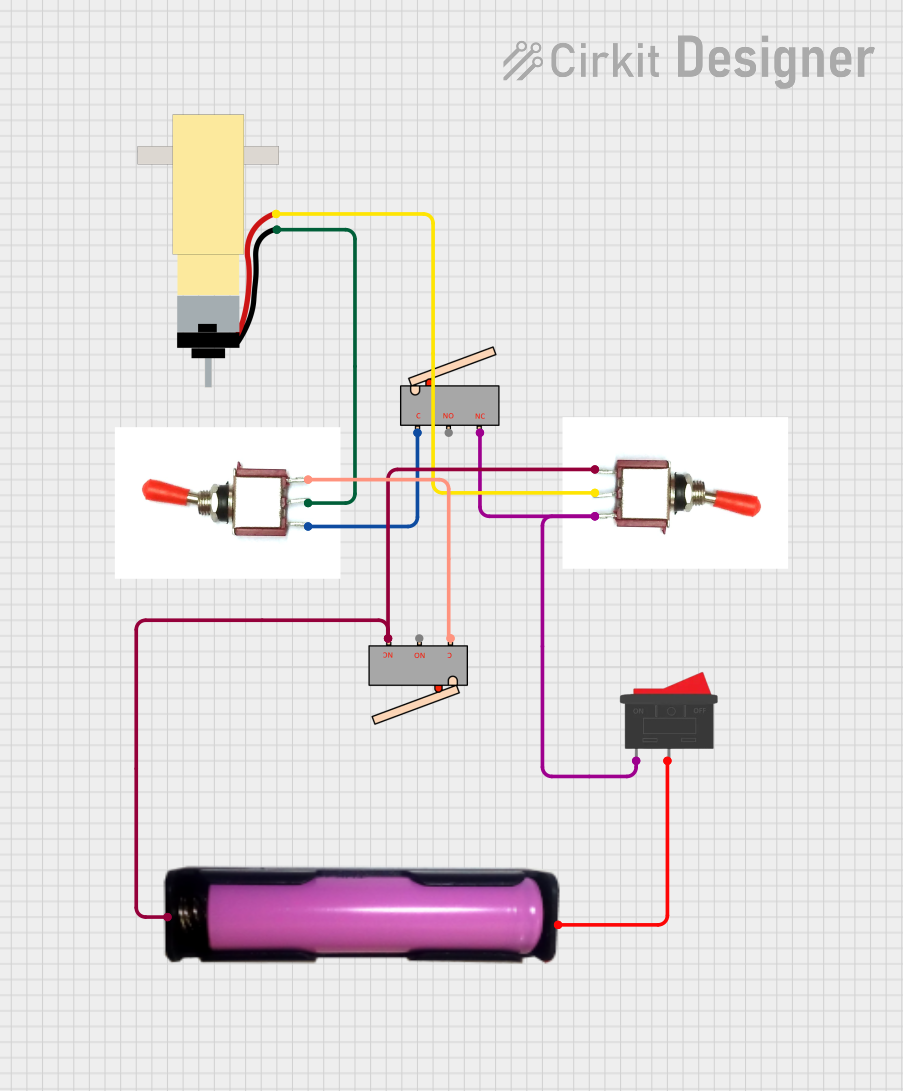

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with throttle

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Automotive engines for speed and power control

- Motorcycles and scooters for acceleration management

- Industrial machinery with internal combustion engines

- Drones and RC vehicles for motor speed regulation

- Electronic throttle control (ETC) systems in modern vehicles

Technical Specifications

Below are the general technical specifications for an electronic throttle or throttle position sensor (TPS). Specific values may vary depending on the manufacturer and model.

General Specifications

- Operating Voltage: 5V DC (typical for electronic throttle sensors)

- Output Signal: Analog voltage (0.5V to 4.5V range)

- Operating Temperature: -40°C to 125°C

- Accuracy: ±1% of full-scale output

- Response Time: <10 ms

- Connector Type: 3-pin or 6-pin (depending on the model)

Pin Configuration and Descriptions

The pin configuration for a typical 3-pin throttle position sensor is as follows:

| Pin | Name | Description |

|---|---|---|

| 1 | VCC | Power supply input (typically 5V DC) |

| 2 | Signal Output | Analog voltage output proportional to throttle angle |

| 3 | Ground (GND) | Ground connection |

For a 6-pin electronic throttle body, the configuration may include additional pins for motor control:

| Pin | Name | Description |

|---|---|---|

| 1 | VCC | Power supply input (typically 5V DC) |

| 2 | Signal Output | Analog voltage output proportional to throttle angle |

| 3 | Ground (GND) | Ground connection |

| 4 | Motor + | Positive terminal for throttle motor |

| 5 | Motor - | Negative terminal for throttle motor |

| 6 | Feedback | Additional signal for position feedback |

Usage Instructions

How to Use the Throttle in a Circuit

- Power the Throttle: Connect the VCC pin to a 5V DC power source and the GND pin to the ground.

- Read the Signal Output: Use an analog input pin on a microcontroller (e.g., Arduino) to read the voltage from the Signal Output pin. This voltage corresponds to the throttle position.

- Motor Control (if applicable): For electronic throttle bodies, connect the Motor + and Motor - pins to an H-bridge motor driver to control the throttle plate's position.

Important Considerations and Best Practices

- Ensure the power supply voltage matches the throttle's specifications to avoid damage.

- Use shielded cables for the signal output to minimize noise interference.

- Calibrate the throttle sensor to ensure accurate readings.

- Avoid exposing the throttle to extreme temperatures or moisture to maintain reliability.

Example: Connecting a Throttle to an Arduino UNO

Below is an example of how to read the throttle position using an Arduino UNO:

// Example code to read throttle position using Arduino UNO

const int throttlePin = A0; // Analog pin connected to throttle Signal Output

int throttleValue = 0; // Variable to store the throttle position value

void setup() {

Serial.begin(9600); // Initialize serial communication for debugging

pinMode(throttlePin, INPUT); // Set throttle pin as input

}

void loop() {

// Read the analog voltage from the throttle

throttleValue = analogRead(throttlePin);

// Map the analog value (0-1023) to a percentage (0-100%)

int throttlePercentage = map(throttleValue, 0, 1023, 0, 100);

// Print the throttle position to the Serial Monitor

Serial.print("Throttle Position: ");

Serial.print(throttlePercentage);

Serial.println("%");

delay(100); // Delay for stability

}

Troubleshooting and FAQs

Common Issues and Solutions

No Signal Output

- Cause: Incorrect wiring or power supply.

- Solution: Verify the connections and ensure the VCC and GND pins are properly connected.

Inaccurate Readings

- Cause: Calibration issues or electrical noise.

- Solution: Calibrate the sensor and use shielded cables to reduce noise.

Throttle Motor Not Responding

- Cause: Faulty motor driver or incorrect wiring.

- Solution: Check the motor driver connections and ensure it is functioning correctly.

Signal Output Stuck at Maximum or Minimum

- Cause: Sensor malfunction or mechanical blockage.

- Solution: Inspect the sensor and throttle mechanism for damage or obstructions.

FAQs

Q: Can I use a throttle with a 3.3V microcontroller?

A: Yes, but you may need a level shifter to ensure compatibility with the 5V signal output.

Q: How do I calibrate a throttle sensor?

A: Calibration typically involves reading the minimum and maximum output voltages and mapping them to the desired range in your microcontroller code.

Q: Can I use the throttle in outdoor applications?

A: Yes, but ensure the throttle is rated for outdoor use and protected from moisture and extreme temperatures.

Q: What happens if the throttle sensor fails?

A: In vehicles, a failed throttle sensor may trigger a "limp mode" to limit engine performance and prevent damage. Replace the sensor promptly.