How to Use 2.2KW Spindle VFD Connections: Examples, Pinouts, and Specs

Design with 2.2KW Spindle VFD Connections in Cirkit Designer

Design with 2.2KW Spindle VFD Connections in Cirkit DesignerIntroduction

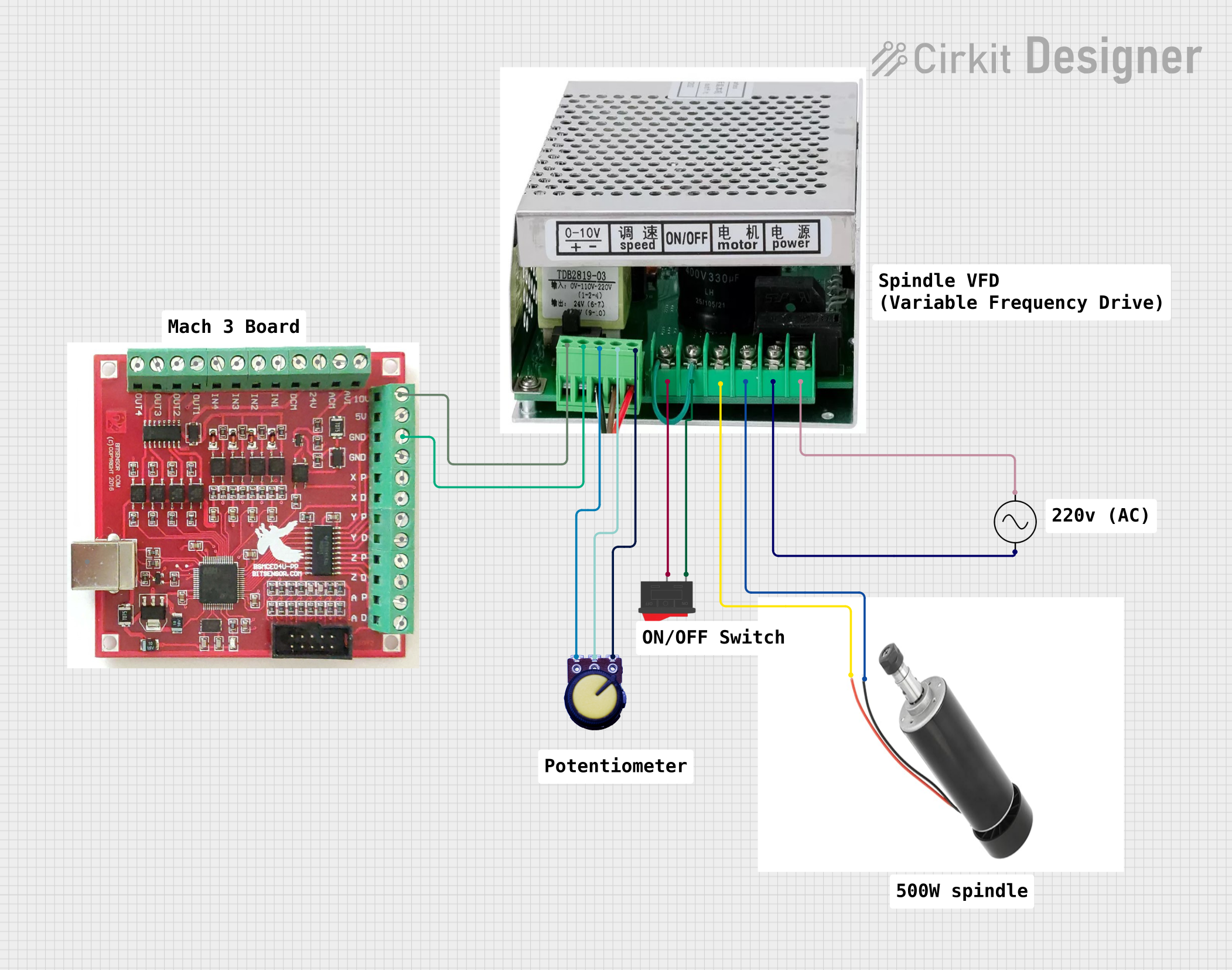

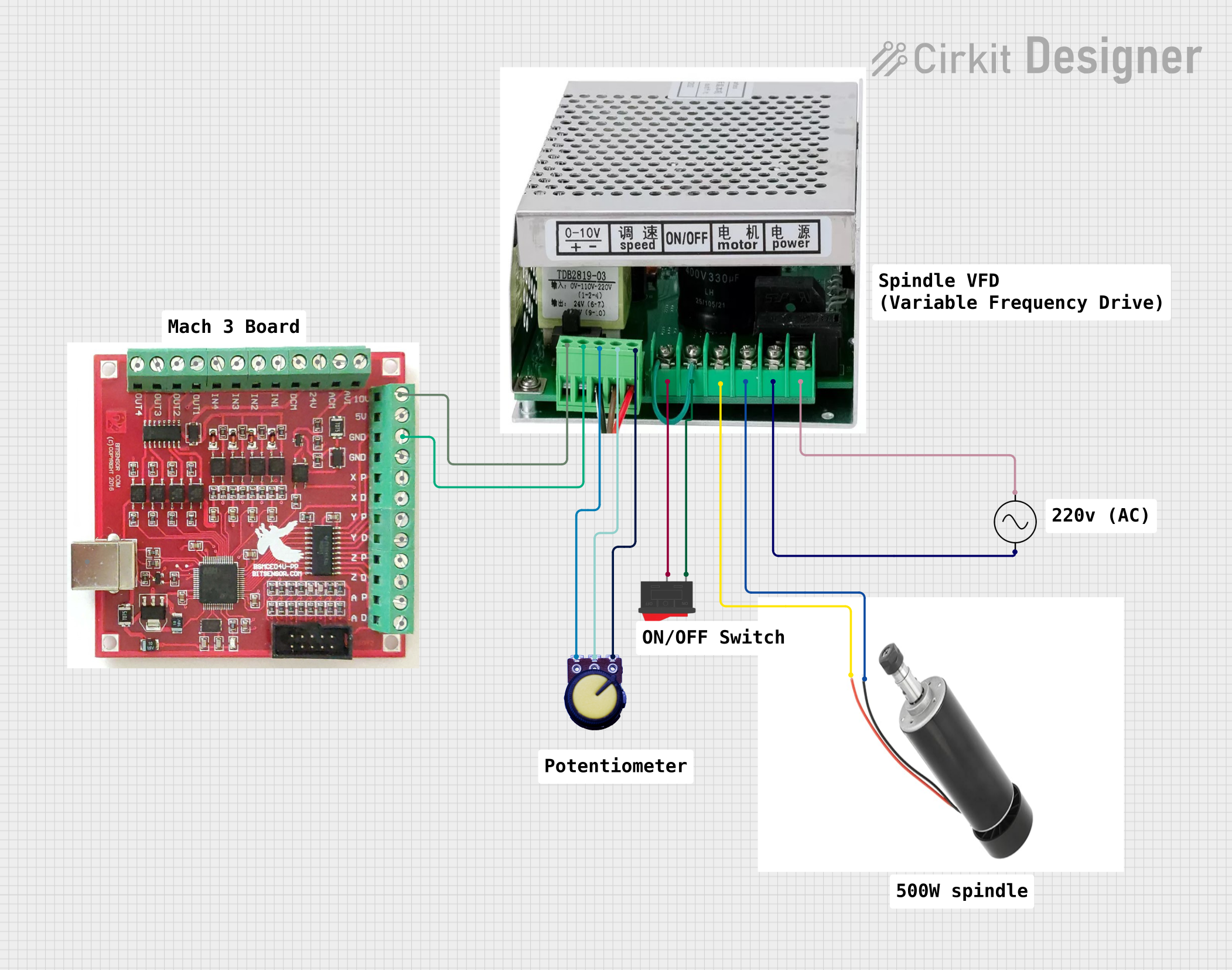

The 2.2KW Spindle Variable Frequency Drive (VFD), manufactured by Zhong Hua Jiang, is a critical component for controlling the speed, torque, and direction of an electric spindle motor. It is widely used in CNC machines, milling machines, lathes, and other industrial applications requiring precise motor control. The VFD allows for smooth acceleration, deceleration, and speed adjustments, making it an essential tool for high-performance machining.

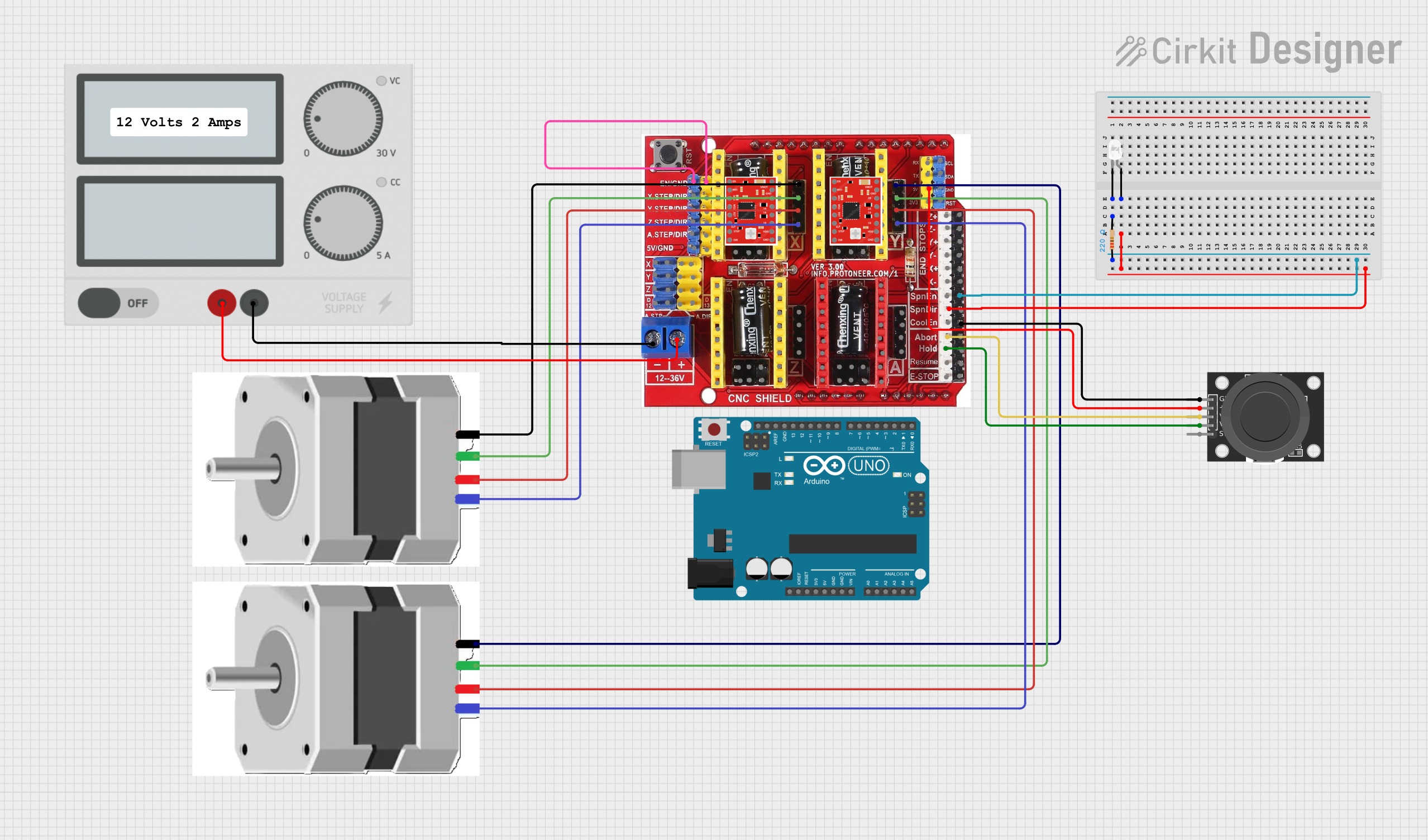

Explore Projects Built with 2.2KW Spindle VFD Connections

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 2.2KW Spindle VFD Connections

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- CNC routers and milling machines

- Lathes and grinding machines

- Industrial automation systems

- HVAC systems for motor control

- Any application requiring variable-speed motor control

Technical Specifications

Below are the key technical details for the 2.2KW Spindle VFD:

| Parameter | Specification |

|---|---|

| Input Voltage | 220V AC (Single-phase or Three-phase) |

| Output Voltage | 0-220V AC |

| Output Power | 2.2KW |

| Frequency Range | 0-400 Hz |

| Control Mode | V/F Control, Vector Control |

| Overload Capacity | 150% of rated current for 1 minute |

| Cooling Method | Forced air cooling |

| Protection Features | Overvoltage, Undervoltage, Overload, Short Circuit |

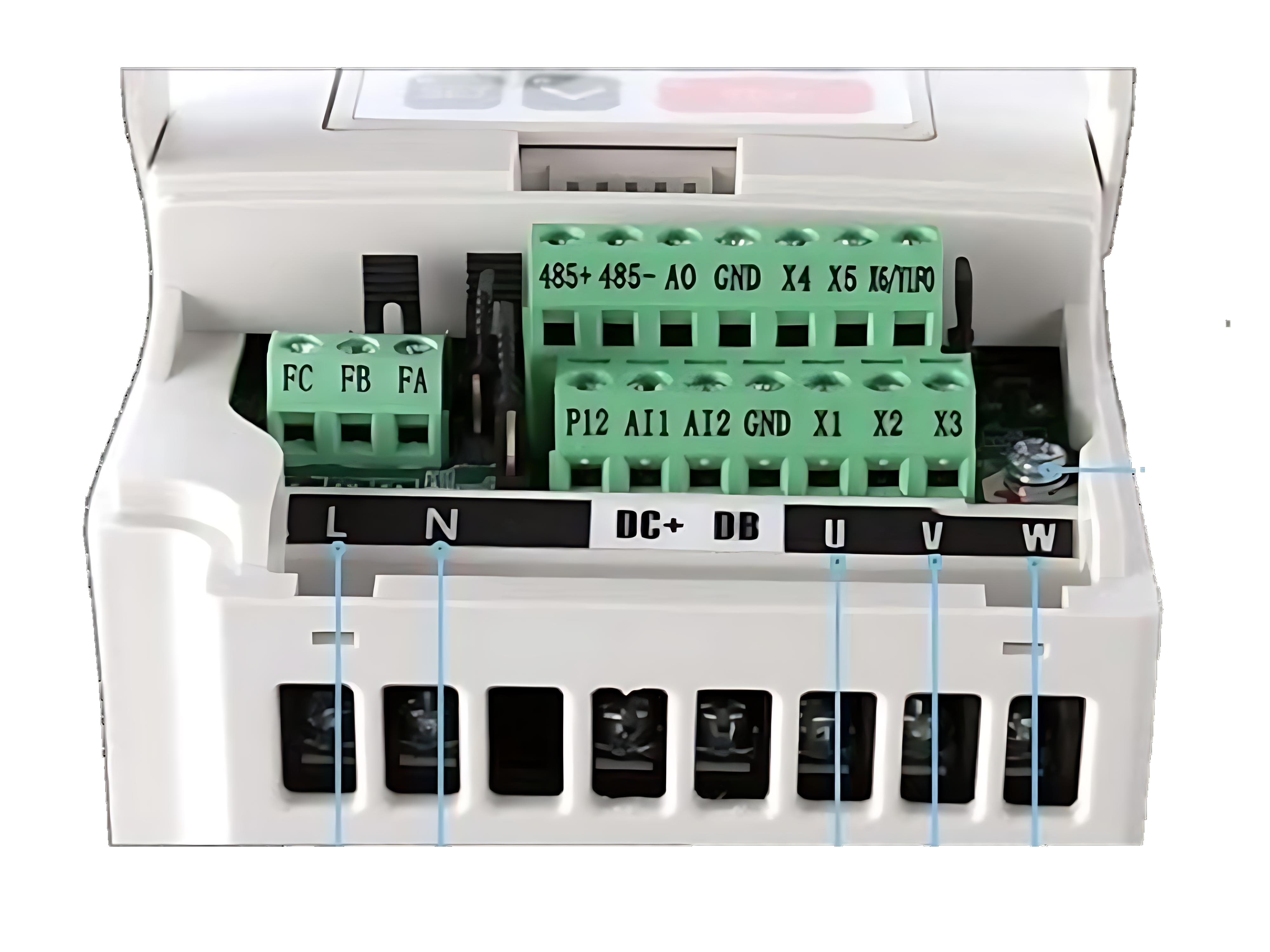

Pin Configuration and Descriptions

The VFD has multiple terminals for power input, motor output, and control signals. Below is the pin configuration:

Power and Motor Terminals

| Terminal | Description |

|---|---|

| R, S, T | AC Input (Single-phase: R, S) |

| U, V, W | Motor Output Terminals |

| PE | Protective Earth (Ground) |

Control Terminals

| Terminal | Description |

|---|---|

| FOR | Forward Run Command Input |

| REV | Reverse Run Command Input |

| COM | Common Ground for Control Signals |

| AI1 | Analog Input (0-10V or 4-20mA for speed control) |

| AO | Analog Output (e.g., for monitoring motor speed) |

| DI1-DI6 | Digital Inputs (programmable for various functions) |

| DO | Digital Output (e.g., fault signal) |

Usage Instructions

Connecting the VFD

- Power Input: Connect the AC input voltage to terminals

RandS(for single-phase) orR,S, andT(for three-phase). Ensure the input voltage matches the VFD's rated input. - Motor Output: Connect the spindle motor to terminals

U,V, andW. Verify the motor's rated voltage and current are compatible with the VFD. - Grounding: Connect the

PEterminal to a reliable earth ground to ensure safety and reduce electrical noise. - Control Signals: Use the control terminals (

FOR,REV,AI1, etc.) to configure the VFD for your application. For example:- Use

AI1for analog speed control (0-10V or 4-20mA). - Use

FORandREVfor forward and reverse operation.

- Use

Programming the VFD

- Access the VFD's control panel to configure parameters such as:

- P00.01: Motor rated voltage

- P00.02: Motor rated current

- P00.03: Maximum frequency

- P00.04: Acceleration time

- P00.05: Deceleration time

- Refer to the manufacturer's manual for a complete list of parameters and their functions.

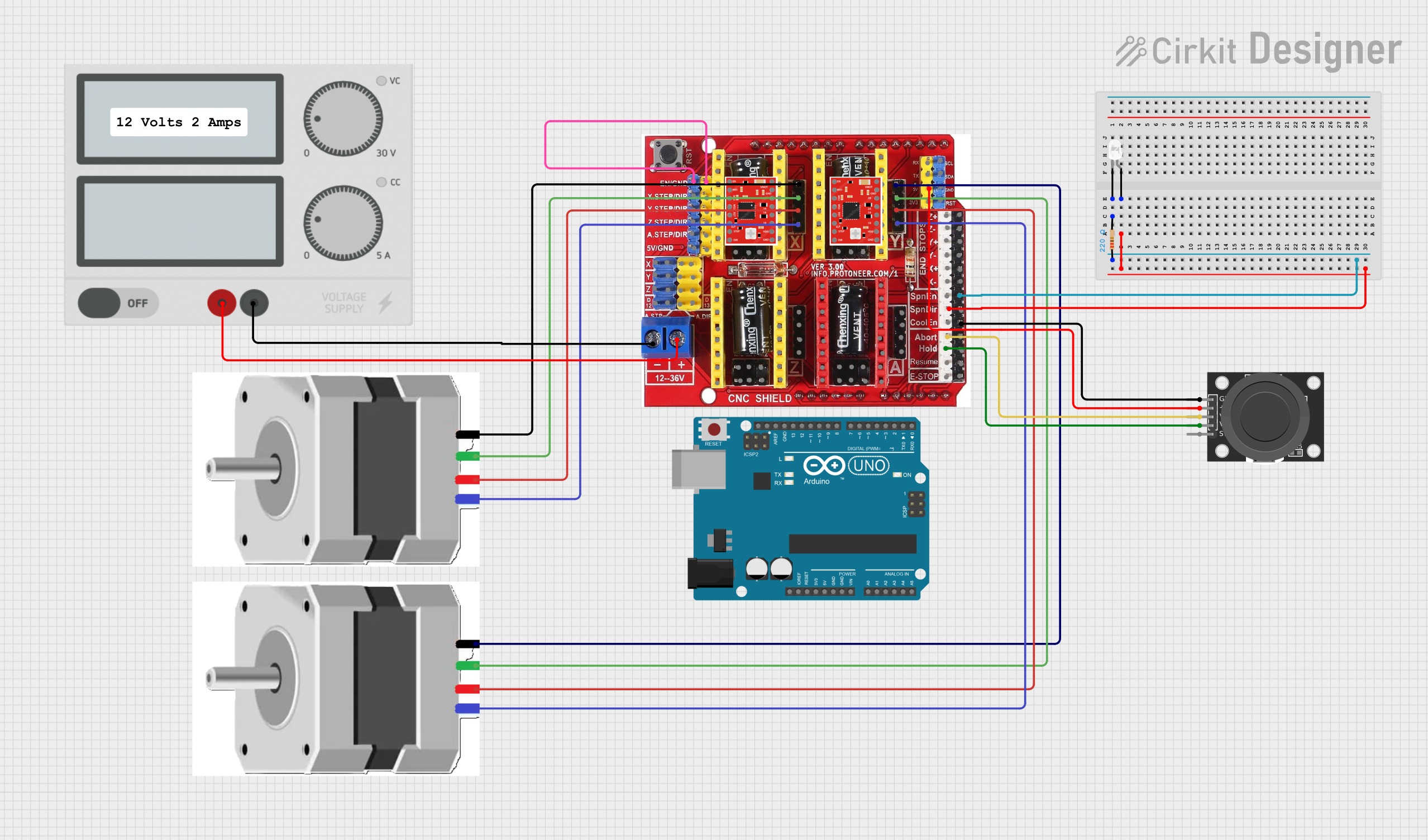

Example: Connecting to an Arduino UNO

To control the spindle speed using an Arduino UNO, you can use the AI1 terminal for analog input. Below is an example code snippet:

// Example code to control spindle speed using Arduino UNO

// The spindle speed is controlled via a PWM signal sent to the VFD's AI1 terminal.

const int pwmPin = 9; // PWM output pin connected to AI1 terminal

void setup() {

pinMode(pwmPin, OUTPUT); // Set the PWM pin as output

}

void loop() {

int speed = 128; // Set spindle speed (0-255, where 255 = max speed)

// Generate PWM signal to control spindle speed

analogWrite(pwmPin, speed);

// Add a delay to simulate continuous operation

delay(1000);

}

Important Considerations

- Always double-check wiring connections before powering on the VFD.

- Use shielded cables for motor connections to minimize electromagnetic interference (EMI).

- Ensure proper cooling and ventilation for the VFD to prevent overheating.

- Follow all safety guidelines and local electrical codes during installation.

Troubleshooting and FAQs

Common Issues and Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| VFD does not power on | No input voltage or incorrect wiring | Check input voltage and wiring |

| Motor does not run | Incorrect parameter settings or wiring | Verify motor wiring and parameter setup |

| Overload or overcurrent fault | Motor is overloaded or short-circuited | Reduce load or check motor connections |

| Excessive noise or vibration | Improper grounding or EMI interference | Ensure proper grounding and use shielded cables |

| Inconsistent speed control | Faulty analog input or incorrect settings | Check analog input signal and parameters |

FAQs

Can I use this VFD with a single-phase motor?

- No, this VFD is designed for three-phase motors only.

What type of cable should I use for motor connections?

- Use shielded, high-quality cables rated for the motor's current and voltage.

How do I reset the VFD to factory settings?

- Refer to the manufacturer's manual for the specific parameter to reset all settings.

Can I control the VFD remotely?

- Yes, the VFD supports remote control via analog inputs, digital inputs, or communication protocols (if supported).

By following this documentation, you can safely and effectively connect and operate the Zhong Hua Jiang 2.2KW Spindle VFD in your application.