How to Use X8-20: Examples, Pinouts, and Specs

Design with X8-20 in Cirkit Designer

Design with X8-20 in Cirkit DesignerIntroduction

The X8-20 is a versatile programmable logic controller (PLC) developed by Myactuator. It is designed for industrial automation and control applications, offering a robust and reliable solution for managing complex processes. The X8-20 features multiple input/output (I/O) channels, supports a variety of communication protocols, and is engineered for ease of programming and integration into existing systems.

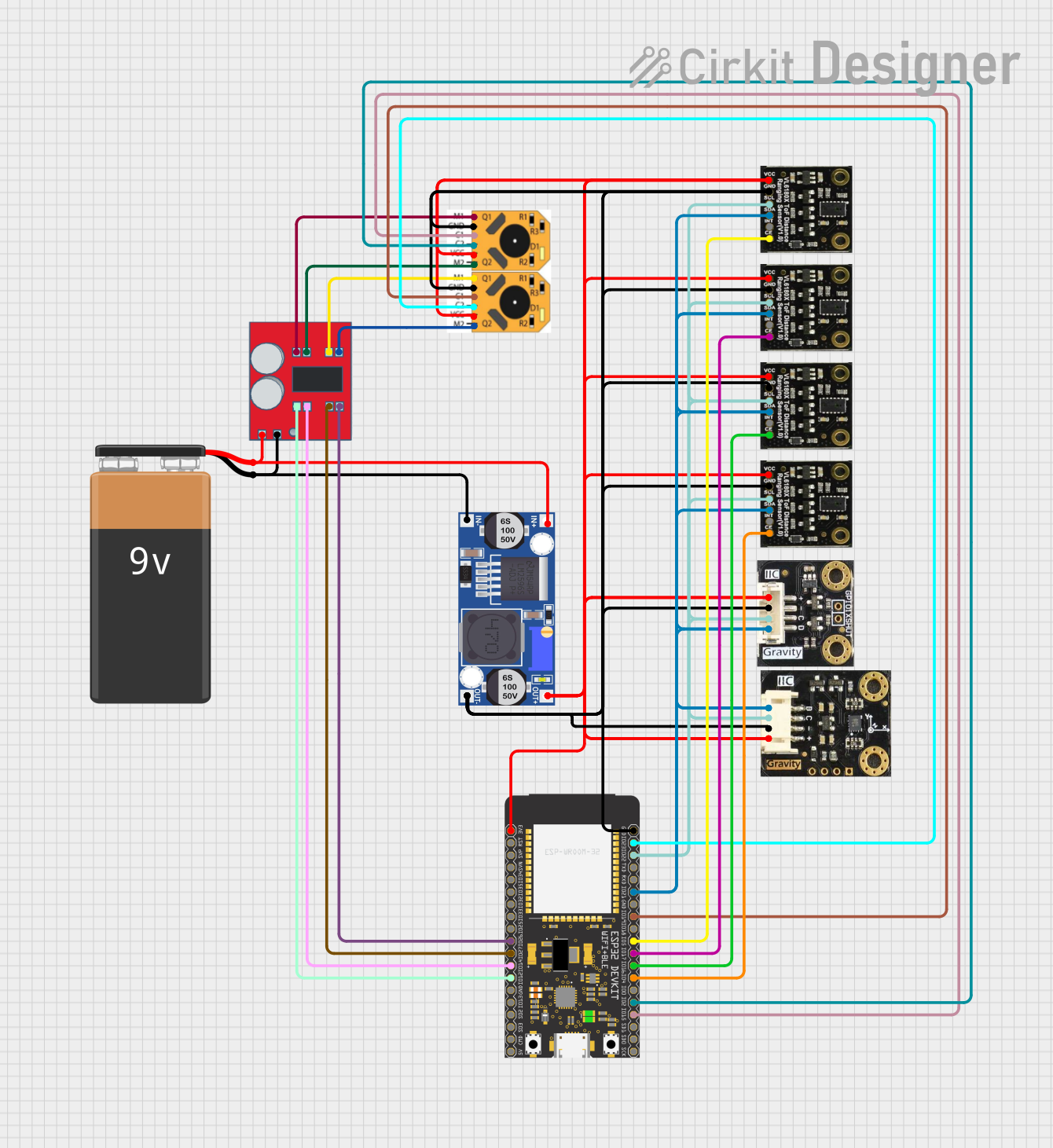

Explore Projects Built with X8-20

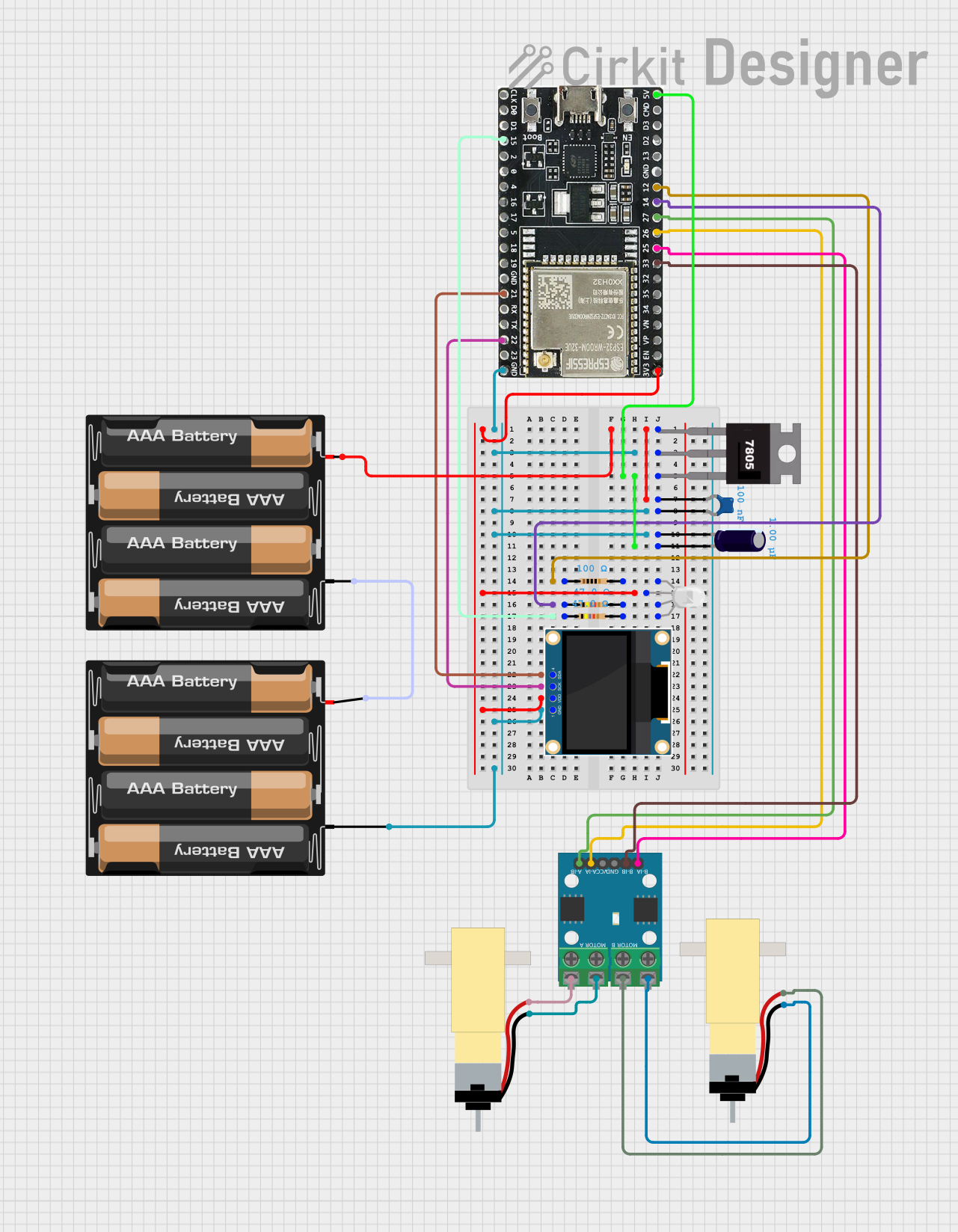

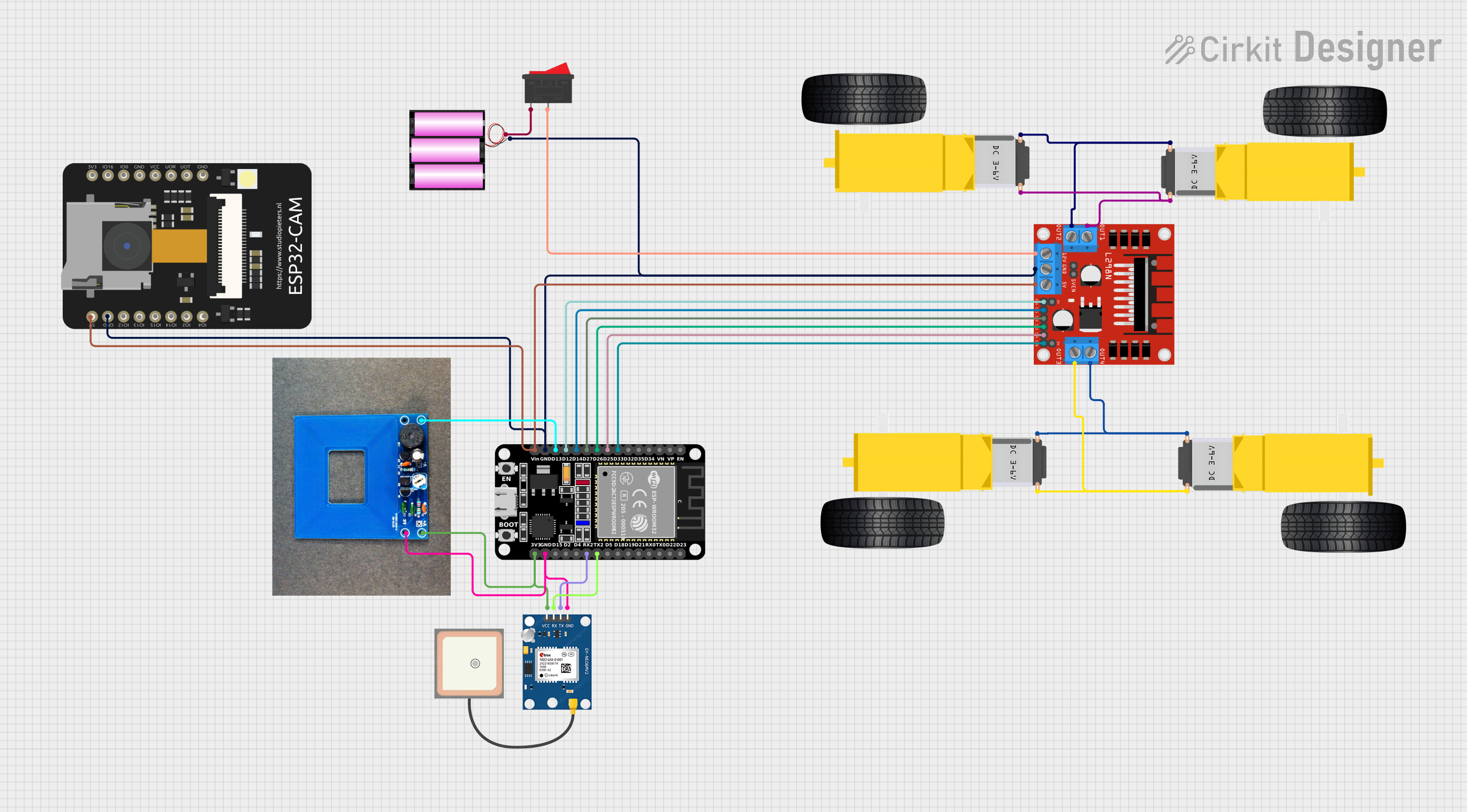

Open Project in Cirkit Designer

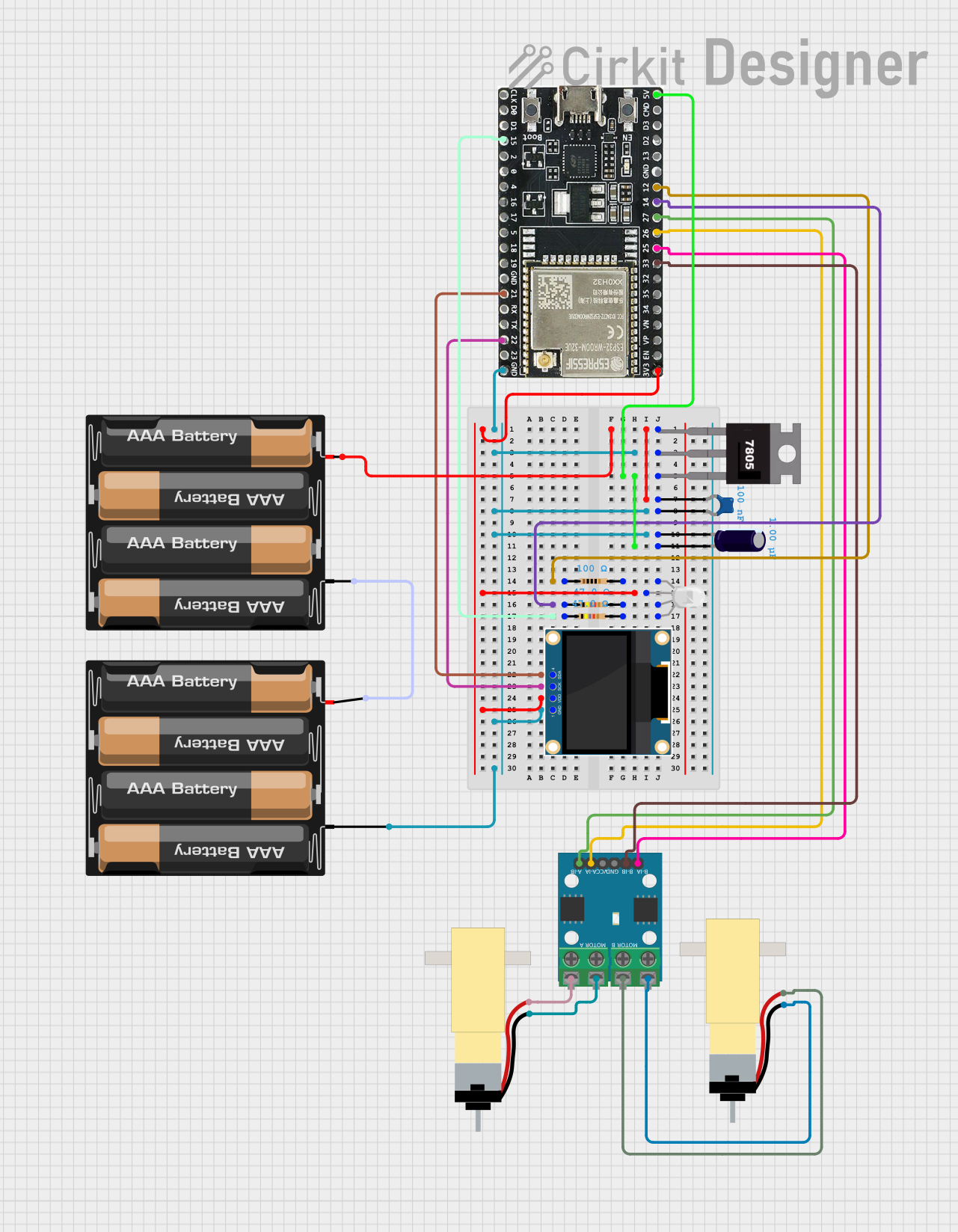

Open Project in Cirkit Designer

Open Project in Cirkit Designer

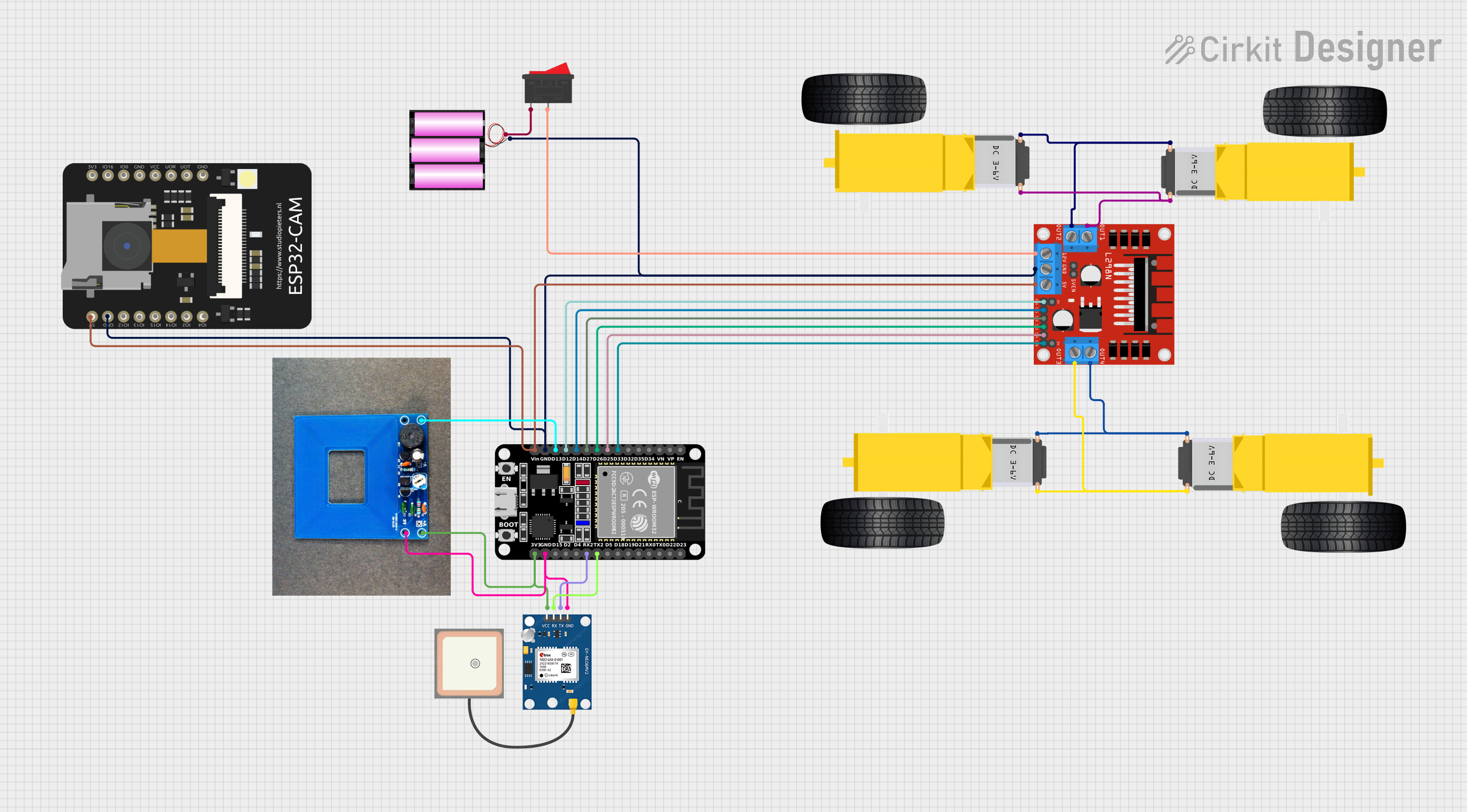

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

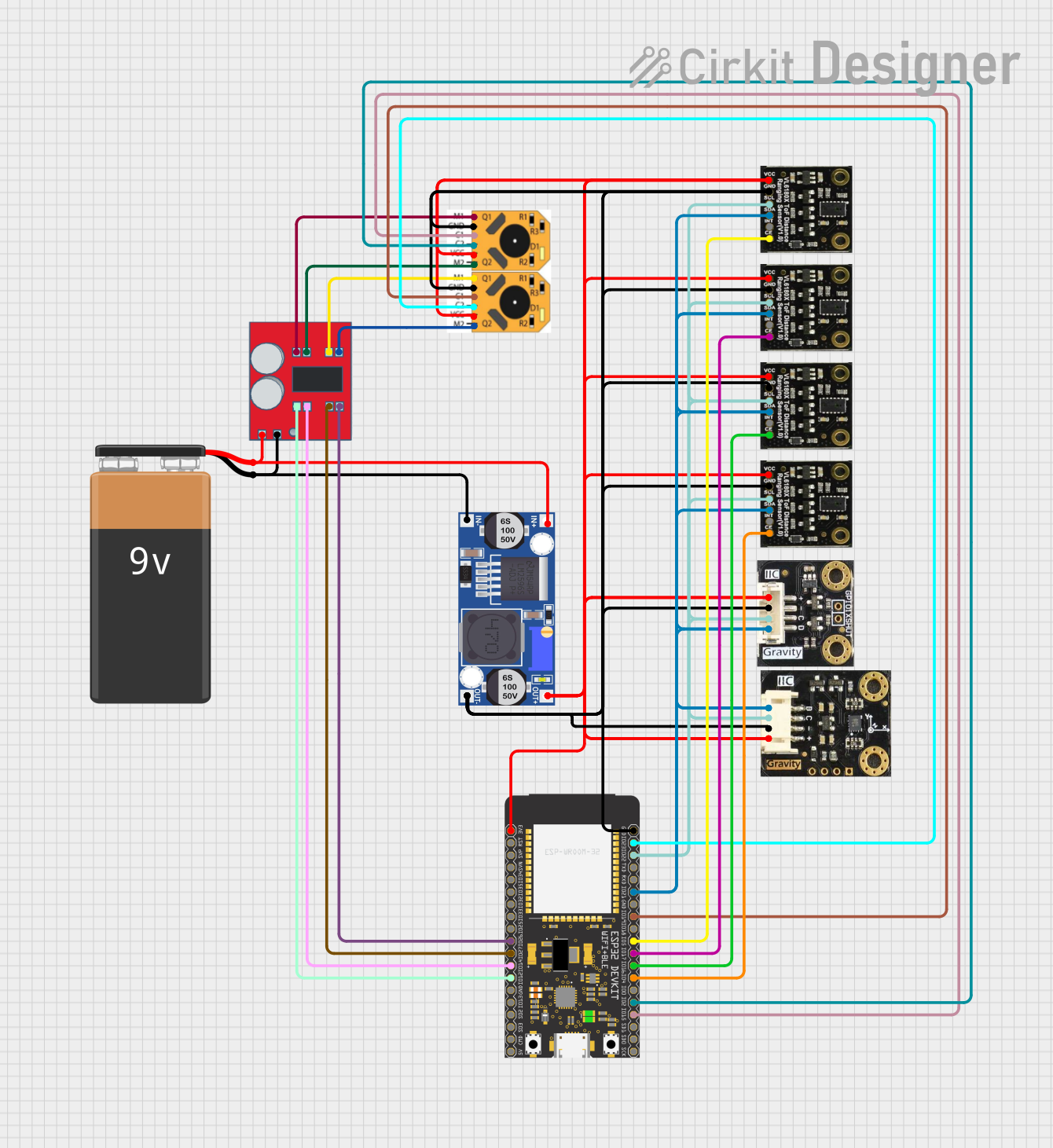

Open Project in Cirkit DesignerExplore Projects Built with X8-20

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Industrial automation and process control

- Machine control and monitoring

- Building management systems (BMS)

- Conveyor systems and robotics

- Data acquisition and remote monitoring

Technical Specifications

The X8-20 is built to handle demanding industrial environments while maintaining high performance and flexibility. Below are its key technical specifications:

General Specifications

| Parameter | Value |

|---|---|

| Supply Voltage | 24V DC |

| Power Consumption | 10W (typical) |

| Operating Temperature | -20°C to 60°C |

| Storage Temperature | -40°C to 85°C |

| Dimensions | 120mm x 90mm x 60mm |

| Weight | 450g |

| Mounting Type | DIN Rail |

Input/Output Specifications

| Type | Channels | Voltage Range | Description |

|---|---|---|---|

| Digital Inputs | 8 | 0-24V DC | Optically isolated inputs |

| Digital Outputs | 8 | 0-24V DC | Relay or transistor outputs |

| Analog Inputs | 4 | 0-10V or 4-20mA | Configurable for voltage/current |

| Analog Outputs | 2 | 0-10V or 4-20mA | Configurable for voltage/current |

Communication Interfaces

| Protocol | Description |

|---|---|

| RS-485 | Modbus RTU support |

| Ethernet | Modbus TCP/IP, HTTP, MQTT |

| USB | Programming and debugging |

| CAN | CANopen protocol support |

Pin Configuration

Power and Communication

| Pin Number | Label | Description |

|---|---|---|

| 1 | V+ | 24V DC Positive Supply |

| 2 | V- | 24V DC Negative Supply |

| 3 | GND | Ground |

| 4 | RS485+ | RS-485 Positive Line |

| 5 | RS485- | RS-485 Negative Line |

| 6 | CAN_H | CAN High Line |

| 7 | CAN_L | CAN Low Line |

Digital Inputs and Outputs

| Pin Number | Label | Description |

|---|---|---|

| 8-15 | DI1-DI8 | Digital Input Channels 1-8 |

| 16-23 | DO1-DO8 | Digital Output Channels 1-8 |

Analog Inputs and Outputs

| Pin Number | Label | Description |

|---|---|---|

| 24-27 | AI1-AI4 | Analog Input Channels 1-4 |

| 28-29 | AO1-AO2 | Analog Output Channels 1-2 |

Usage Instructions

The X8-20 is designed for ease of use in industrial environments. Follow the steps below to integrate and program the device:

Step 1: Powering the X8-20

- Connect a 24V DC power supply to the V+ and V- terminals.

- Ensure the power supply is stable and within the specified voltage range.

Step 2: Connecting Inputs and Outputs

- Digital Inputs: Connect sensors or switches to the DI1-DI8 terminals. Ensure the input voltage does not exceed 24V DC.

- Digital Outputs: Connect actuators, relays, or other devices to the DO1-DO8 terminals.

- Analog Inputs: Configure the AI1-AI4 channels for voltage (0-10V) or current (4-20mA) as required.

- Analog Outputs: Use AO1-AO2 for controlling devices like variable frequency drives (VFDs) or proportional valves.

Step 3: Communication Setup

- Use the RS-485 or Ethernet interface for communication with other devices or systems.

- Configure the communication protocol (e.g., Modbus RTU or TCP/IP) using the provided software.

Step 4: Programming the X8-20

- Install the Myactuator programming software on your PC.

- Connect the X8-20 to your PC via the USB port.

- Use the graphical programming interface to create logic for your application.

- Upload the program to the X8-20 and test its functionality.

Example: Controlling an LED with Arduino UNO

The X8-20 can be interfaced with an Arduino UNO for additional control. Below is an example code to toggle a digital output on the X8-20:

// Example: Controlling X8-20 Digital Output with Arduino UNO

// Connect Arduino pin 7 to the X8-20's DO1 terminal

#define X8_20_DO1 7 // Define Arduino pin connected to X8-20 DO1

void setup() {

pinMode(X8_20_DO1, OUTPUT); // Set pin as output

}

void loop() {

digitalWrite(X8_20_DO1, HIGH); // Turn on the output

delay(1000); // Wait for 1 second

digitalWrite(X8_20_DO1, LOW); // Turn off the output

delay(1000); // Wait for 1 second

}

Best Practices

- Use proper shielding for communication cables to avoid interference.

- Ensure all connections are secure to prevent accidental disconnections.

- Regularly back up your programs and configurations.

Troubleshooting and FAQs

Common Issues

Device Not Powering On

- Check the power supply voltage and connections.

- Ensure the polarity of the power supply is correct.

Communication Failure

- Verify the communication protocol and settings (e.g., baud rate, parity).

- Check the integrity of the communication cables.

Inputs/Outputs Not Responding

- Ensure the connected devices are functioning properly.

- Verify the configuration of the I/O channels in the programming software.

FAQs

Q: Can the X8-20 be used in outdoor environments?

A: The X8-20 is not weatherproof. Use it in a controlled environment or within a protective enclosure.

Q: What programming languages are supported?

A: The X8-20 supports ladder logic and function block programming via the Myactuator software.

Q: How do I reset the X8-20 to factory settings?

A: Refer to the Myactuator user manual for detailed instructions on performing a factory reset.

Q: Can I expand the I/O channels?

A: Yes, the X8-20 supports expansion modules for additional I/O channels. Contact Myactuator for compatible modules.

By following this documentation, users can effectively integrate and operate the X8-20 in their automation projects.