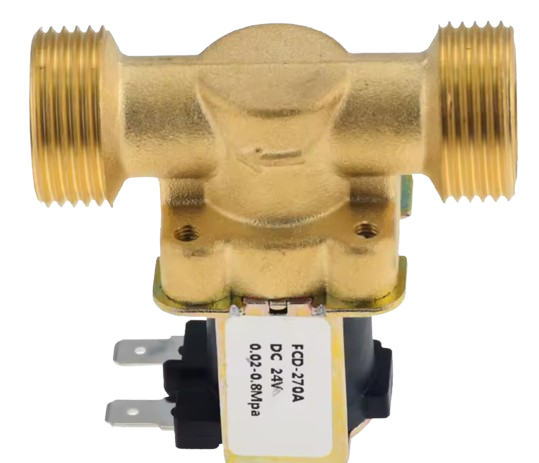

How to Use solenoid electrovalve: Examples, Pinouts, and Specs

Design with solenoid electrovalve in Cirkit Designer

Design with solenoid electrovalve in Cirkit DesignerIntroduction

A solenoid electrovalve is an electromechanical device that uses an electromagnetic solenoid to control the flow of fluids or gases. When electrical current is applied, the solenoid generates a magnetic field that moves a plunger, opening or closing the valve to regulate flow. These valves are widely used in automation systems, fluid control applications, and industrial processes.

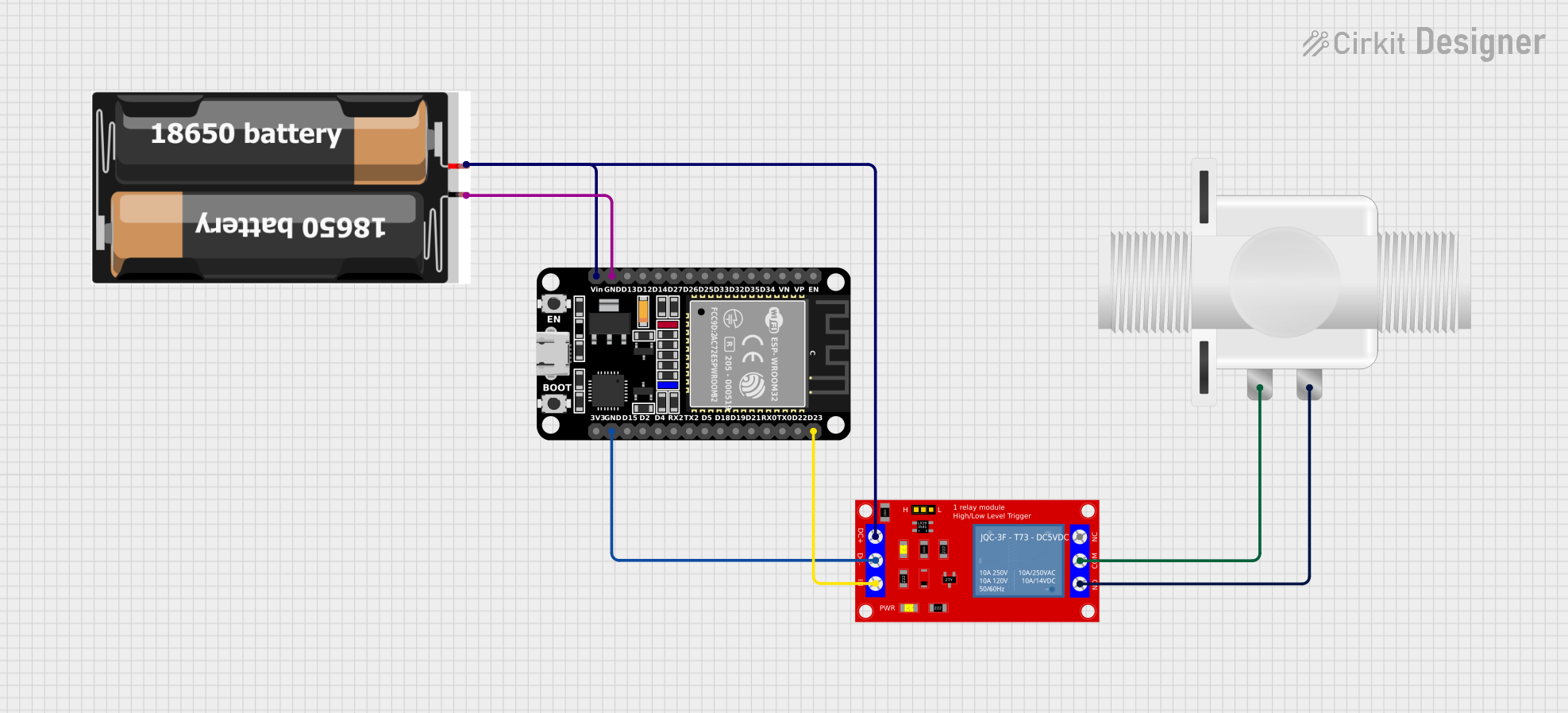

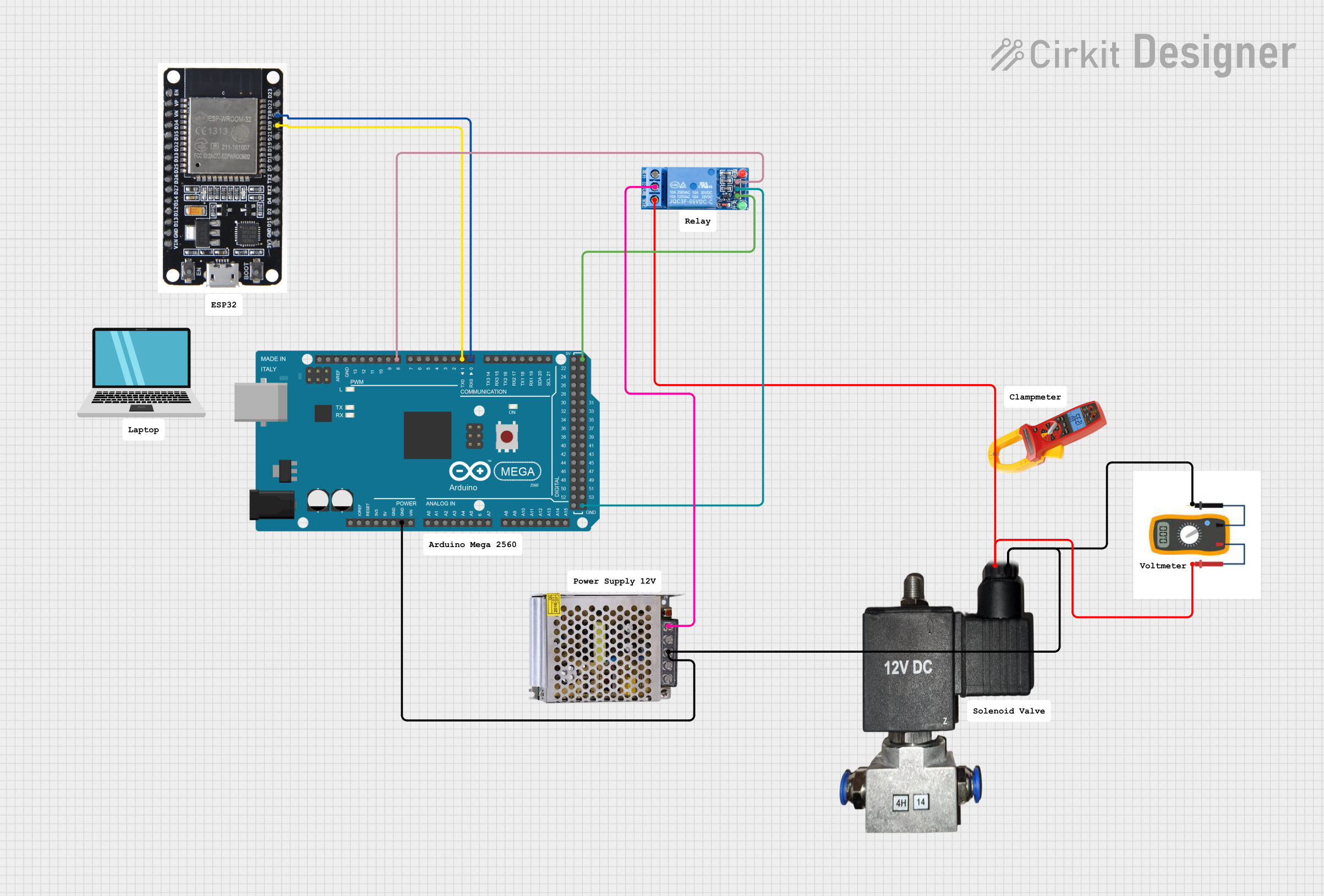

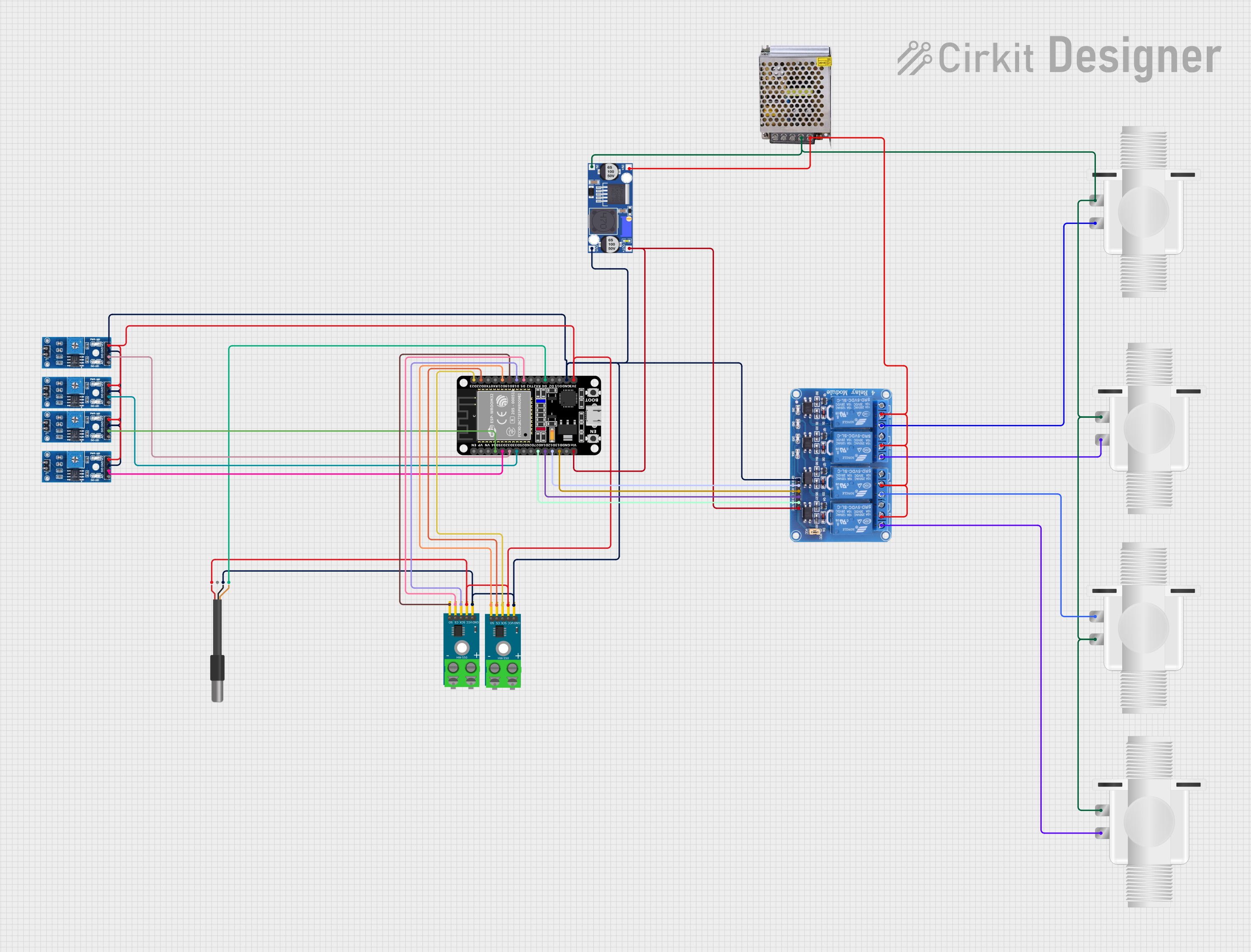

Explore Projects Built with solenoid electrovalve

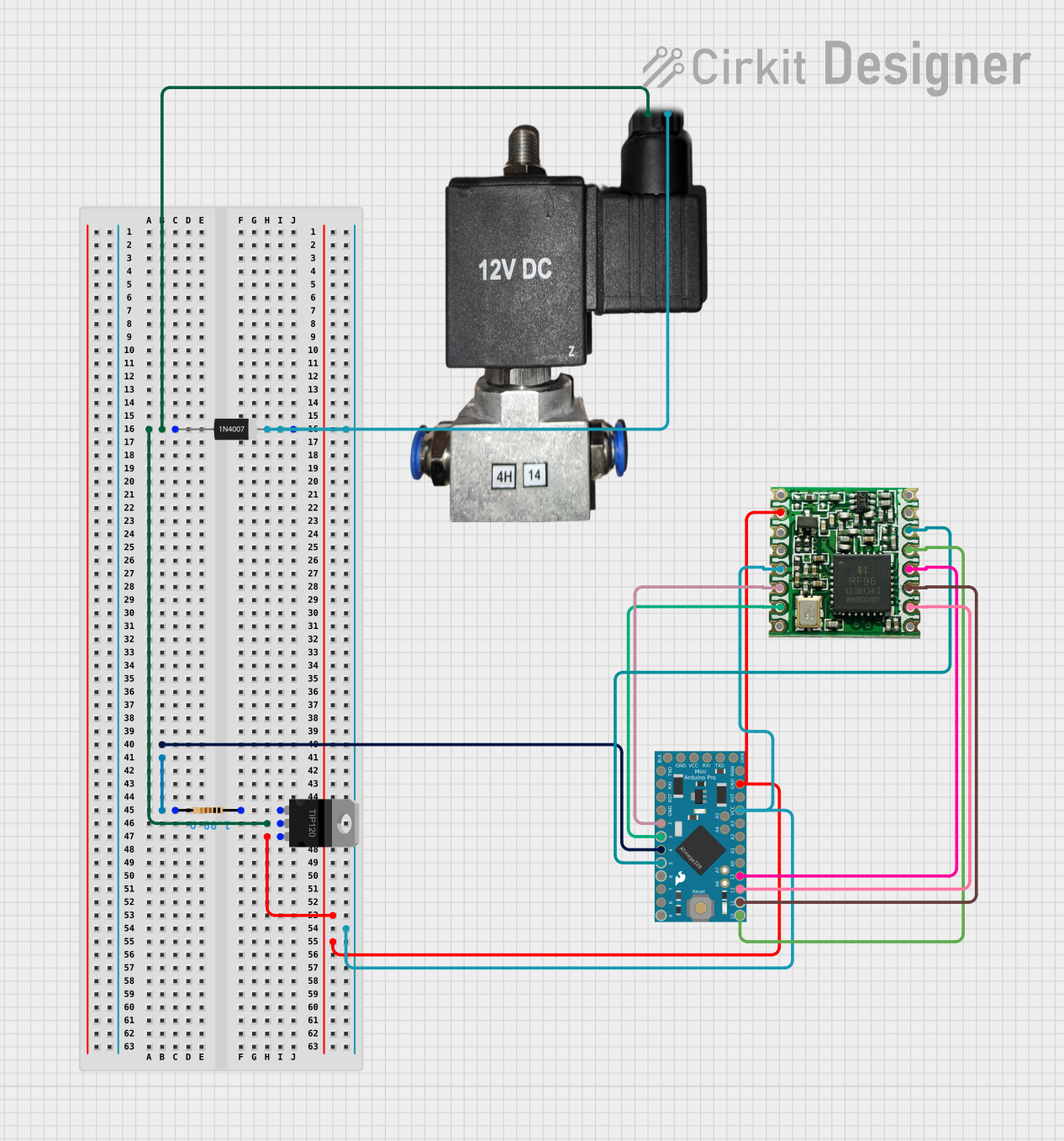

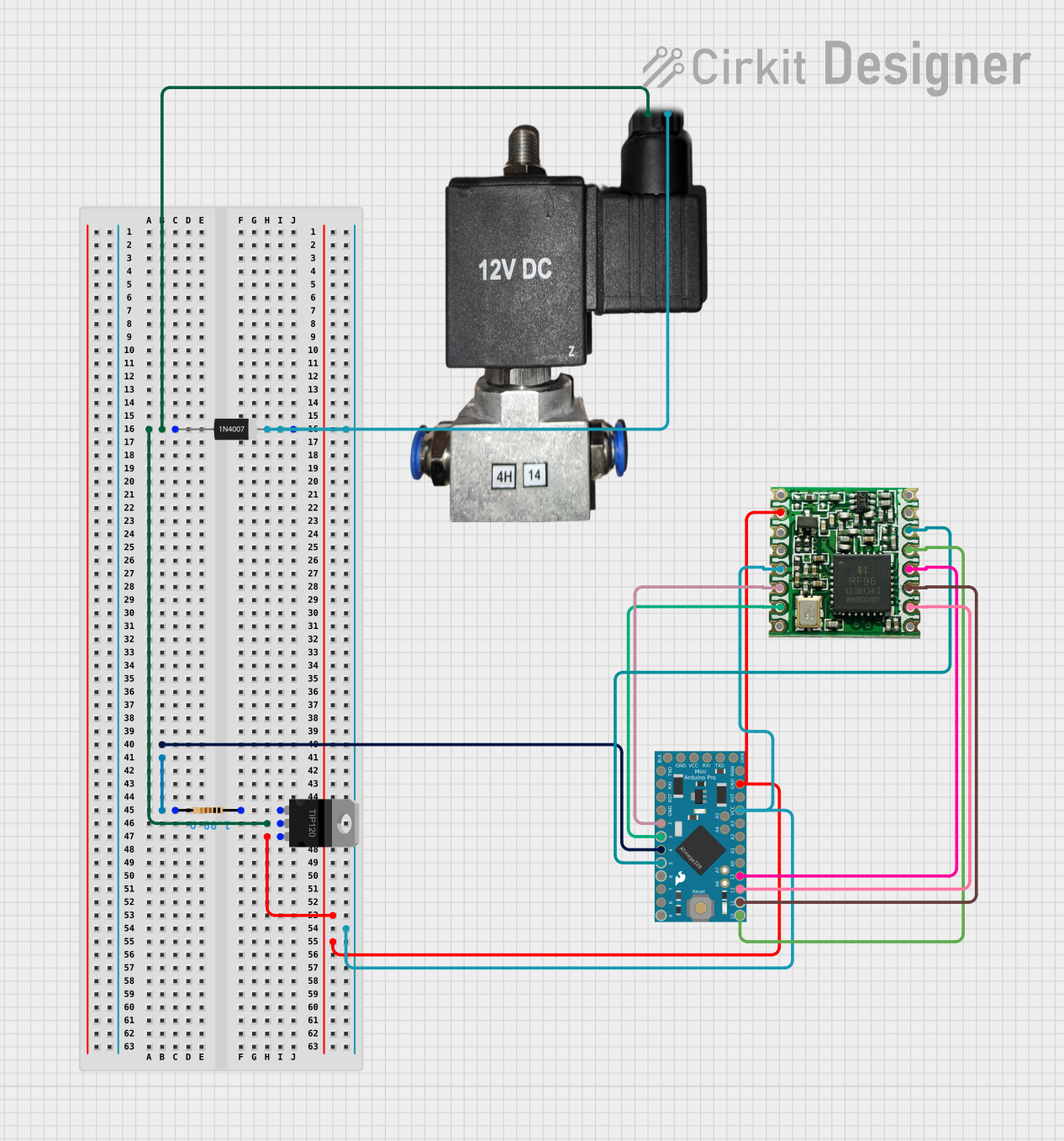

Open Project in Cirkit Designer

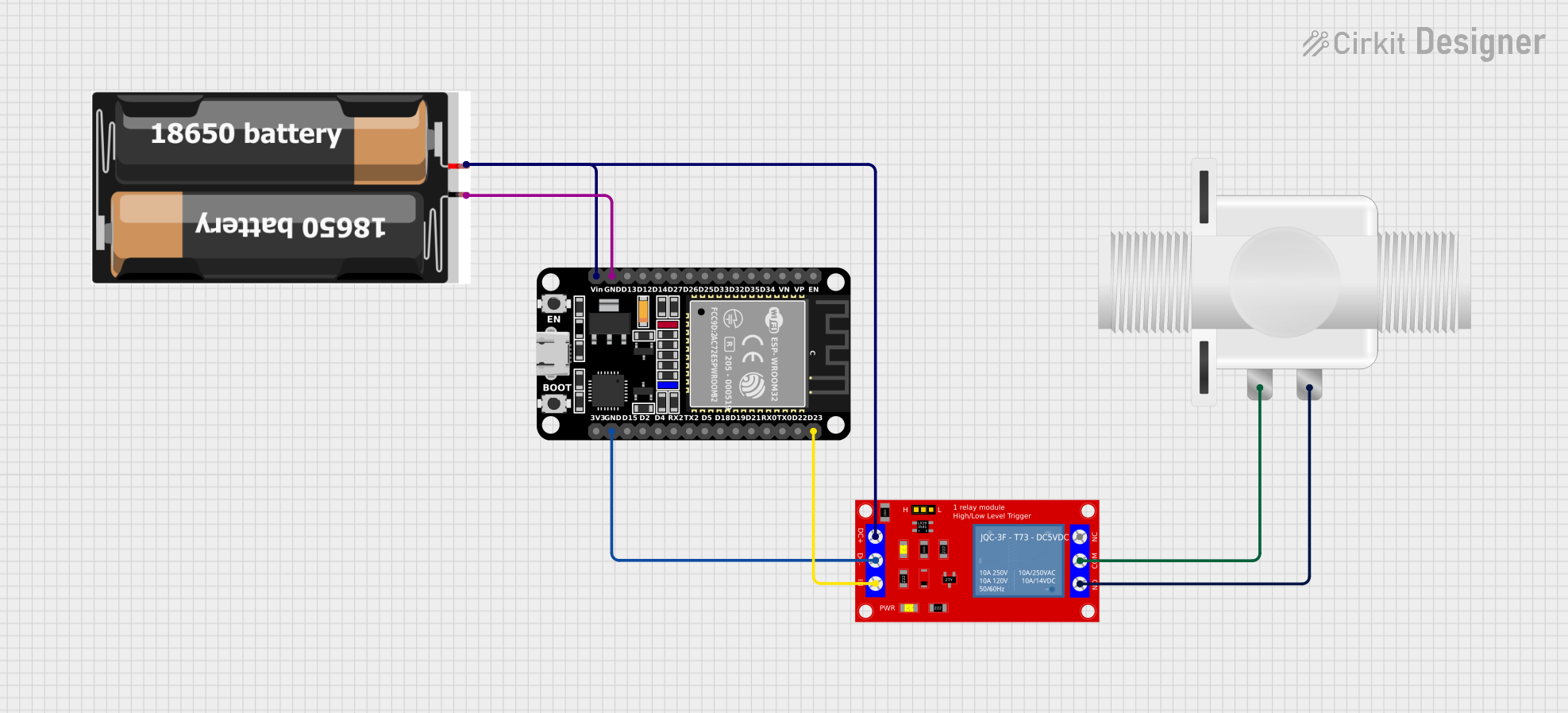

Open Project in Cirkit Designer

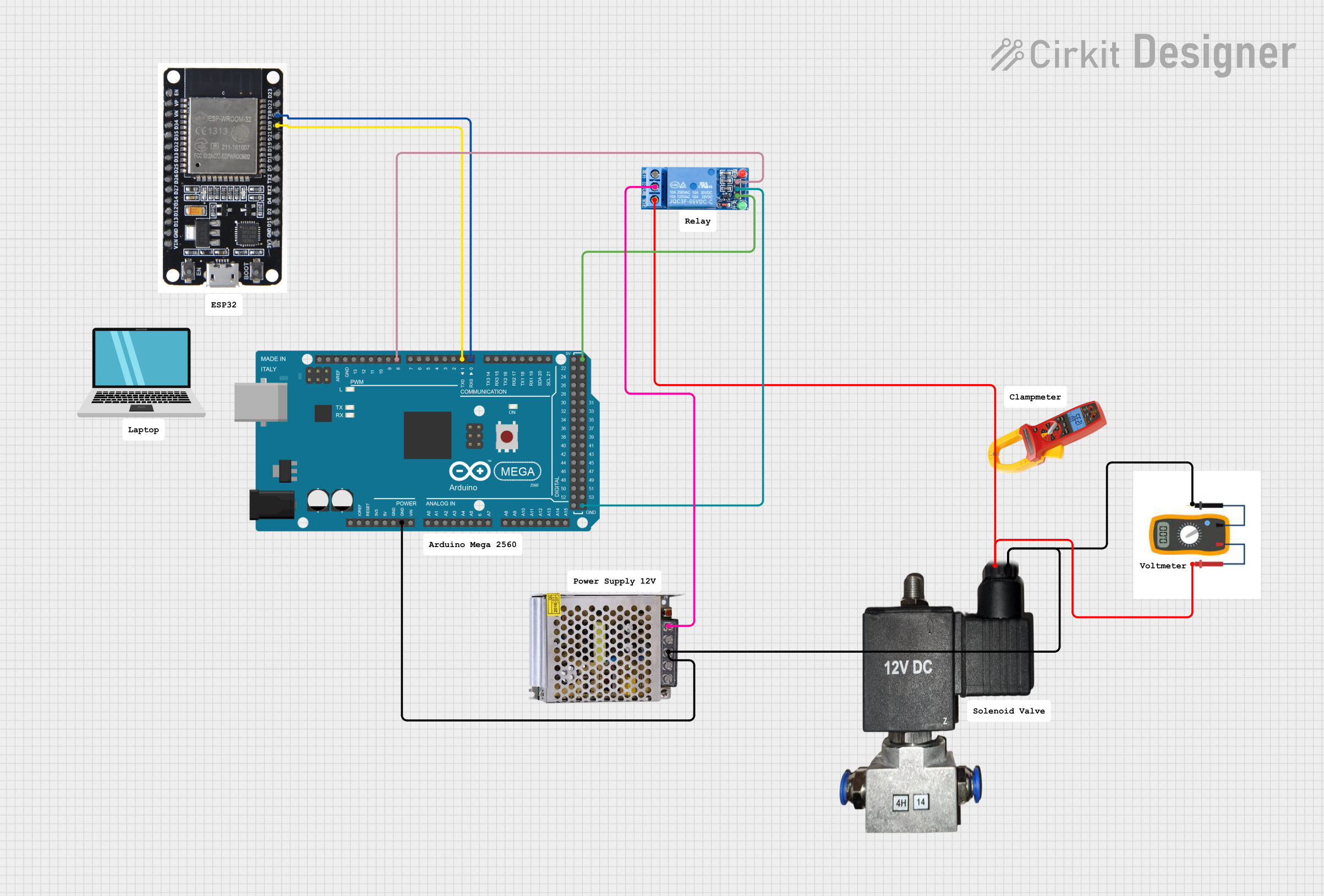

Open Project in Cirkit Designer

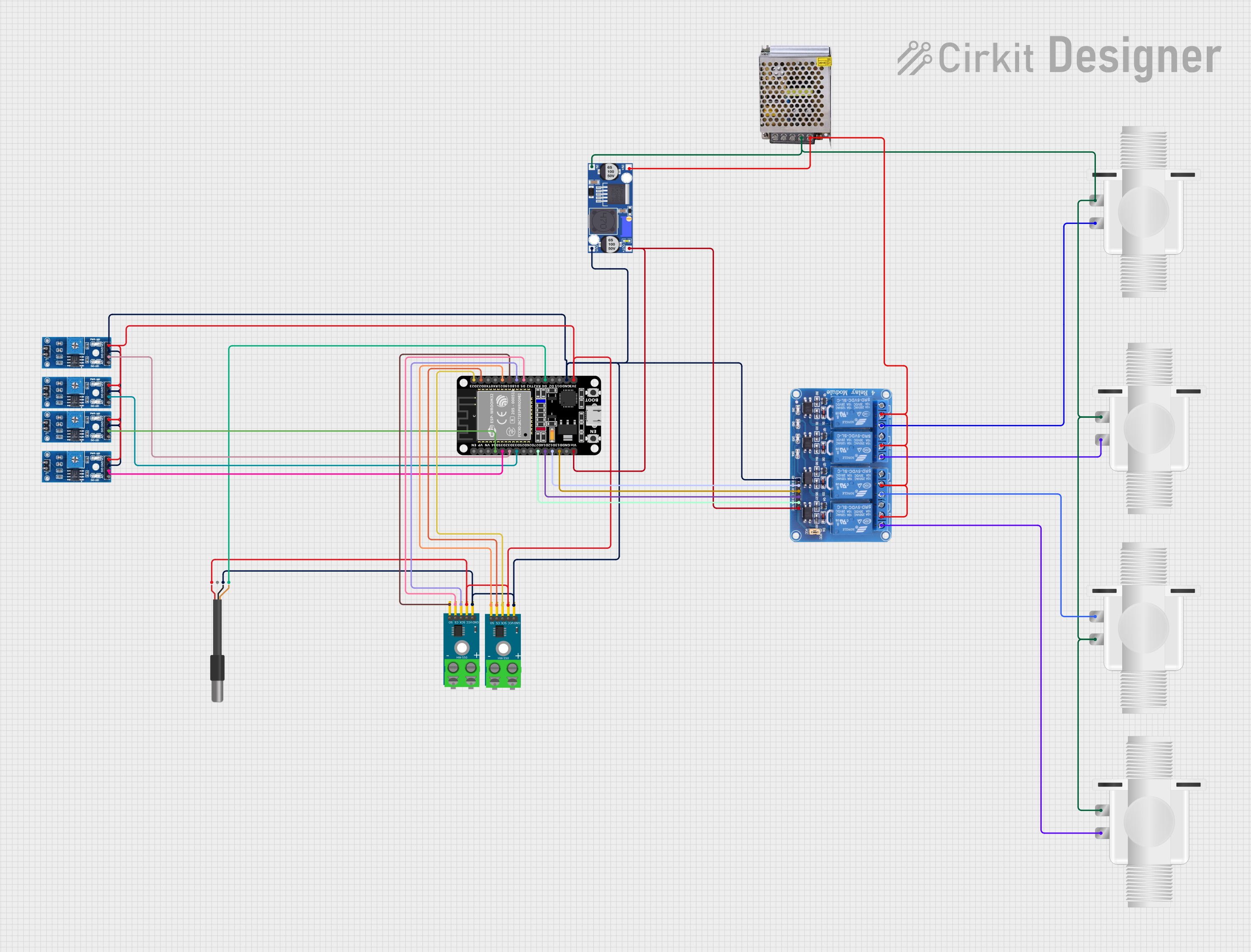

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with solenoid electrovalve

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Irrigation systems: Automated water flow control for agricultural or landscaping purposes.

- HVAC systems: Regulating refrigerants or air in heating, ventilation, and air conditioning systems.

- Medical devices: Controlling the flow of gases or liquids in medical equipment.

- Industrial automation: Managing fluid or gas flow in manufacturing processes.

- Home appliances: Found in washing machines, dishwashers, and coffee machines.

Technical Specifications

Key Technical Details

- Operating Voltage: Typically 12V DC or 24V DC (varies by model).

- Current Consumption: 0.2A to 1A (depending on the valve size and type).

- Power Rating: 2W to 24W.

- Operating Pressure: 0.1 to 10 bar (varies by model).

- Flow Rate: Depends on the valve size, typically 0.1 to 10 liters per minute.

- Material: Brass, stainless steel, or plastic (depending on the application).

- Port Size: Commonly 1/8", 1/4", 1/2", or 1" NPT or BSP threads.

Pin Configuration and Descriptions

The solenoid electrovalve typically has two electrical terminals for connection. These terminals are not polarized unless specified otherwise.

| Pin | Description |

|---|---|

| Pin 1 | Positive terminal (VCC) |

| Pin 2 | Negative terminal (GND) |

Note: Some solenoid valves may include additional features like a manual override or a ground wire. Refer to the specific datasheet for details.

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect the solenoid electrovalve to a DC power source that matches its rated voltage (e.g., 12V or 24V DC). Use a regulated power supply to avoid voltage fluctuations.

- Control Circuit: Use a relay, transistor, or MOSFET to control the solenoid valve. This allows you to switch the valve on and off using a microcontroller or other control logic.

- Diode Protection: Place a flyback diode (e.g., 1N4007) across the solenoid terminals to protect the circuit from voltage spikes caused by the collapsing magnetic field when the solenoid is turned off.

- Connections:

- Connect the positive terminal of the solenoid to the power supply through the control circuit.

- Connect the negative terminal to the ground.

Important Considerations and Best Practices

- Voltage Matching: Ensure the power supply voltage matches the solenoid valve's rated voltage to prevent damage.

- Current Handling: Verify that the control circuit (e.g., relay or transistor) can handle the solenoid's current requirements.

- Heat Dissipation: Solenoid valves can generate heat during prolonged operation. Ensure proper ventilation or cooling if necessary.

- Fluid Compatibility: Check that the valve's material is compatible with the fluid or gas being controlled.

- Orientation: Install the valve in the correct orientation as specified in the datasheet to ensure proper operation.

Example: Connecting a Solenoid Electrovalve to an Arduino UNO

Below is an example of how to control a 12V solenoid electrovalve using an Arduino UNO and an NPN transistor (e.g., 2N2222).

Circuit Diagram

- Components:

- 12V solenoid electrovalve

- NPN transistor (e.g., 2N2222)

- Flyback diode (e.g., 1N4007)

- 1kΩ resistor

- External 12V power supply

Code Example

// Define the pin connected to the transistor's base

const int solenoidPin = 9;

void setup() {

pinMode(solenoidPin, OUTPUT); // Set the solenoid pin as an output

}

void loop() {

digitalWrite(solenoidPin, HIGH); // Turn the solenoid ON

delay(5000); // Keep the solenoid ON for 5 seconds

digitalWrite(solenoidPin, LOW); // Turn the solenoid OFF

delay(5000); // Keep the solenoid OFF for 5 seconds

}

Note: Ensure the Arduino's ground is connected to the ground of the external power supply.

Troubleshooting and FAQs

Common Issues and Solutions

The solenoid valve does not activate:

- Check the power supply voltage and current to ensure they meet the valve's requirements.

- Verify the control circuit (e.g., relay or transistor) is functioning correctly.

- Inspect the wiring for loose or incorrect connections.

The solenoid valve gets too hot:

- Ensure the valve is not being powered continuously for longer than its rated duty cycle.

- Check for proper ventilation or cooling around the valve.

The valve leaks or does not fully close:

- Inspect the valve for debris or blockages that may prevent proper sealing.

- Verify the operating pressure is within the valve's specified range.

Voltage spikes damage the circuit:

- Ensure a flyback diode is installed across the solenoid terminals to suppress voltage spikes.

FAQs

Can I use an AC solenoid valve with a DC power supply? No, AC solenoid valves are designed for alternating current and will not function properly with a DC power supply. Use a valve rated for DC operation.

What happens if I exceed the valve's rated voltage? Exceeding the rated voltage can damage the solenoid coil and may cause overheating or failure.

Can I control multiple solenoid valves with one Arduino? Yes, but ensure each valve has its own control circuit (e.g., transistor or relay) and that the Arduino can handle the combined current requirements.

How do I clean a solenoid valve? Disconnect the valve from the power supply and fluid system, then disassemble it according to the manufacturer's instructions. Clean the internal components with a suitable solvent and reassemble.

By following this documentation, you can effectively integrate and troubleshoot a solenoid electrovalve in your projects.