How to Use Adafruit Motor, Stepper & Servo Shield: Examples, Pinouts, and Specs

Design with Adafruit Motor, Stepper & Servo Shield in Cirkit Designer

Design with Adafruit Motor, Stepper & Servo Shield in Cirkit DesignerIntroduction

The Adafruit Motor, Stepper & Servo Shield is a comprehensive motor control shield designed for use with the Arduino platform. This shield allows users to control up to 4 DC motors, 2 stepper motors, or 2 servos simultaneously. It is an ideal choice for hobbyists and engineers working on robotics, automation projects, or any application requiring motor control.

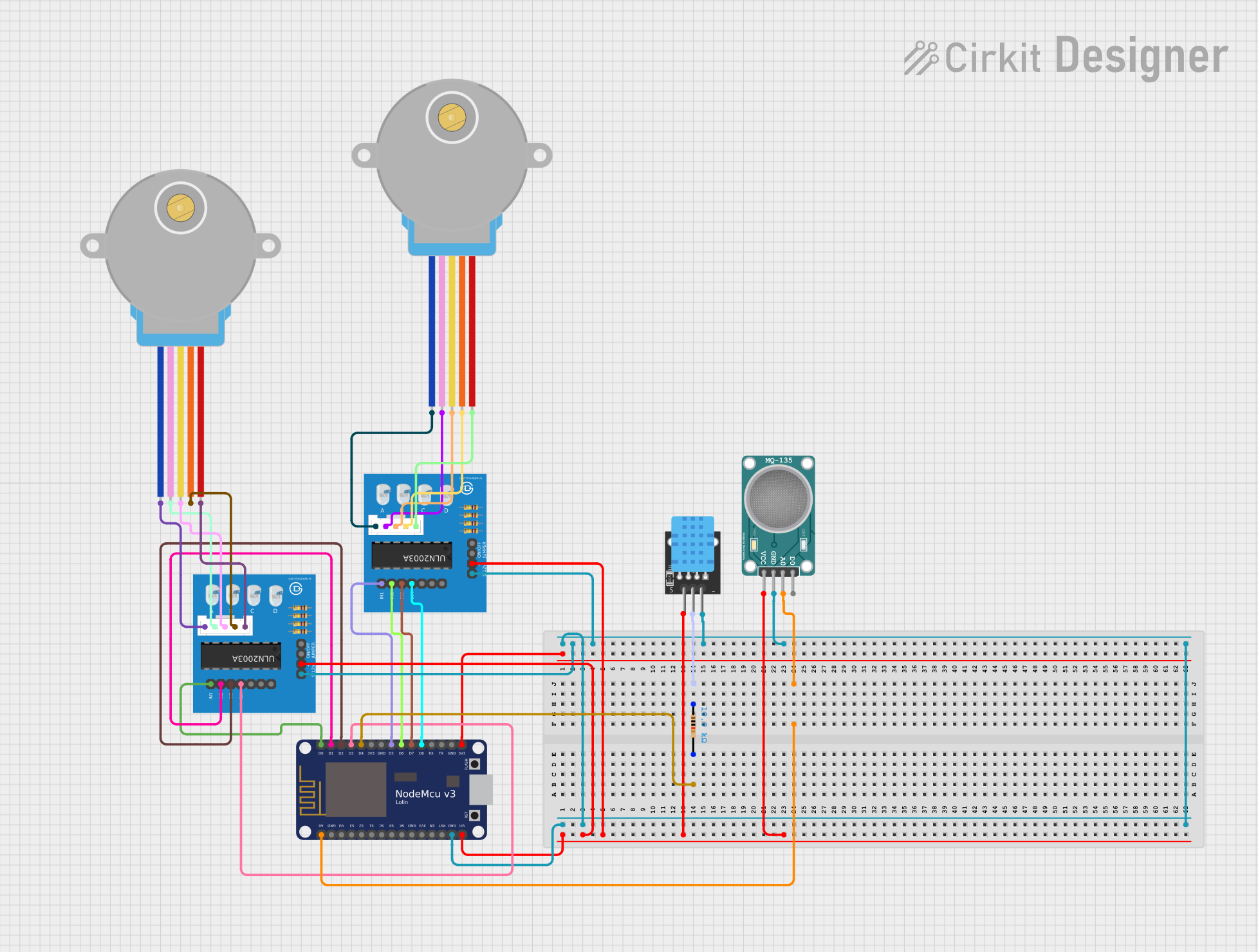

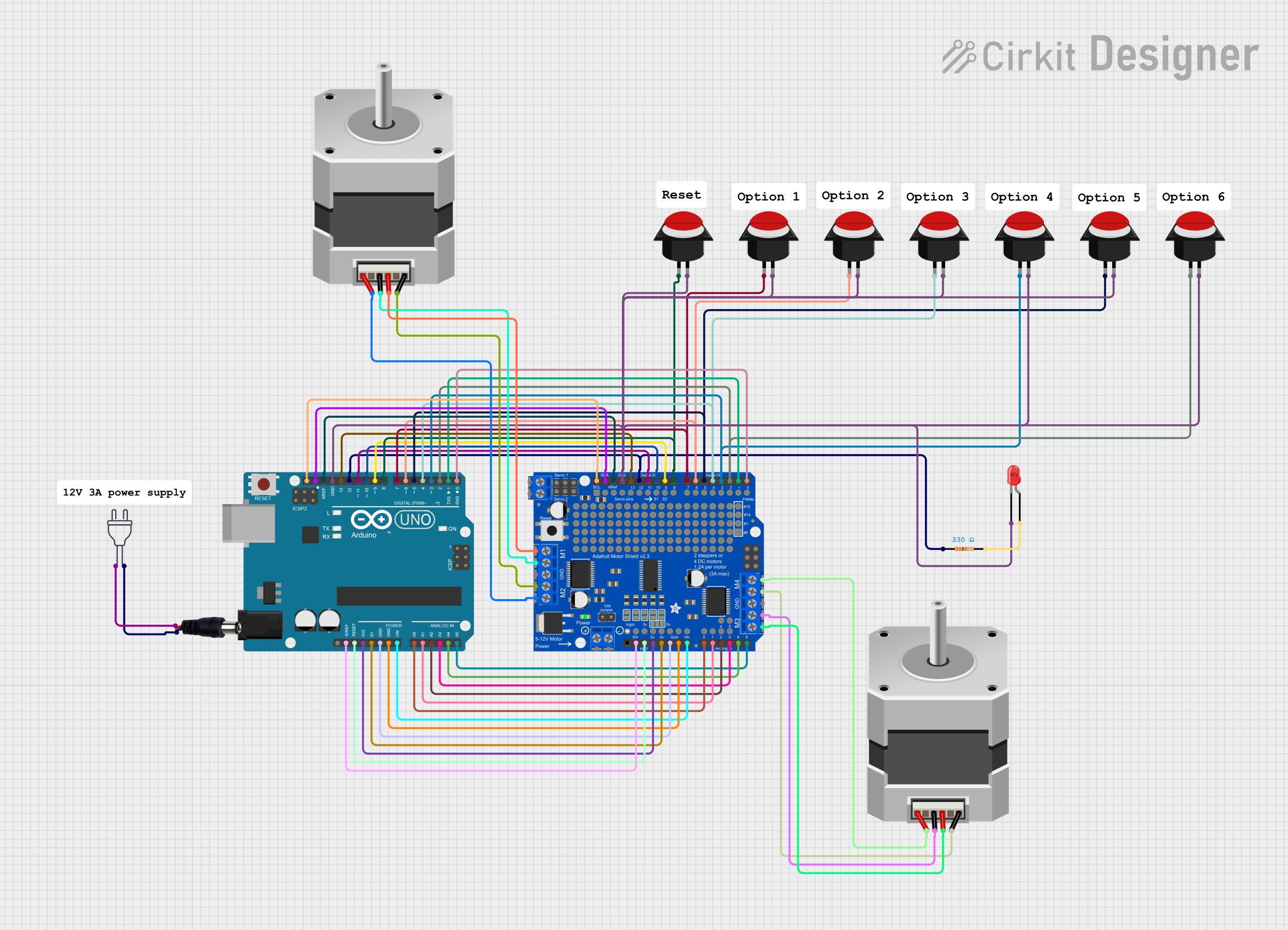

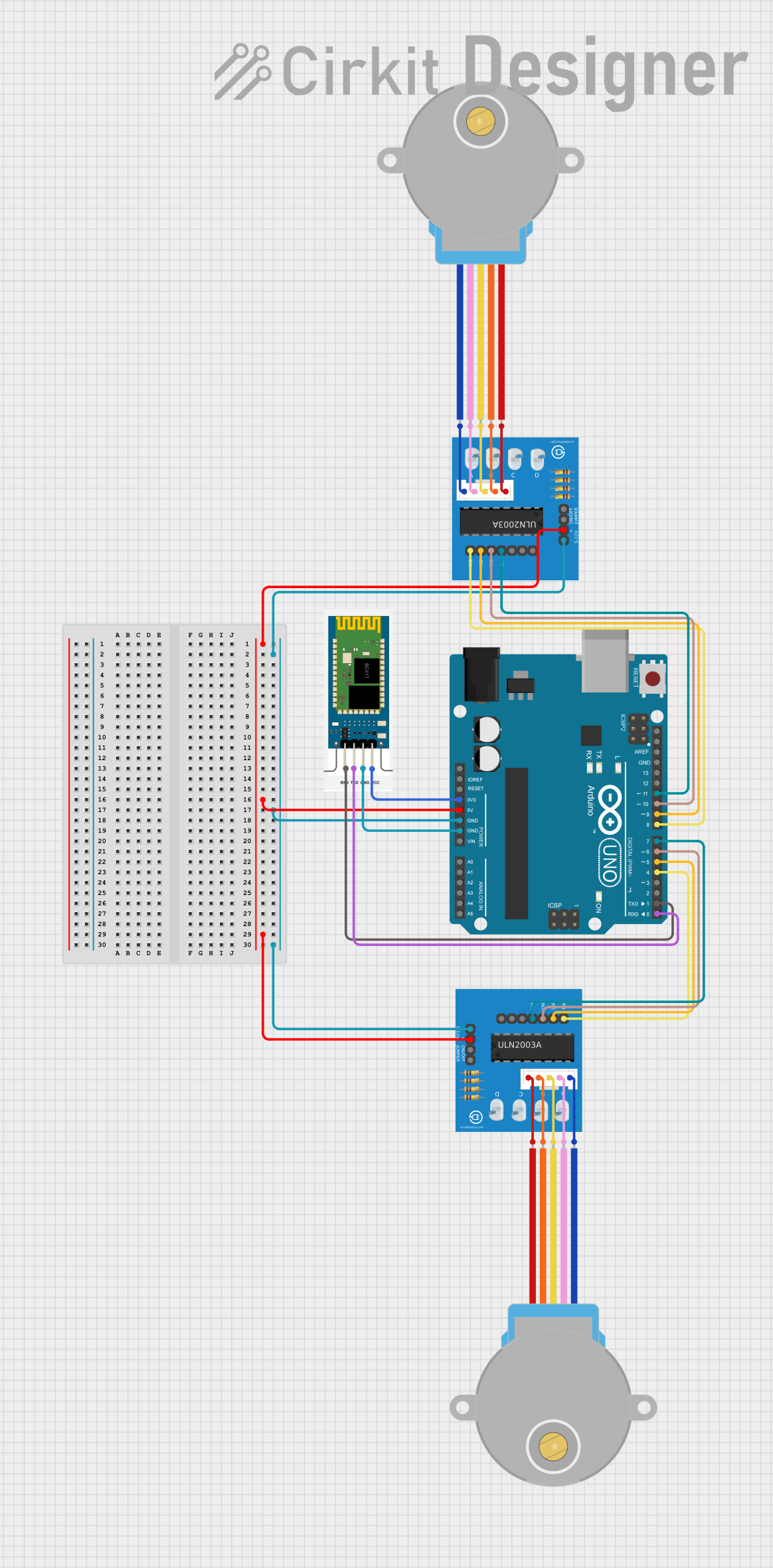

Explore Projects Built with Adafruit Motor, Stepper & Servo Shield

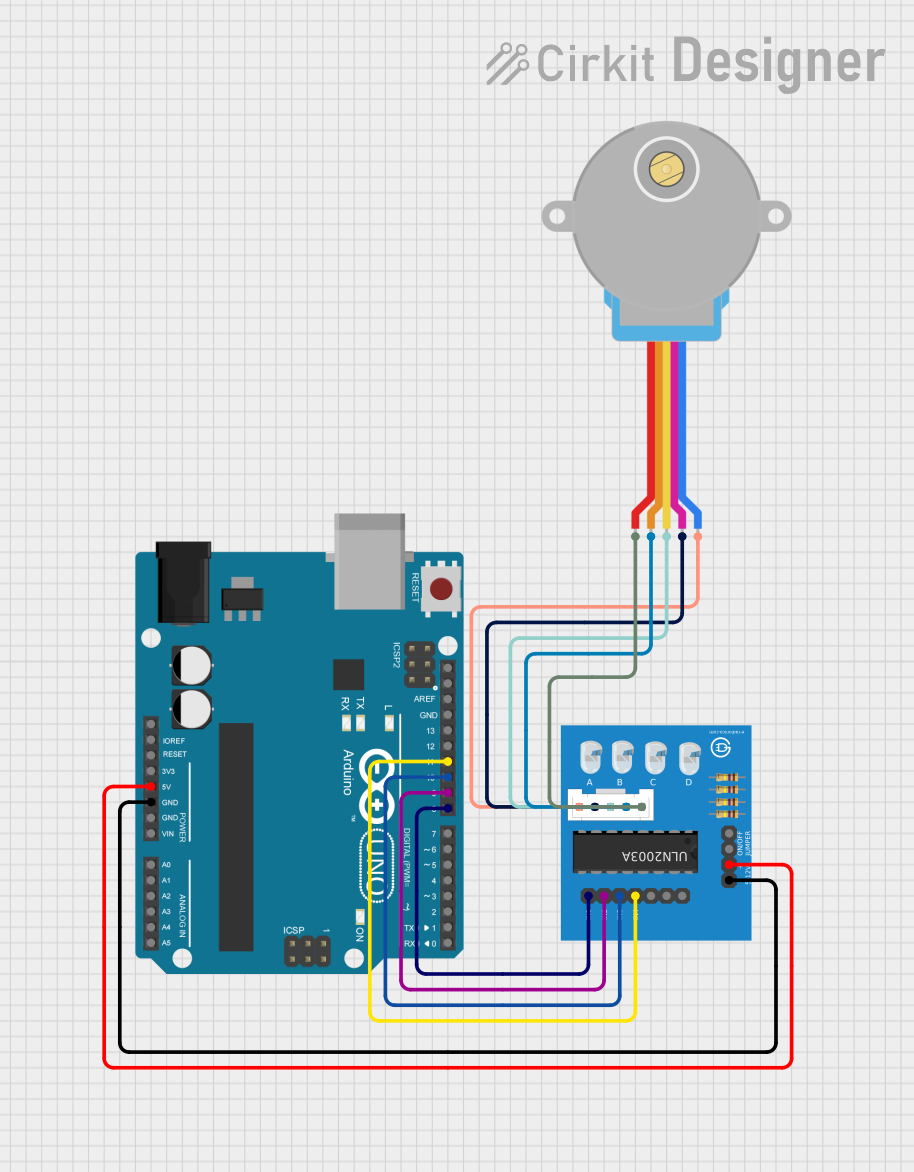

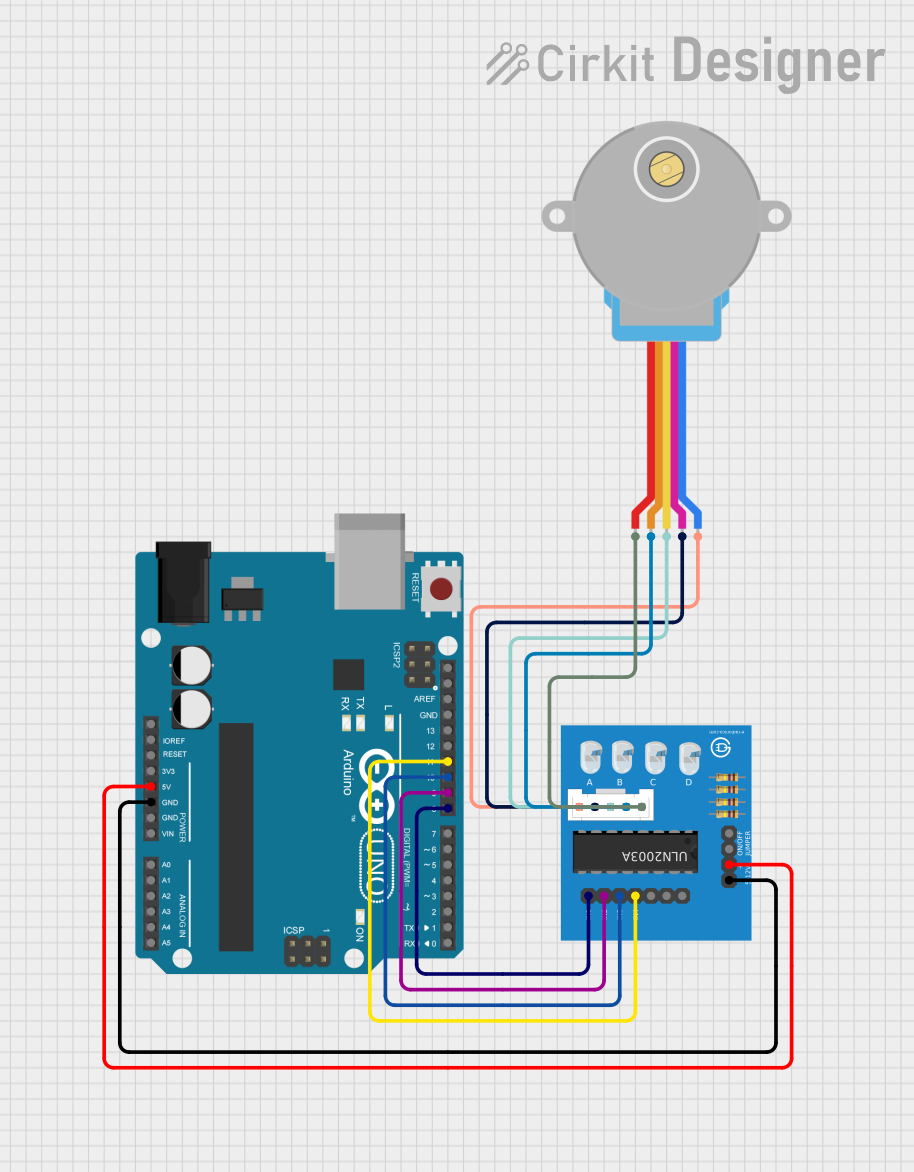

Open Project in Cirkit Designer

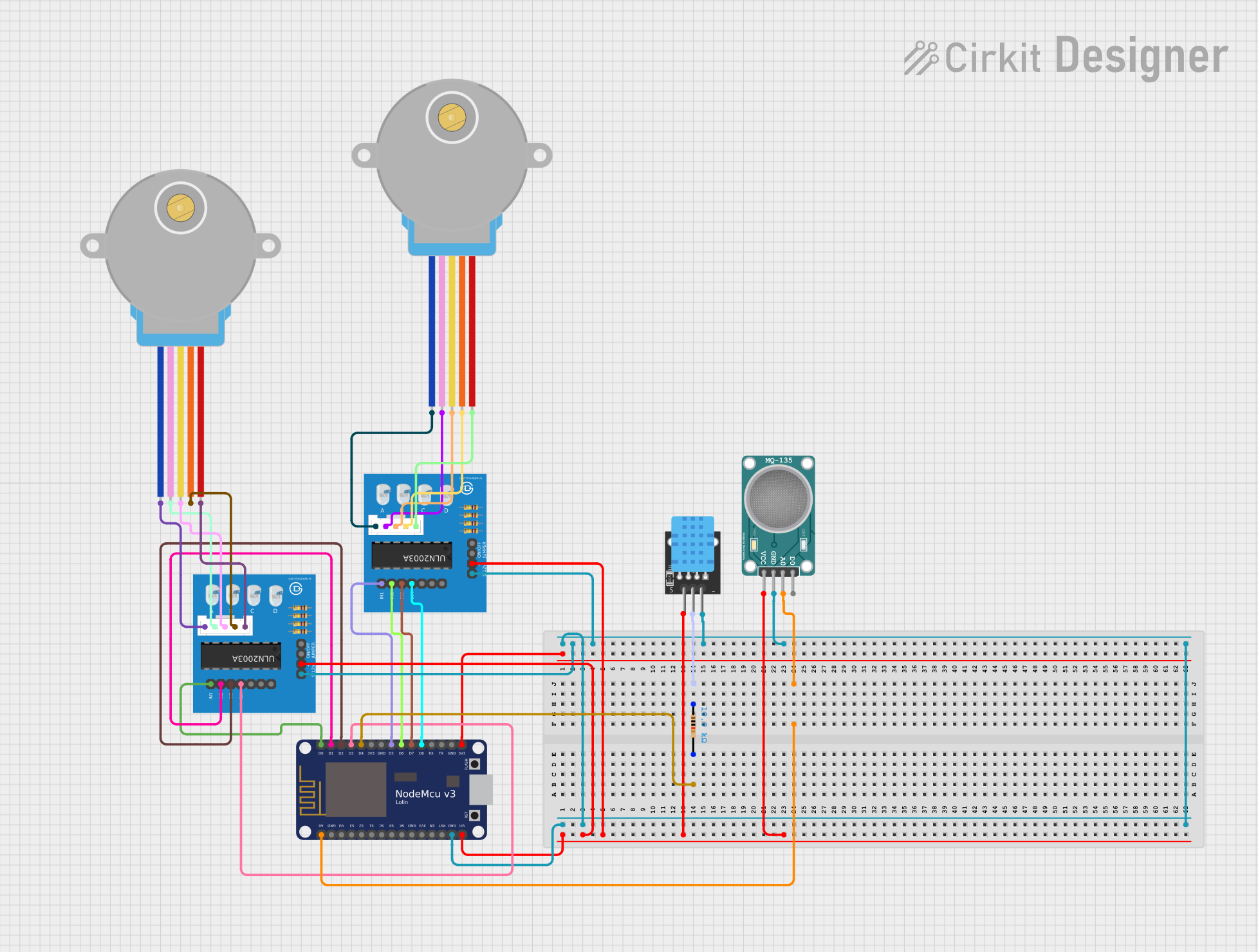

Open Project in Cirkit Designer

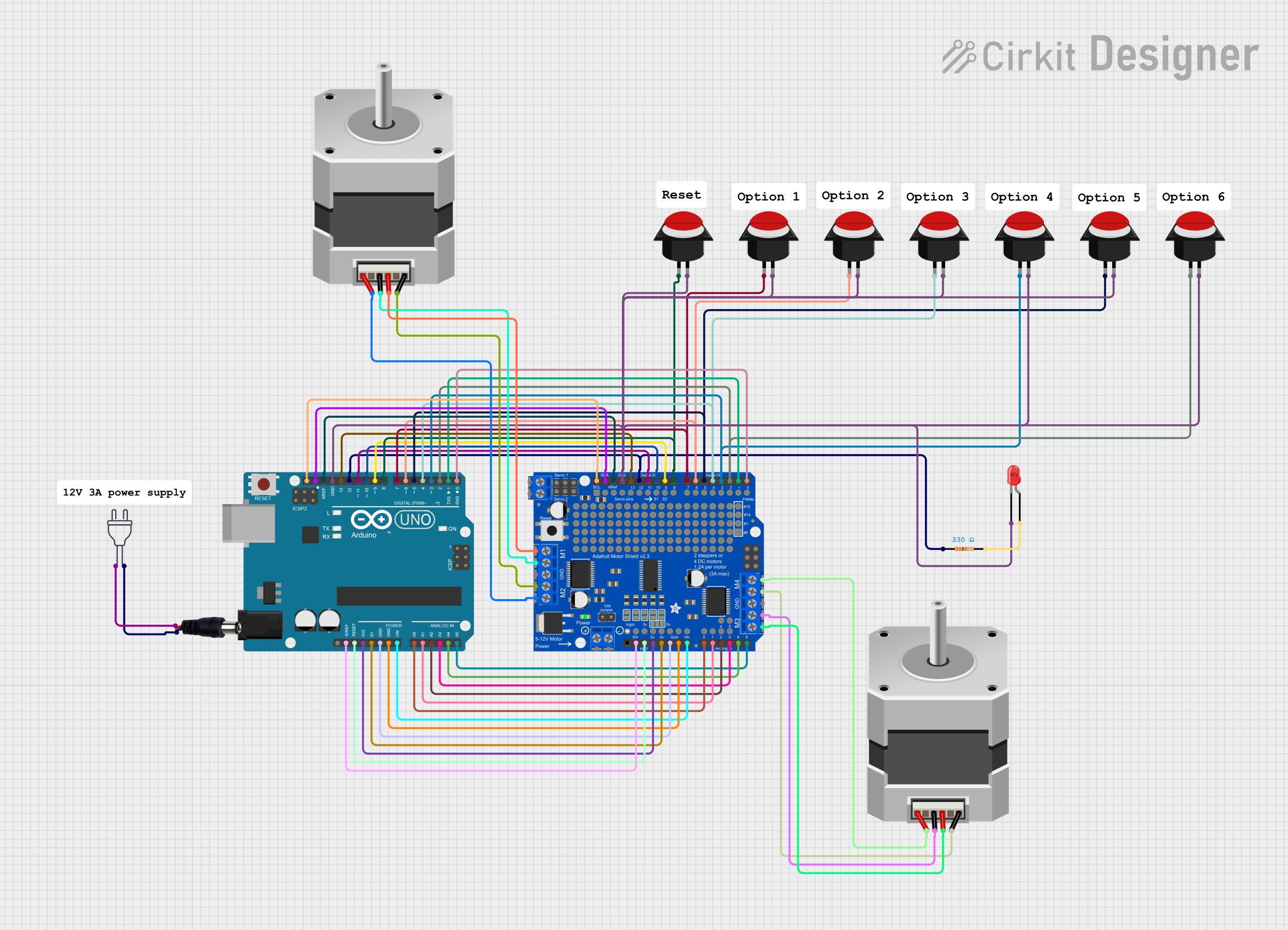

Open Project in Cirkit Designer

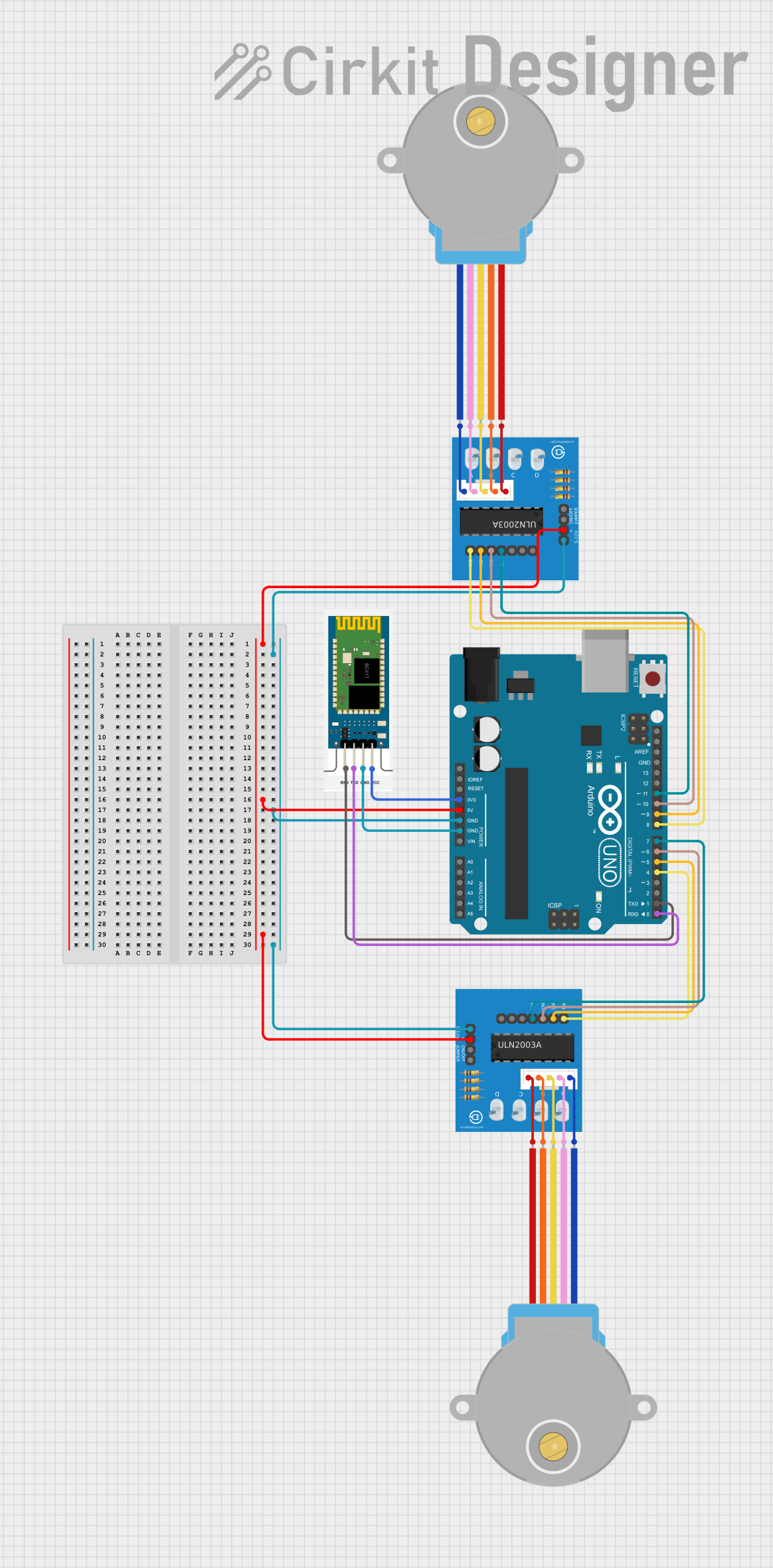

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Adafruit Motor, Stepper & Servo Shield

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics

- CNC machines

- Automated equipment

- Art installations

Technical Specifications

Key Technical Details

- Operating Voltage: 5V to 12V DC

- Logic Voltage: 3.3V or 5V (matches Arduino logic level)

- Motor Driver: TB6612 MOSFET drivers with 1.2A per channel (3A peak)

- Servo Channels: Up to 2 servo motors

- Stepper Motors: Up to 2 (unipolar or bipolar) with single coil, double coil, or interleaved stepping

- DC Motors: Up to 4 DC motors with speed control

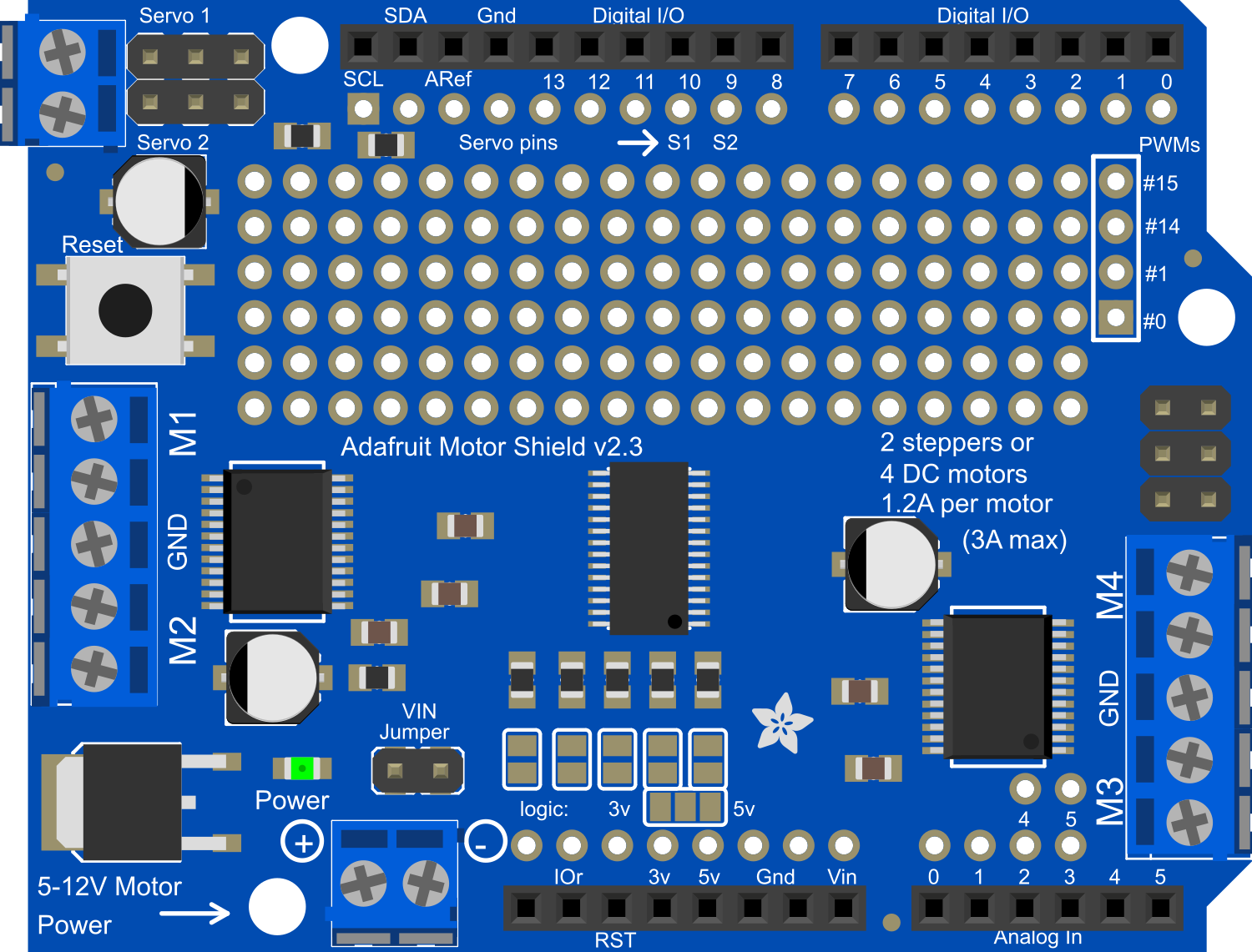

Pin Configuration and Descriptions

| Pin | Function | Description |

|---|---|---|

| M1 | Motor 1 | Connects to DC Motor 1 or one coil of a stepper motor |

| M2 | Motor 2 | Connects to DC Motor 2 or one coil of a stepper motor |

| M3 | Motor 3 | Connects to DC Motor 3 or one coil of a stepper motor |

| M4 | Motor 4 | Connects to DC Motor 4 or one coil of a stepper motor |

| S1 | Servo 1 | Connects to Servo Motor 1 |

| S2 | Servo 2 | Connects to Servo Motor 2 |

| A0-A5 | Analog Inputs | Used for additional functionalities like sensors |

| 5V | Power | Supplies 5V to the shield from the Arduino |

| GND | Ground | Common ground for the circuit |

Usage Instructions

How to Use the Component in a Circuit

- Mounting the Shield: Carefully align the shield's pins with the headers on the Arduino UNO and press down to seat the shield.

- Connecting Motors:

- DC Motors: Connect the motors to the M1, M2, M3, and M4 terminals.

- Stepper Motors: Connect the stepper motor coils to the M1/M2 and M3/M4 terminals.

- Servo Motors: Plug the servo connectors into the S1 and S2 pins.

- Power Supply: Connect an external power supply to the shield to power the motors. Ensure the voltage matches the requirements of your motors.

- Programming: Upload the appropriate code to the Arduino to control the motors.

Important Considerations and Best Practices

- Power: Do not power high-current motors directly from the Arduino's 5V pin.

- Heat Dissipation: Ensure adequate ventilation around the shield to prevent overheating.

- Motor Ratings: Check the motor specifications to avoid exceeding the shield's current limits.

- Shield Stacking: If stacking other shields on top, ensure they do not interfere with the motor shield's functionality.

Example Code for Arduino UNO

#include <Adafruit_MotorShield.h>

#include <Wire.h>

// Create the motor shield object with the default I2C address

Adafruit_MotorShield AFMS = Adafruit_MotorShield();

// Connect a stepper motor with 200 steps per revolution to port #2

Adafruit_StepperMotor *myMotor = AFMS.getStepper(200, 2);

void setup() {

AFMS.begin(); // Create with the default frequency 1.6KHz

myMotor->setSpeed(10); // Set the speed to 10 rpm

}

void loop() {

myMotor->step(100, FORWARD, SINGLE);

delay(500);

myMotor->step(100, BACKWARD, SINGLE);

delay(500);

}

Troubleshooting and FAQs

Common Issues Users Might Face

- Motors not running: Ensure that the external power supply is properly connected and turned on.

- Inconsistent motor behavior: Check for loose connections and verify that the code uploaded to the Arduino is correct.

- Overheating: If the shield or motors are overheating, reduce the load or improve cooling.

Solutions and Tips for Troubleshooting

- Power Supply: Use a separate power supply for the motors, and do not draw power from the Arduino's 5V pin for the motors.

- Connections: Double-check all connections, including the shield's seating on the Arduino.

- Code: Review the code for any errors and ensure that the correct motor type is being controlled as intended.

FAQs

Q: Can I control a 24V motor with this shield? A: No, the shield is designed for motors that operate between 5V and 12V.

Q: How many motors can I control with this shield? A: You can control up to 4 DC motors, 2 stepper motors, or 2 servos, but not all at the same time.

Q: Can I use this shield with Arduino Mega or other models? A: Yes, the shield is compatible with the Arduino UNO form factor, which is also present on other models like the Mega. However, you may need to adjust the code for different I/O pin assignments.