How to Use Yellow Geared Motor with Encoder: Examples, Pinouts, and Specs

Design with Yellow Geared Motor with Encoder in Cirkit Designer

Design with Yellow Geared Motor with Encoder in Cirkit DesignerIntroduction

The Yellow Geared Motor with Encoder (Manufacturer Part ID: FIT0450) by DFRobot Accessories is a compact and versatile motor designed for robotics and automation applications. It combines a gear mechanism for torque amplification and an encoder for precise position and speed feedback. This motor is ideal for projects requiring controlled motion, such as robotic arms, wheeled robots, and conveyor systems.

Explore Projects Built with Yellow Geared Motor with Encoder

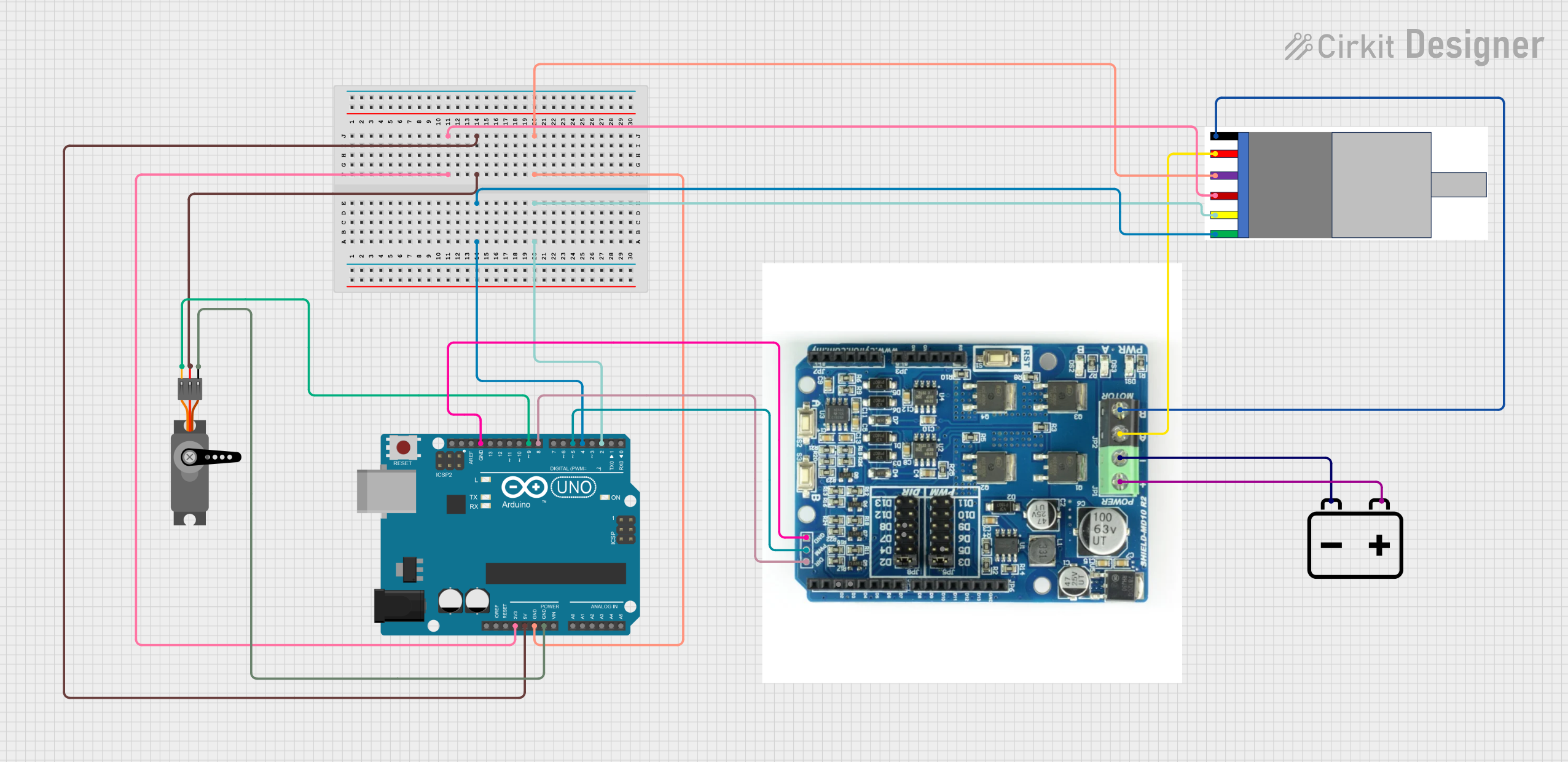

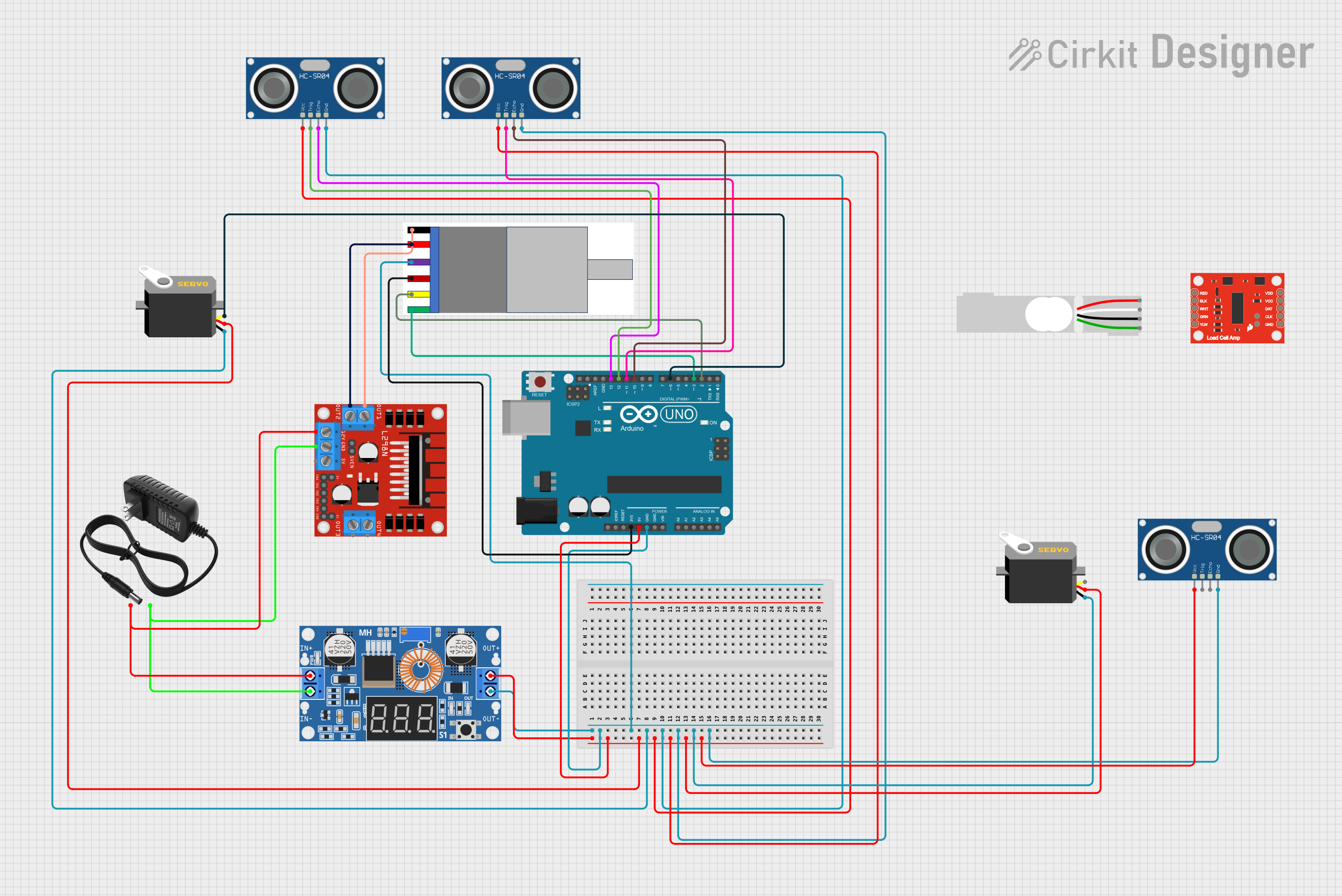

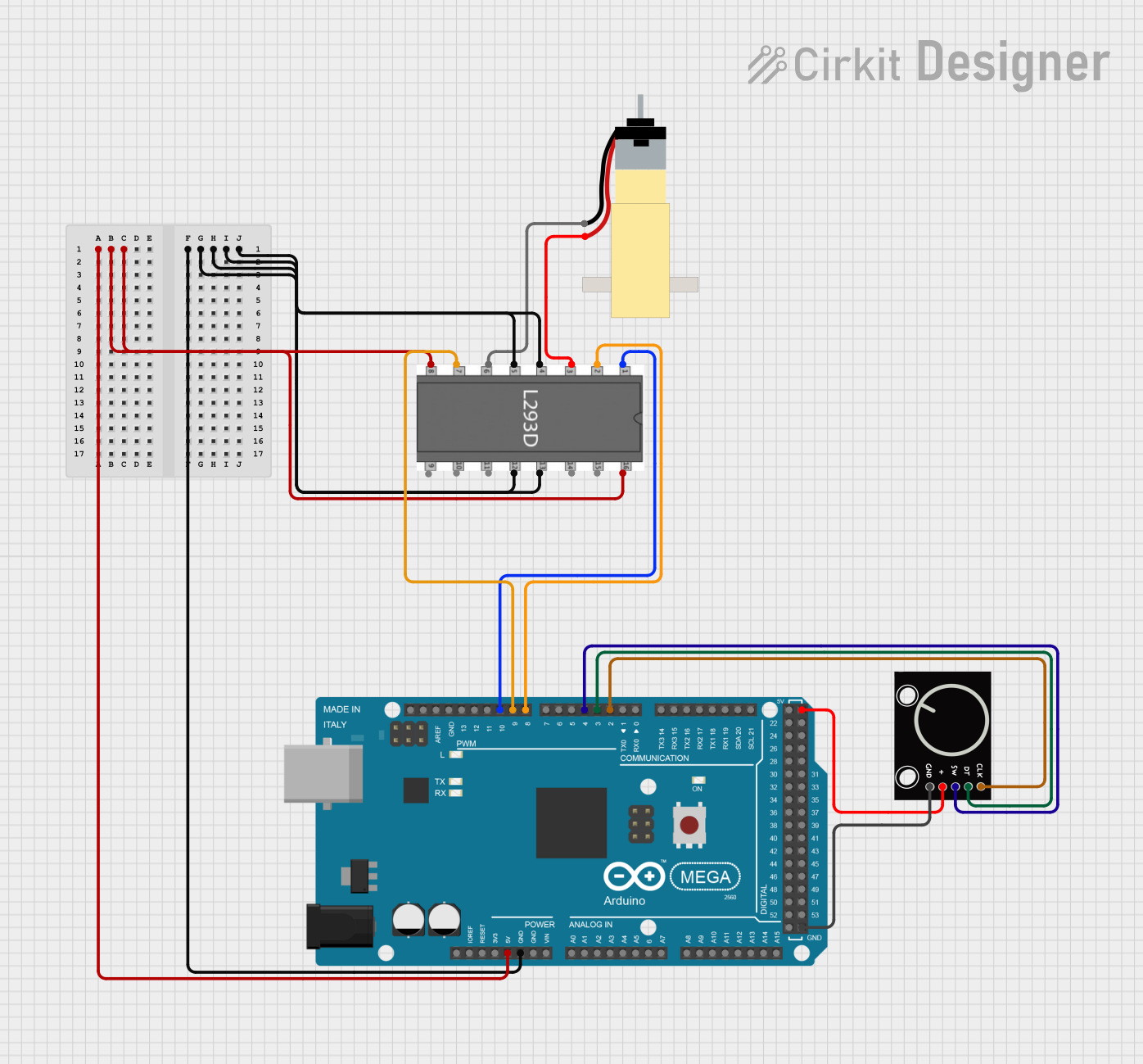

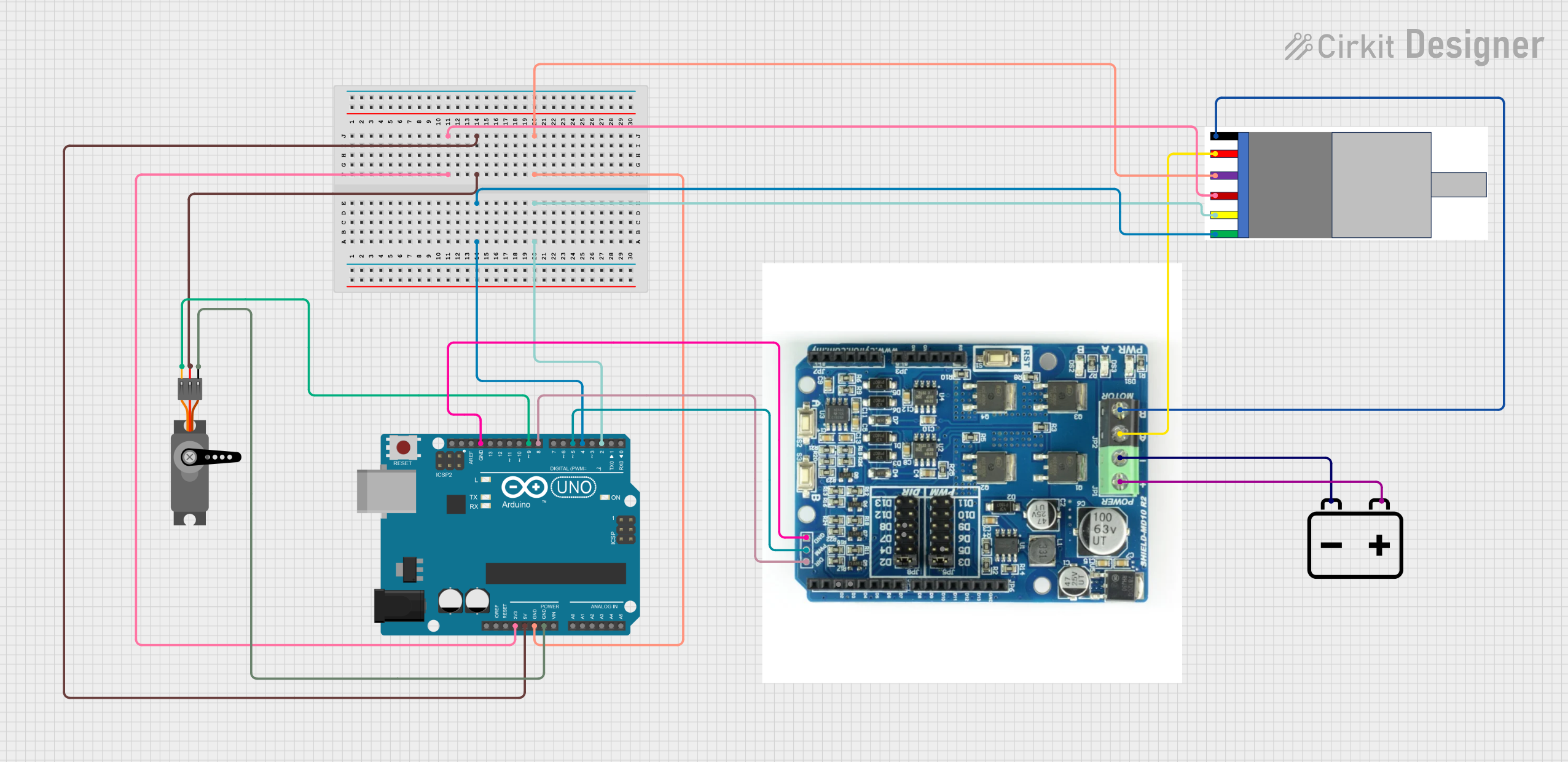

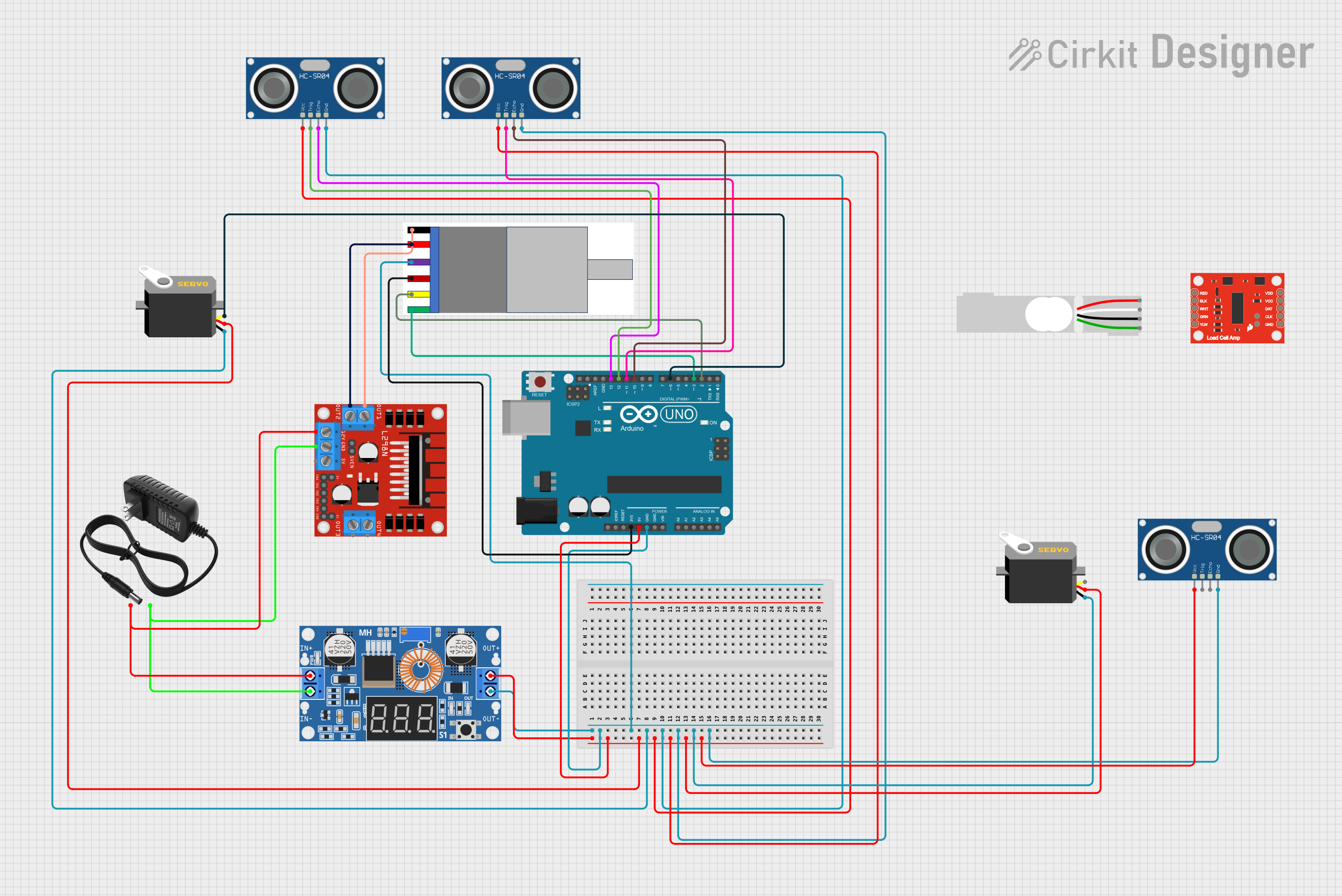

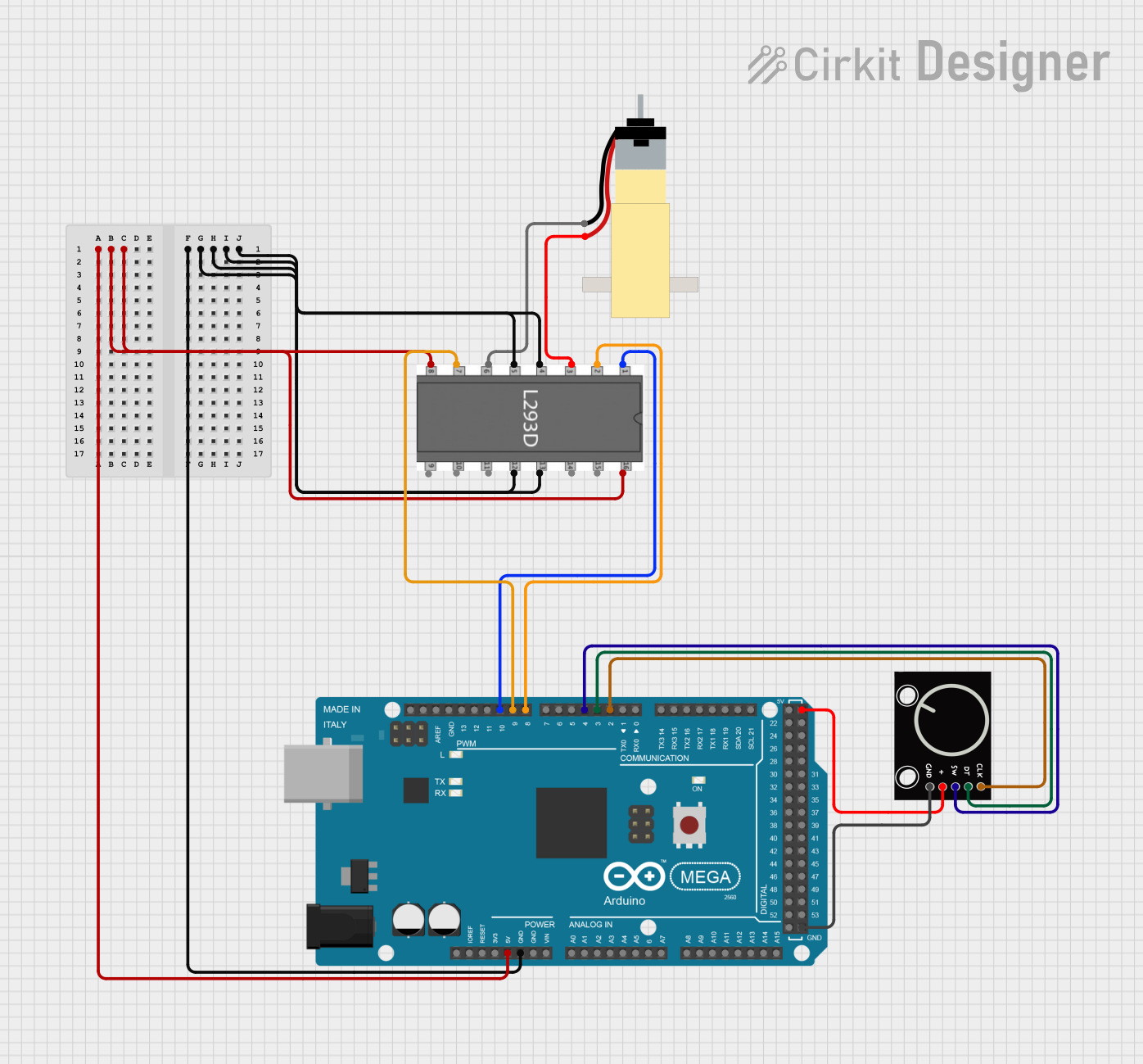

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Yellow Geared Motor with Encoder

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Robotics (e.g., mobile robots, robotic arms)

- Automated conveyor systems

- Precision motion control in DIY projects

- Educational and prototyping purposes

Technical Specifications

Below are the key technical details of the Yellow Geared Motor with Encoder:

| Parameter | Value |

|---|---|

| Operating Voltage | 3V - 6V DC |

| Rated Voltage | 6V DC |

| No-Load Speed | 150 RPM (at 6V) |

| Stall Torque | 1.5 kg·cm (at 6V) |

| Stall Current | 0.8 A (at 6V) |

| Gear Ratio | 1:48 |

| Encoder Resolution | 11 pulses per revolution (PPR) |

| Shaft Diameter | 5.5 mm |

| Motor Dimensions | 70 mm x 22 mm x 18 mm |

| Weight | 45 g |

Pin Configuration and Descriptions

The motor comes with a 4-pin connector for the encoder and two terminals for the motor power. Below is the pinout:

Motor Power Terminals

| Terminal | Description |

|---|---|

+ |

Positive motor terminal |

- |

Negative motor terminal |

Encoder Pinout

| Pin | Wire Color | Description |

|---|---|---|

VCC |

Red | Power supply for the encoder (3.3V-5V) |

GND |

Black | Ground |

A |

Yellow | Encoder output channel A |

B |

Green | Encoder output channel B |

Usage Instructions

How to Use the Component in a Circuit

- Powering the Motor: Connect the motor terminals to a DC power supply or motor driver. Ensure the voltage does not exceed 6V to avoid damage.

- Connecting the Encoder:

- Connect the

VCCandGNDpins of the encoder to a 3.3V or 5V power source. - Connect the

AandBpins to the digital input pins of a microcontroller (e.g., Arduino UNO) to read encoder signals.

- Connect the

- Motor Driver: Use an H-bridge motor driver (e.g., L298N or L293D) to control the motor's direction and speed.

Important Considerations and Best Practices

- Voltage Limits: Operate the motor within the specified voltage range (3V-6V) to prevent overheating or damage.

- Current Requirements: Ensure your power supply or motor driver can handle the stall current (0.8A at 6V).

- Encoder Signal Handling: Use pull-up resistors if the encoder signals are unstable.

- Mounting: Secure the motor properly to avoid vibrations that may affect encoder readings.

Example: Using with Arduino UNO

Below is an example of how to connect and use the motor with an Arduino UNO to read encoder signals and control the motor:

Circuit Connections

- Connect the motor terminals to an H-bridge motor driver.

- Connect the encoder pins as follows:

VCCto Arduino5VGNDto ArduinoGNDAto Arduino digital pin2Bto Arduino digital pin3

Arduino Code

// Define encoder pins

const int encoderPinA = 2; // Channel A connected to digital pin 2

const int encoderPinB = 3; // Channel B connected to digital pin 3

volatile int encoderCount = 0; // Variable to store encoder count

void setup() {

pinMode(encoderPinA, INPUT); // Set encoder pin A as input

pinMode(encoderPinB, INPUT); // Set encoder pin B as input

// Attach interrupt to encoder pin A

attachInterrupt(digitalPinToInterrupt(encoderPinA), encoderISR, CHANGE);

Serial.begin(9600); // Initialize serial communication

}

void loop() {

// Print the encoder count to the Serial Monitor

Serial.print("Encoder Count: ");

Serial.println(encoderCount);

delay(100); // Delay for readability

}

// Interrupt Service Routine (ISR) for encoder

void encoderISR() {

// Read the state of channel B

int stateB = digitalRead(encoderPinB);

// Determine direction based on channel B state

if (stateB == HIGH) {

encoderCount++; // Increment count for forward rotation

} else {

encoderCount--; // Decrement count for reverse rotation

}

}

Notes:

- The encoder count can be used to calculate the motor's position or speed.

- Use a motor driver to control the motor's speed and direction.

Troubleshooting and FAQs

Common Issues

Motor Not Spinning:

- Cause: Insufficient power supply or incorrect wiring.

- Solution: Verify the power supply voltage and check the motor connections.

Encoder Not Providing Signals:

- Cause: Incorrect wiring or insufficient power to the encoder.

- Solution: Ensure the encoder

VCCandGNDare connected properly, and check the connections to the microcontroller.

Unstable Encoder Readings:

- Cause: Electrical noise or lack of pull-up resistors.

- Solution: Add pull-up resistors to the encoder signal lines and ensure proper grounding.

Motor Overheating:

- Cause: Operating the motor beyond its voltage or current limits.

- Solution: Use a power supply within the specified range and avoid prolonged stall conditions.

FAQs

Q: Can I use this motor with a 12V power supply?

A: No, the motor is rated for a maximum of 6V. Using a higher voltage may damage the motor.

Q: How do I calculate the motor's speed using the encoder?

A: Measure the time between encoder pulses and use the gear ratio and encoder resolution to calculate the speed.

Q: Can I use this motor without the encoder?

A: Yes, the motor can be used without the encoder for simple applications where position or speed feedback is not required.