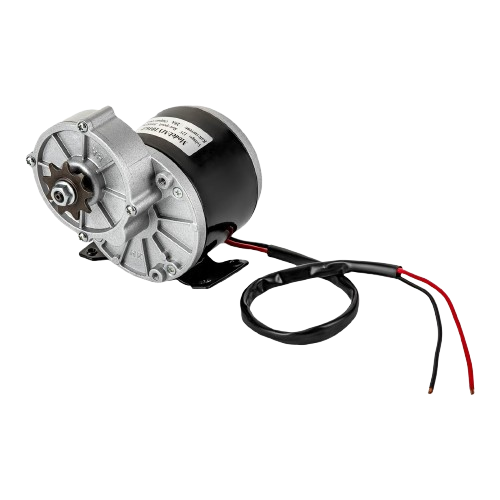

How to Use 250W 12V ELECTRIC MOTOR BRUSH MOTOR DC: Examples, Pinouts, and Specs

Design with 250W 12V ELECTRIC MOTOR BRUSH MOTOR DC in Cirkit Designer

Design with 250W 12V ELECTRIC MOTOR BRUSH MOTOR DC in Cirkit DesignerIntroduction

The 250W 12V Electric Brushed DC Motor is a robust and efficient motor designed for a variety of applications that require reliable and controlled motion. This motor is commonly used in electric scooters, bicycles, small vehicles, and DIY projects where a compact and powerful motor is needed.

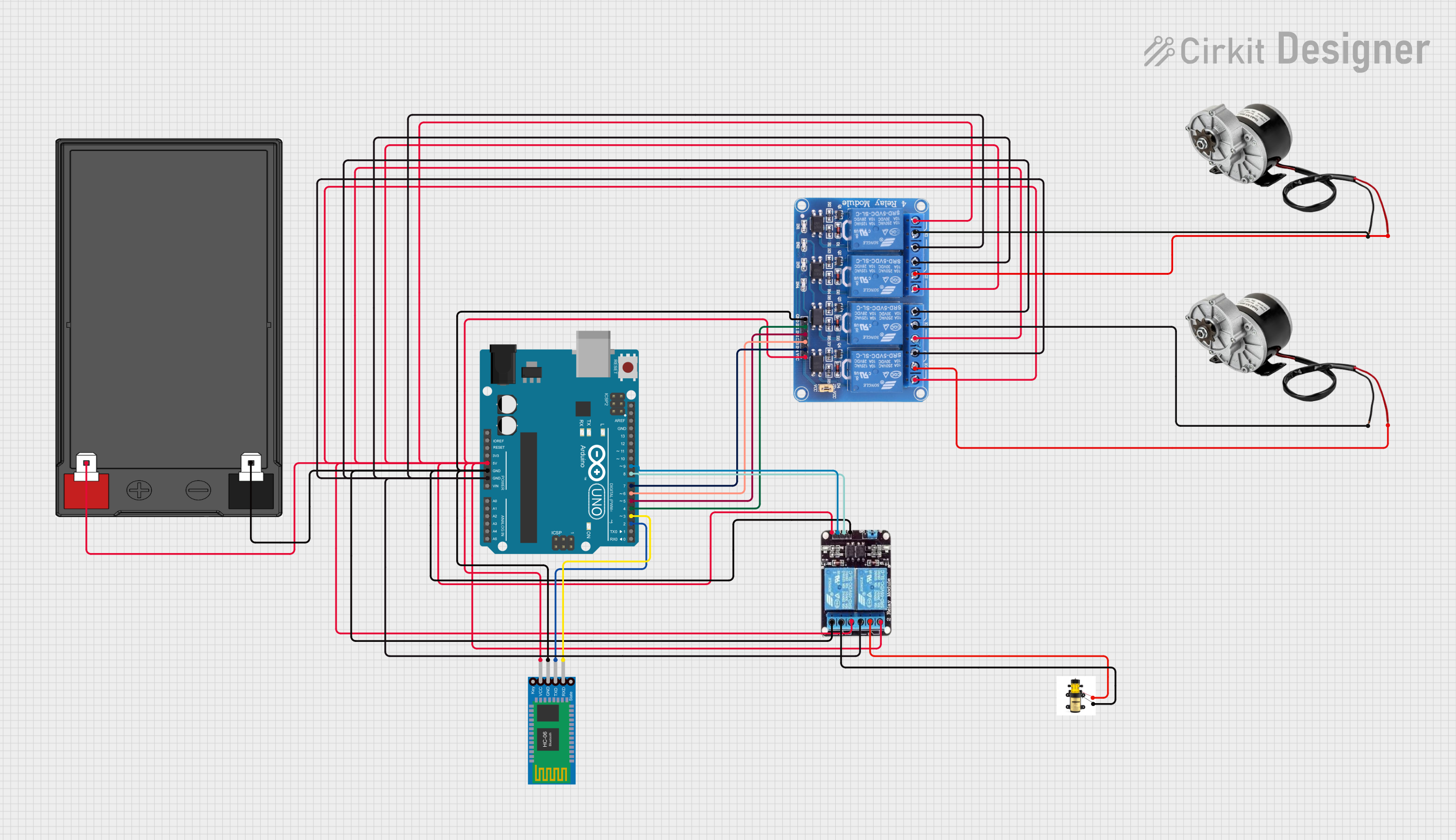

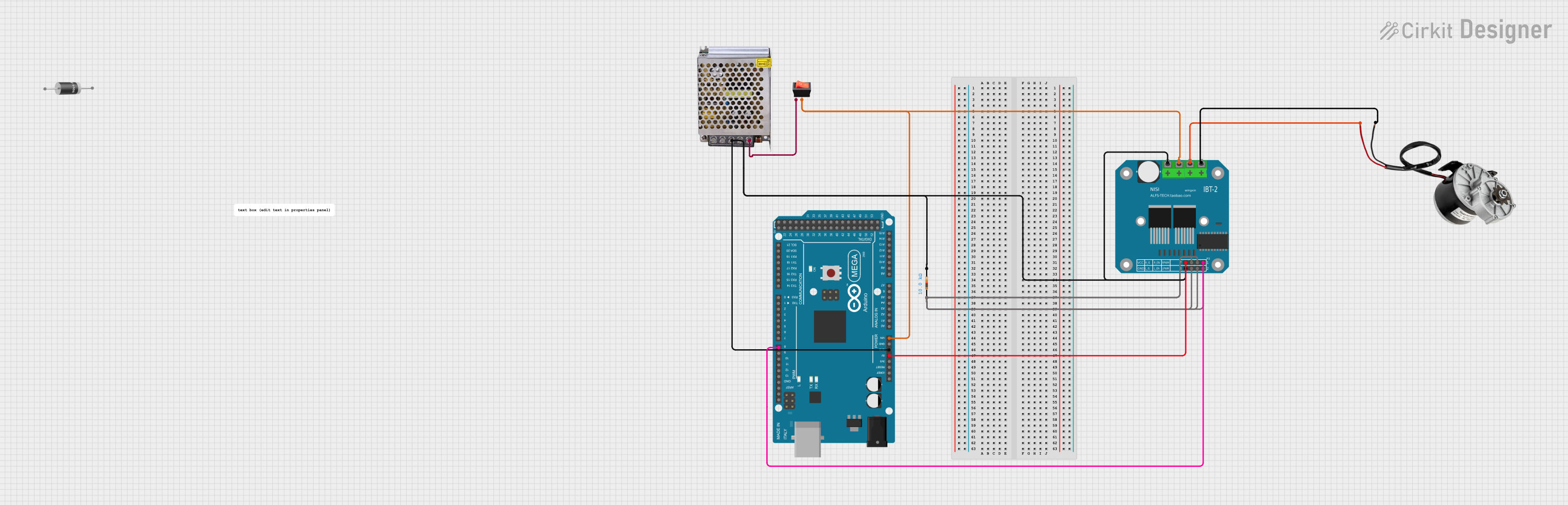

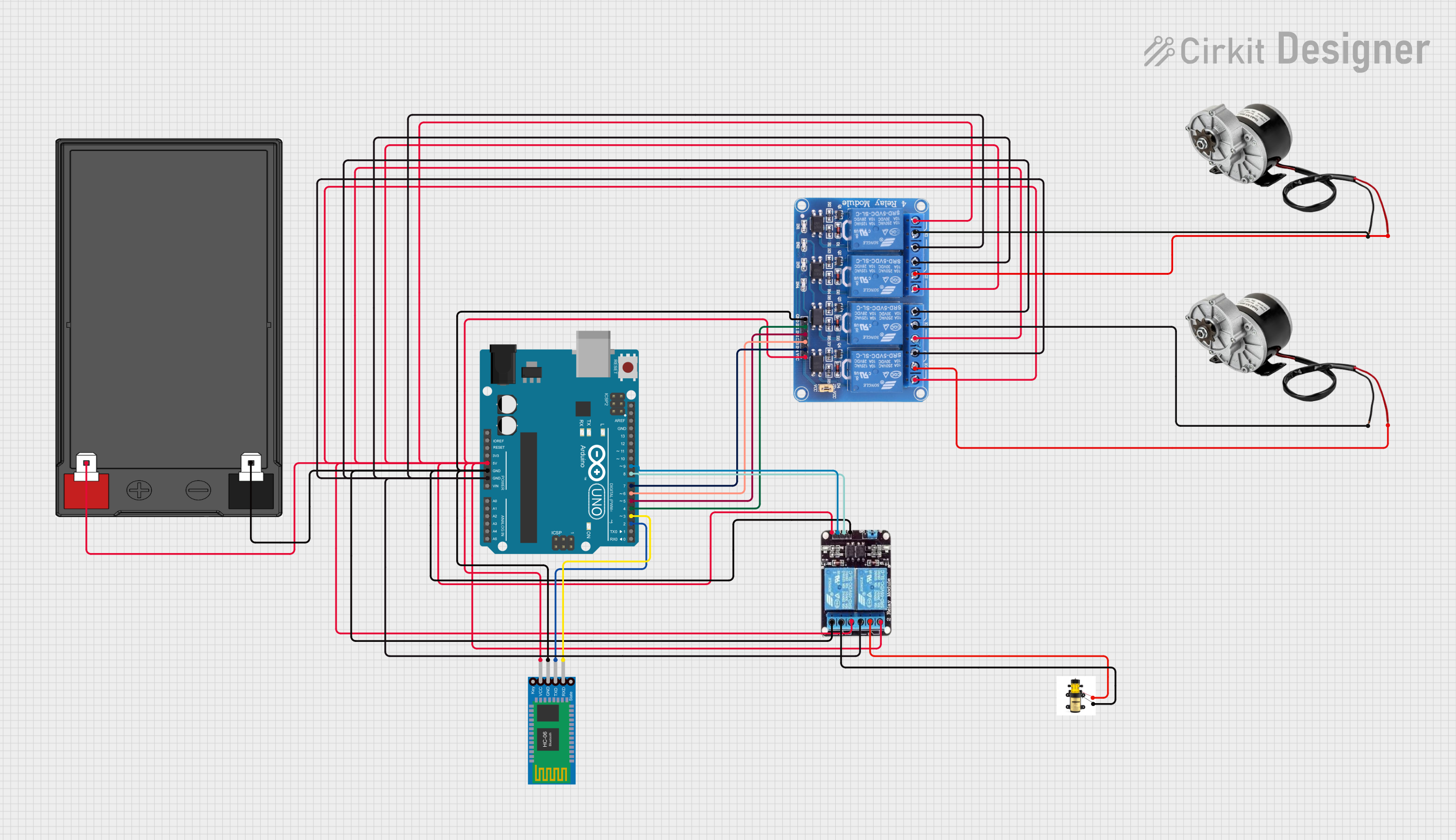

Explore Projects Built with 250W 12V ELECTRIC MOTOR BRUSH MOTOR DC

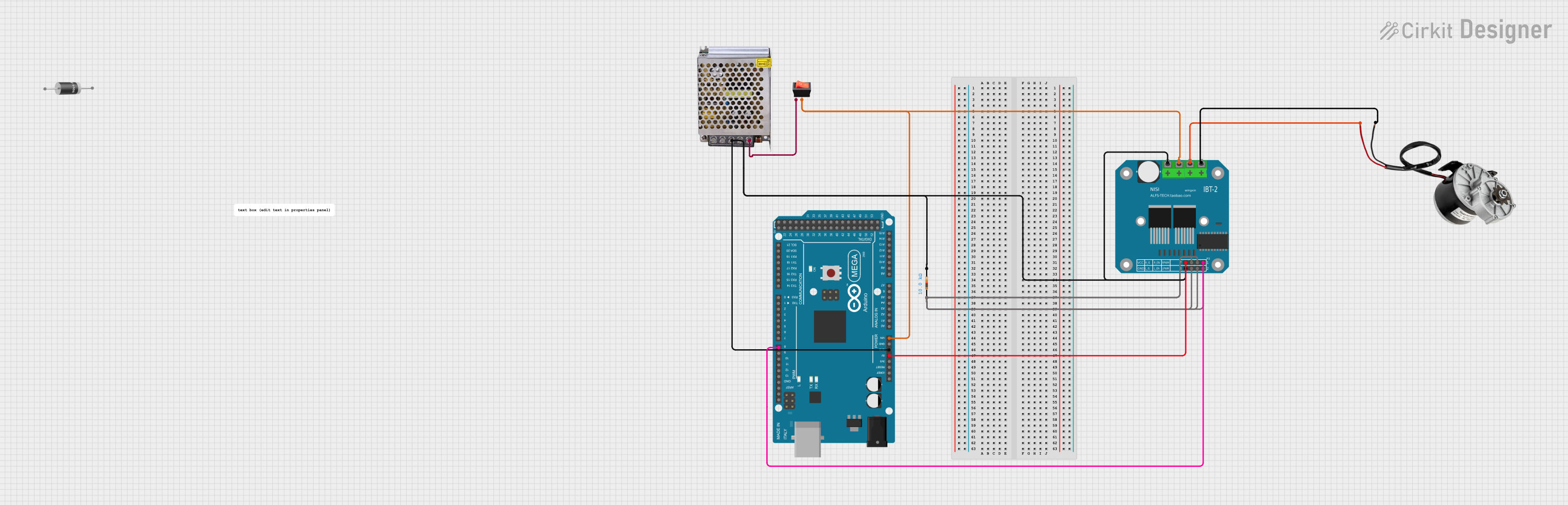

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 250W 12V ELECTRIC MOTOR BRUSH MOTOR DC

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Electric scooters and bicycles

- Small electric vehicles

- Robotics and automation projects

- DIY electric-powered machines and tools

Technical Specifications

Key Technical Details

| Specification | Value |

|---|---|

| Power Rating | 250 Watts |

| Nominal Voltage | 12 Volts DC |

| No-load Current | < 2.0 Amps |

| Load Current | 20.8 Amps |

| Rated Speed | 2750 RPM |

| Torque | 0.80 Nm |

| Efficiency | > 75% |

| Insulation Class | Class B |

| Operating Temperature | -10°C to +40°C |

Pin Configuration and Descriptions

Since this is a motor, it does not have a pin configuration in the traditional sense. Instead, it has two terminals for power connection:

| Terminal | Description |

|---|---|

| + | Positive Lead |

| - | Negative Lead |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Ensure that the power supply can handle the motor's nominal voltage of 12V and the load current of up to 20.8A.

- Motor Controller: Use a suitable motor controller that can handle the power requirements and provide speed and direction control.

- Wiring: Connect the motor to the motor controller. The positive lead should go to the positive output of the controller, and the negative lead to the negative output.

- Activation: Use the motor controller to start, stop, and control the speed of the motor.

Important Considerations and Best Practices

- Current Draw: Ensure that all components in the circuit can handle the maximum current draw of the motor.

- Heat Dissipation: The motor can generate heat; provide adequate cooling if necessary.

- Overload Protection: Use fuses or circuit breakers to protect against overcurrent conditions.

- Mounting: Secure the motor firmly to prevent vibrations and ensure stable operation.

Troubleshooting and FAQs

Common Issues Users Might Face

- Motor Does Not Start: Check power supply and connections. Ensure the motor controller is functioning correctly.

- Excessive Noise or Vibration: Ensure the motor is mounted securely. Check for any obstructions or damage to the motor.

- Overheating: Ensure adequate cooling and that the motor is not overloaded.

Solutions and Tips for Troubleshooting

- Check Connections: Loose connections can cause intermittent or no operation.

- Inspect for Damage: Physical damage to the motor or its terminals can cause failure.

- Test Power Supply: Verify that the power supply is delivering the correct voltage and current.

FAQs

Q: Can I run this motor at a voltage higher than 12V? A: Running the motor at a higher voltage than its rated voltage can lead to overheating and reduced lifespan.

Q: What type of motor controller should I use? A: Use a DC motor controller that can handle at least 250W and 20.8A of current.

Q: How do I reverse the direction of the motor? A: Reverse the polarity of the motor connections, either manually or using a motor controller with this feature.

Q: Can this motor be used for regenerative braking? A: This motor does not support regenerative braking inherently. Additional circuitry and a compatible motor controller are required.

Q: Is this motor waterproof? A: Typically, brushed DC motors are not waterproof. Protect the motor from moisture to prevent damage.

Example Arduino UNO Code

This example demonstrates how to control the 250W 12V Electric Brushed DC Motor using an Arduino UNO and a compatible motor controller.

// Define motor control pins

const int motorEnablePin = 9; // PWM pin to enable motor

const int motorDirectionPin = 2; // Digital pin to control motor direction

void setup() {

// Set motor control pins as outputs

pinMode(motorEnablePin, OUTPUT);

pinMode(motorDirectionPin, OUTPUT);

}

void loop() {

// Set motor direction to forward

digitalWrite(motorDirectionPin, HIGH);

// Start the motor at half speed

analogWrite(motorEnablePin, 127); // 50% duty cycle for PWM

delay(5000); // Run for 5 seconds

// Stop the motor

analogWrite(motorEnablePin, 0);

delay(2000); // Wait for 2 seconds

// Set motor direction to reverse

digitalWrite(motorDirectionPin, LOW);

// Start the motor at full speed

analogWrite(motorEnablePin, 255); // 100% duty cycle for PWM

delay(5000); // Run for 5 seconds

// Stop the motor

analogWrite(motorEnablePin, 0);

delay(2000); // Wait for 2 seconds

}

Note: The above code assumes the use of a motor controller that interfaces with the Arduino UNO. The motor controller must be capable of handling the motor's power requirements. Always refer to the motor controller's datasheet for wiring and programming instructions.