How to Use L9110 Bridge Motor Driver IC DIP 8: Examples, Pinouts, and Specs

Design with L9110 Bridge Motor Driver IC DIP 8 in Cirkit Designer

Design with L9110 Bridge Motor Driver IC DIP 8 in Cirkit DesignerIntroduction

The L9110 is a dual H-bridge motor driver IC in a compact DIP-8 package. It is designed to control the direction and speed of DC motors, making it an essential component for motorized projects. The IC can drive two DC motors simultaneously, with independent control over each motor. Its small size and ease of use make it ideal for applications in robotics, automation, and other motor control systems.

Explore Projects Built with L9110 Bridge Motor Driver IC DIP 8

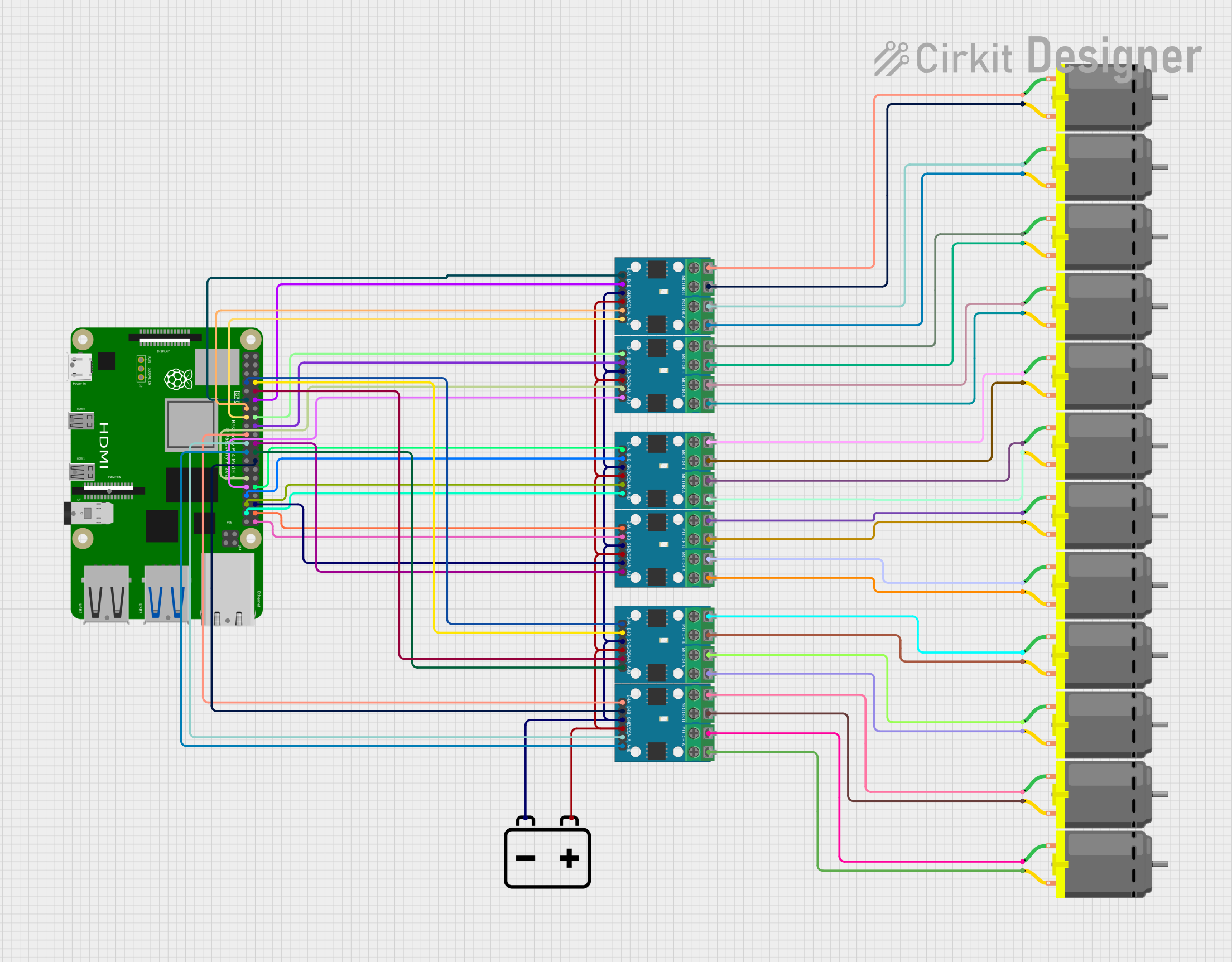

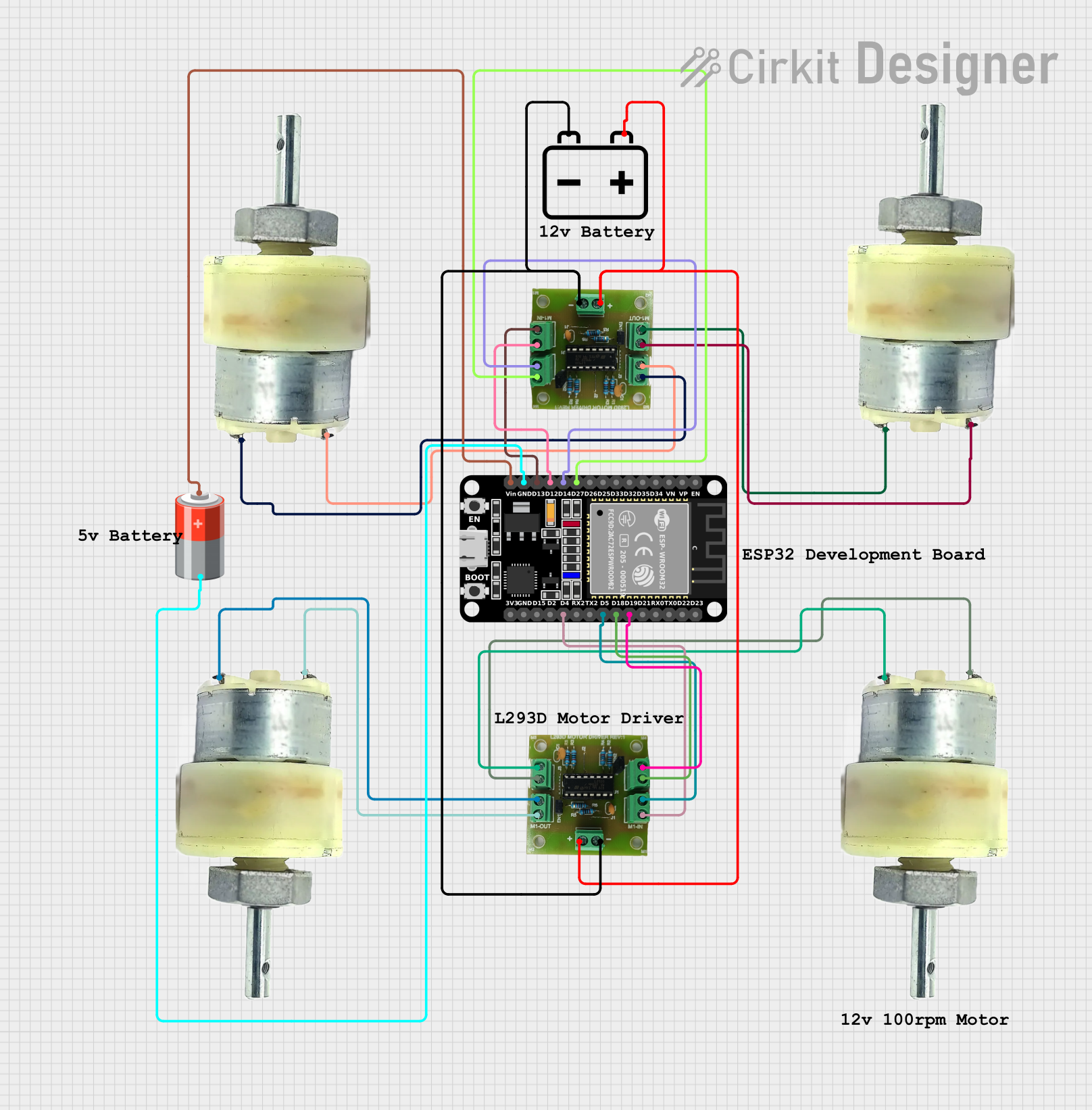

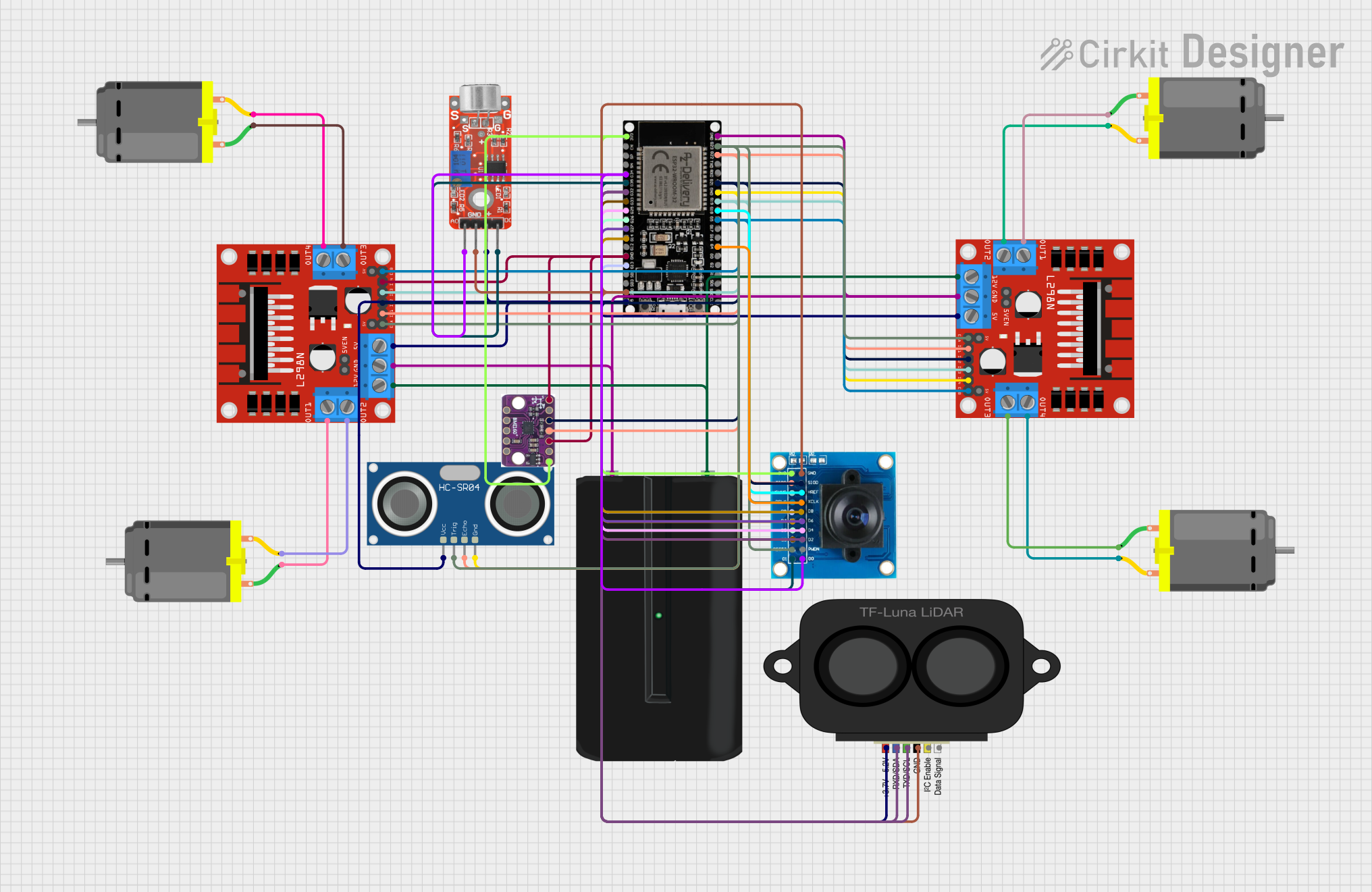

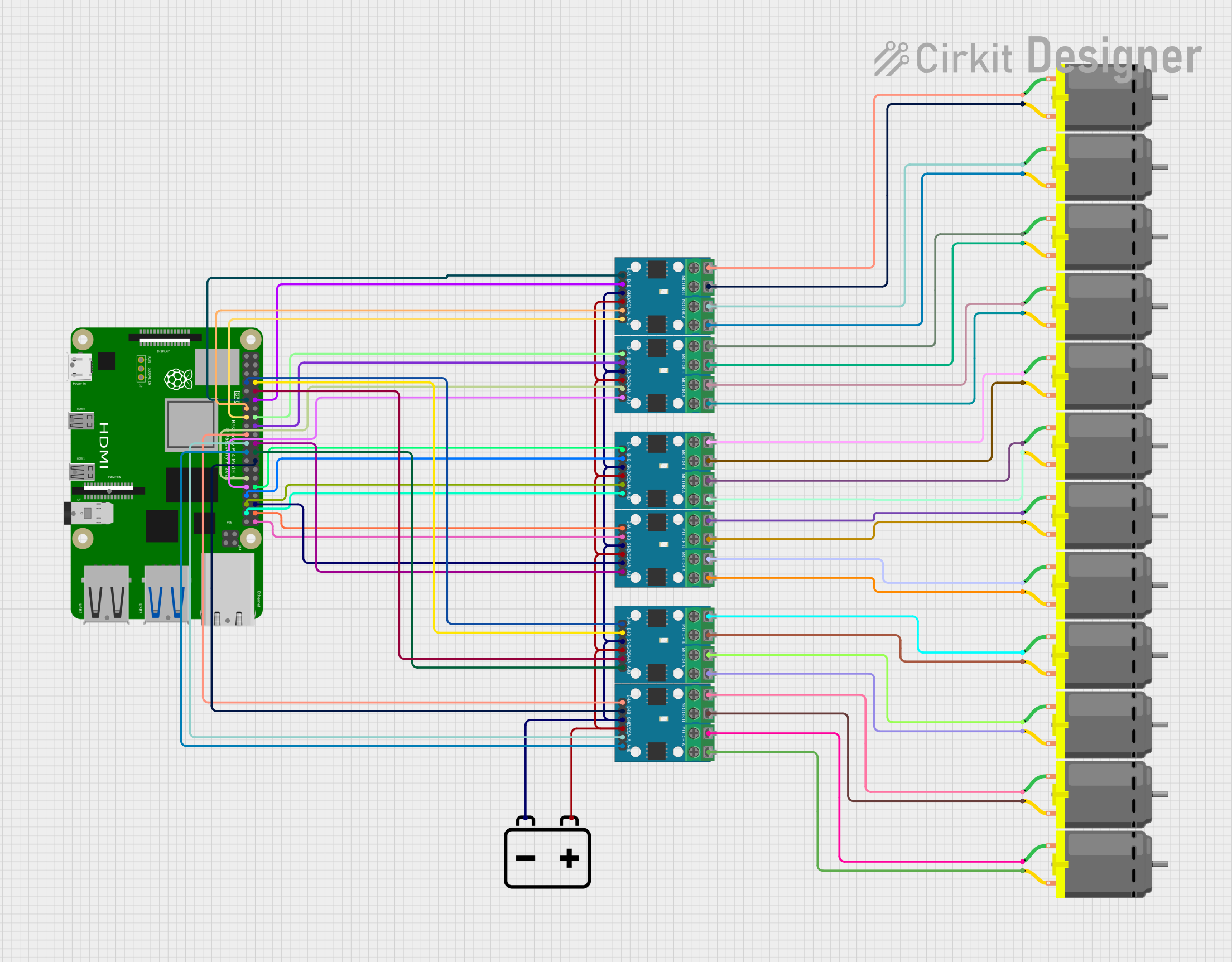

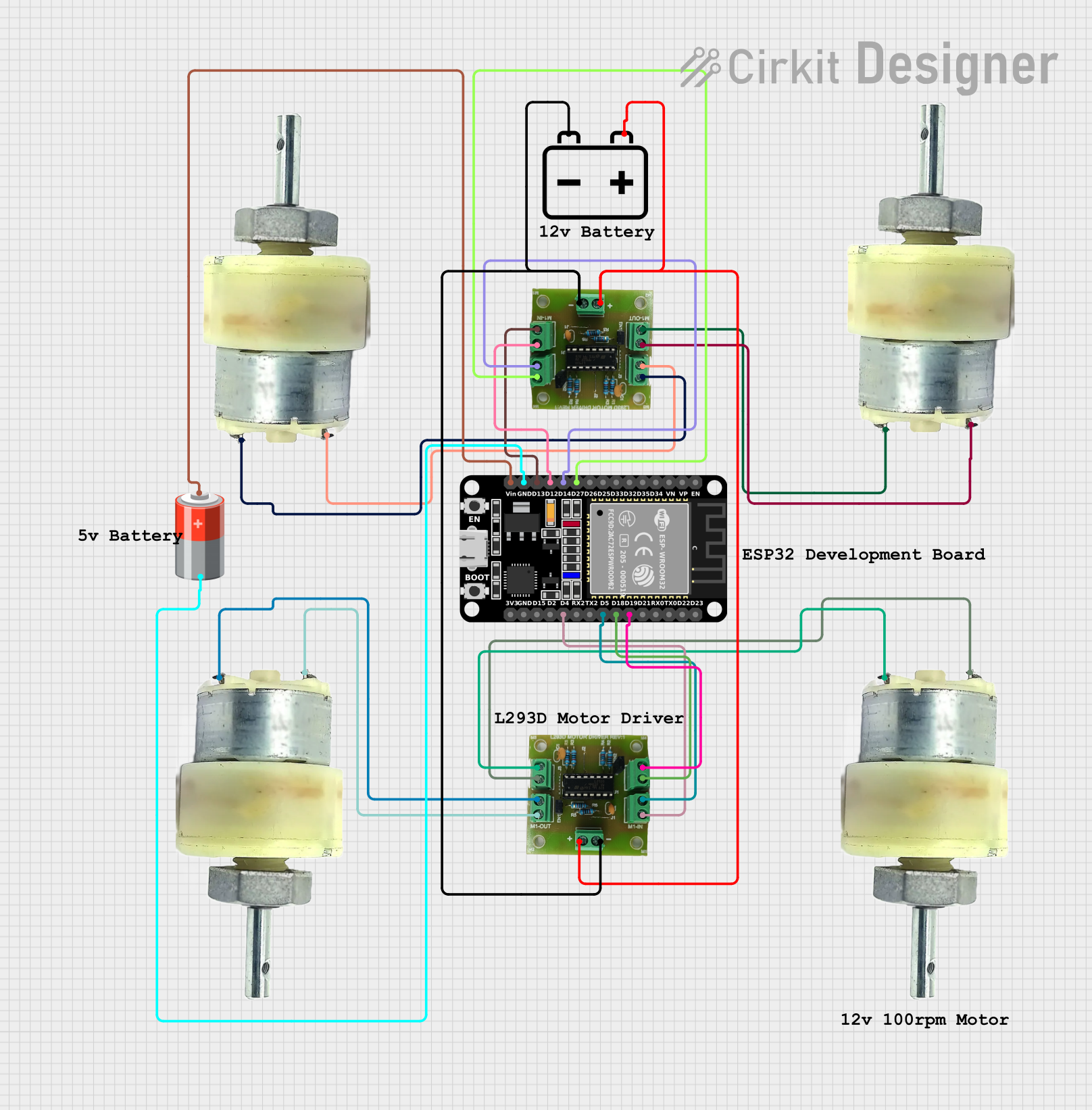

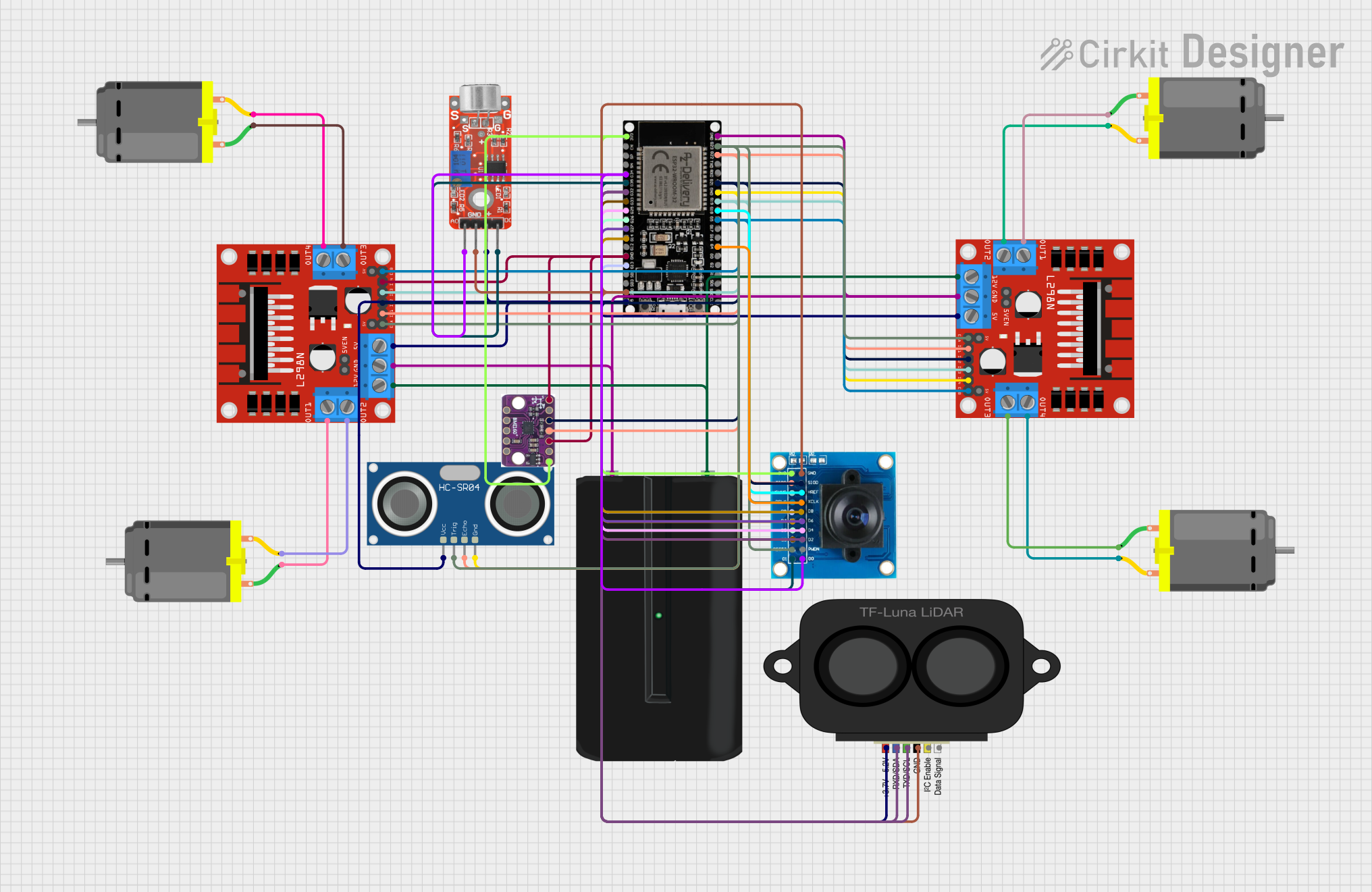

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with L9110 Bridge Motor Driver IC DIP 8

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Robotics (e.g., motorized wheels, robotic arms)

- Automation systems

- Small motorized toys

- DIY electronics projects

- Conveyor belt systems

Technical Specifications

The L9110 motor driver IC is designed for low-power motor control applications. Below are its key technical details:

| Parameter | Value |

|---|---|

| Operating Voltage | 2.5V to 12V |

| Output Current (per channel) | 800mA (continuous) |

| Peak Output Current | 1.5A |

| Logic Input Voltage | 0V to 5V |

| Number of Channels | 2 (dual H-bridge) |

| Package Type | DIP-8 |

| Operating Temperature | -40°C to +85°C |

Pin Configuration and Descriptions

The L9110 IC has 8 pins, as described in the table below:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | A-1A | Input signal for Motor A (controls direction) |

| 2 | A-1B | Input signal for Motor A (controls direction) |

| 3 | GND | Ground (0V reference) |

| 4 | VCC | Power supply for the IC (2.5V to 12V) |

| 5 | B-1B | Input signal for Motor B (controls direction) |

| 6 | B-1A | Input signal for Motor B (controls direction) |

| 7 | Motor B+ | Output terminal for Motor B |

| 8 | Motor A+ | Output terminal for Motor A |

Usage Instructions

The L9110 motor driver IC is straightforward to use in motor control circuits. Below are the steps and considerations for using it effectively:

Connecting the L9110 to a Circuit

- Power Supply: Connect the VCC pin (Pin 4) to a power source (2.5V to 12V) and the GND pin (Pin 3) to ground.

- Motor Connections:

- Connect the Motor A terminals to Pin 8 (Motor A+) and Pin 3 (GND).

- Connect the Motor B terminals to Pin 7 (Motor B+) and Pin 3 (GND).

- Control Signals:

- Use Pins 1 (A-1A) and 2 (A-1B) to control the direction of Motor A.

- Use Pins 5 (B-1B) and 6 (B-1A) to control the direction of Motor B.

- Logic Inputs: Provide logic-level signals (0V or 5V) to the input pins to control motor direction and speed.

Example Arduino UNO Code

The L9110 can be easily interfaced with an Arduino UNO for motor control. Below is an example code snippet to control two DC motors:

// Define motor control pins

const int motorA1 = 2; // Pin connected to A-1A

const int motorA2 = 3; // Pin connected to A-1B

const int motorB1 = 4; // Pin connected to B-1A

const int motorB2 = 5; // Pin connected to B-1B

void setup() {

// Set motor control pins as outputs

pinMode(motorA1, OUTPUT);

pinMode(motorA2, OUTPUT);

pinMode(motorB1, OUTPUT);

pinMode(motorB2, OUTPUT);

}

void loop() {

// Rotate Motor A forward

digitalWrite(motorA1, HIGH);

digitalWrite(motorA2, LOW);

// Rotate Motor B backward

digitalWrite(motorB1, LOW);

digitalWrite(motorB2, HIGH);

delay(2000); // Run motors for 2 seconds

// Stop both motors

digitalWrite(motorA1, LOW);

digitalWrite(motorA2, LOW);

digitalWrite(motorB1, LOW);

digitalWrite(motorB2, LOW);

delay(2000); // Wait for 2 seconds

}

Important Considerations

- Power Supply: Ensure the power supply voltage matches the motor's requirements and does not exceed the IC's maximum rating (12V).

- Heat Dissipation: For prolonged use at high currents, consider adding a heat sink to prevent overheating.

- Input Logic Levels: Use 0V (LOW) and 5V (HIGH) signals for the input pins to ensure proper operation.

- Motor Ratings: Ensure the motors' current and voltage ratings are within the IC's specifications.

Troubleshooting and FAQs

Common Issues and Solutions

Motors Not Spinning:

- Check the power supply connections to the IC and motors.

- Verify that the input control signals are correctly configured.

- Ensure the motor is functional by testing it directly with a power source.

Overheating:

- Ensure the motors' current draw does not exceed the IC's maximum rating.

- Add a heat sink or improve ventilation around the IC.

Erratic Motor Behavior:

- Check for loose or faulty connections in the circuit.

- Ensure the input logic signals are stable and not fluctuating.

One Motor Not Working:

- Verify the connections for the non-functional motor.

- Test the motor independently to ensure it is not damaged.

FAQs

Q: Can the L9110 drive stepper motors?

A: Yes, the L9110 can drive small stepper motors by controlling the coils in sequence. However, a dedicated stepper motor driver may provide better performance.

Q: What is the maximum motor voltage the L9110 can handle?

A: The L9110 can handle motor voltages up to 12V, as long as the current draw is within the specified limits.

Q: Can I use the L9110 with a 3.3V microcontroller?

A: Yes, the L9110 is compatible with 3.3V logic levels, but ensure the motor voltage is sufficient for your application.

Q: How do I control motor speed with the L9110?

A: Use PWM (Pulse Width Modulation) signals on the input pins to control the motor speed. For example, you can use the analogWrite() function on an Arduino.

By following this documentation, you can effectively use the L9110 motor driver IC in your projects.