How to Use 28BYJ-48 Motor Driver: Examples, Pinouts, and Specs

Design with 28BYJ-48 Motor Driver in Cirkit Designer

Design with 28BYJ-48 Motor Driver in Cirkit DesignerIntroduction

The 28BYJ-48 Motor Driver is a compact and efficient driver module designed to control the 28BYJ-48 stepper motor. This driver enables precise control of the motor's rotation and position, making it ideal for applications requiring accurate movement. It is commonly used in robotics, automation systems, 3D printers, and other projects where stepper motors are employed. The driver is typically paired with microcontrollers, such as Arduino, for seamless integration and control.

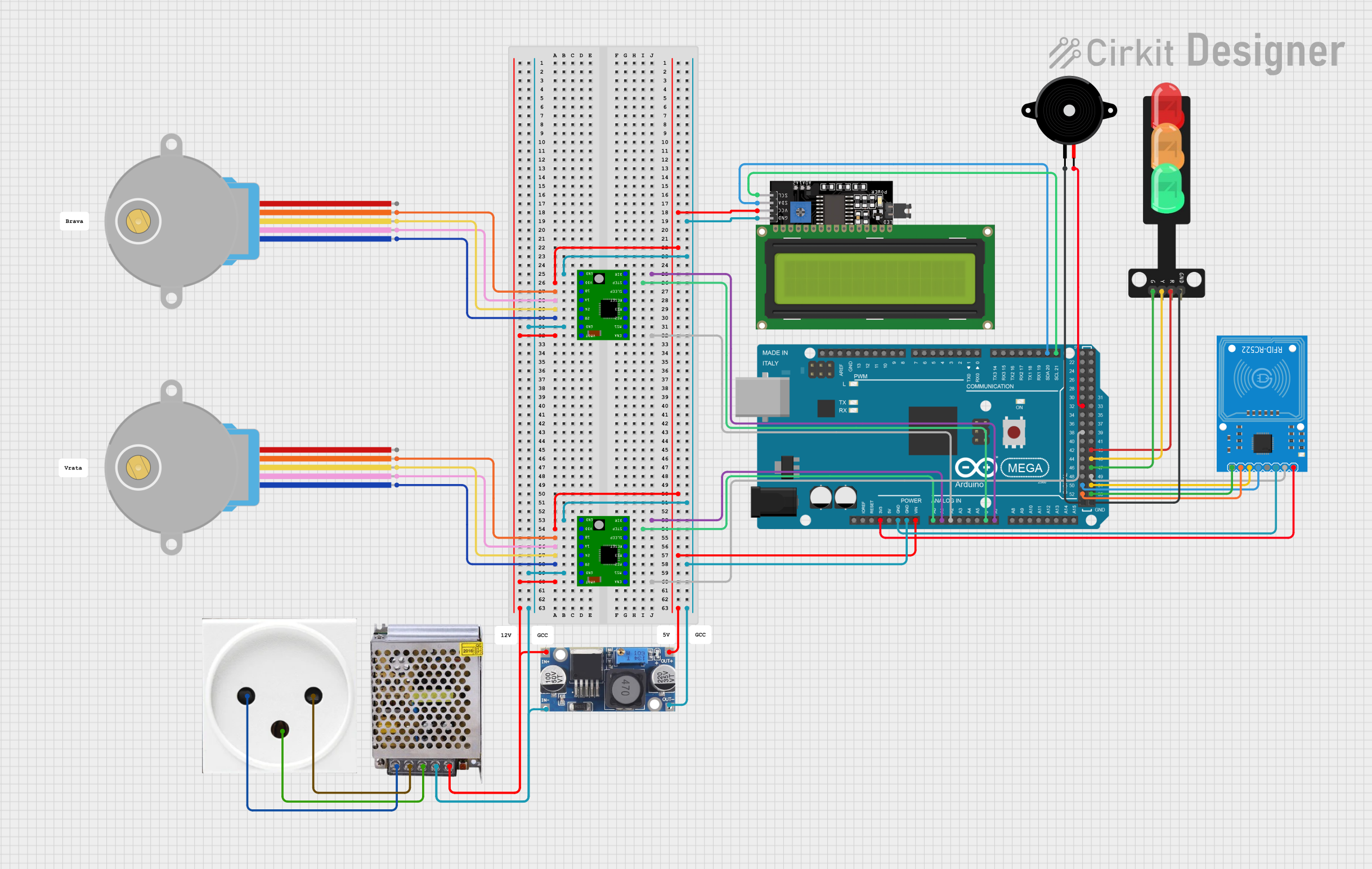

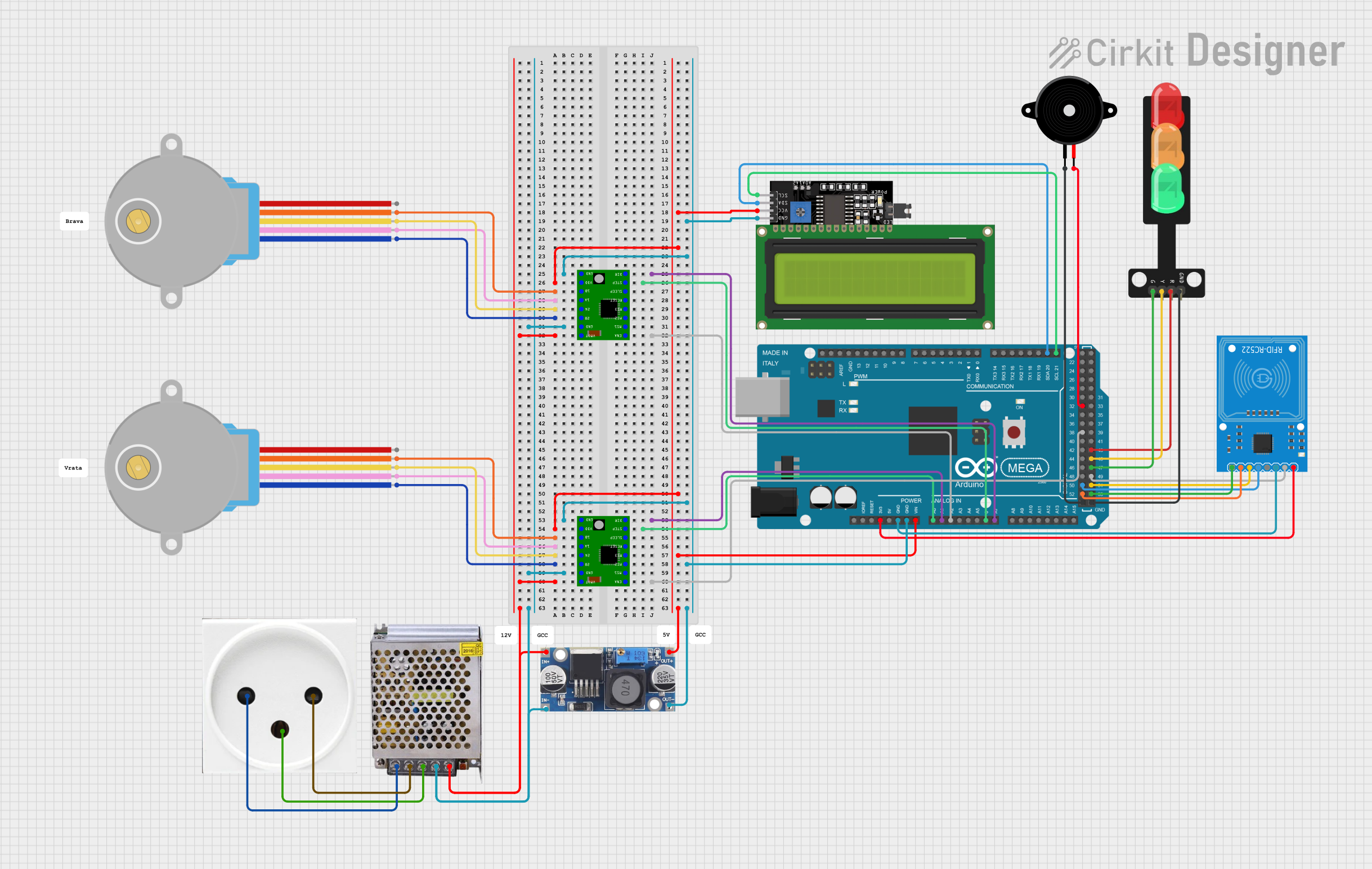

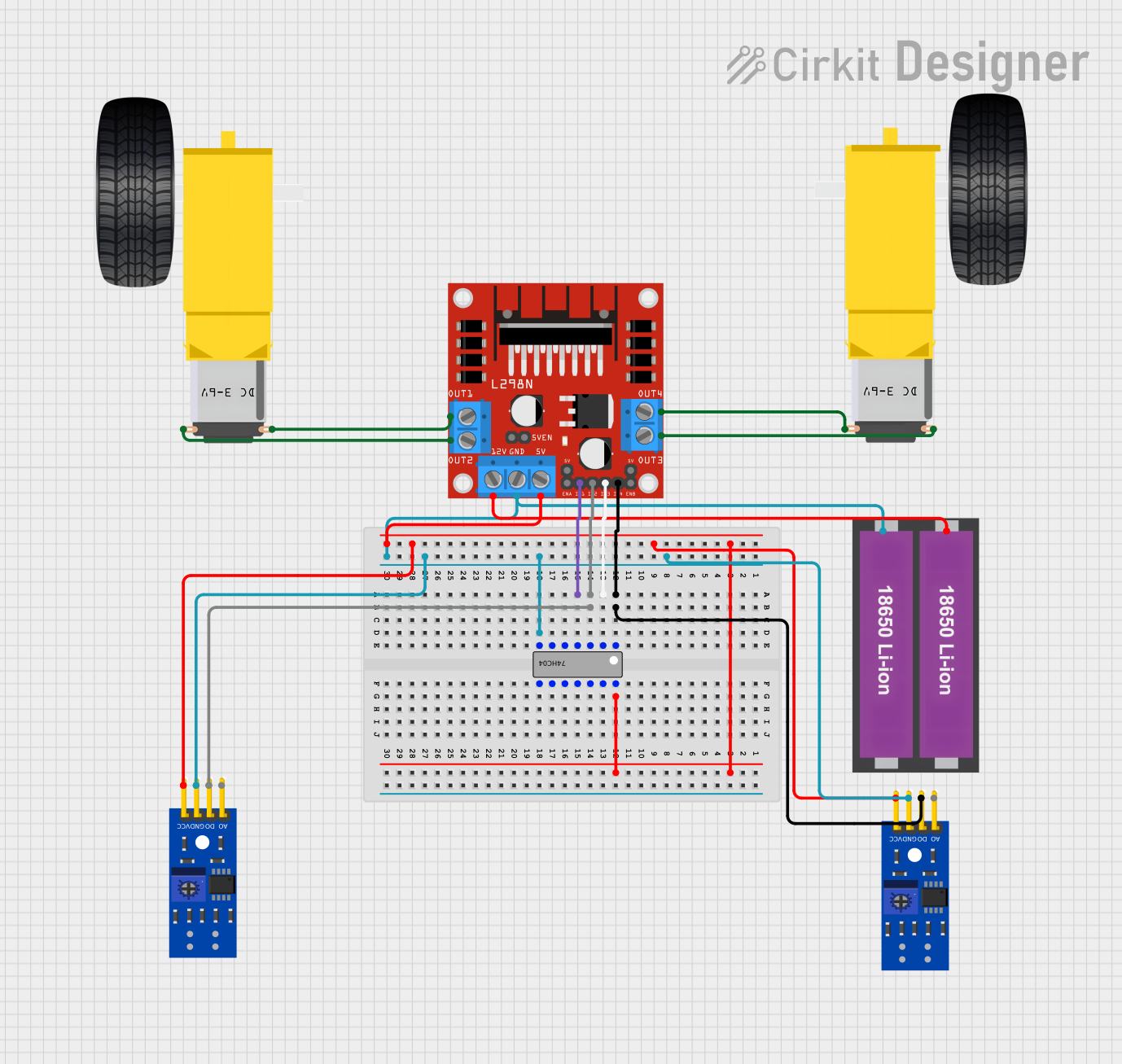

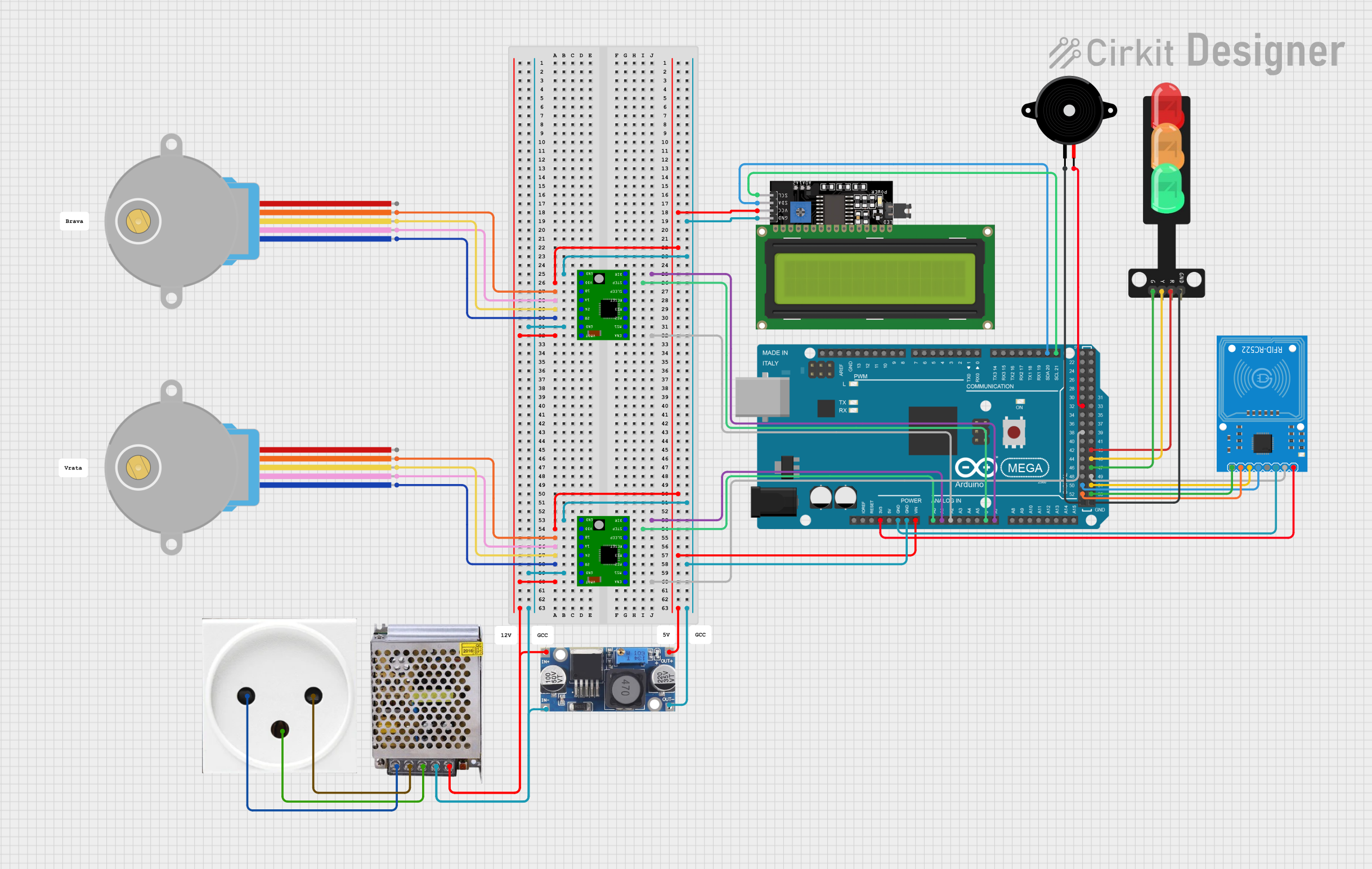

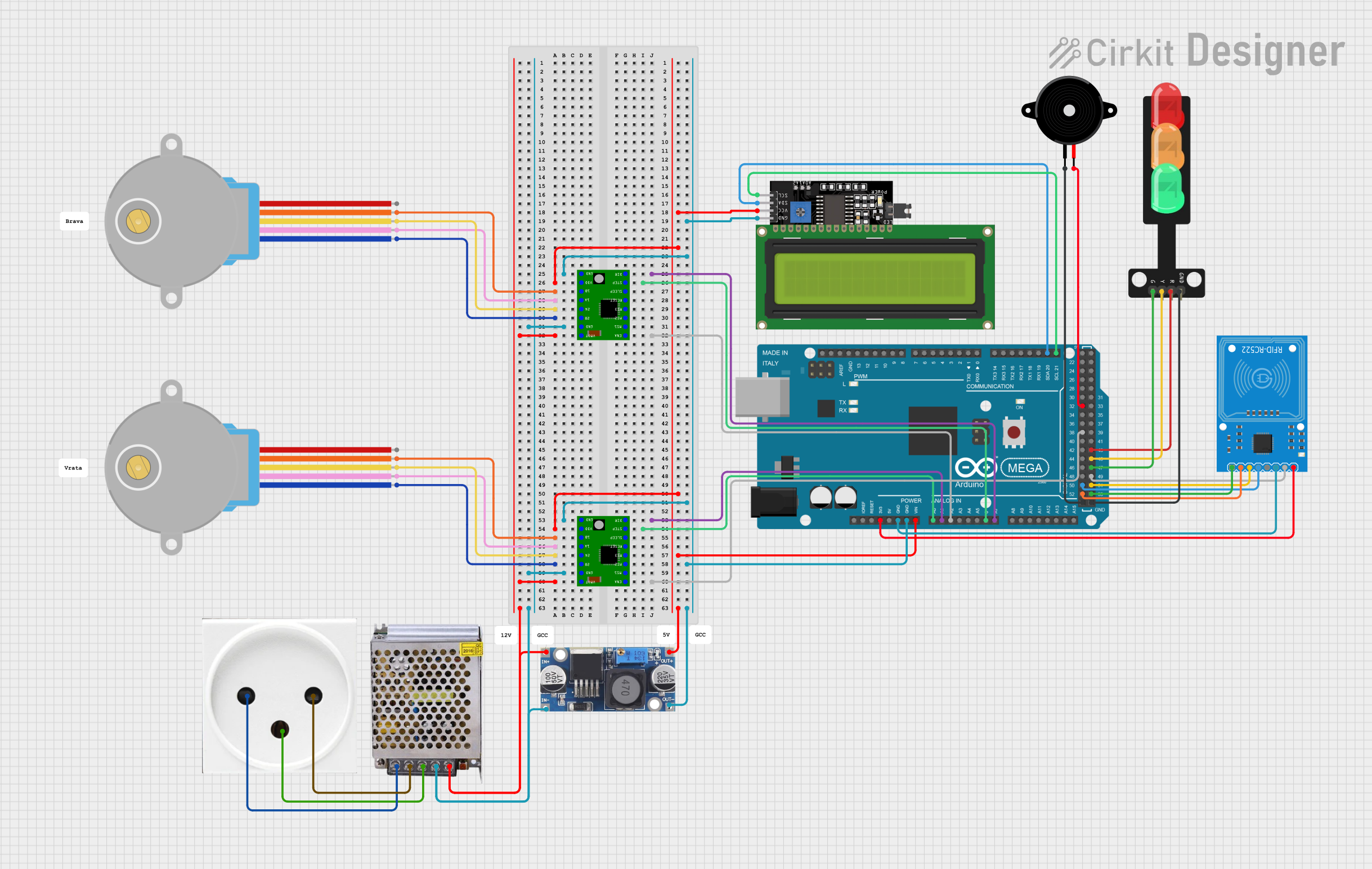

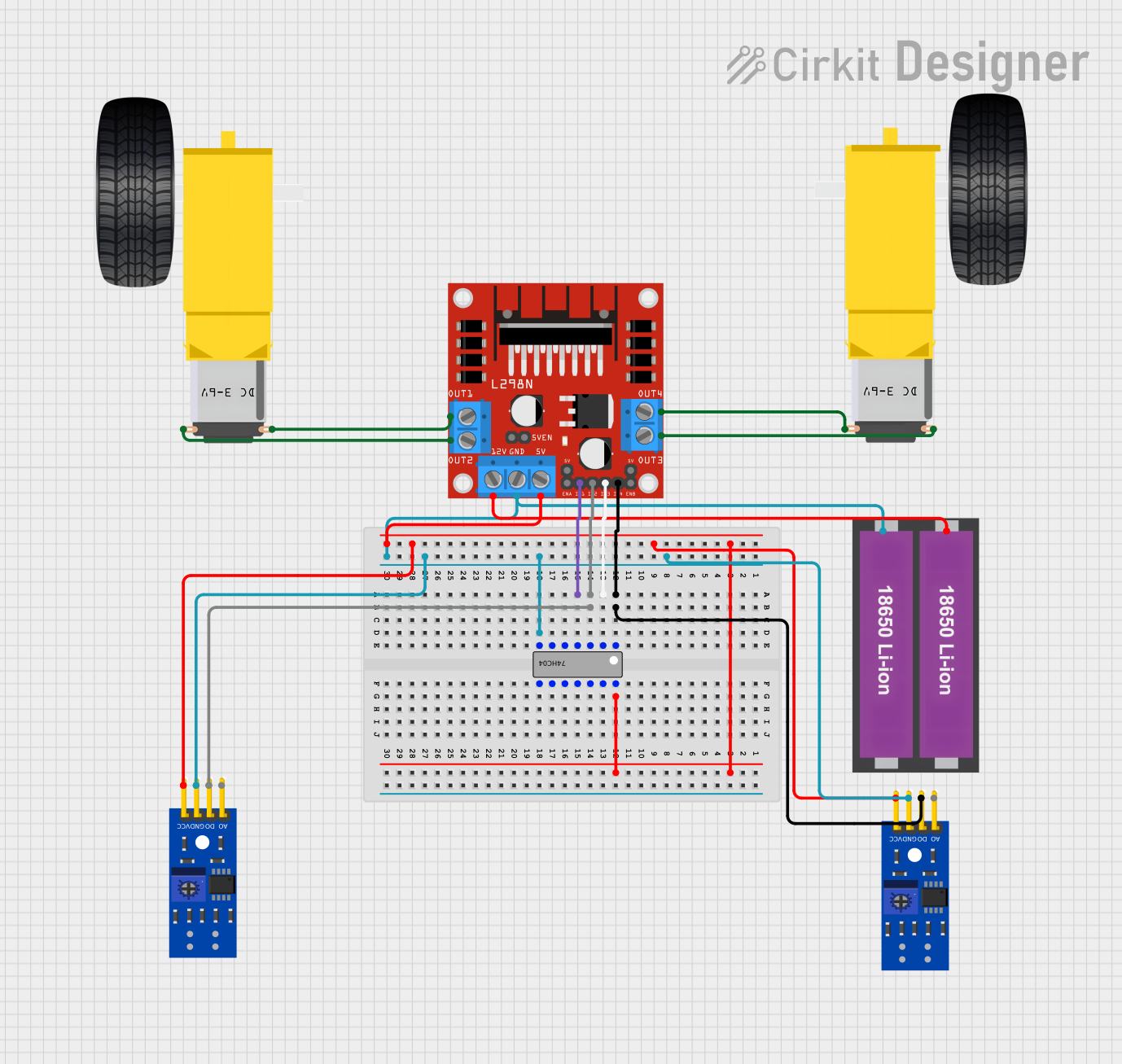

Explore Projects Built with 28BYJ-48 Motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 28BYJ-48 Motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

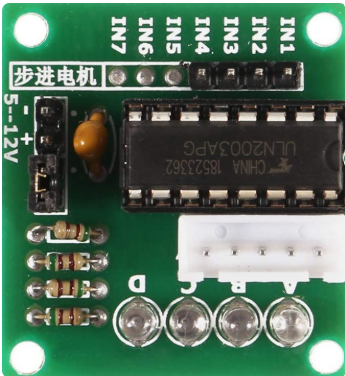

The 28BYJ-48 Motor Driver is often based on the ULN2003 Darlington transistor array, which provides the necessary current amplification to drive the stepper motor. Below are the key technical details:

Key Specifications

| Parameter | Value |

|---|---|

| Operating Voltage | 5V DC |

| Maximum Output Current | 500 mA per channel |

| Number of Output Channels | 4 |

| Step Resolution | Full-step and Half-step modes |

| Compatible Motor | 28BYJ-48 Stepper Motor |

| Dimensions | ~31mm x 35mm |

Pin Configuration and Descriptions

The 28BYJ-48 Motor Driver typically has a 10-pin header for motor and power connections. Below is the pinout:

| Pin Number | Label | Description |

|---|---|---|

| 1 | IN1 | Input signal for coil A |

| 2 | IN2 | Input signal for coil B |

| 3 | IN3 | Input signal for coil C |

| 4 | IN4 | Input signal for coil D |

| 5 | VCC | Power supply input (5V DC) |

| 6 | GND | Ground connection |

| 7-10 | Motor Pins | Connects to the 28BYJ-48 stepper motor coils |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect the VCC pin to a 5V DC power source and the GND pin to the ground.

- Motor Connection: Attach the 4-pin connector of the 28BYJ-48 stepper motor to the motor pins on the driver module.

- Microcontroller Interface: Connect the IN1, IN2, IN3, and IN4 pins to the digital output pins of a microcontroller (e.g., Arduino).

- Programming: Use a stepper motor library or write custom code to control the motor's steps and direction.

Important Considerations and Best Practices

- Power Supply: Ensure the power supply can provide sufficient current for the motor and driver.

- Heat Dissipation: Avoid prolonged operation at high currents to prevent overheating.

- Step Sequence: Use the correct step sequence (full-step or half-step) to avoid motor misalignment.

- Decoupling Capacitor: Add a decoupling capacitor (e.g., 100 µF) across the VCC and GND pins to stabilize the power supply.

Example Code for Arduino UNO

Below is an example code to control the 28BYJ-48 stepper motor using the Arduino UNO:

#include <Stepper.h>

// Define the number of steps per revolution for the 28BYJ-48 motor

#define STEPS_PER_REV 2048

// Initialize the Stepper library with the motor's step sequence pins

Stepper stepper(STEPS_PER_REV, 8, 10, 9, 11);

void setup() {

// Set the motor speed (in RPM)

stepper.setSpeed(10); // 10 RPM

Serial.begin(9600);

Serial.println("28BYJ-48 Stepper Motor Test");

}

void loop() {

// Rotate the motor 1 revolution clockwise

Serial.println("Rotating clockwise...");

stepper.step(STEPS_PER_REV);

delay(1000); // Wait for 1 second

// Rotate the motor 1 revolution counterclockwise

Serial.println("Rotating counterclockwise...");

stepper.step(-STEPS_PER_REV);

delay(1000); // Wait for 1 second

}

Note: Ensure the pins in the Stepper constructor match the connections to the motor driver (e.g., pins 8, 10, 9, and 11 in this example).

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Moving:

- Cause: Incorrect wiring or loose connections.

- Solution: Double-check all connections between the motor, driver, and microcontroller.

Motor Vibrates but Does Not Rotate:

- Cause: Incorrect step sequence or insufficient power supply.

- Solution: Verify the step sequence in the code and ensure the power supply provides adequate current.

Overheating Driver:

- Cause: Prolonged operation at high current.

- Solution: Reduce the motor speed or add a heat sink to the driver.

Erratic Motor Movement:

- Cause: Electrical noise or unstable power supply.

- Solution: Add a decoupling capacitor across the VCC and GND pins.

FAQs

Q: Can I use a 12V power supply with the 28BYJ-48 Motor Driver?

A: No, the driver is designed for 5V operation. Using a higher voltage may damage the driver or motor.Q: How do I increase the torque of the 28BYJ-48 motor?

A: You can increase the torque by reducing the motor speed or using a higher current-rated driver.Q: Can I control multiple motors with one Arduino?

A: Yes, you can control multiple motors by using additional motor drivers and assigning separate pins for each driver.

This documentation provides a comprehensive guide to using the 28BYJ-48 Motor Driver effectively in your projects.