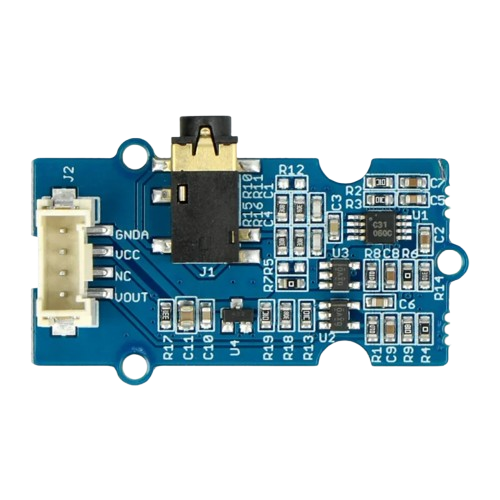

How to Use Groove EMG Sensor: Examples, Pinouts, and Specs

Design with Groove EMG Sensor in Cirkit Designer

Design with Groove EMG Sensor in Cirkit DesignerIntroduction

The Groove EMG Sensor is a specialized electronic component designed to detect the electrical activity generated by skeletal muscles. By measuring the electromyographic (EMG) signals, this sensor enables the monitoring of muscle contractions and movements. It is widely used in applications such as prosthetics, robotics, medical diagnostics, and human-computer interaction systems.

Common use cases include:

- Monitoring muscle activity for rehabilitation or fitness tracking

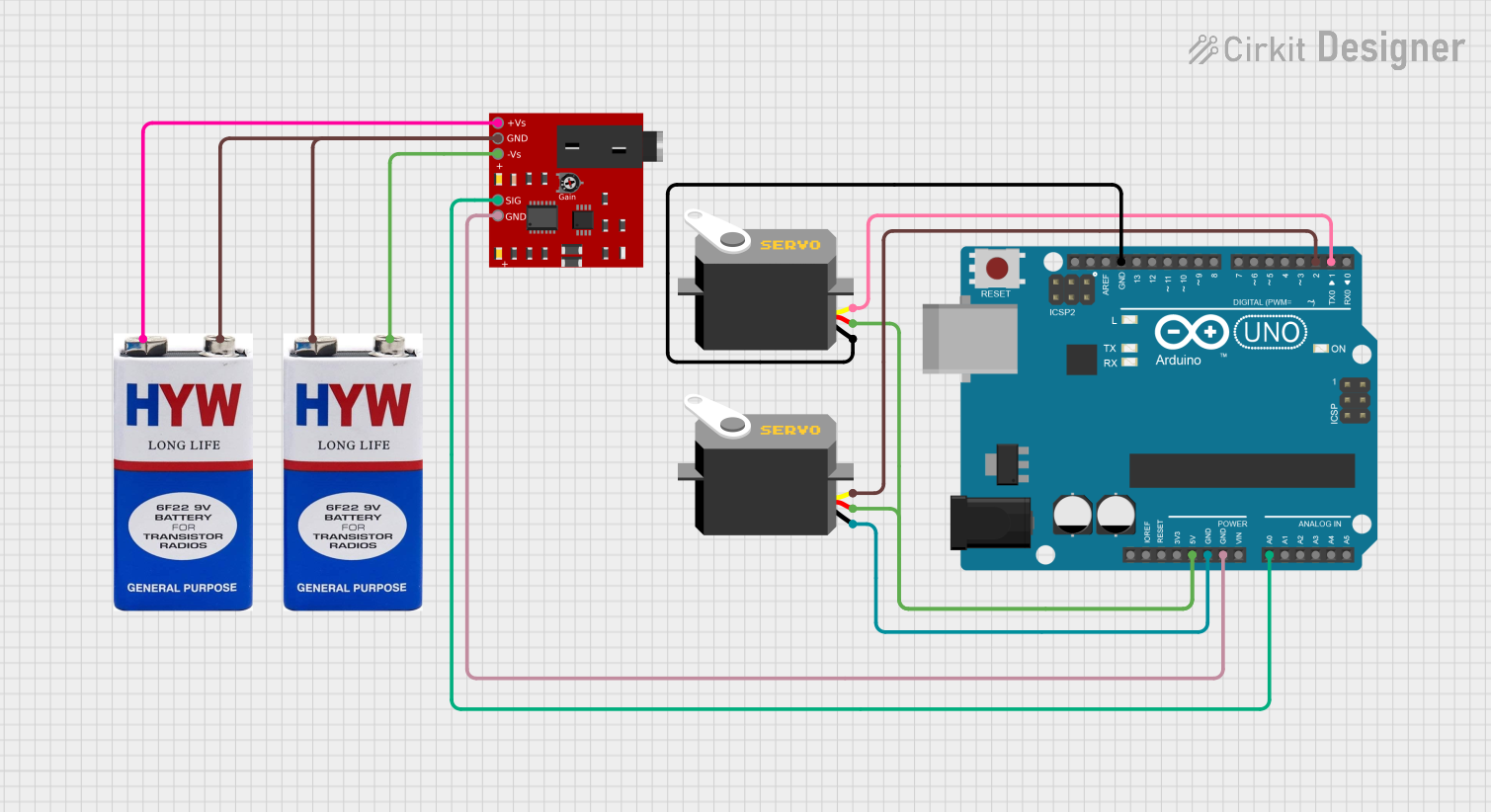

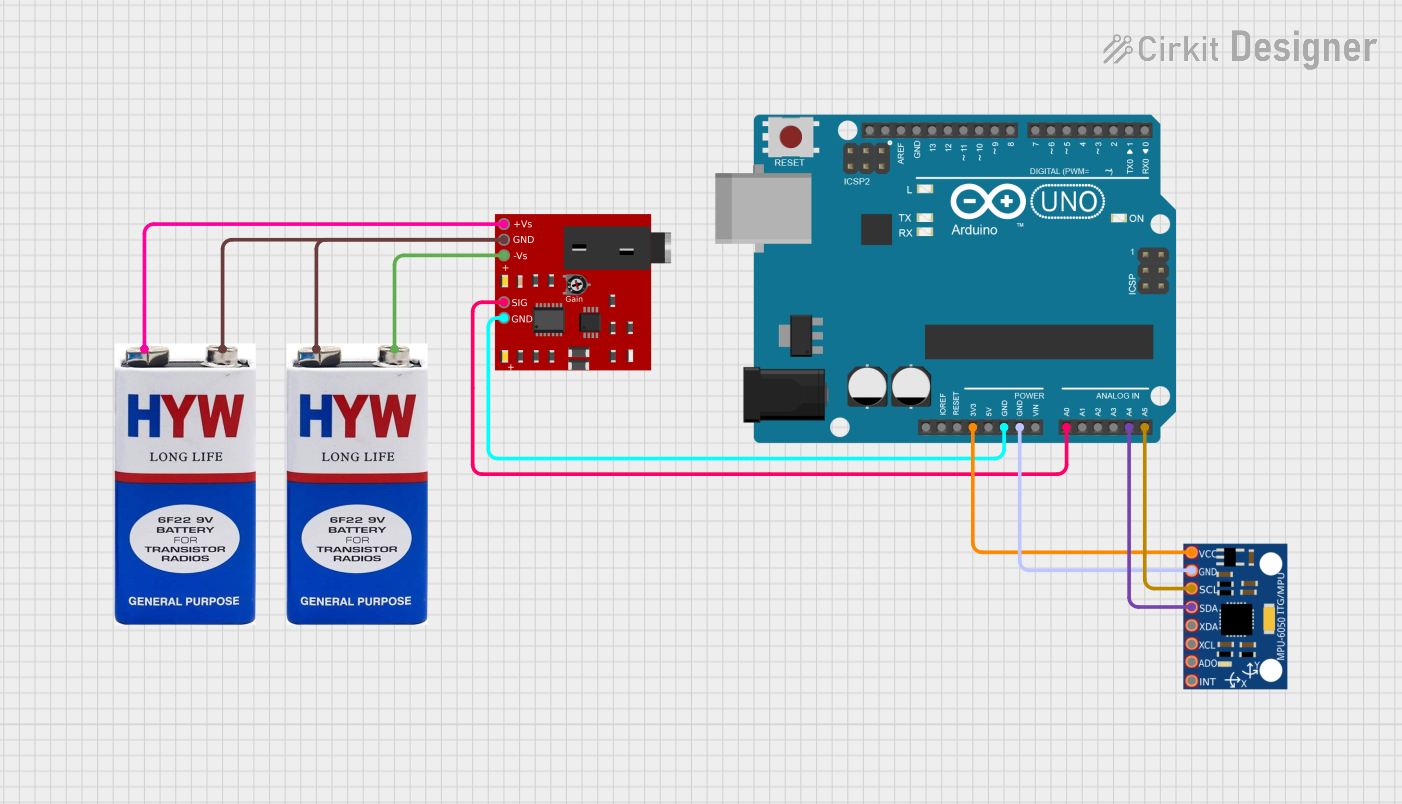

- Controlling robotic systems or prosthetic devices

- Gesture recognition for gaming or virtual reality

- Research in biomechanics and neuromuscular studies

Explore Projects Built with Groove EMG Sensor

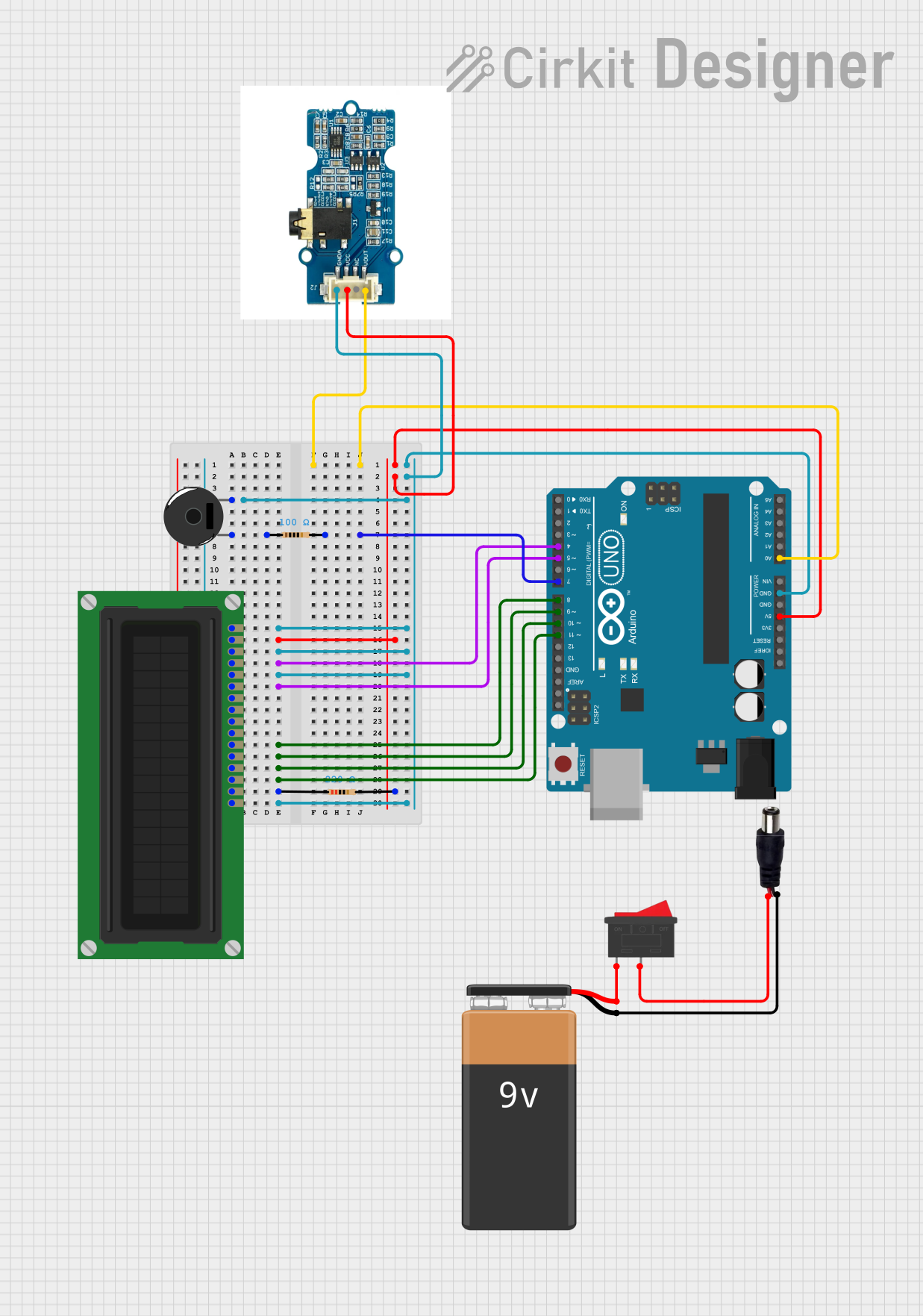

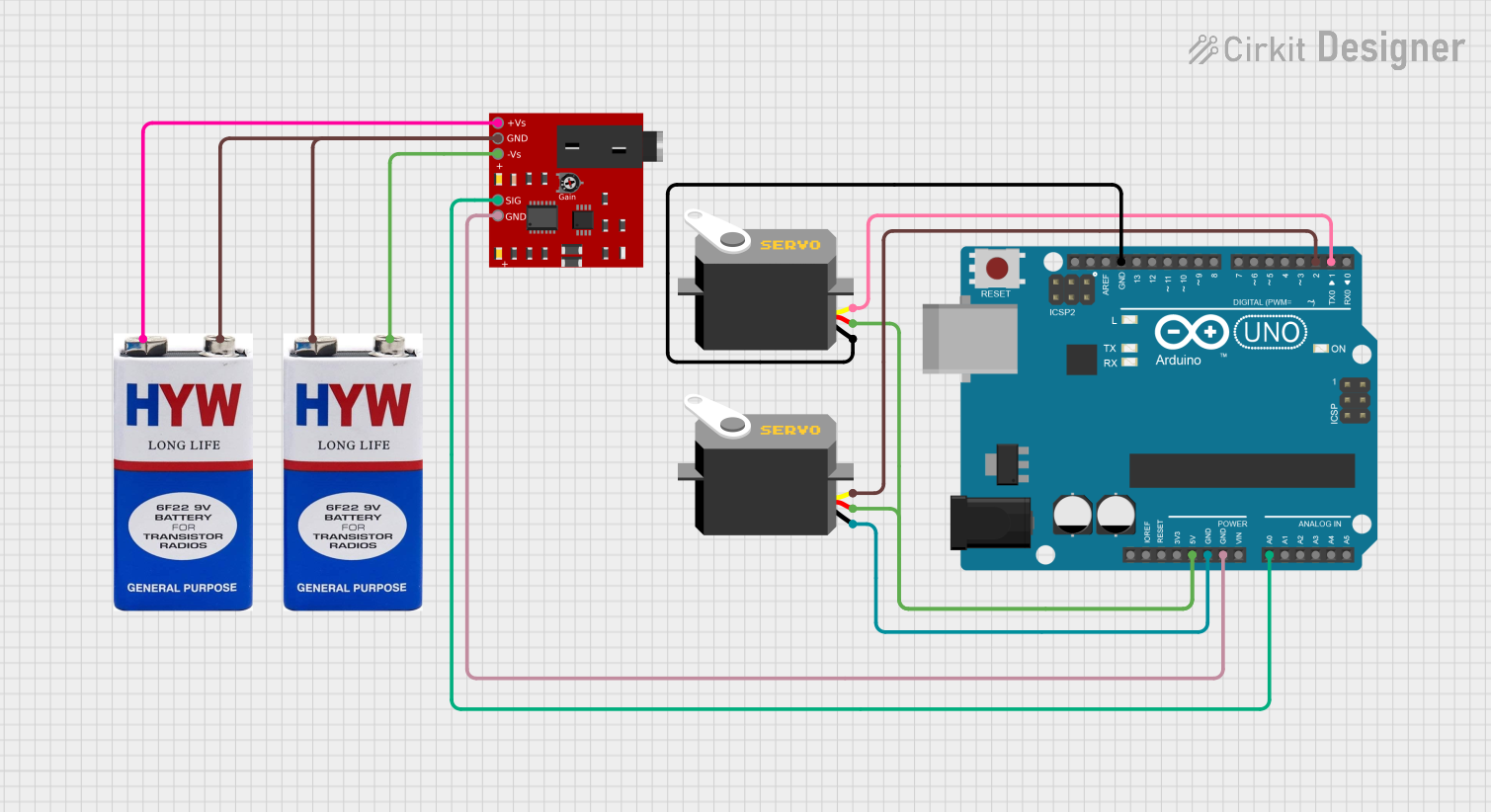

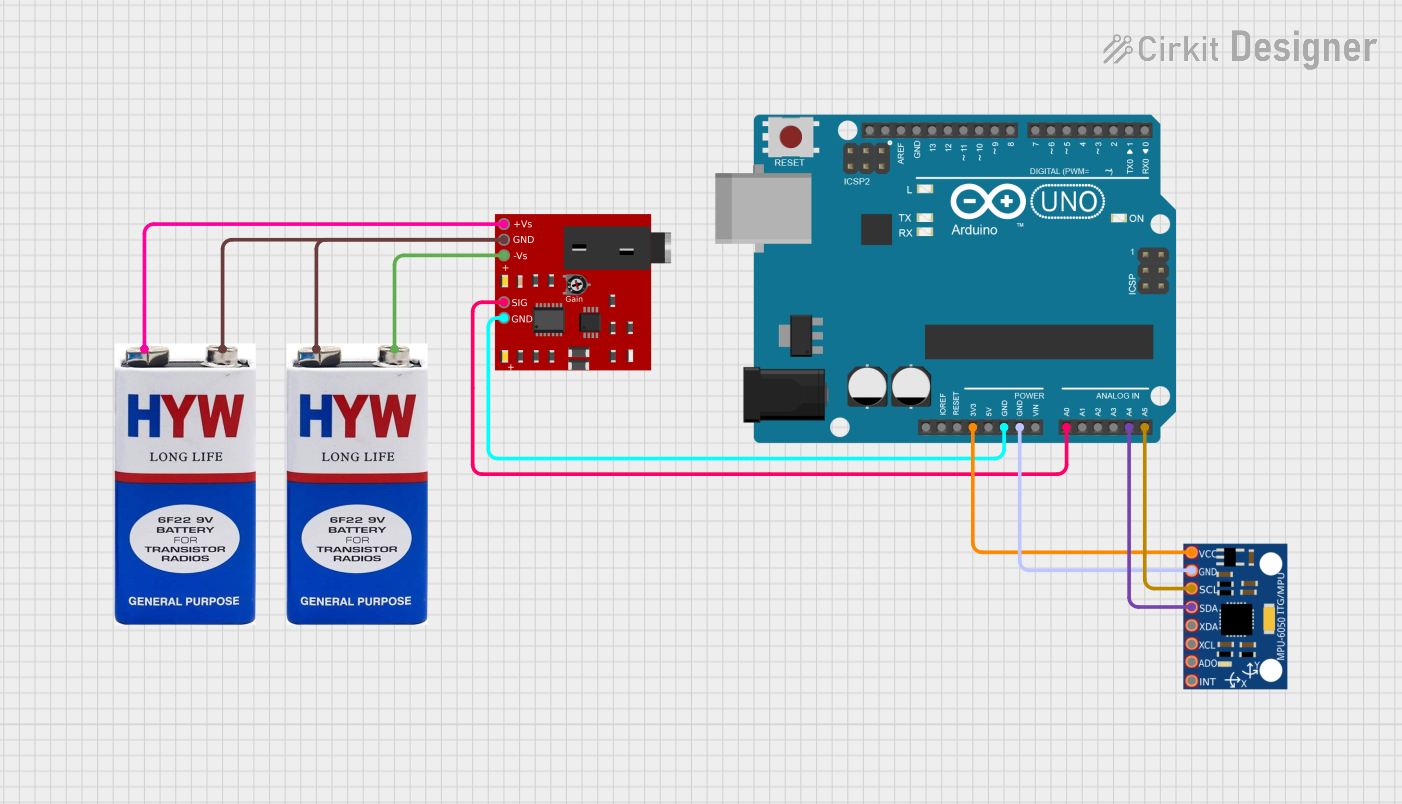

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Groove EMG Sensor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

The Groove EMG Sensor is designed for ease of use and compatibility with microcontrollers like Arduino. Below are its key technical details:

| Parameter | Value |

|---|---|

| Operating Voltage | 3.3V to 5V |

| Operating Current | < 10mA |

| Output Signal Range | 0.3V to 1.5V (depending on muscle activity) |

| Gain | Adjustable (default: 1000x) |

| Interface Type | Analog |

| Dimensions | 40mm x 20mm x 10mm |

Pin Configuration and Descriptions

The Groove EMG Sensor has a 4-pin interface for easy connection. The pinout is as follows:

| Pin | Name | Description |

|---|---|---|

| 1 | VCC | Power supply pin (3.3V to 5V) |

| 2 | GND | Ground connection |

| 3 | SIG | Analog output signal representing muscle activity |

| 4 | NC | Not connected (reserved for future use) |

Usage Instructions

Connecting the Groove EMG Sensor

- Power Supply: Connect the

VCCpin to a 3.3V or 5V power source and theGNDpin to the ground of your circuit. - Signal Output: Connect the

SIGpin to an analog input pin on your microcontroller (e.g., Arduino). - Electrode Placement: Attach the included electrodes to the muscle area you want to monitor. Ensure proper skin contact for accurate readings.

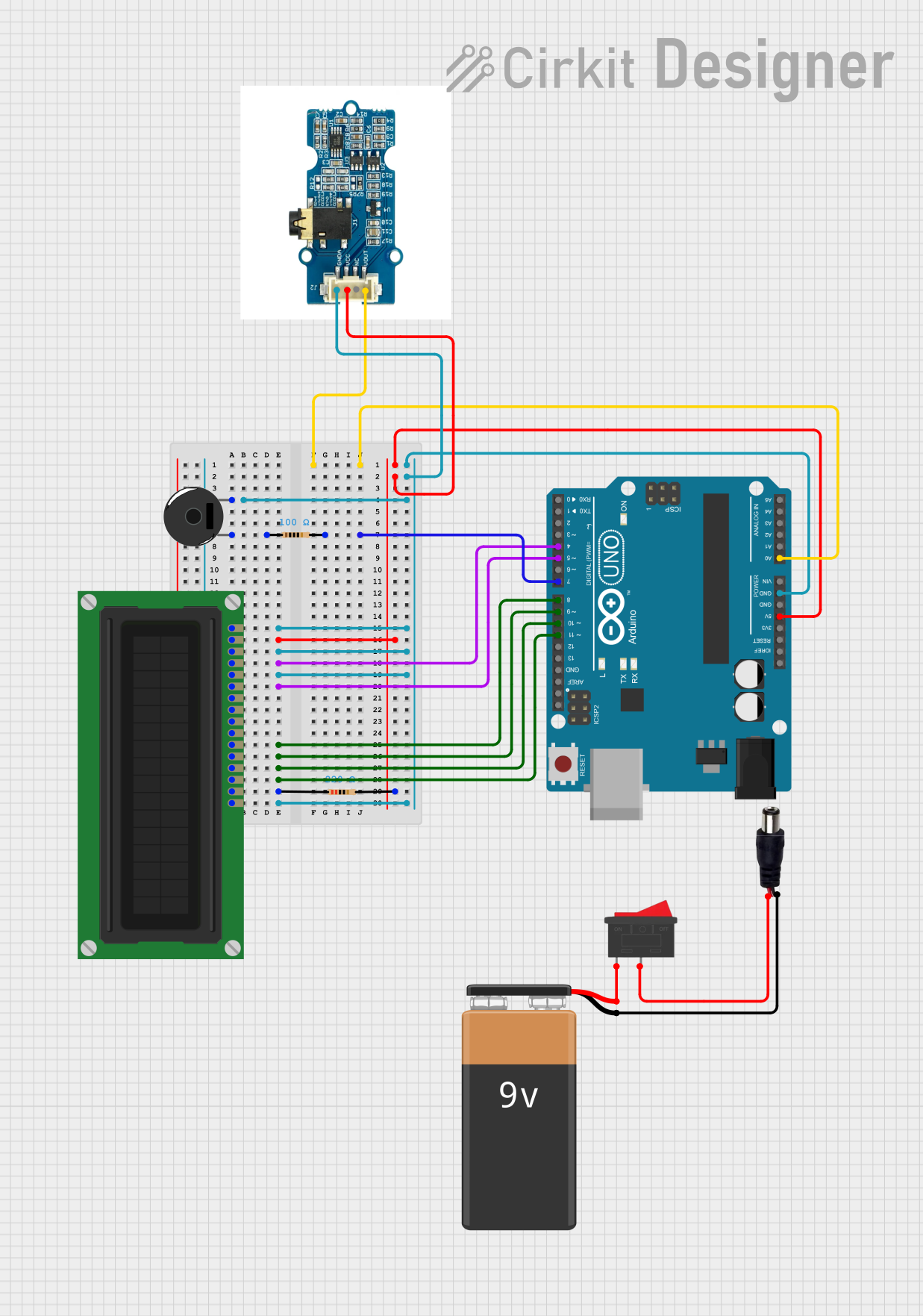

Example Circuit

Below is an example of how to connect the Groove EMG Sensor to an Arduino UNO:

VCC→ 5V pin on ArduinoGND→ GND pin on ArduinoSIG→ A0 (analog input pin) on Arduino

Sample Arduino Code

The following code reads the EMG signal and outputs the values to the Serial Monitor:

// Groove EMG Sensor Example Code

// Connect SIG to A0, VCC to 5V, and GND to GND on Arduino UNO

const int emgPin = A0; // Analog pin connected to SIG

int emgValue = 0; // Variable to store the EMG signal value

void setup() {

Serial.begin(9600); // Initialize serial communication at 9600 baud

pinMode(emgPin, INPUT); // Set the EMG pin as input

}

void loop() {

emgValue = analogRead(emgPin); // Read the analog value from the sensor

Serial.print("EMG Signal: "); // Print label for clarity

Serial.println(emgValue); // Print the EMG signal value

delay(100); // Delay for stability (adjust as needed)

}

Best Practices

- Ensure the skin is clean and dry before attaching electrodes to improve signal quality.

- Avoid placing electrodes near joints or bony areas for better readings.

- Use shielded cables to minimize noise interference in the signal.

- Calibrate the sensor gain if necessary to match your application requirements.

Troubleshooting and FAQs

Common Issues and Solutions

No Signal Detected:

- Ensure the electrodes are properly attached to the skin.

- Verify that the sensor is powered correctly (check VCC and GND connections).

- Check the analog input pin connection to the microcontroller.

Noisy or Unstable Readings:

- Ensure good skin contact and clean the skin before attaching electrodes.

- Use shorter or shielded cables to reduce electrical noise.

- Place the sensor away from high-frequency noise sources (e.g., motors).

Low Signal Amplitude:

- Adjust the gain setting on the sensor if possible.

- Reposition the electrodes closer to the muscle of interest.

FAQs

Q: Can the Groove EMG Sensor be used with a 3.3V microcontroller?

A: Yes, the sensor operates within a voltage range of 3.3V to 5V, making it compatible with 3.3V systems like the ESP32.

Q: How do I clean the electrodes?

A: Use a damp cloth with mild soap to clean reusable electrodes. For disposable electrodes, replace them after each use.

Q: Can this sensor measure heart activity (ECG)?

A: No, the Groove EMG Sensor is specifically designed for muscle activity detection and is not suitable for ECG applications.

Q: What is the maximum distance between the sensor and the electrodes?

A: For best results, keep the distance as short as possible (less than 1 meter) to minimize signal degradation.

By following this documentation, you can effectively integrate the Groove EMG Sensor into your projects and achieve reliable results.