How to Use TB6600: Examples, Pinouts, and Specs

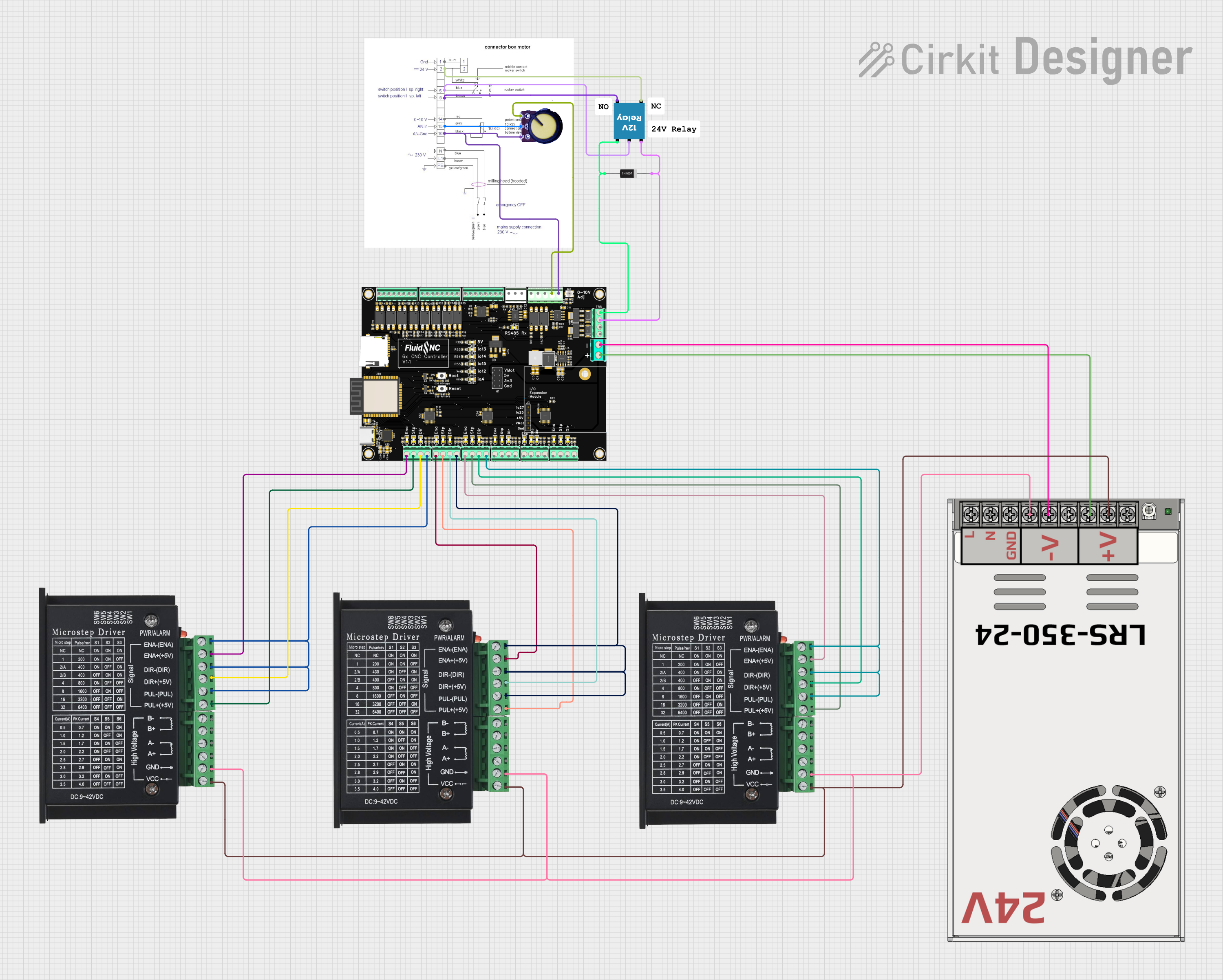

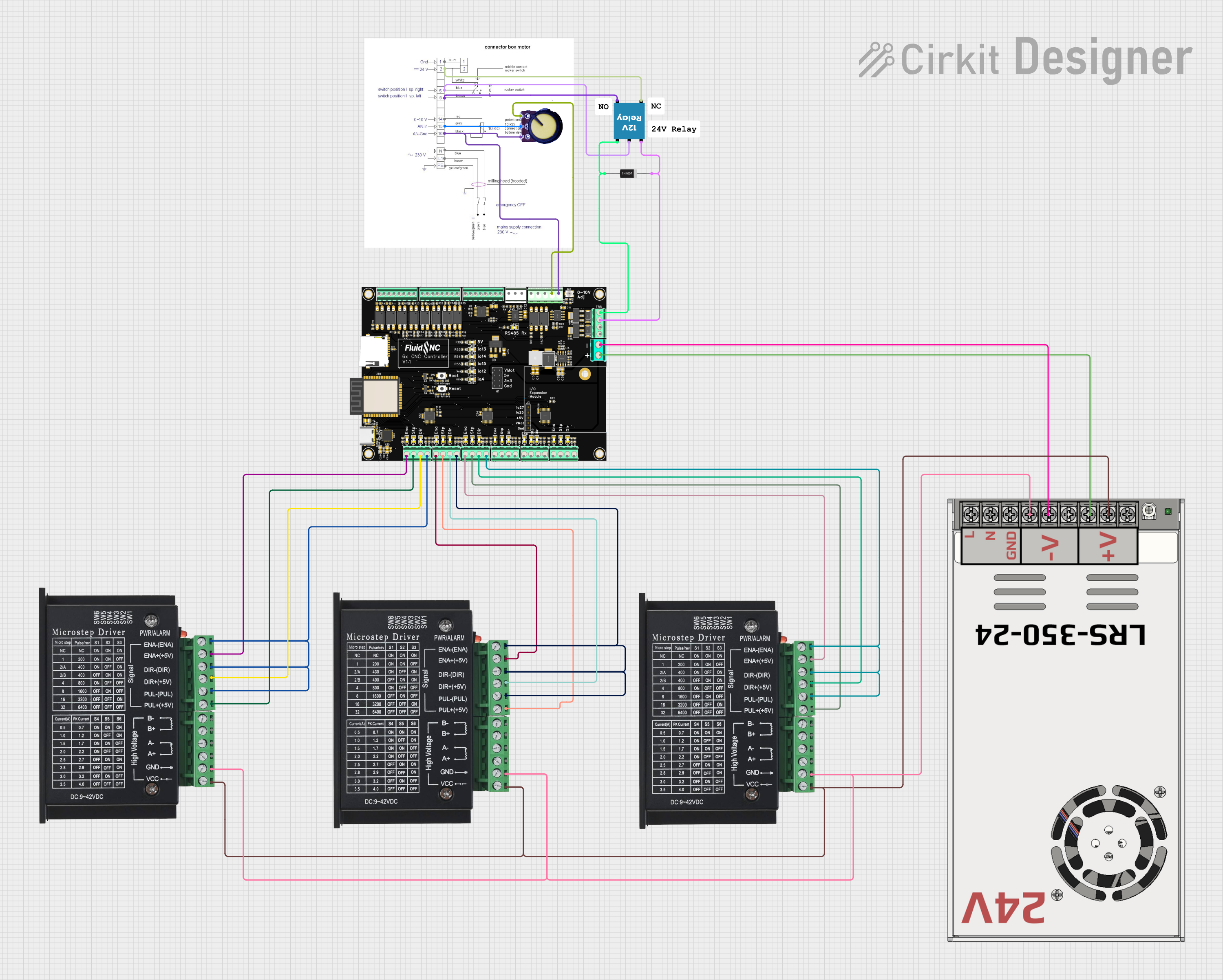

Design with TB6600 in Cirkit Designer

Design with TB6600 in Cirkit DesignerIntroduction

The TB6600 is a high-performance microstepping driver designed for bipolar stepper motors. It is capable of driving motors with a current rating of up to 4.5A, making it suitable for demanding applications. The driver supports adjustable current control, multiple microstepping options, and includes built-in protection features such as overcurrent and overheating safeguards. These features make the TB6600 a popular choice for CNC machines, 3D printers, robotics, and other precision motion control systems.

Explore Projects Built with TB6600

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with TB6600

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- CNC machines for precise motion control

- 3D printers for accurate layer positioning

- Robotics for stepper motor actuation

- Automated machinery and conveyor systems

- DIY projects requiring stepper motor control

Technical Specifications

The TB6600 offers robust performance and flexibility for stepper motor control. Below are its key technical details:

Key Specifications

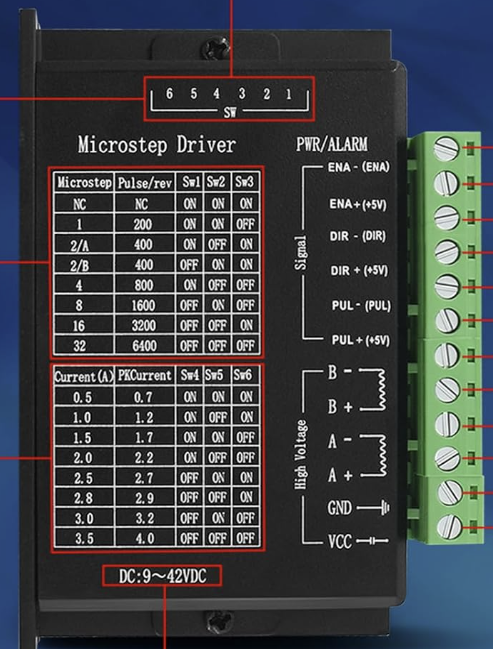

| Parameter | Value |

|---|---|

| Input Voltage Range | 9V to 42V DC |

| Maximum Output Current | 4.5A |

| Microstepping Options | Full, 1/2, 1/4, 1/8, 1/16 |

| Control Signal Voltage | 3.3V to 5V |

| Operating Temperature | -10°C to +45°C |

| Protection Features | Overcurrent, Overheating |

Pin Configuration and Descriptions

The TB6600 driver typically has the following pin configuration:

Input Pins

| Pin Name | Description |

|---|---|

| PUL+ | Pulse signal input (positive terminal) |

| PUL- | Pulse signal input (negative terminal) |

| DIR+ | Direction signal input (positive terminal) |

| DIR- | Direction signal input (negative terminal) |

| ENA+ | Enable signal input (positive terminal) (optional, used to enable/disable) |

| ENA- | Enable signal input (negative terminal) |

Output Pins

| Pin Name | Description |

|---|---|

| A+ | Stepper motor coil A positive terminal |

| A- | Stepper motor coil A negative terminal |

| B+ | Stepper motor coil B positive terminal |

| B- | Stepper motor coil B negative terminal |

Power Pins

| Pin Name | Description |

|---|---|

| VCC | Power supply input (9V to 42V DC) |

| GND | Ground connection |

Usage Instructions

How to Use the TB6600 in a Circuit

Connect the Power Supply:

- Connect a DC power supply (9V to 42V) to the VCC and GND pins of the TB6600.

- Ensure the power supply can provide sufficient current for the stepper motor.

Connect the Stepper Motor:

- Connect the stepper motor's coil wires to the A+, A-, B+, and B- output pins.

- Refer to the motor's datasheet to identify the correct coil pairs.

Connect Control Signals:

- Connect the PUL+, DIR+, and ENA+ pins to the control signals from a microcontroller (e.g., Arduino).

- Connect the PUL-, DIR-, and ENA- pins to the ground of the microcontroller.

Set Microstepping and Current:

- Use the DIP switches on the TB6600 to configure the desired microstepping mode and current limit.

- Refer to the TB6600 datasheet for the DIP switch settings.

Test the Setup:

- Power on the system and send pulse and direction signals from the microcontroller to control the motor.

Important Considerations

- Heat Dissipation: The TB6600 can generate significant heat during operation. Use a heatsink or active cooling to prevent overheating.

- Current Settings: Set the current limit to match the stepper motor's rated current to avoid damage.

- Signal Voltage: Ensure the control signals from the microcontroller are within the 3.3V to 5V range.

Example: Using the TB6600 with Arduino UNO

Below is an example Arduino sketch to control a stepper motor using the TB6600:

// Define control pins for the TB6600

const int pulsePin = 3; // Pin connected to PUL+ on TB6600

const int dirPin = 4; // Pin connected to DIR+ on TB6600

const int enablePin = 5; // Pin connected to ENA+ on TB6600

void setup() {

// Set control pins as outputs

pinMode(pulsePin, OUTPUT);

pinMode(dirPin, OUTPUT);

pinMode(enablePin, OUTPUT);

// Enable the driver

digitalWrite(enablePin, LOW); // LOW enables the driver

}

void loop() {

// Set direction

digitalWrite(dirPin, HIGH); // HIGH for one direction, LOW for the other

// Generate pulses to move the motor

for (int i = 0; i < 200; i++) { // 200 steps for one revolution (example)

digitalWrite(pulsePin, HIGH); // Send a HIGH pulse

delayMicroseconds(500); // Pulse duration (adjust for speed)

digitalWrite(pulsePin, LOW); // Send a LOW pulse

delayMicroseconds(500); // Delay between pulses

}

delay(1000); // Wait 1 second before reversing direction

// Reverse direction

digitalWrite(dirPin, LOW);

for (int i = 0; i < 200; i++) {

digitalWrite(pulsePin, HIGH);

delayMicroseconds(500);

digitalWrite(pulsePin, LOW);

delayMicroseconds(500);

}

delay(1000); // Wait 1 second before repeating

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Moving:

- Cause: Incorrect wiring or insufficient power supply.

- Solution: Double-check all connections and ensure the power supply meets the voltage and current requirements.

Motor Vibrates but Does Not Rotate:

- Cause: Incorrect coil wiring.

- Solution: Verify the stepper motor's coil pairs and ensure they are connected correctly to the A+/A- and B+/B- pins.

Driver Overheating:

- Cause: Excessive current or poor heat dissipation.

- Solution: Reduce the current setting using the DIP switches and add a heatsink or fan.

Stepper Motor Skipping Steps:

- Cause: Insufficient current or incorrect microstepping settings.

- Solution: Increase the current setting and verify the microstepping configuration.

No Response from the Driver:

- Cause: Control signals not reaching the driver.

- Solution: Check the microcontroller's output pins and ensure proper signal levels (3.3V to 5V).

FAQs

Q1: Can the TB6600 drive unipolar stepper motors?

A1: No, the TB6600 is designed for bipolar stepper motors only.

Q2: What is the maximum step frequency supported by the TB6600?

A2: The TB6600 supports a maximum step frequency of approximately 200 kHz.

Q3: Can I use the TB6600 with a 12V power supply?

A3: Yes, the TB6600 supports input voltages from 9V to 42V, so a 12V power supply is compatible.

Q4: How do I select the correct microstepping mode?

A4: Use the DIP switches on the TB6600 to configure the microstepping mode. Refer to the datasheet for the switch settings.

Q5: Is the ENA+ pin mandatory for operation?

A5: No, the ENA+ pin is optional. If not used, leave it unconnected or tied to the ground.