How to Use DRV8825: Examples, Pinouts, and Specs

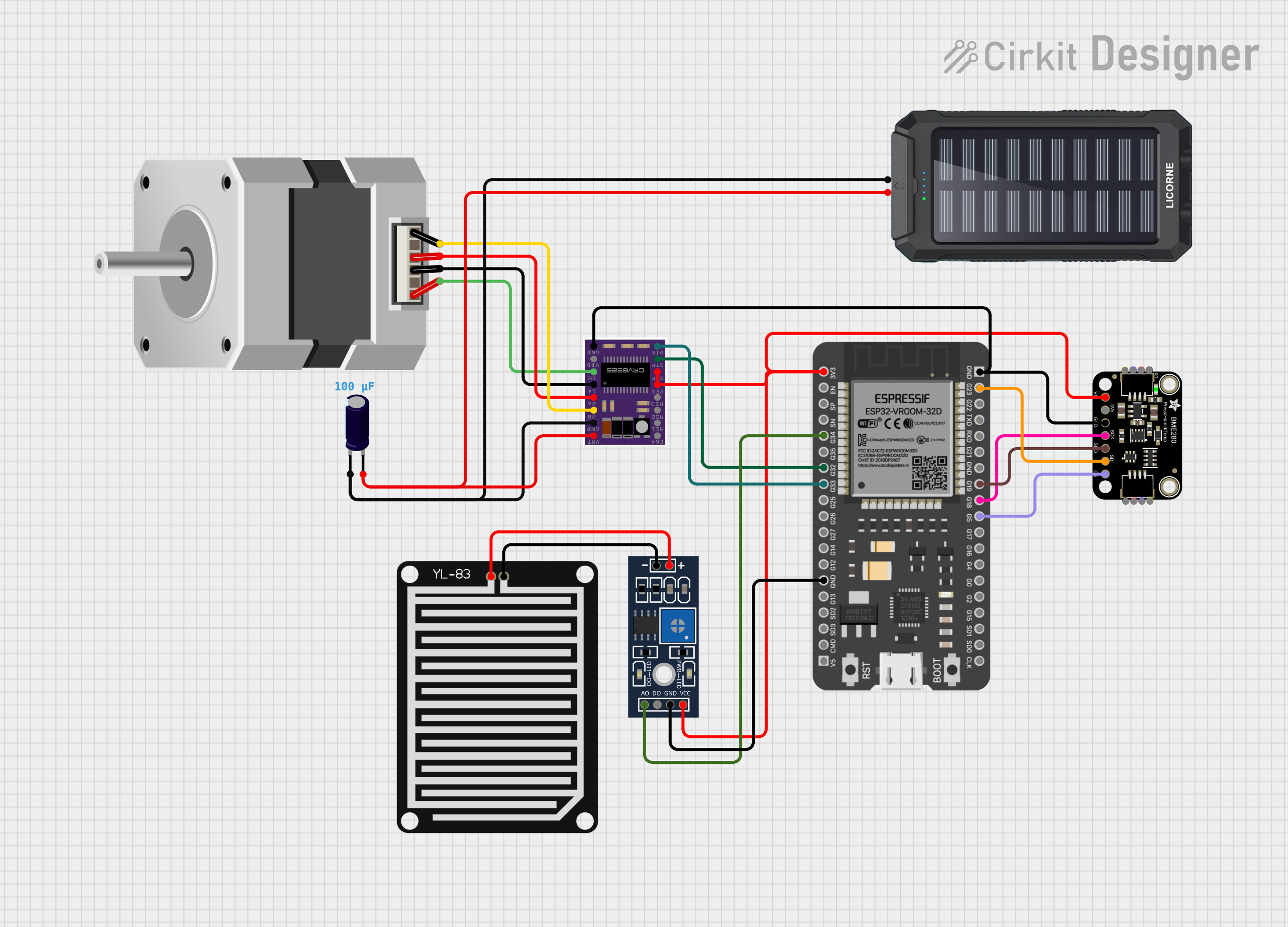

Design with DRV8825 in Cirkit Designer

Design with DRV8825 in Cirkit DesignerIntroduction

The DRV8825 is a versatile microstepping driver for controlling bipolar stepper motors. With its adjustable current limiting, built-in over-current and over-temperature protection, and six microstep resolutions, it is suitable for a wide range of applications, including 3D printers, CNC machines, and robotics.

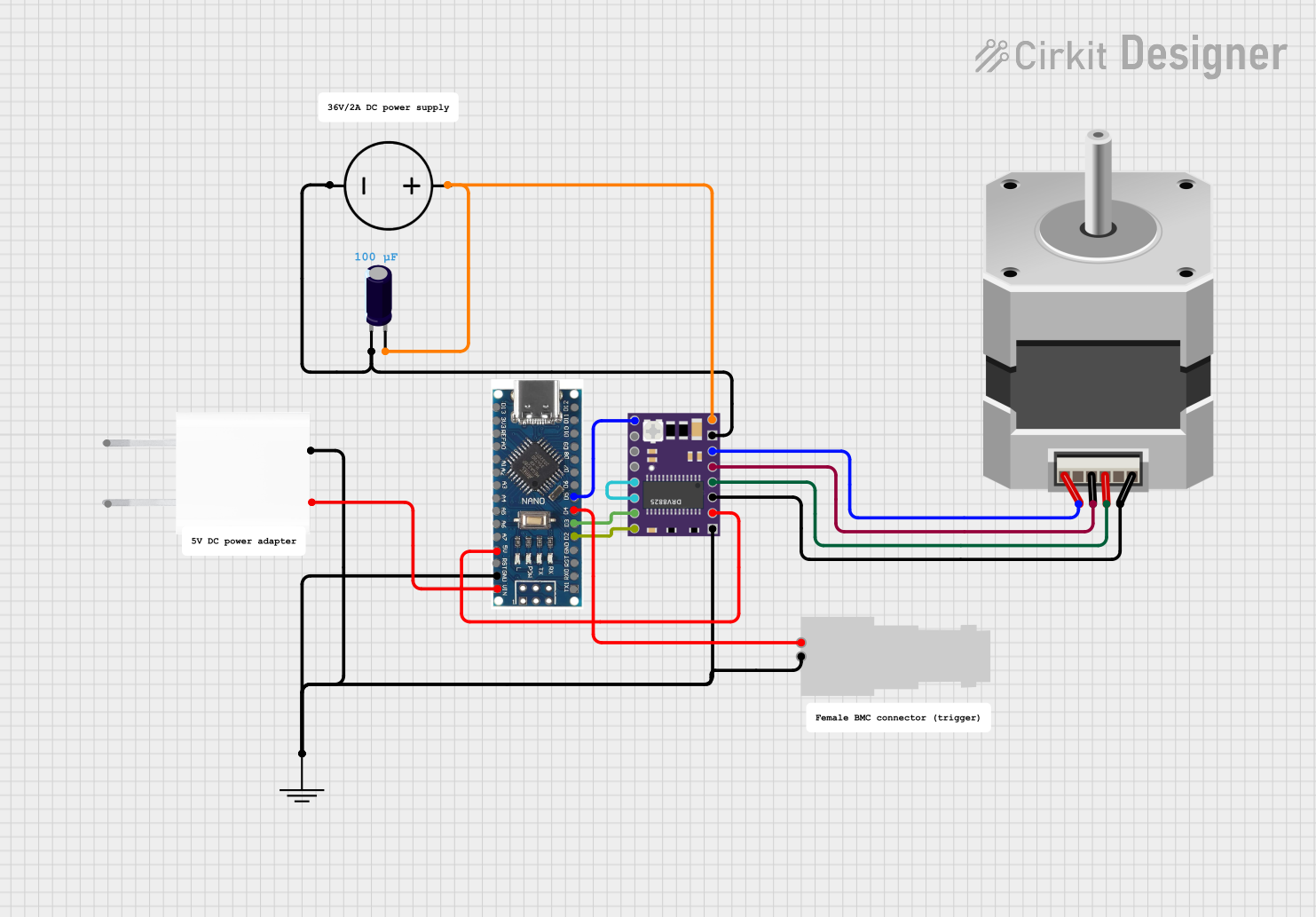

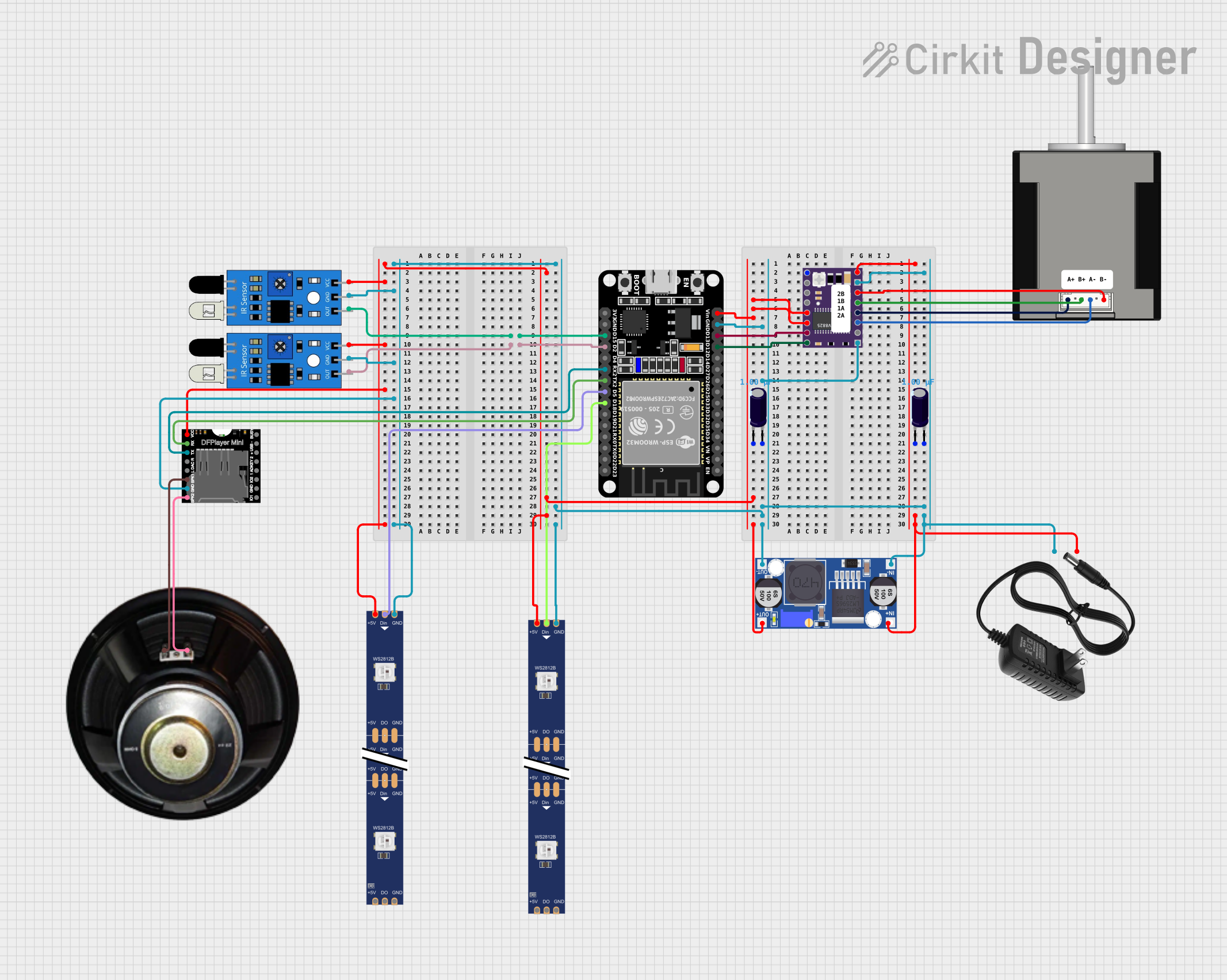

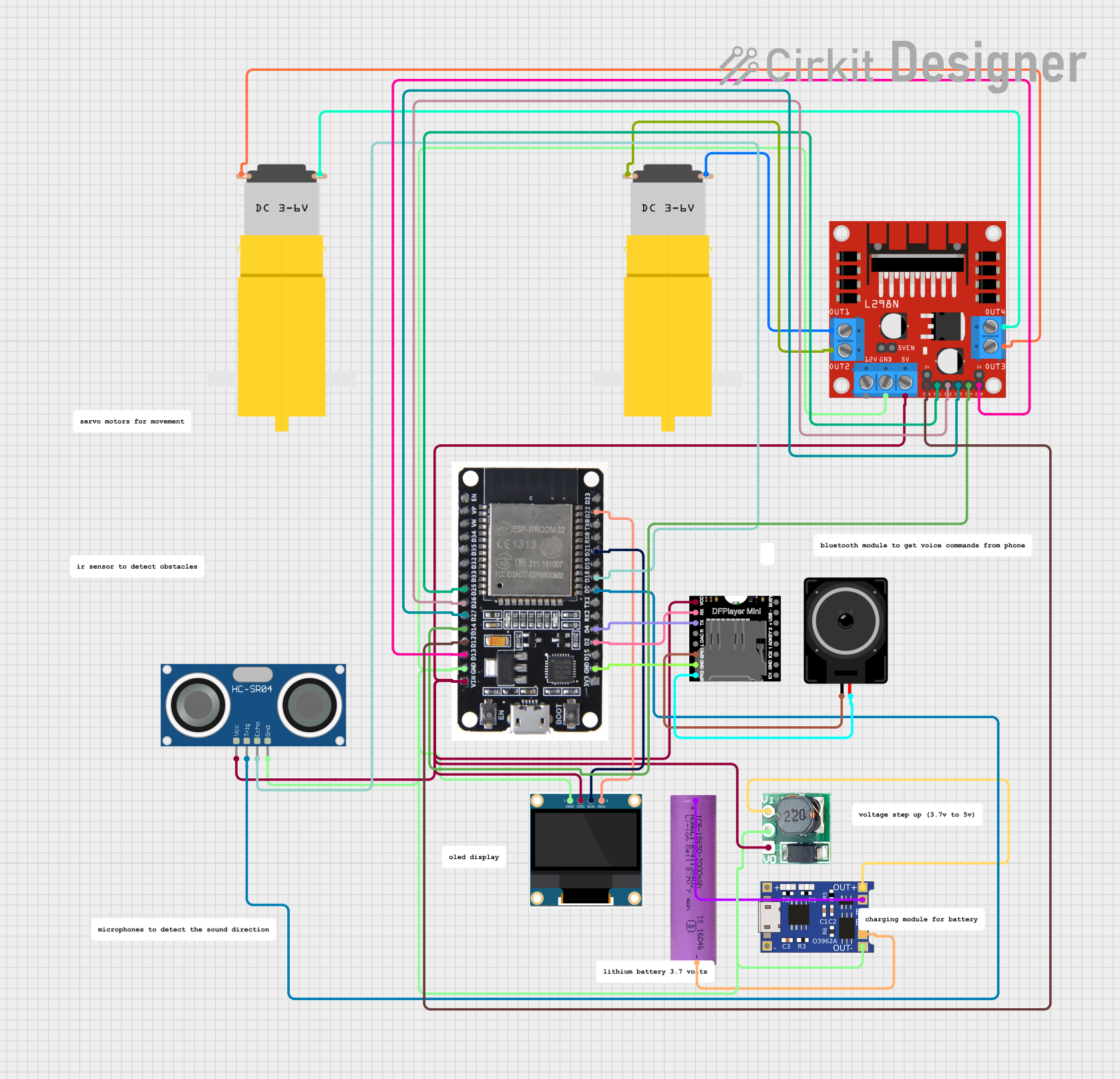

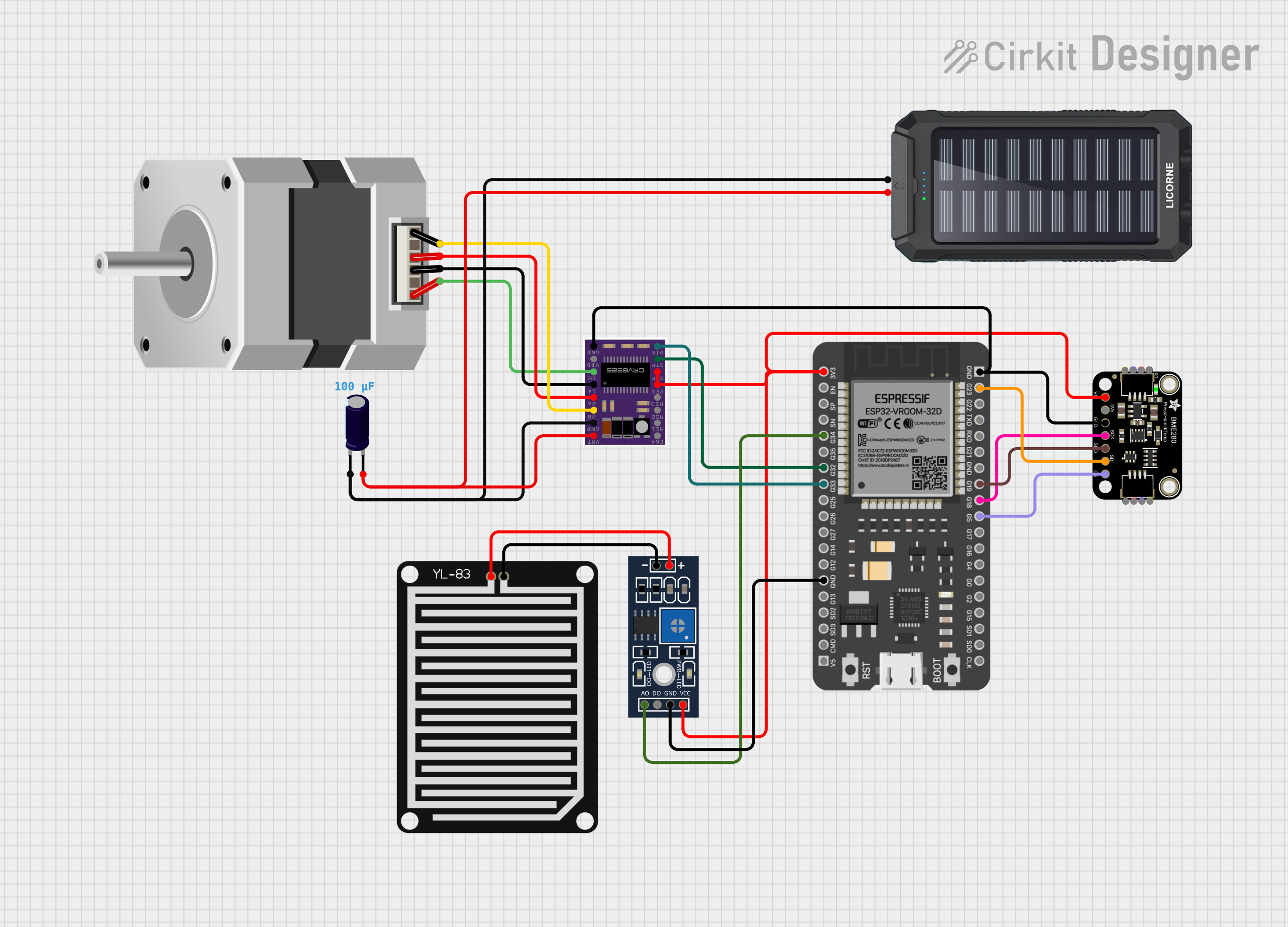

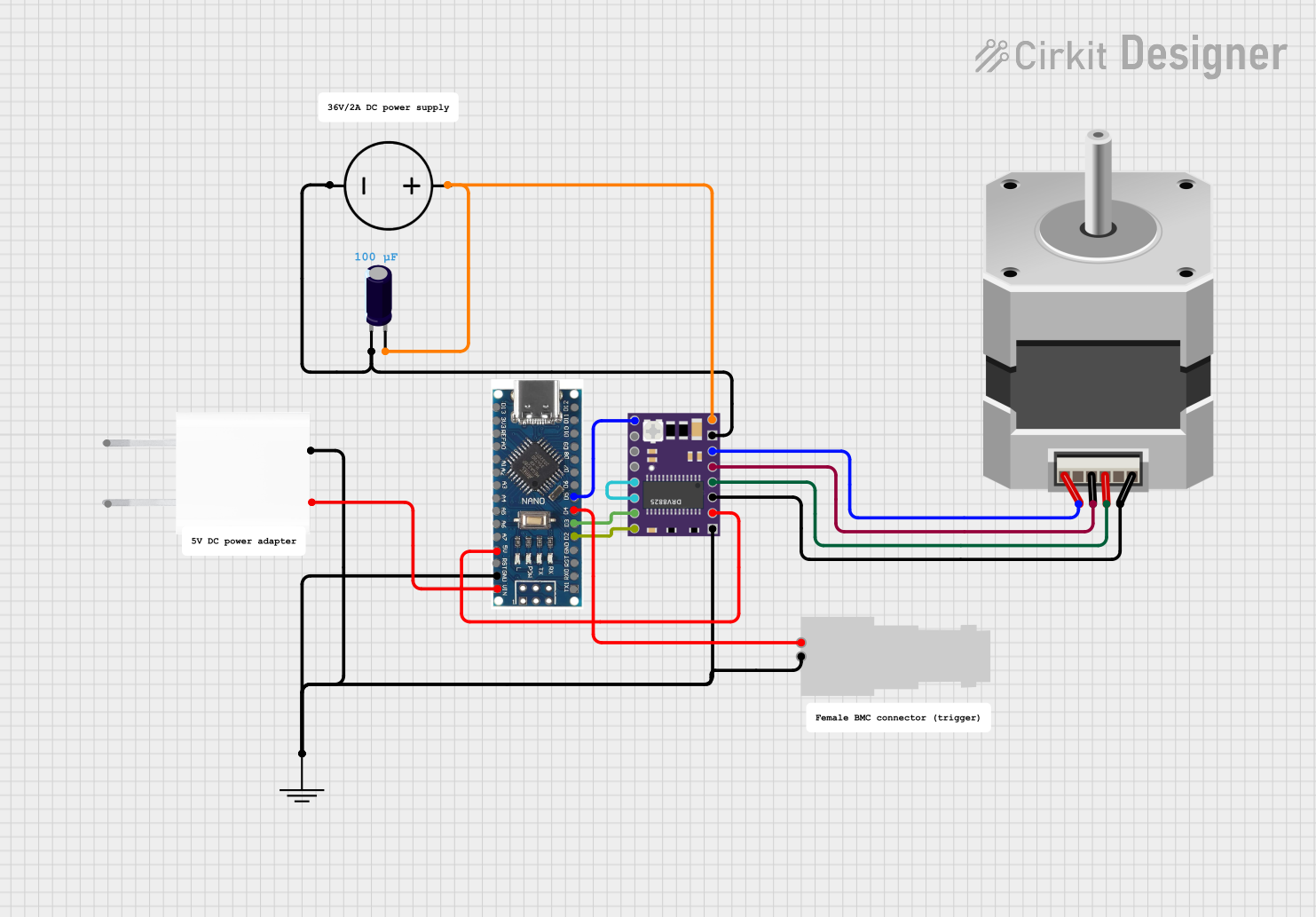

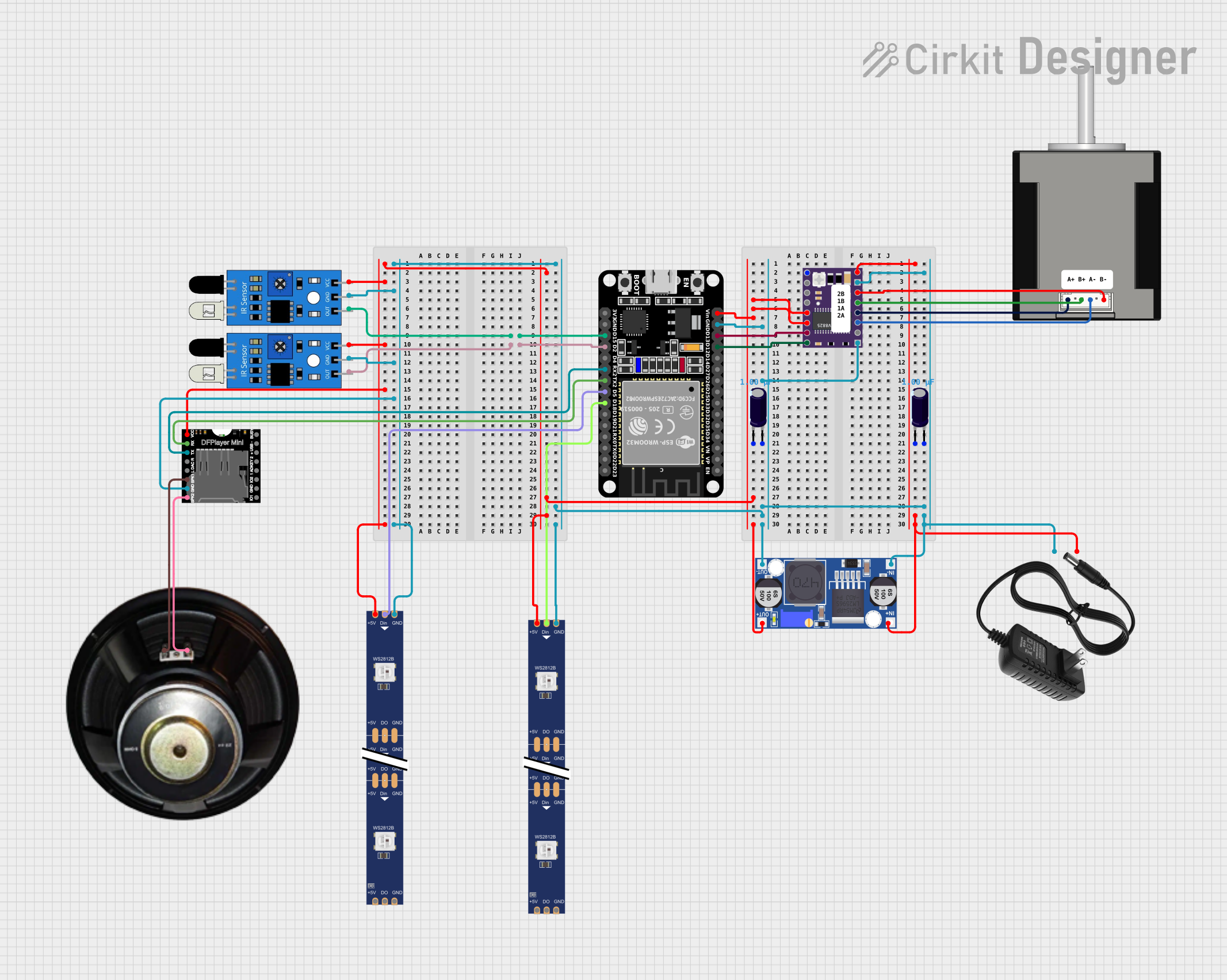

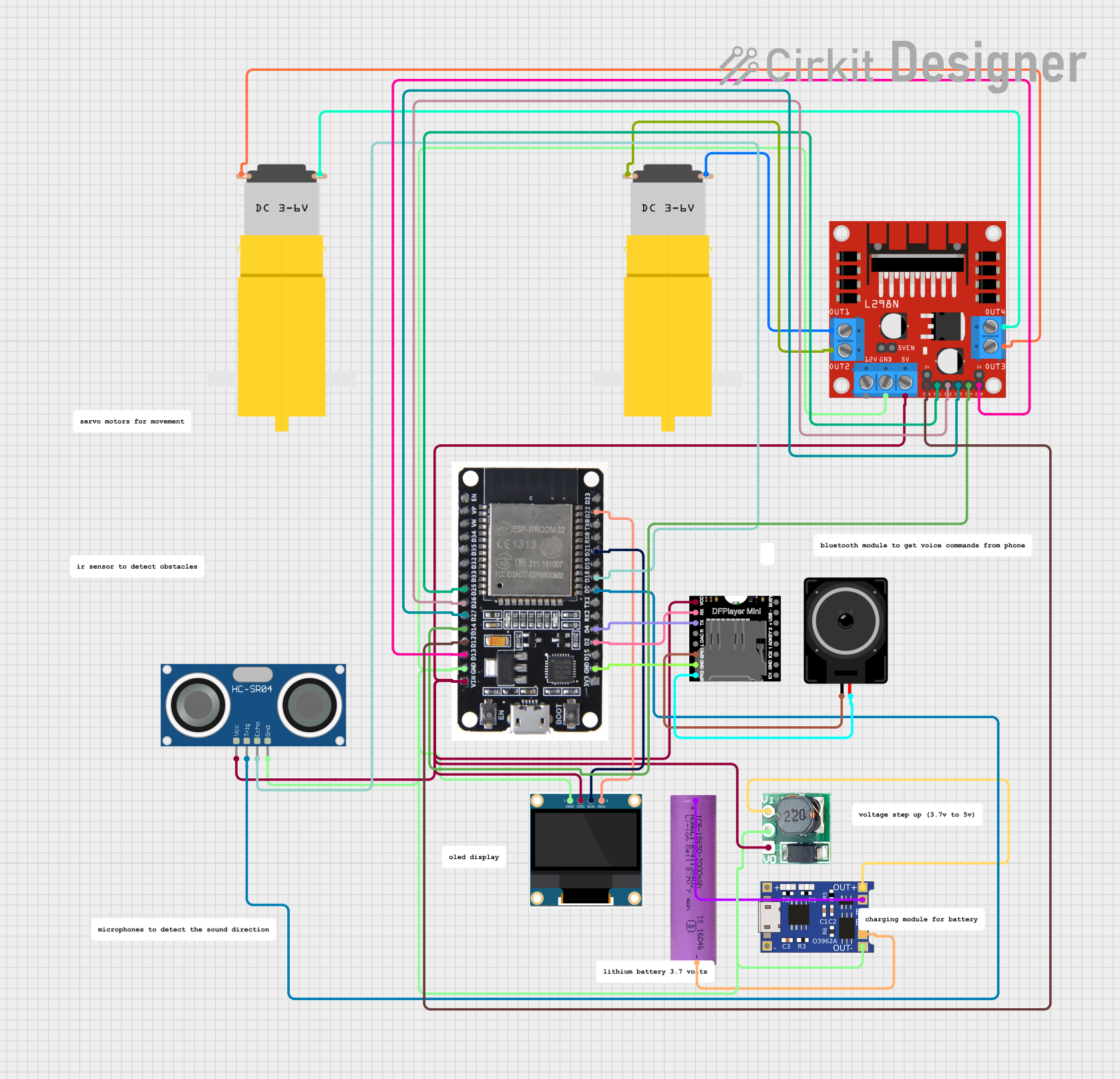

Explore Projects Built with DRV8825

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with DRV8825

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Precision control in 3D printers

- CNC machines for milling and laser cutting

- Robotic arms and actuators

- Automated equipment and animatronics

Technical Specifications

Key Technical Details

- Motor Supply Voltage (VM): 8.2 – 45 V

- Logic Supply Voltage (VDD): 2.5 – 5.25 V

- Output Current (per channel): 1.5 A (with sufficient additional cooling up to 2.2 A)

- Microstep Resolutions: Full, 1/2, 1/4, 1/8, 1/16, 1/32

- Thermal Overload Protection: Yes

- Under-voltage Lockout: Yes

- Overcurrent Protection: Yes

- Fault Indicator: Yes

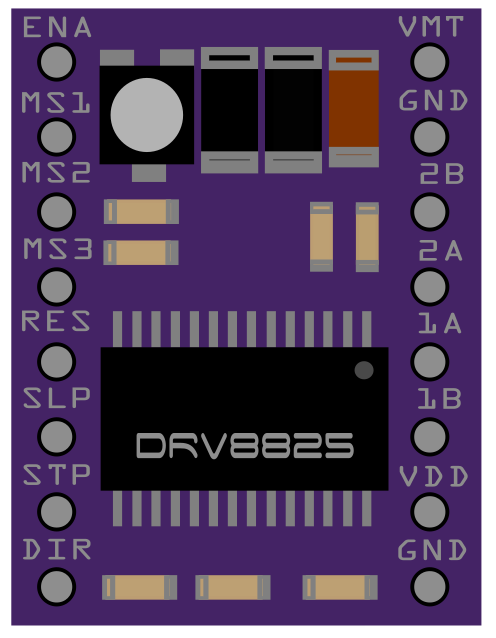

Pin Configuration and Descriptions

| Pin Name | Description |

|---|---|

| VM | Motor voltage supply (8.2 – 45 V) |

| GND | Ground connection |

| 2B, 2A | Motor coil 1 connections |

| 1A, 1B | Motor coil 2 connections |

| VDD | Logic voltage supply (2.5 – 5.25 V) |

| RESET | Resets the driver when pulled low |

| SLEEP | Puts the driver into a low-power sleep mode when pulled low |

| STEP | Logic input that advances the motor one step per pulse |

| DIR | Logic input that controls the direction of the motor |

| M0, M1, M2 | Microstep resolution selection inputs |

| FAULT | Logic output that indicates an overcurrent or thermal shutdown condition |

Usage Instructions

How to Use the Component in a Circuit

Power Connections: Connect the motor supply voltage (VM) to the motor power supply and the ground (GND) to the power supply ground. Connect VDD to the logic power supply (2.5 – 5.25 V).

Motor Connections: Connect the motor coils to the 2B, 2A, 1A, and 1B pins. Ensure the motor phases match the driver's outputs.

Control Inputs: Connect the STEP and DIR pins to the control signals, typically from a microcontroller like an Arduino UNO. The RESET and SLEEP pins can be connected to digital outputs or tied together if not used.

Microstep Selection: Set the microstep resolution by configuring the M0, M1, and M2 pins according to the truth table in the datasheet.

Current Limiting: Adjust the current limiting potentiometer on the DRV8825 board to match the current rating of your stepper motor.

Important Considerations and Best Practices

- Always ensure the power supply voltage and current ratings are within the specifications of the DRV8825.

- Configure the current limit to prevent damage to the motor due to overcurrent.

- Use appropriate decoupling capacitors to minimize voltage spikes on the power supply lines.

- Avoid disconnecting the motor while the driver is powered to prevent damage to the DRV8825.

- Provide adequate cooling if the driver is expected to handle currents near the upper limit of its capability.

Example Code for Arduino UNO

// Define the stepper motor connections and steps per revolution

#define DIR_PIN 2

#define STEP_PIN 3

#define STEPS_PER_REV 200

void setup() {

// Set the motor control pins as outputs

pinMode(DIR_PIN, OUTPUT);

pinMode(STEP_PIN, OUTPUT);

}

void loop() {

// Set the motor direction to clockwise

digitalWrite(DIR_PIN, HIGH);

// Move the motor one revolution

for (int i = 0; i < STEPS_PER_REV; i++) {

// Pulse the STEP pin to move the motor one step

digitalWrite(STEP_PIN, HIGH);

delayMicroseconds(1000); // Adjust the speed as necessary

digitalWrite(STEP_PIN, LOW);

delayMicroseconds(1000);

}

// Pause before changing direction

delay(1000);

// Set the motor direction to counterclockwise

digitalWrite(DIR_PIN, LOW);

// Move the motor one revolution in the other direction

for (int i = 0; i < STEPS_PER_REV; i++) {

digitalWrite(STEP_PIN, HIGH);

delayMicroseconds(1000);

digitalWrite(STEP_PIN, LOW);

delayMicroseconds(1000);

}

// Pause before the next revolution

delay(1000);

}

Troubleshooting and FAQs

Common Issues Users Might Face

- Motor not moving: Check power supply connections, ensure the current limit is correctly set, and verify that the motor coils are properly connected.

- Overheating: Ensure adequate cooling, and check if the current limit is set too high.

- Inconsistent movement: Verify microstep resolution settings and ensure the control signals are clean and without noise.

Solutions and Tips for Troubleshooting

- Motor Stalls or Misses Steps: Reduce the speed or acceleration of the motor, increase the current limit slightly, or check for mechanical obstructions.

- Driver Resets or Shuts Down: Check for overcurrent conditions or thermal overload. Add a heatsink or improve airflow around the DRV8825.

- Noise or Vibration: Experiment with different microstep resolutions or dampening materials to reduce resonance.

FAQs

Q: Can I run the DRV8825 without a heatsink? A: Yes, for low to moderate current levels. However, for currents approaching the upper limit, a heatsink is recommended.

Q: What is the maximum current the DRV8825 can handle? A: The DRV8825 can handle up to 1.5 A per channel without additional cooling. With sufficient cooling, it can handle up to 2.2 A per channel.

Q: How do I adjust the current limit on the DRV8825? A: Turn the potentiometer on the DRV8825 module while measuring the voltage on the REF pin or by following the VREF formula provided in the datasheet.

Q: What should I do if the FAULT pin goes high? A: Check for overcurrent or overheating conditions. Let the driver cool down and ensure that the current limit is set correctly before resuming operation.