How to Use 12V DC Motor Encoder: Examples, Pinouts, and Specs

Design with 12V DC Motor Encoder in Cirkit Designer

Design with 12V DC Motor Encoder in Cirkit DesignerIntroduction

A 12V DC Motor Encoder is an essential component in robotics and automation, providing precise feedback on motor position, speed, and direction. This feedback is crucial for applications requiring accurate motor control, such as in conveyor belts, positioning systems, and robotic arms. By integrating an encoder with a DC motor, users can achieve closed-loop control, enhancing the performance of their systems.

Explore Projects Built with 12V DC Motor Encoder

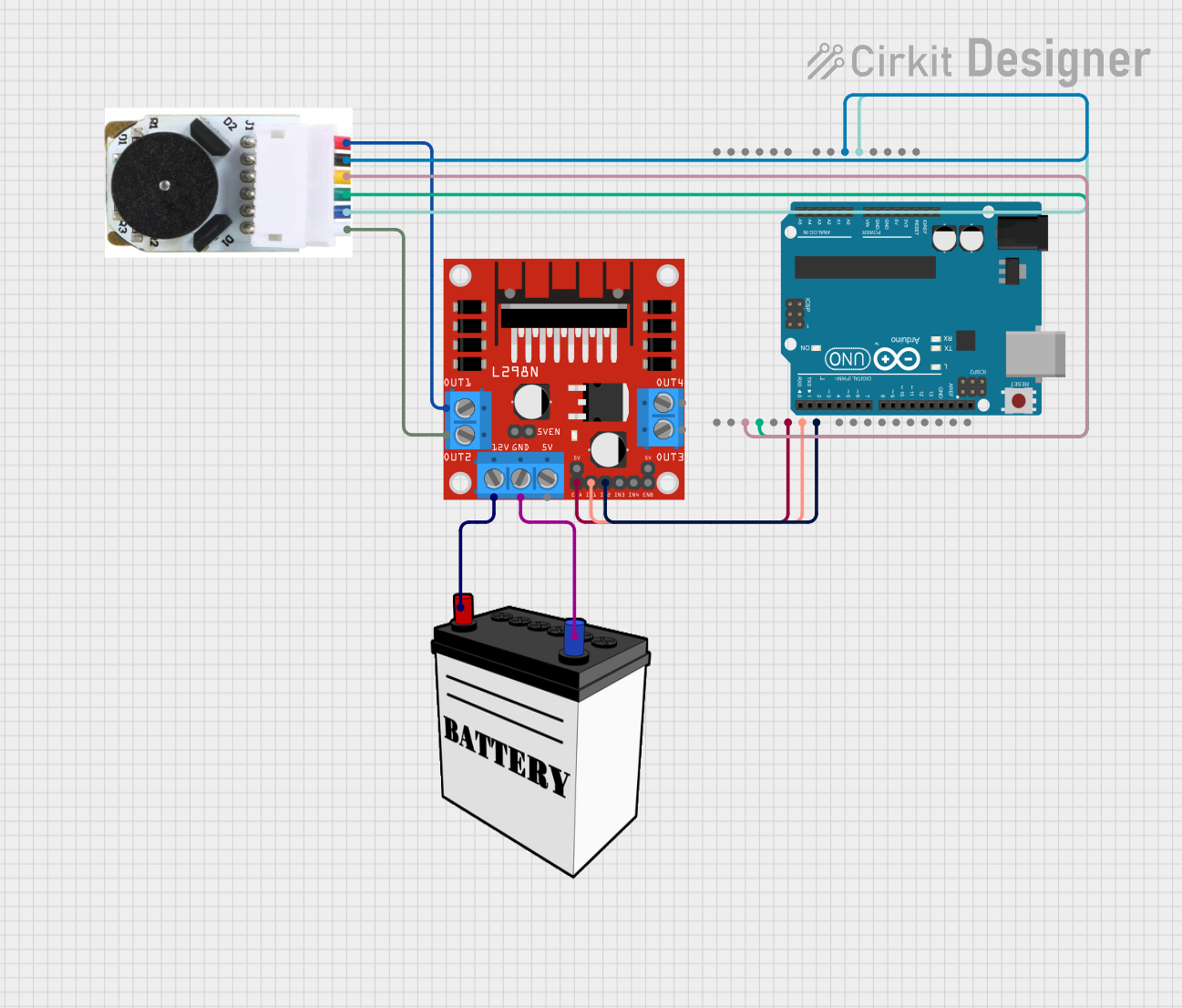

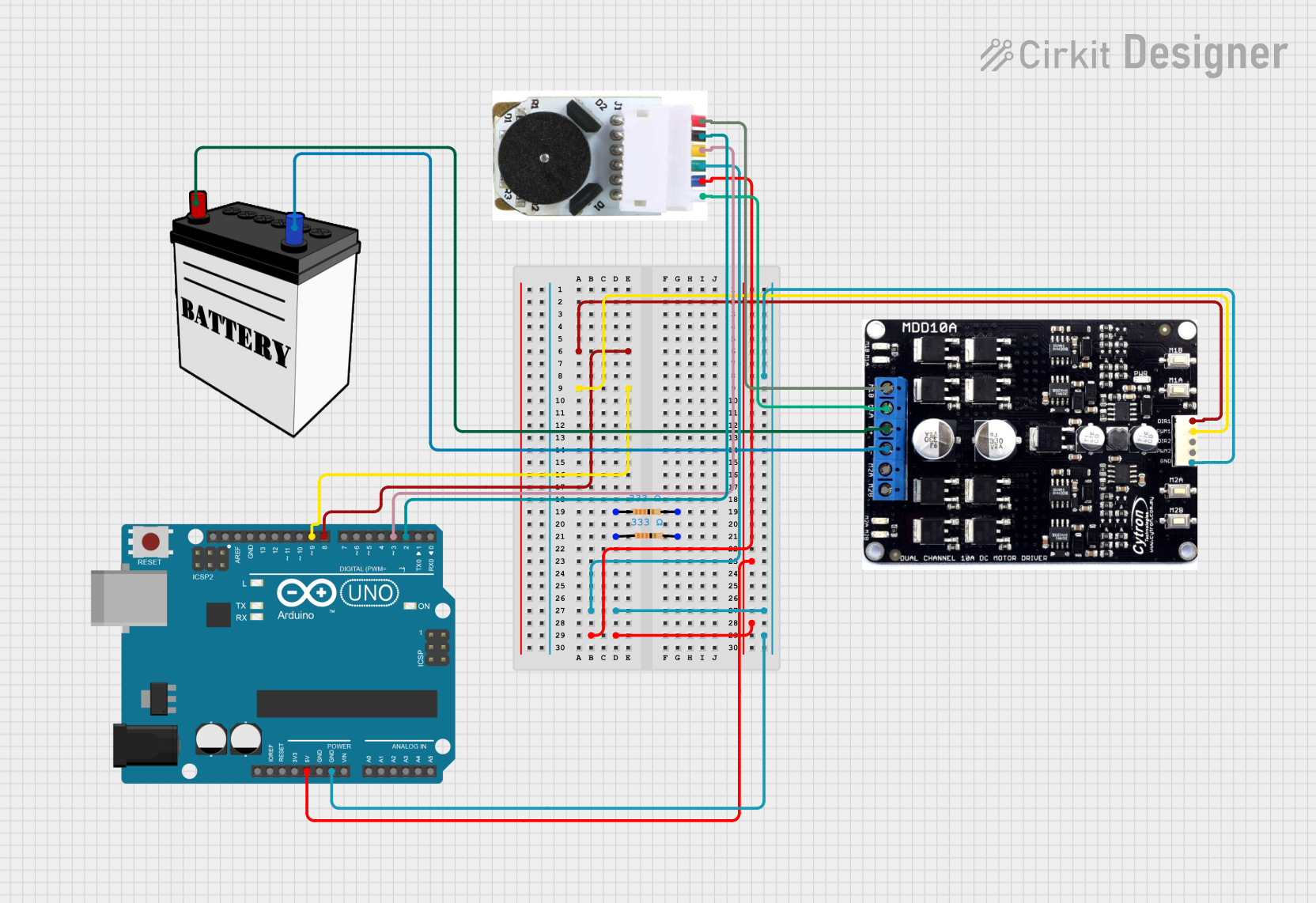

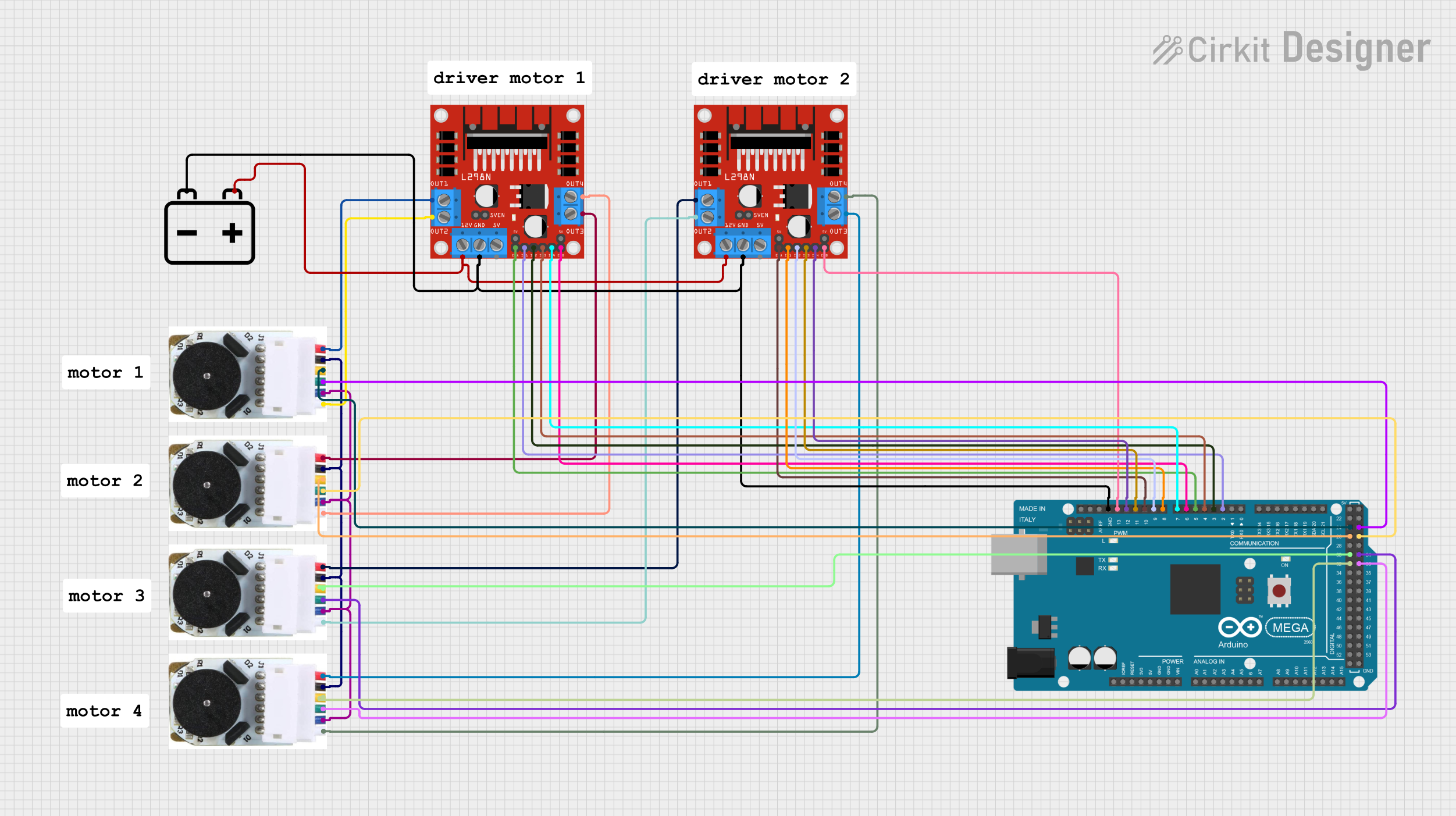

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 12V DC Motor Encoder

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

General Specifications

- Operating Voltage: 12V DC

- Output: Quadrature encoder signals (A and B)

- Pulses per Revolution (PPR): Typically 100 to 2000 (varies by model)

- Maximum Rotational Speed: Depends on the motor specifications

- Operating Temperature Range: -10°C to +70°C (14°F to 158°F)

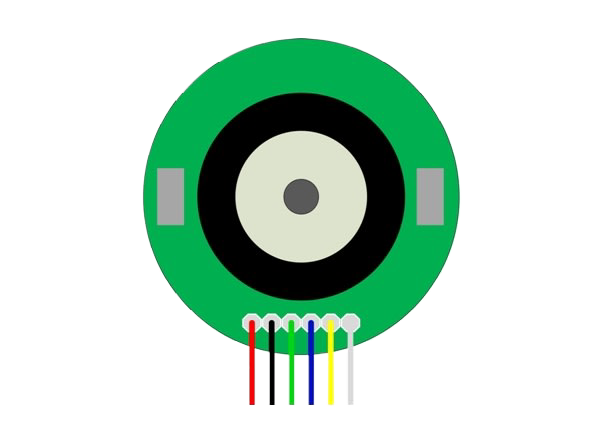

Pin Configuration and Descriptions

| Pin Number | Description | Notes |

|---|---|---|

| 1 | Vcc (Power Supply) | Connect to 12V DC |

| 2 | Ground (GND) | Connect to system ground |

| 3 | Encoder Output A | Quadrature output A |

| 4 | Encoder Output B | Quadrature output B |

| 5 | Index (Optional) | Pulse per revolution (if present) |

| 6 | Motor + | Connect to positive motor lead |

| 7 | Motor - | Connect to negative motor lead |

Note: The pin configuration may vary depending on the manufacturer. Always refer to the datasheet of the specific model you are using.

Usage Instructions

Wiring the Encoder to a Circuit

- Connect the Vcc pin to a 12V DC power supply.

- Connect the GND pin to the common ground in your circuit.

- Connect Encoder Output A and B to the input pins on your microcontroller or interface board.

- If available, connect the Index pin to another input pin for additional feedback.

- Connect Motor + and Motor - to the motor driver or H-bridge circuit controlling the motor.

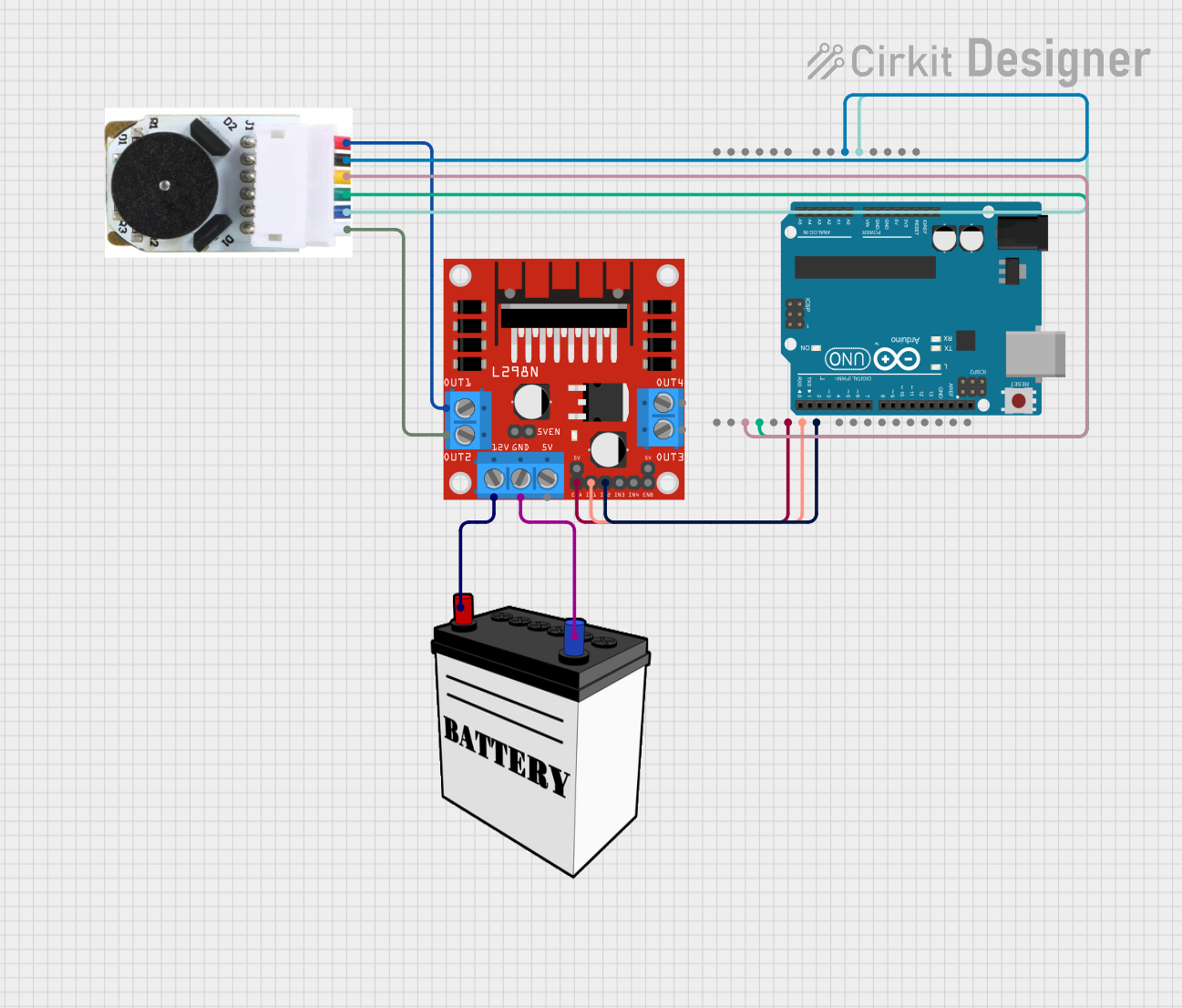

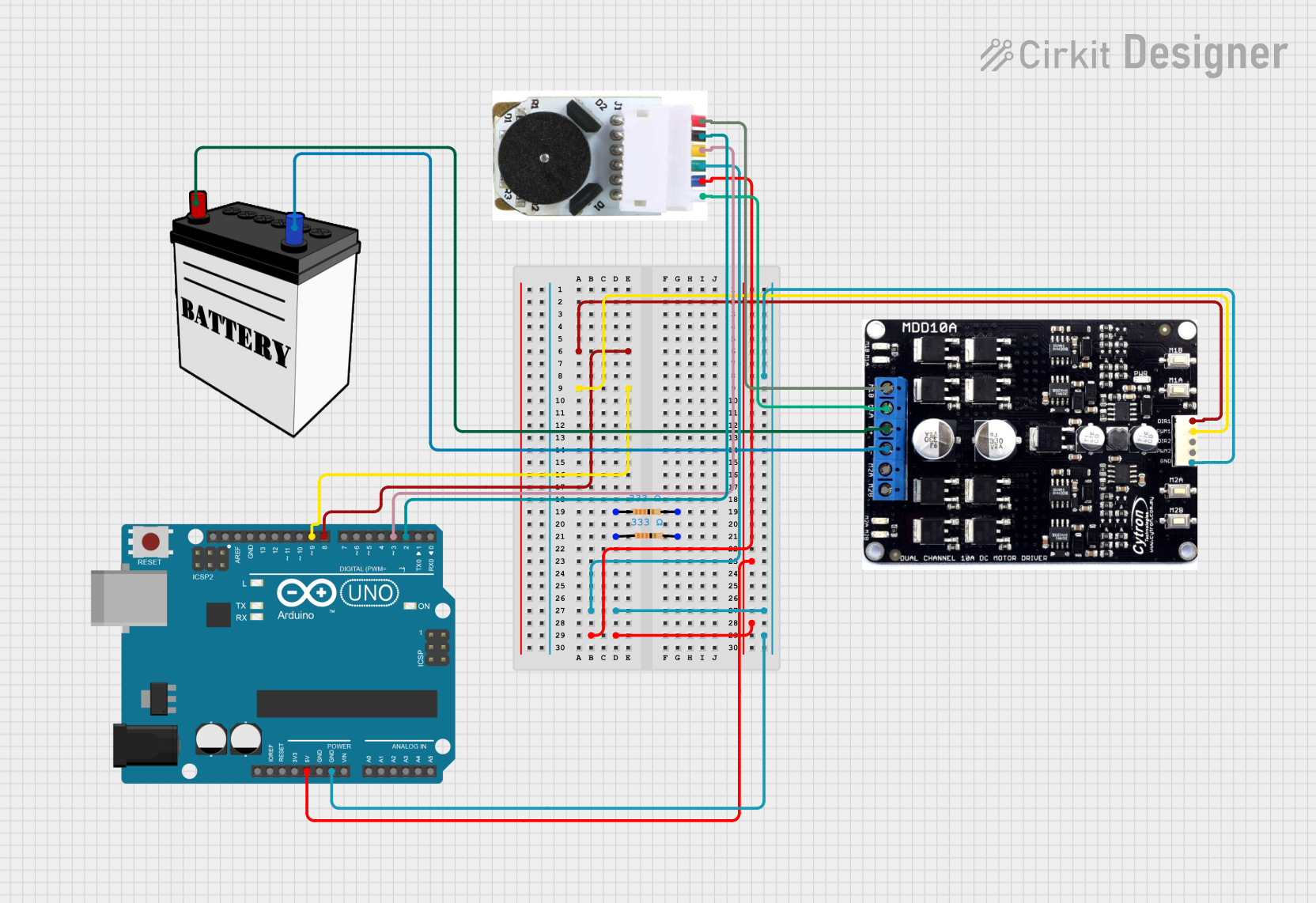

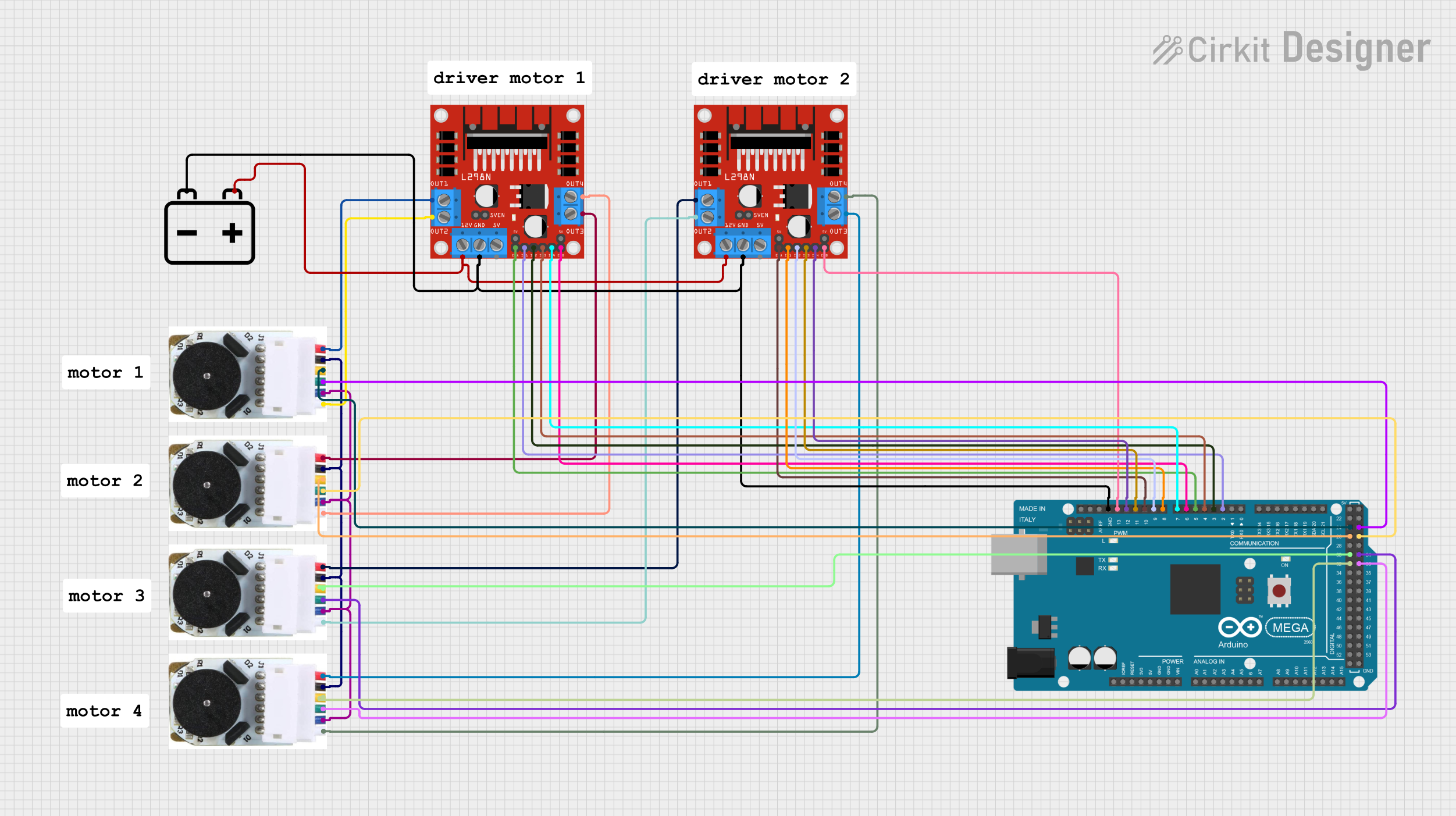

Interfacing with an Arduino UNO

To interface the 12V DC Motor Encoder with an Arduino UNO, follow these steps:

- Connect the encoder outputs to two digital pins on the Arduino (e.g., pins 2 and 3).

- Connect the motor leads to a motor driver compatible with the Arduino.

- Supply the motor driver with 12V DC for motor power.

Sample Arduino Code

// Define the encoder pins

const int encoderPinA = 2;

const int encoderPinB = 3;

// Variables to hold encoder count

volatile long encoderCount = 0;

// Interrupt service routine for encoder A

void encoderISR() {

if (digitalRead(encoderPinA) == digitalRead(encoderPinB)) {

encoderCount++;

} else {

encoderCount--;

}

}

void setup() {

// Set encoder pins as inputs

pinMode(encoderPinA, INPUT);

pinMode(encoderPinB, INPUT);

// Attach interrupt for encoder pin A

attachInterrupt(digitalPinToInterrupt(encoderPinA), encoderISR, CHANGE);

Serial.begin(9600); // Start serial communication at 9600 baud

}

void loop() {

// Print the encoder count value

Serial.println(encoderCount);

delay(1000); // Update every second

}

Note: The above code assumes that the encoder generates interrupts on both rising and falling edges of signal A. Adjust the interrupt type if necessary.

Troubleshooting and FAQs

Common Issues

- Motor not responding: Ensure that the motor is properly powered and that the encoder is correctly wired to the microcontroller.

- Inaccurate readings: Check for any loose connections and verify that the encoder's PPR matches the expected value in your code.

- Noisy signals: Use proper shielding and grounding techniques to minimize electrical noise.

FAQs

Q: Can I use this encoder with a 5V system? A: While the motor requires 12V, the encoder signals can often be read by a 5V system. Check the datasheet to ensure compatibility.

Q: How do I determine the direction of the motor? A: By comparing the phase relationship between Encoder Output A and B, you can determine the direction of rotation.

Q: What is the purpose of the Index pin? A: The Index pin provides a single pulse per revolution, which can be used for more precise control or for establishing a reference position.

Q: How can I increase the accuracy of the encoder? A: Use encoders with a higher PPR value for more precise feedback and ensure that your code correctly handles the encoder signals.

For further assistance, consult the manufacturer's datasheet and technical support resources.