How to Use Pressure Pad: Examples, Pinouts, and Specs

Design with Pressure Pad in Cirkit Designer

Design with Pressure Pad in Cirkit DesignerIntroduction

A pressure pad is a type of sensor designed to detect physical pressure applied to its surface. It operates by converting mechanical force into an electrical signal, which can then be processed by a circuit or microcontroller. Pressure pads are widely used in applications such as security systems (e.g., detecting intrusions), gaming controllers (e.g., pressure-sensitive buttons), and interactive electronic devices. Their simplicity, reliability, and versatility make them a popular choice for various projects and commercial products.

Explore Projects Built with Pressure Pad

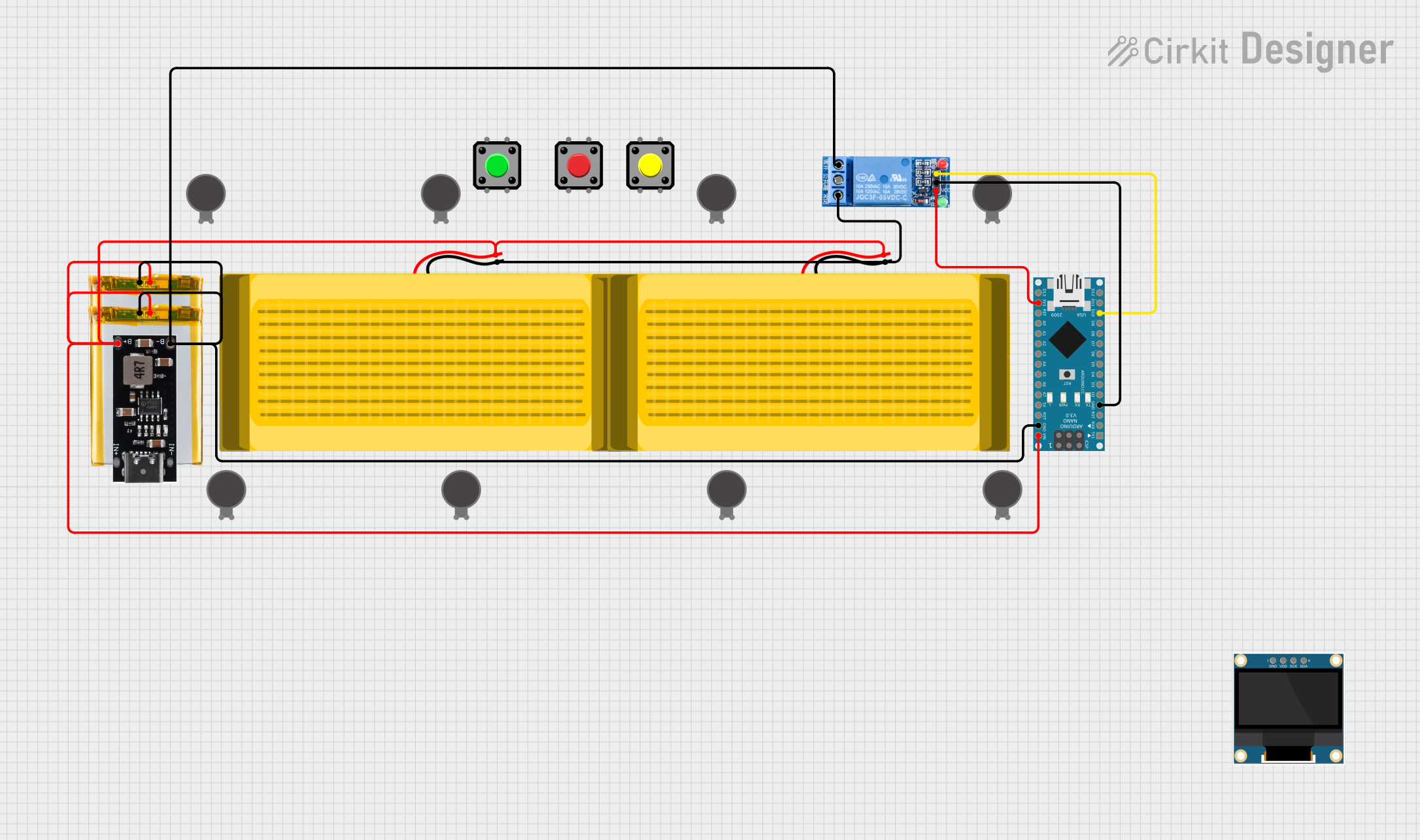

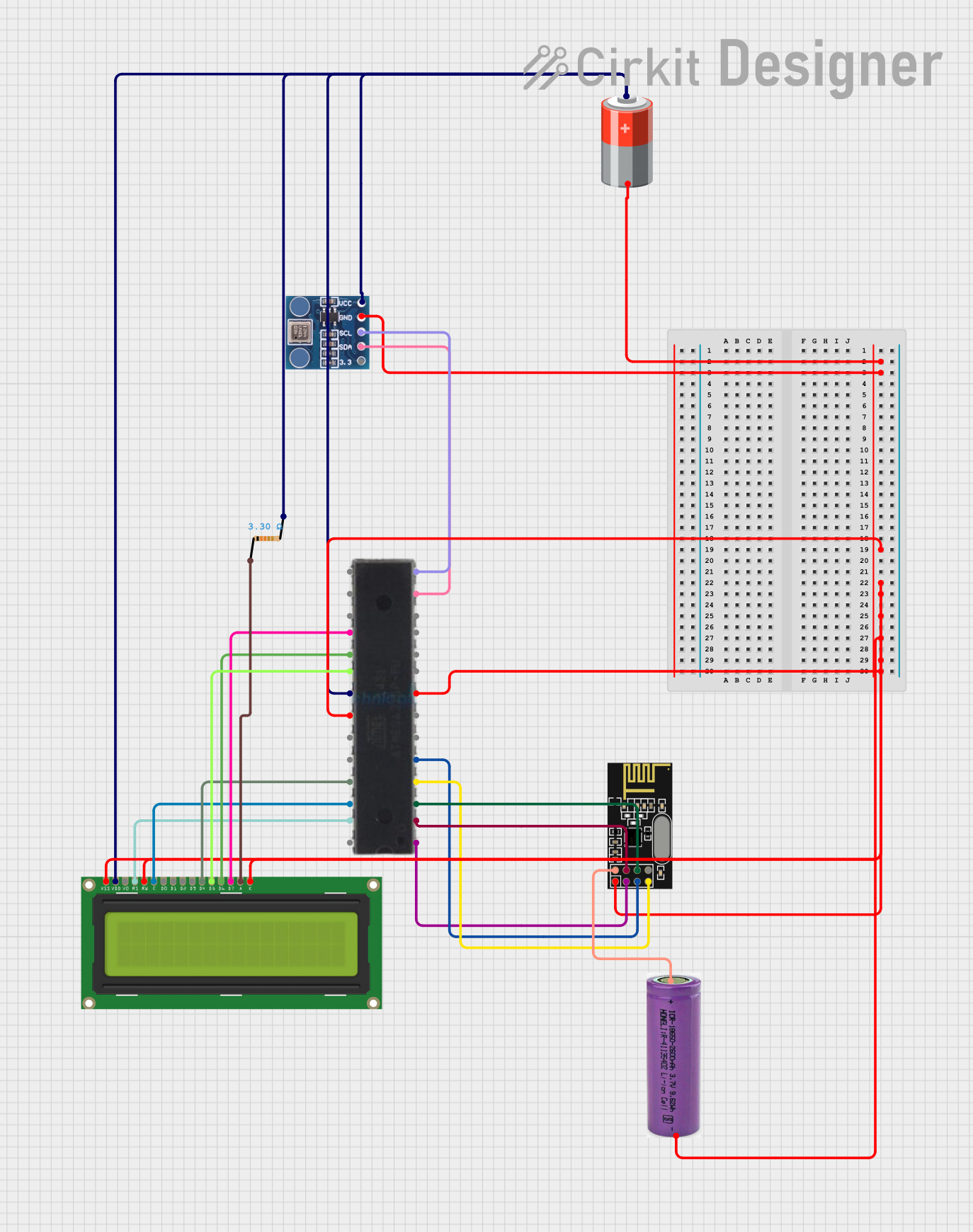

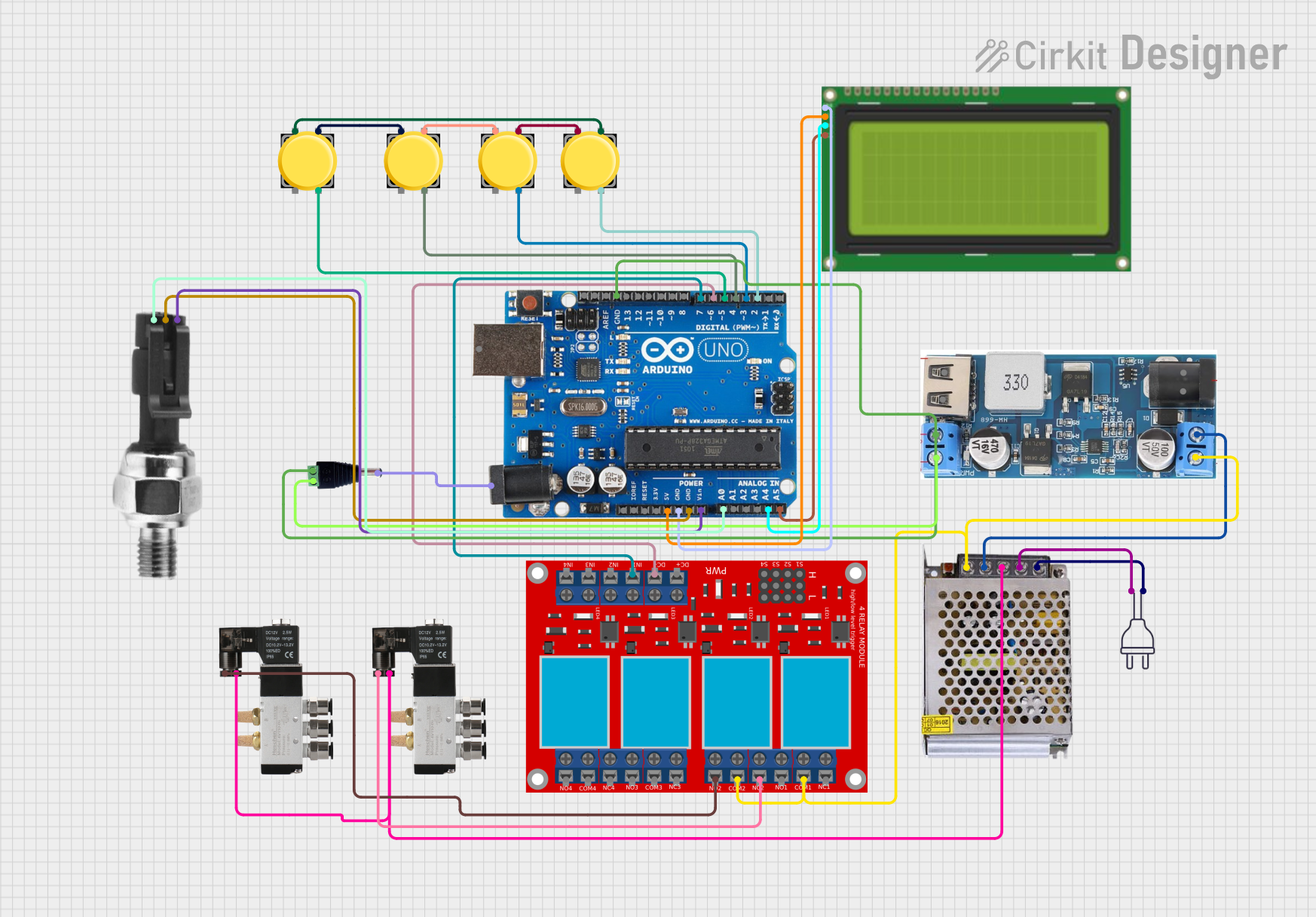

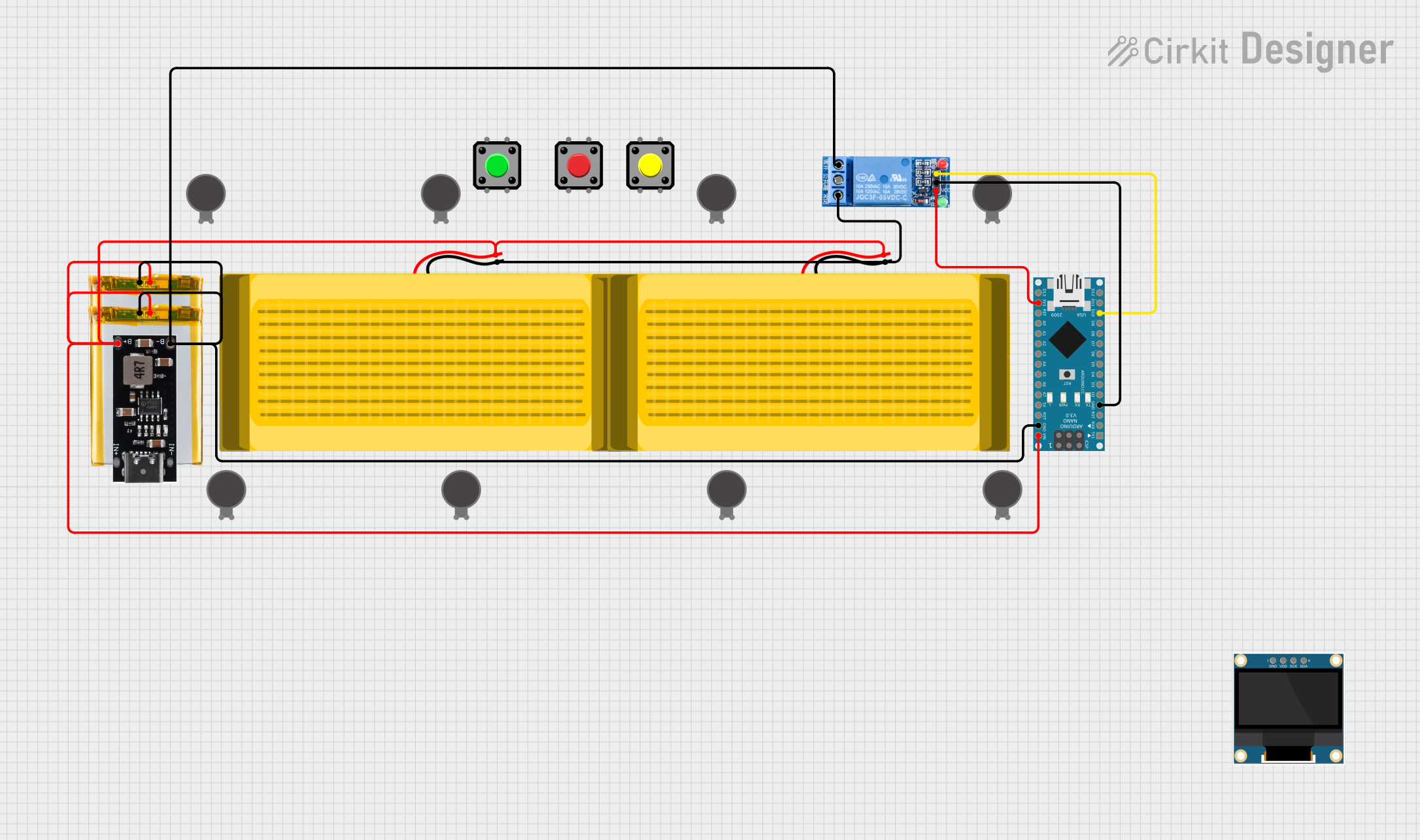

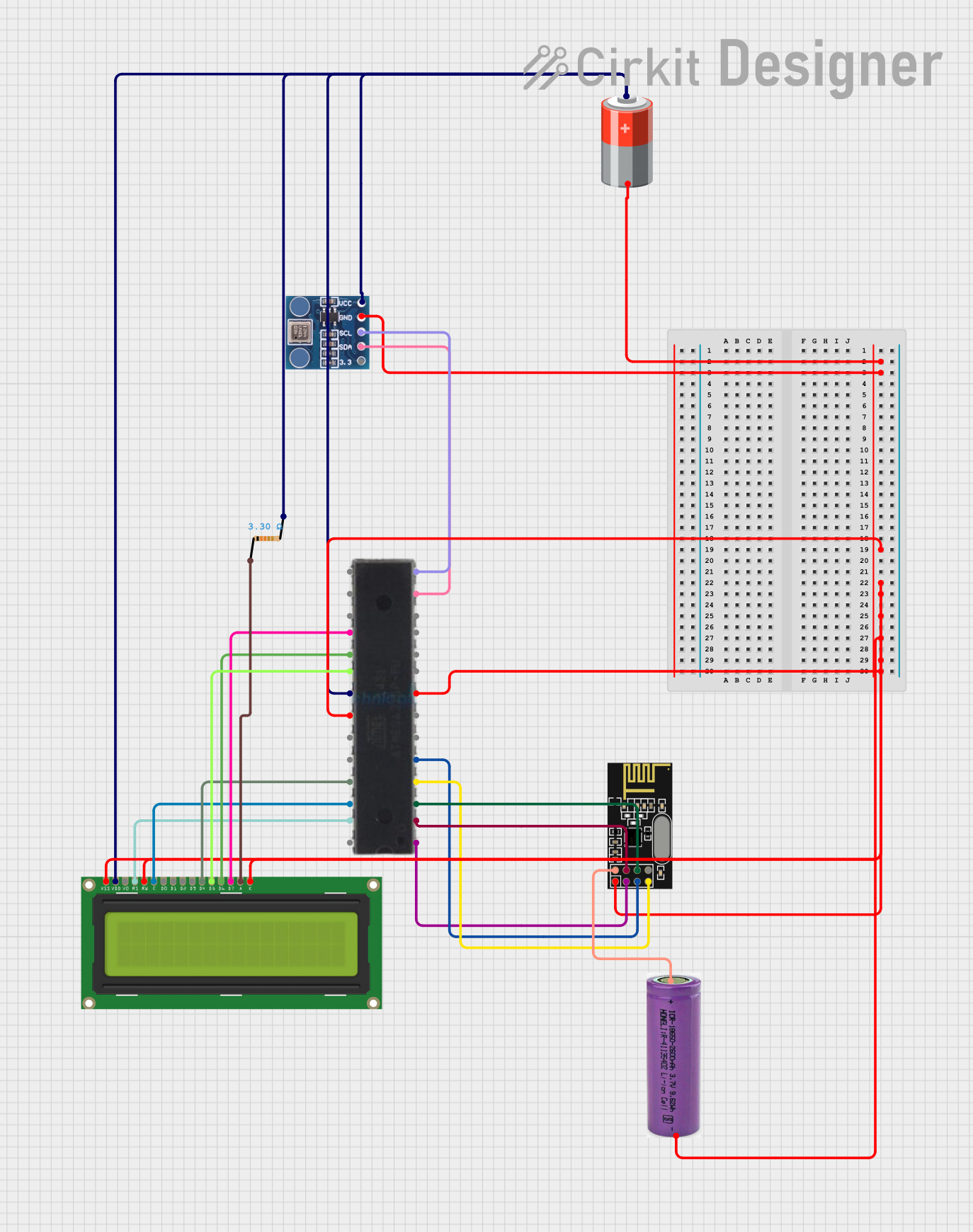

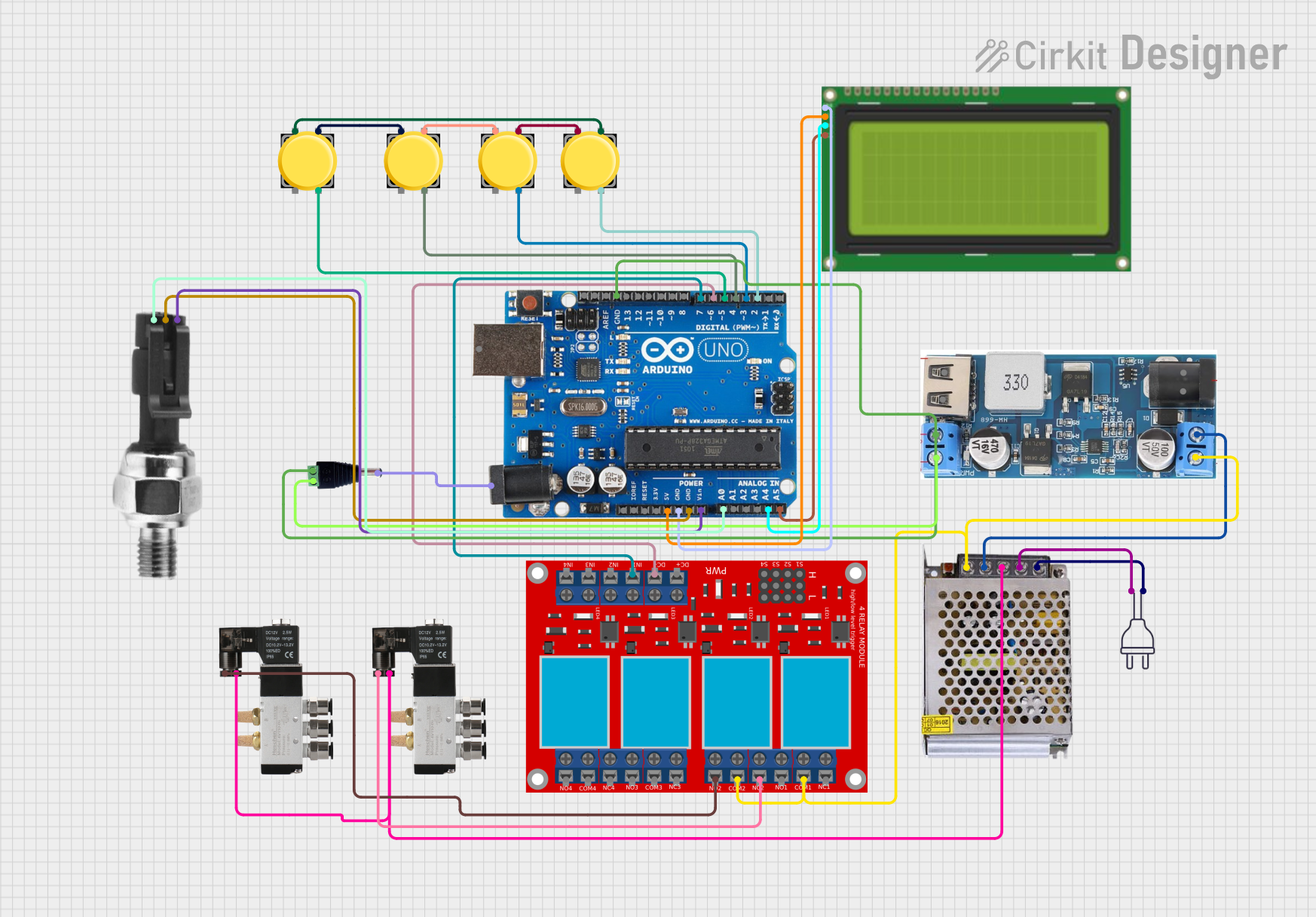

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Pressure Pad

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Below are the general technical specifications for a standard pressure pad. Note that specific models may vary slightly in their ratings and features.

- Operating Voltage: 3.3V to 5V DC

- Operating Current: < 10mA

- Output Type: Analog or Digital (depending on the model)

- Pressure Sensitivity: Typically ranges from 100g to 10kg

- Response Time: < 10ms

- Operating Temperature: -10°C to 50°C

- Lifespan: Up to 1 million activations (varies by manufacturer)

Pin Configuration and Descriptions

The pressure pad typically has two or three pins, depending on the model. Below is a table describing the pin configuration:

| Pin | Name | Description |

|---|---|---|

| 1 | Signal (OUT) | Outputs the signal based on the pressure applied. Can be analog or digital. |

| 2 | VCC | Connects to the positive voltage supply (3.3V or 5V). |

| 3 | GND | Connects to the ground of the circuit. |

For two-pin models, the pins are typically Signal and GND, with the signal pin also serving as the power input.

Usage Instructions

How to Use the Pressure Pad in a Circuit

Wiring the Pressure Pad:

- Connect the VCC pin to a 3.3V or 5V power source.

- Connect the GND pin to the ground of your circuit.

- Connect the Signal (OUT) pin to an analog or digital input pin on your microcontroller (e.g., Arduino).

Reading the Output:

- For analog pressure pads, the output voltage varies with the applied pressure. Use an analog-to-digital converter (ADC) to read the signal.

- For digital pressure pads, the output is either HIGH (when pressure is detected) or LOW (when no pressure is detected).

Example Circuit:

- Use a pull-down resistor (10kΩ) on the signal pin to ensure stable readings.

- Optionally, add a capacitor (e.g., 0.1µF) across the power pins to filter noise.

Arduino UNO Example Code

Below is an example of how to use a pressure pad with an Arduino UNO:

// Define the pin connected to the pressure pad

const int pressurePadPin = A0; // Analog pin A0 for reading pressure pad signal

void setup() {

Serial.begin(9600); // Initialize serial communication at 9600 baud

pinMode(pressurePadPin, INPUT); // Set the pressure pad pin as input

}

void loop() {

// Read the analog value from the pressure pad

int pressureValue = analogRead(pressurePadPin);

// Print the pressure value to the Serial Monitor

Serial.print("Pressure Value: ");

Serial.println(pressureValue);

// Add a small delay to stabilize readings

delay(100);

}

Important Considerations and Best Practices

- Voltage Compatibility: Ensure the pressure pad's operating voltage matches your circuit's power supply.

- Debouncing: For digital pressure pads, implement software debouncing to avoid false triggers.

- Placement: Install the pressure pad on a flat, stable surface to ensure accurate readings.

- Load Limits: Avoid exceeding the pressure pad's maximum load capacity to prevent damage.

Troubleshooting and FAQs

Common Issues and Solutions

No Output Signal:

- Check the wiring and ensure all connections are secure.

- Verify that the power supply voltage matches the pressure pad's requirements.

- Test the pressure pad with a multimeter to confirm functionality.

Inconsistent Readings:

- Add a pull-down resistor to stabilize the signal.

- Ensure the pressure pad is not exposed to excessive vibrations or environmental noise.

- Use a capacitor to filter out electrical noise.

Signal Always HIGH or LOW:

- Verify that the pressure pad is not damaged or worn out.

- Check for short circuits or loose connections in the wiring.

FAQs

Q: Can I use a pressure pad with a Raspberry Pi?

A: Yes, you can connect a pressure pad to a Raspberry Pi. For analog pressure pads, use an external ADC module since the Raspberry Pi lacks built-in analog input.

Q: How do I clean a pressure pad?

A: Use a soft, dry cloth to clean the surface. Avoid using water or harsh chemicals, as they may damage the sensor.

Q: Can I use multiple pressure pads in one circuit?

A: Yes, you can connect multiple pressure pads to different input pins on your microcontroller. Ensure each pad has its own pull-down resistor if needed.

Q: What happens if I exceed the pressure pad's load limit?

A: Exceeding the load limit may permanently damage the pressure pad or reduce its lifespan. Always adhere to the manufacturer's specifications.