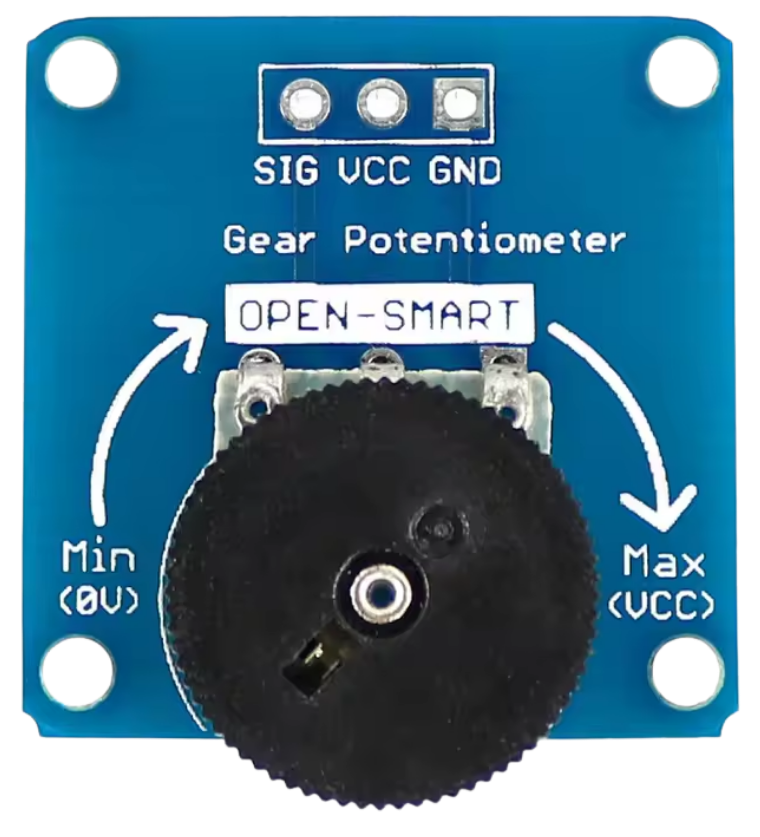

How to Use Gear Potentiometer: Examples, Pinouts, and Specs

Design with Gear Potentiometer in Cirkit Designer

Design with Gear Potentiometer in Cirkit DesignerIntroduction

A gear potentiometer is a type of variable resistor that incorporates a gear mechanism to adjust its resistance. This design allows for precise and smooth control over electrical signals, making it ideal for applications where fine-tuning is essential. Gear potentiometers are commonly used in audio equipment for volume and tone control, robotics for position sensing, and industrial systems for feedback and calibration.

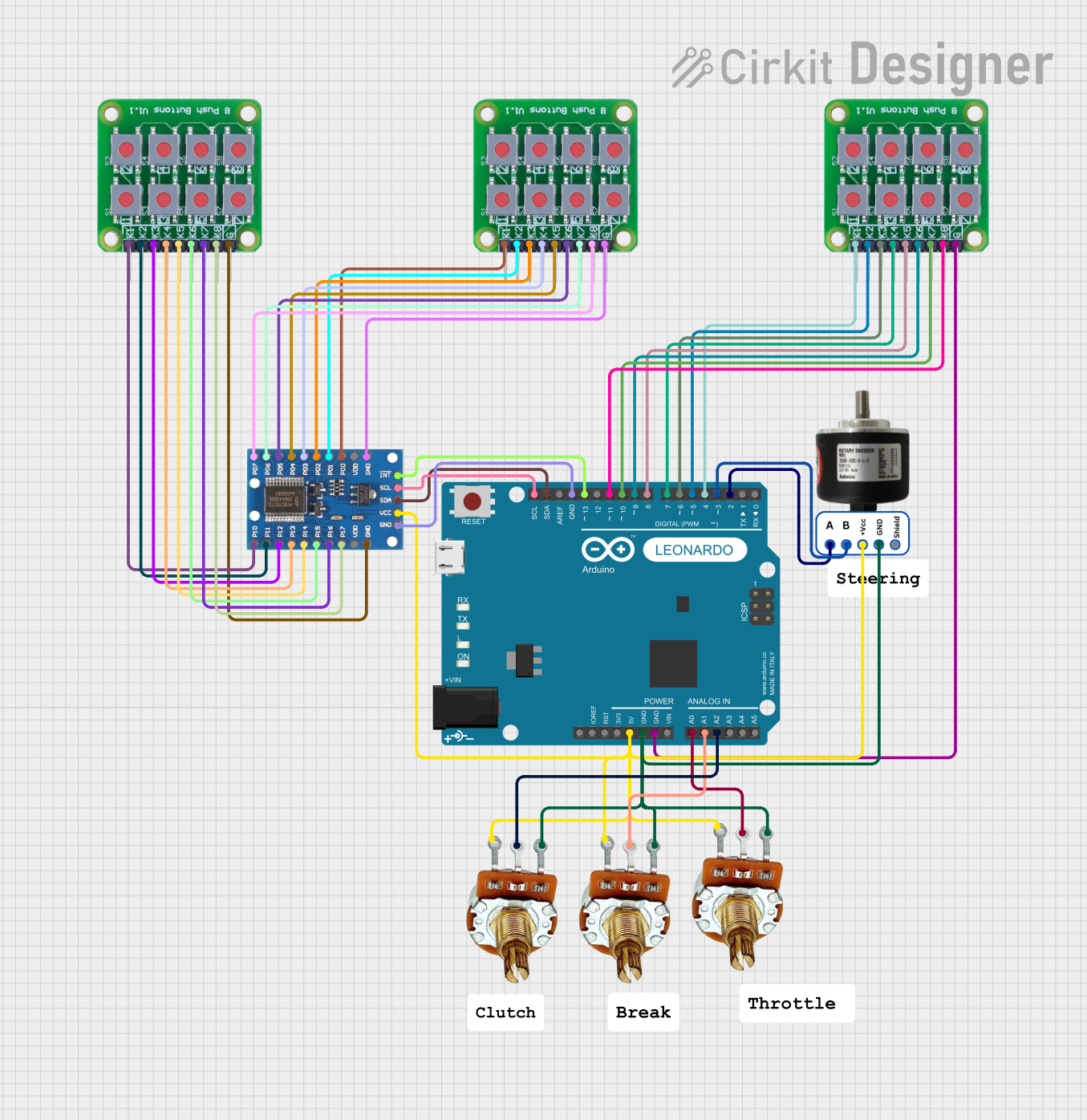

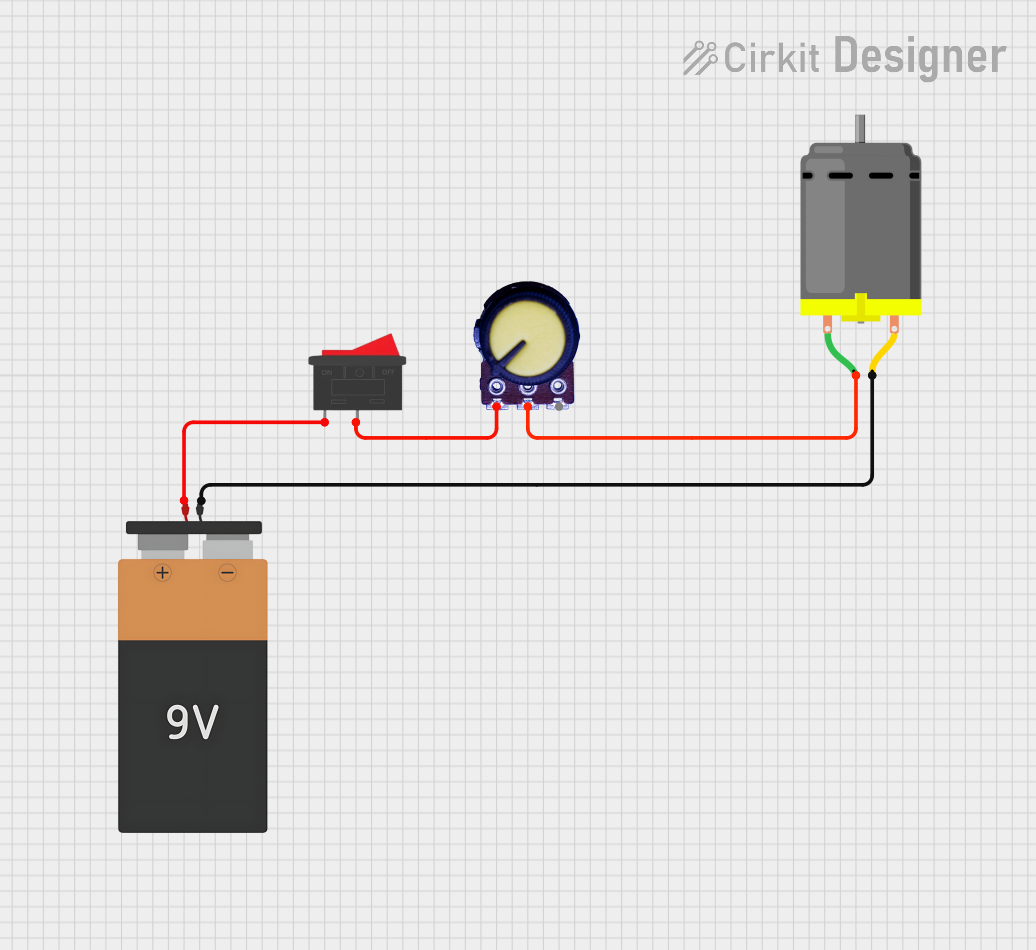

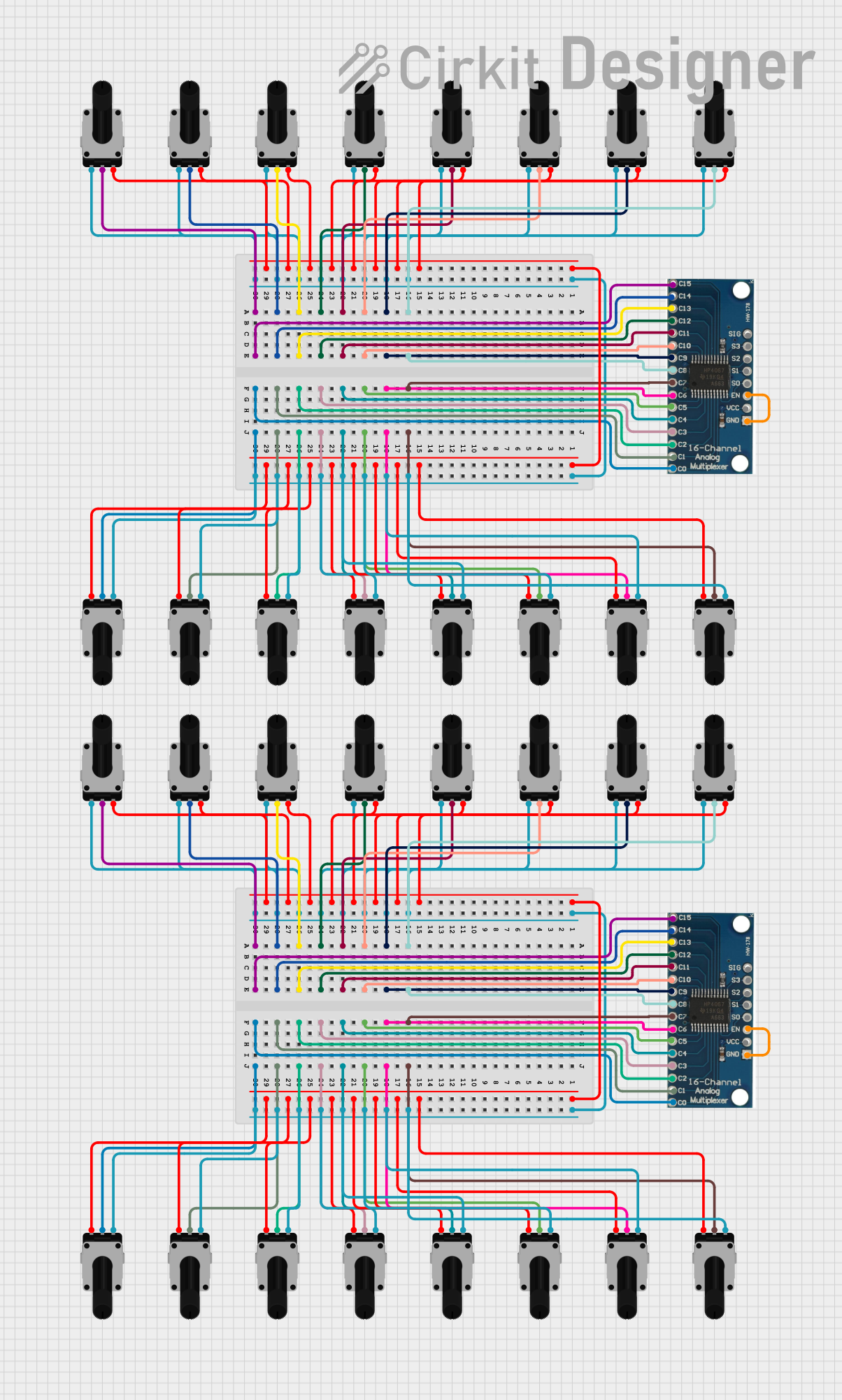

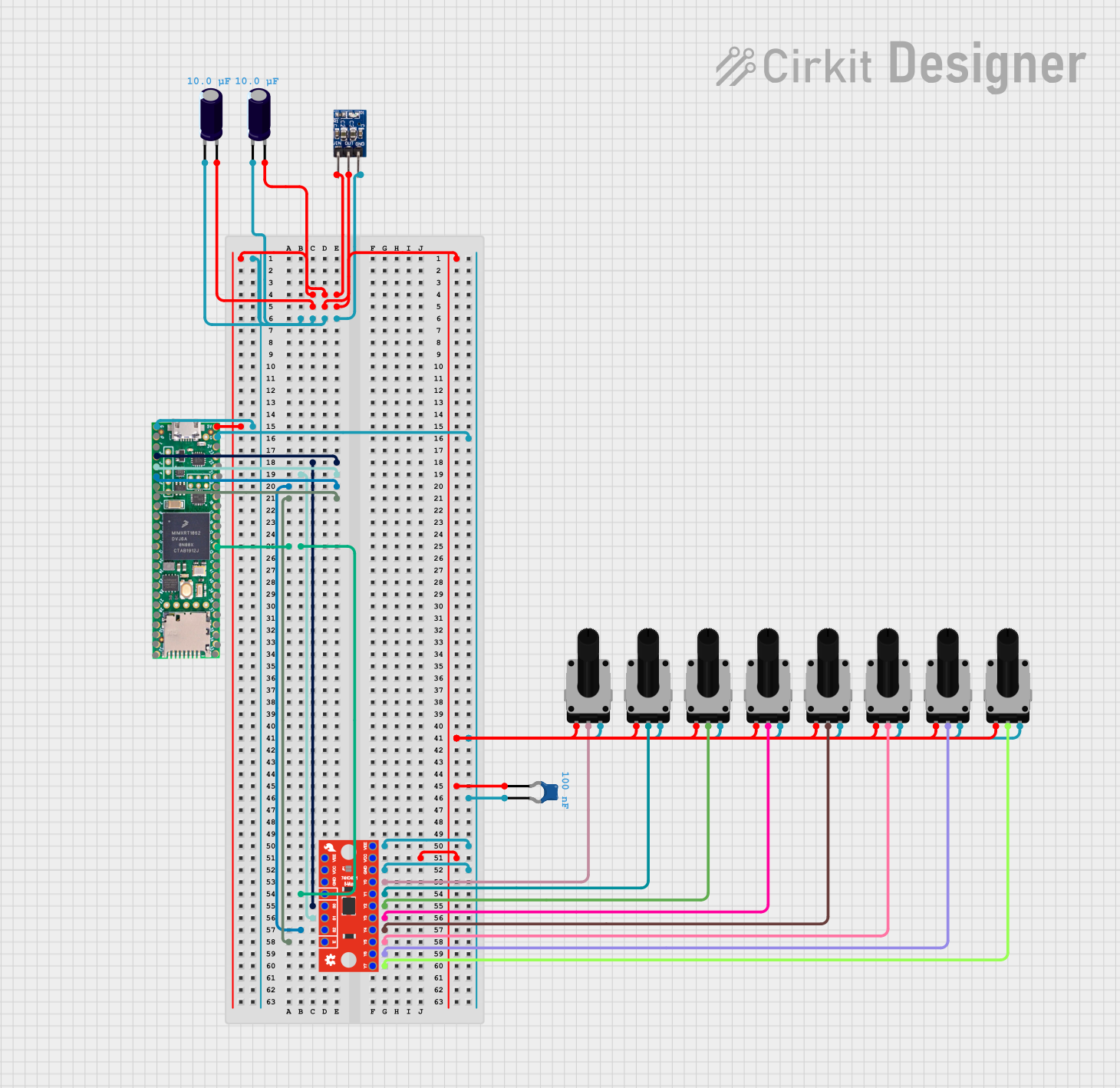

Explore Projects Built with Gear Potentiometer

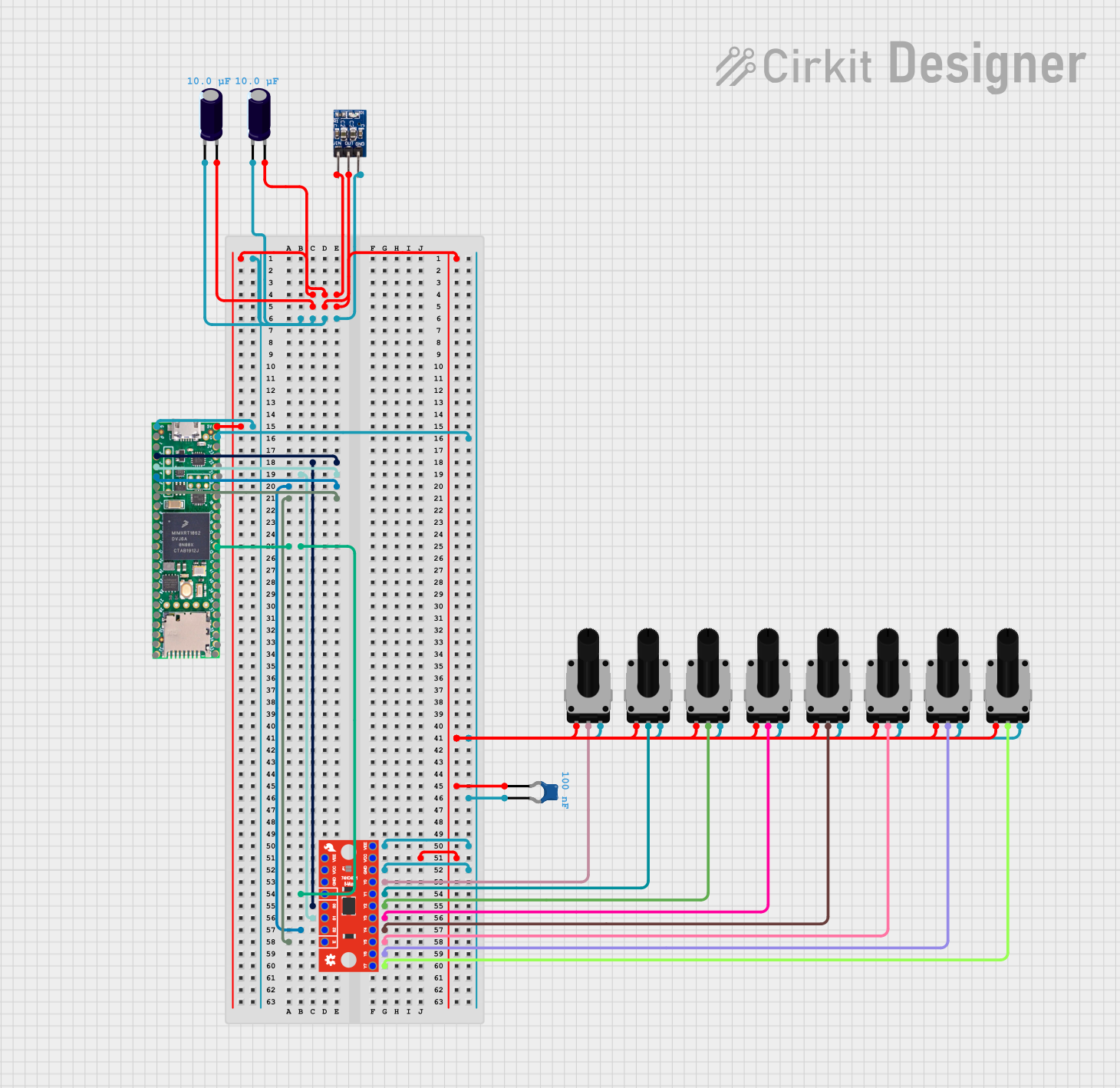

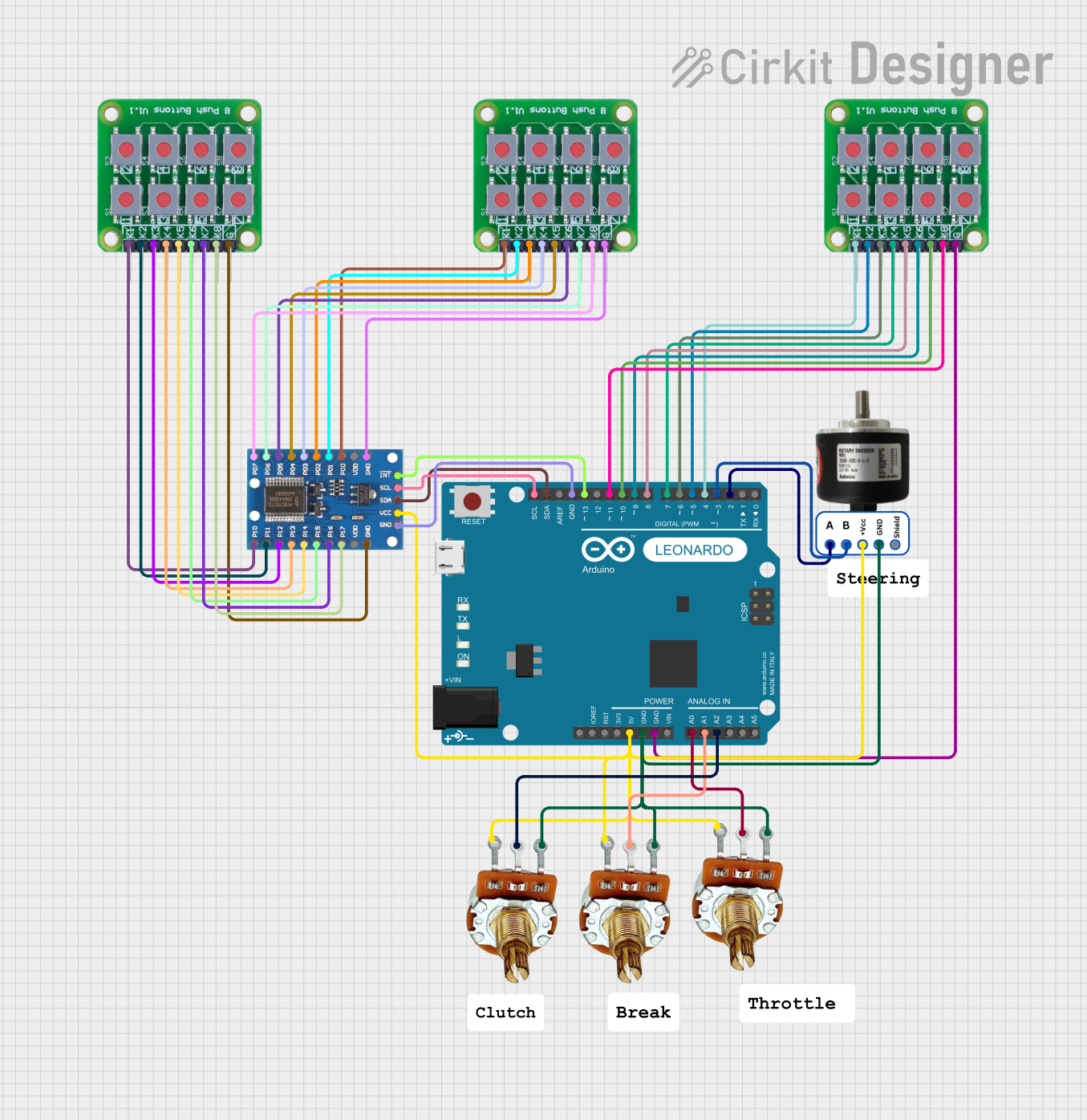

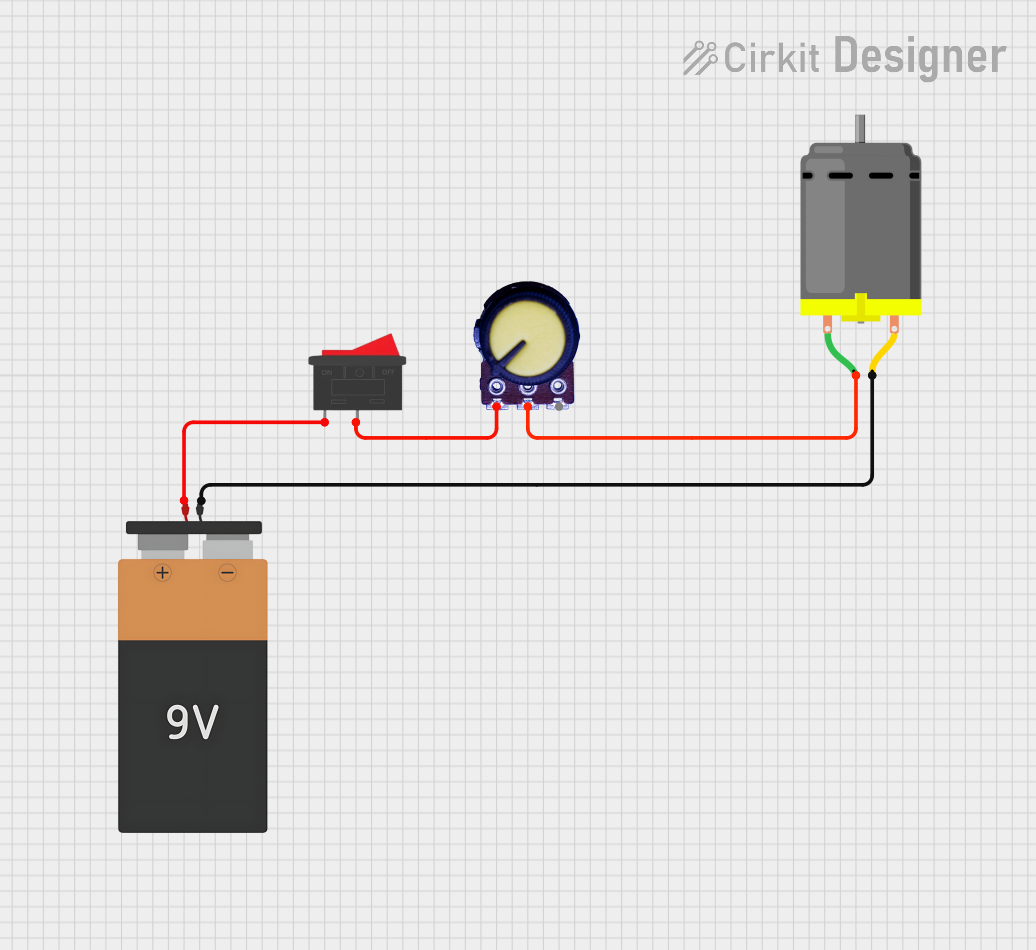

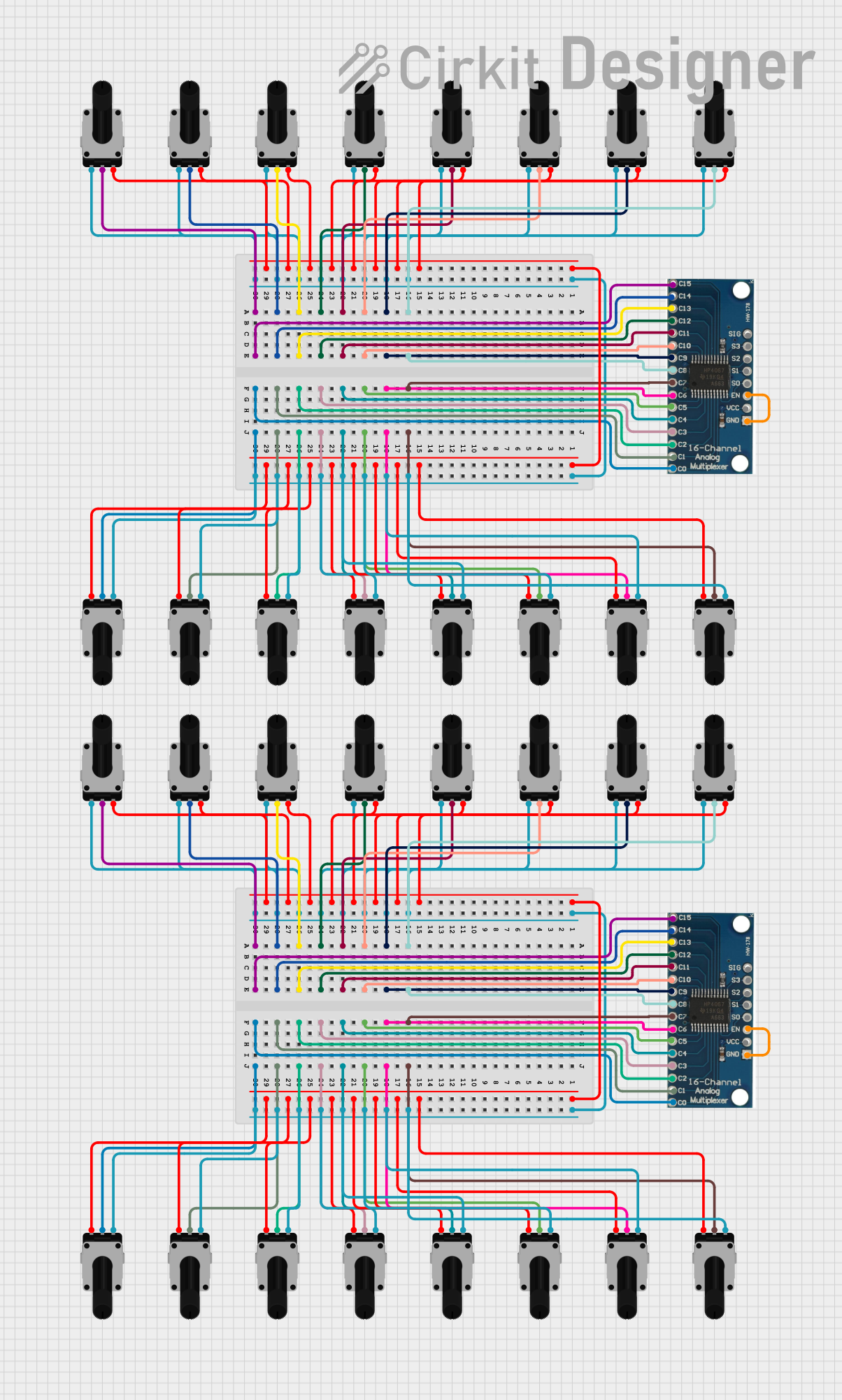

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Gear Potentiometer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Below are the key technical details of a typical gear potentiometer:

- Resistance Range: 1 kΩ to 100 kΩ (varies by model)

- Tolerance: ±5% to ±10%

- Power Rating: 0.25 W to 2 W

- Maximum Voltage: 250 V DC

- Rotation Angle: 270° to 360° (depending on the gear design)

- Gear Ratio: Typically 1:4 or 1:6 for finer adjustments

- Operating Temperature: -40°C to +85°C

- Shaft Diameter: 6 mm (standard)

- Lifespan: 10,000 to 50,000 cycles

Pin Configuration and Descriptions

The gear potentiometer typically has three pins, as described in the table below:

| Pin | Name | Description |

|---|---|---|

| 1 | Terminal 1 | One end of the resistive element. Connect to ground or a reference voltage. |

| 2 | Wiper (Output) | The adjustable output that provides a variable resistance based on the gear's position. |

| 3 | Terminal 2 | The other end of the resistive element. Connect to a power source or signal input. |

Usage Instructions

How to Use the Component in a Circuit

Basic Connection:

- Connect Pin 1 to ground (GND).

- Connect Pin 3 to the positive voltage supply (e.g., 5V or 3.3V).

- Use Pin 2 (wiper) as the output to obtain a variable voltage or resistance.

Adjusting Resistance:

- Rotate the gear mechanism to change the position of the wiper along the resistive element.

- The output voltage at the wiper (Pin 2) will vary proportionally to the rotation angle.

Example Circuit:

- Use the gear potentiometer as a voltage divider to control the brightness of an LED or as an input to a microcontroller for analog signal reading.

Important Considerations and Best Practices

- Avoid Overloading: Ensure the power rating of the potentiometer is not exceeded to prevent damage.

- Mechanical Stress: Do not apply excessive force to the gear mechanism to avoid wear or breakage.

- Debouncing: If used in digital circuits, consider implementing software debouncing to handle noise from mechanical adjustments.

- Mounting: Secure the potentiometer properly to prevent movement during operation, especially in robotics or industrial applications.

Arduino UNO Example Code

Below is an example of how to use a gear potentiometer with an Arduino UNO to read its analog output and control an LED's brightness:

// Define the pin connections

const int potPin = A0; // Connect the wiper (Pin 2) to analog pin A0

const int ledPin = 9; // Connect an LED to digital pin 9 (PWM-enabled)

void setup() {

pinMode(ledPin, OUTPUT); // Set the LED pin as an output

Serial.begin(9600); // Initialize serial communication for debugging

}

void loop() {

int potValue = analogRead(potPin); // Read the potentiometer value (0-1023)

// Map the potentiometer value to a PWM range (0-255)

int ledBrightness = map(potValue, 0, 1023, 0, 255);

analogWrite(ledPin, ledBrightness); // Set the LED brightness

// Print the potentiometer value for debugging

Serial.print("Potentiometer Value: ");

Serial.println(potValue);

delay(100); // Small delay for stability

}

Troubleshooting and FAQs

Common Issues Users Might Face

No Output Voltage:

- Cause: Incorrect wiring or loose connections.

- Solution: Verify that all pins are connected properly and securely.

Inconsistent or Noisy Output:

- Cause: Dust or wear on the resistive element.

- Solution: Clean the potentiometer with contact cleaner or replace it if worn out.

Gear Mechanism Stuck or Slipping:

- Cause: Mechanical damage or debris in the gear system.

- Solution: Inspect and clean the gear mechanism. Avoid applying excessive force.

Overheating:

- Cause: Exceeding the power rating.

- Solution: Ensure the potentiometer is used within its specified power and voltage limits.

Solutions and Tips for Troubleshooting

- Check Resistance: Use a multimeter to measure the resistance between Pins 1 and 3 to ensure it matches the specified range.

- Test the Wiper: Measure the resistance between Pin 1 and Pin 2 while rotating the gear to confirm smooth variation.

- Secure Mounting: Ensure the potentiometer is firmly mounted to avoid mechanical stress during operation.

By following this documentation, users can effectively integrate and troubleshoot a gear potentiometer in their projects.