How to Use Servo MG996R: Examples, Pinouts, and Specs

Design with Servo MG996R in Cirkit Designer

Design with Servo MG996R in Cirkit DesignerIntroduction

The MG996R is a high-torque servo motor widely used in robotics, automation, and remote-controlled systems. It is equipped with a durable metal gear train, ensuring long-lasting performance even under high-stress conditions. The servo provides precise control over angular position, making it ideal for applications requiring strong, reliable, and repeatable movement. Its versatility and robust design make it a popular choice for hobbyists and professionals alike.

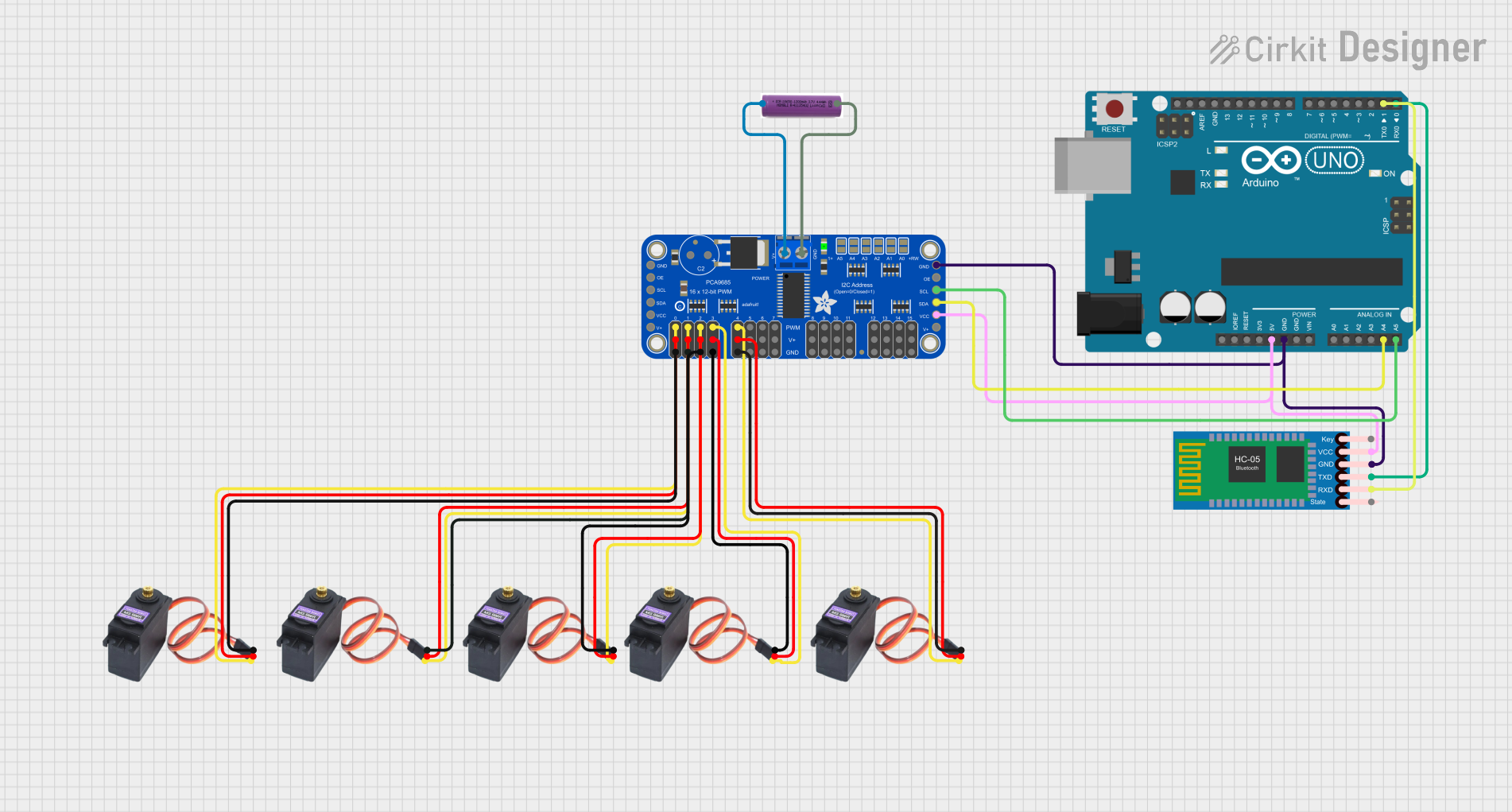

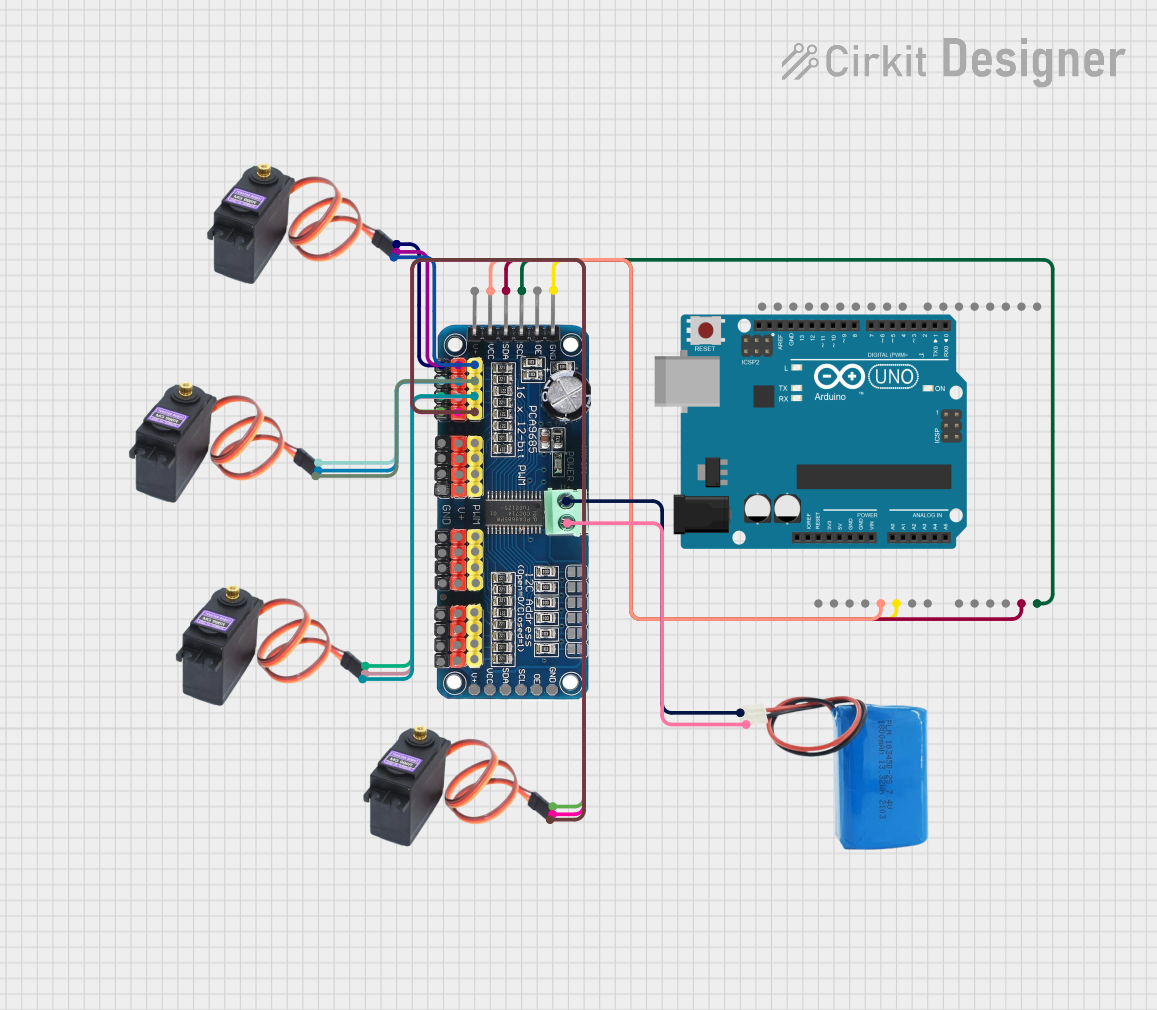

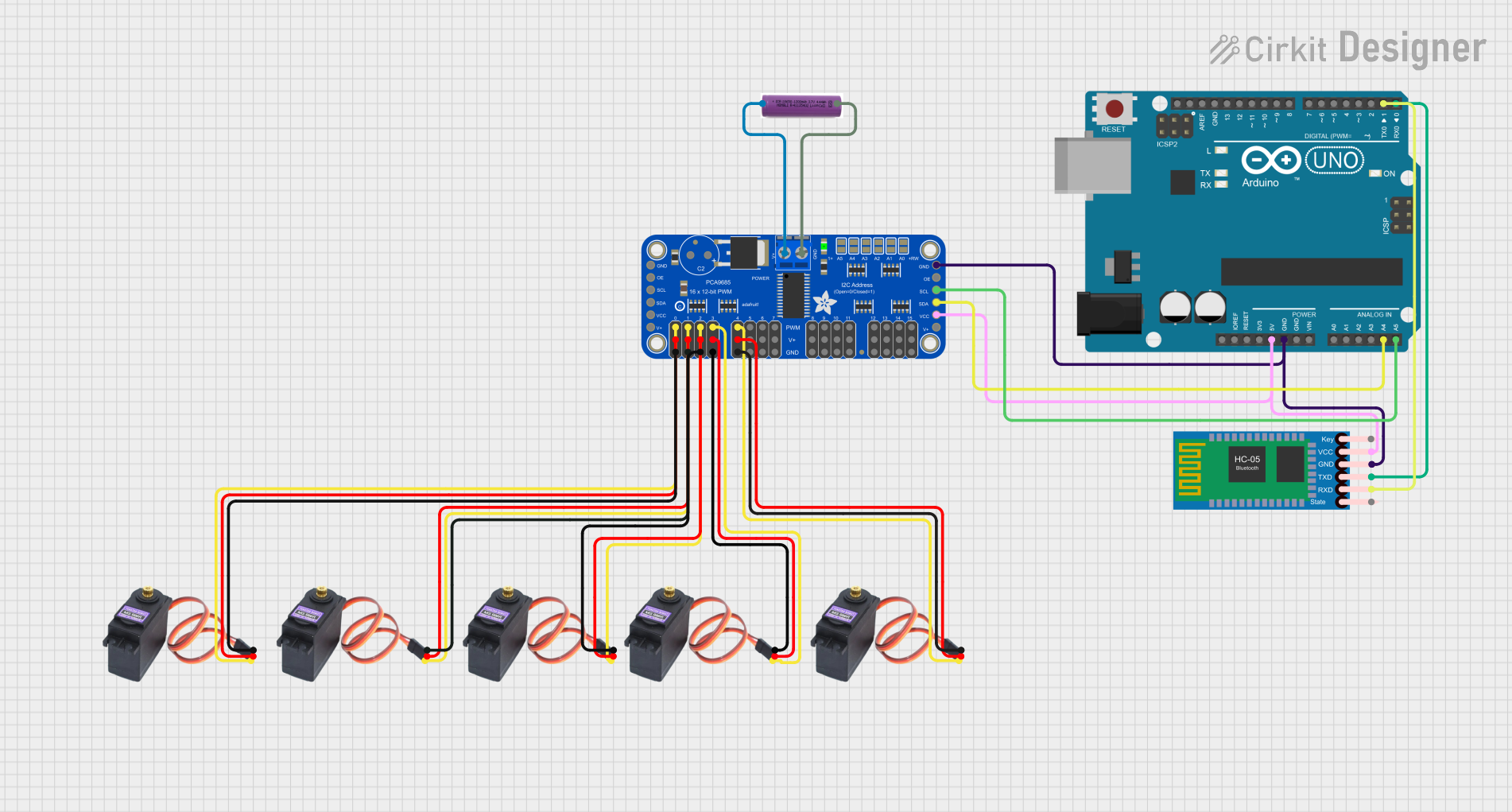

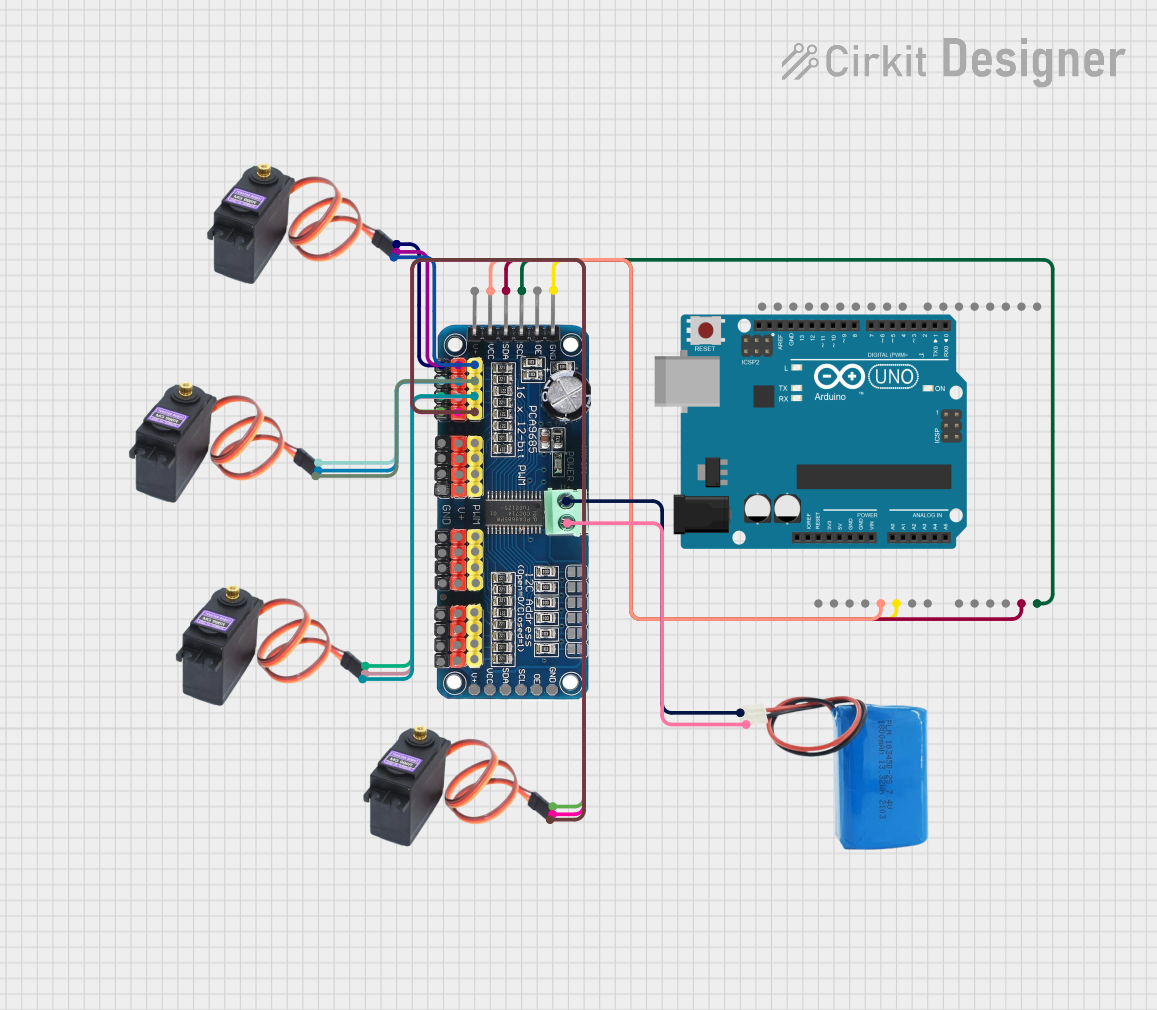

Explore Projects Built with Servo MG996R

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Servo MG996R

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Robotic arms and grippers

- RC vehicles (cars, boats, planes)

- Pan-tilt camera systems

- Automated mechanisms in industrial systems

- DIY projects requiring precise angular motion

Technical Specifications

Below are the key technical details of the MG996R servo motor:

| Parameter | Value |

|---|---|

| Operating Voltage | 4.8V to 7.2V |

| Stall Torque | 9.4 kg·cm (4.8V), 11 kg·cm (6V) |

| Operating Speed | 0.19 s/60° (4.8V), 0.14 s/60° (6V) |

| Gear Type | Metal |

| Weight | 55g |

| Dimensions | 40.7mm x 19.7mm x 42.9mm |

| Control Signal | PWM (Pulse Width Modulation) |

| PWM Pulse Range | 500µs to 2500µs |

| Rotation Angle | 0° to 180° |

| Connector Type | 3-pin female header (Dupont) |

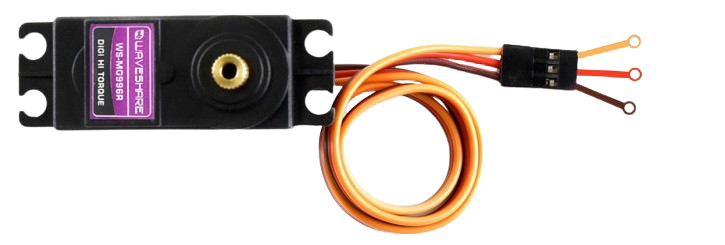

Pin Configuration

The MG996R servo motor has a 3-pin connector. Below is the pinout description:

| Pin | Wire Color | Description |

|---|---|---|

| 1 | Brown | Ground (GND) |

| 2 | Red | Power Supply (VCC) |

| 3 | Orange | Signal (PWM control input) |

Usage Instructions

How to Use the MG996R in a Circuit

- Power Supply: Connect the red wire to a power source (4.8V to 7.2V). Ensure the power supply can provide sufficient current (at least 2A) to handle the servo's peak load.

- Ground Connection: Connect the brown wire to the ground (GND) of your circuit.

- Signal Input: Connect the orange wire to a PWM-capable pin of your microcontroller (e.g., Arduino UNO).

Important Considerations

- Power Requirements: The MG996R can draw significant current, especially under load. Use a separate power supply for the servo to avoid overloading your microcontroller.

- PWM Signal: The servo responds to PWM signals with a pulse width between 500µs (0°) and 2500µs (180°). A 1500µs pulse corresponds to the neutral position (90°).

- Mechanical Limits: Do not force the servo beyond its physical rotation limits (0° to 180°) to avoid damaging the gears.

- Heat Management: Prolonged operation under heavy load may cause the servo to heat up. Allow it to cool periodically to prevent overheating.

Example: Controlling the MG996R with Arduino UNO

Below is an example code to control the MG996R servo motor using an Arduino UNO:

#include <Servo.h> // Include the Servo library

Servo myServo; // Create a Servo object to control the MG996R

void setup() {

myServo.attach(9); // Attach the servo to pin 9 on the Arduino

}

void loop() {

myServo.write(0); // Move the servo to 0 degrees

delay(1000); // Wait for 1 second

myServo.write(90); // Move the servo to 90 degrees

delay(1000); // Wait for 1 second

myServo.write(180); // Move the servo to 180 degrees

delay(1000); // Wait for 1 second

}

Best Practices

- Use a capacitor (e.g., 100µF) across the power supply terminals to stabilize voltage.

- Avoid sudden, large changes in position to reduce stress on the servo.

- Test the servo without load before integrating it into your project.

Troubleshooting and FAQs

Common Issues and Solutions

Servo Not Moving

- Cause: Insufficient power supply.

- Solution: Ensure the power source provides at least 2A of current.

Servo Jittering

- Cause: Unstable PWM signal or noisy power supply.

- Solution: Use a decoupling capacitor across the power supply and verify the PWM signal.

Overheating

- Cause: Prolonged operation under heavy load.

- Solution: Allow the servo to cool periodically and avoid overloading it.

Limited Rotation

- Cause: Incorrect PWM signal range.

- Solution: Ensure the PWM pulse width is between 500µs and 2500µs.

FAQs

Q: Can the MG996R rotate continuously?

A: No, the MG996R is a standard servo with a rotation range of 0° to 180°. For continuous rotation, use a modified or continuous rotation servo.

Q: Can I power the MG996R directly from the Arduino?

A: It is not recommended, as the Arduino cannot supply enough current for the servo under load. Use an external power source.

Q: How do I know if the servo is receiving a signal?

A: The servo will make a slight noise or move slightly when powered and receiving a valid PWM signal.

Q: Can I use the MG996R for high-speed applications?

A: The MG996R is designed for high torque rather than high speed. For faster movement, consider a servo with a higher operating speed.