How to Use MG996R: Examples, Pinouts, and Specs

Design with MG996R in Cirkit Designer

Design with MG996R in Cirkit DesignerIntroduction

The MG996R is a high-torque digital servo motor that is widely used in the field of robotics and remote-controlled (RC) applications. It is an upgrade to the popular MG995 servo and is known for its improved performance and durability. The MG996R is suitable for various applications, including robotic arms, RC cars, helicopters, airplanes, and boats.

Explore Projects Built with MG996R

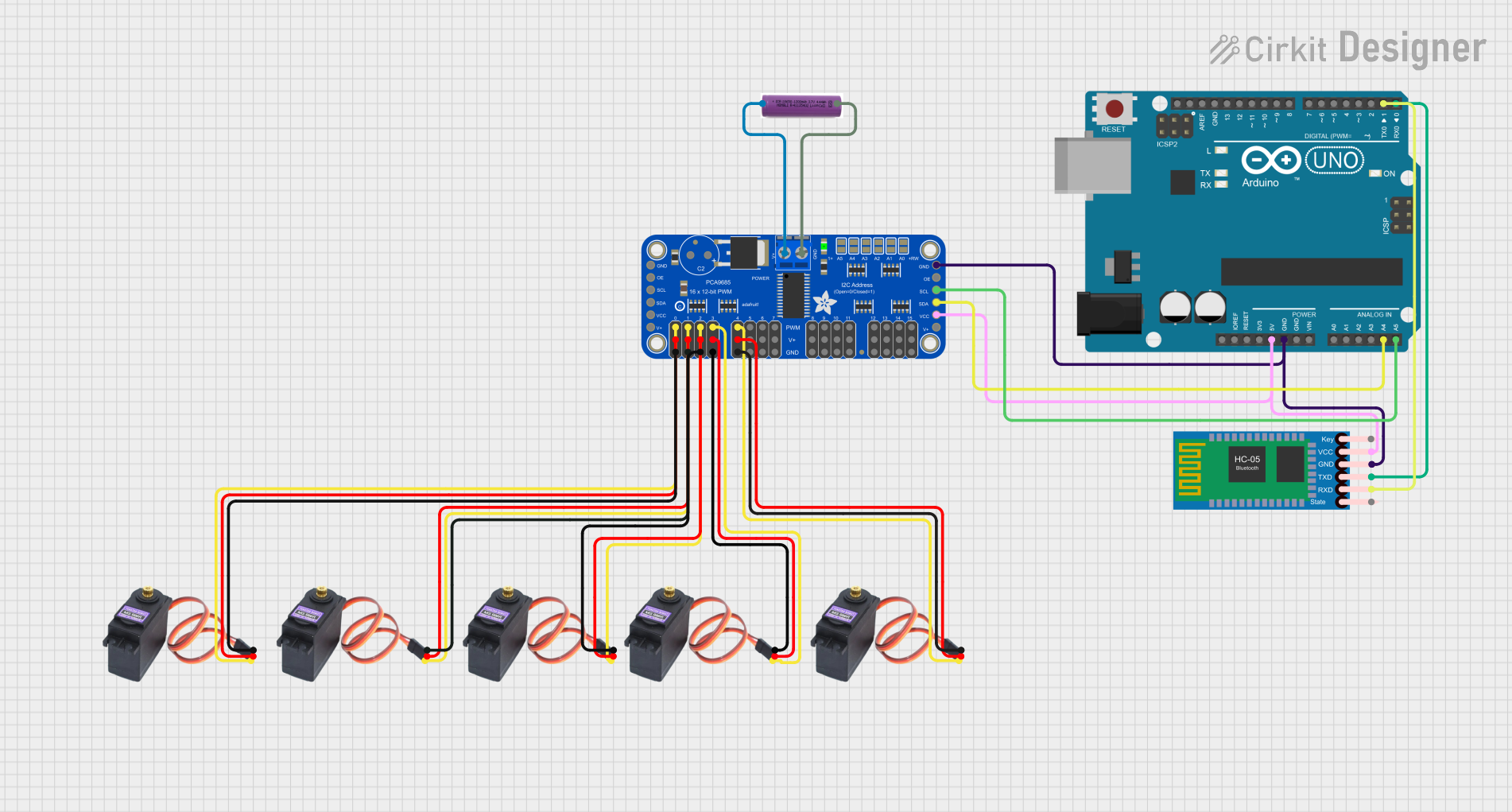

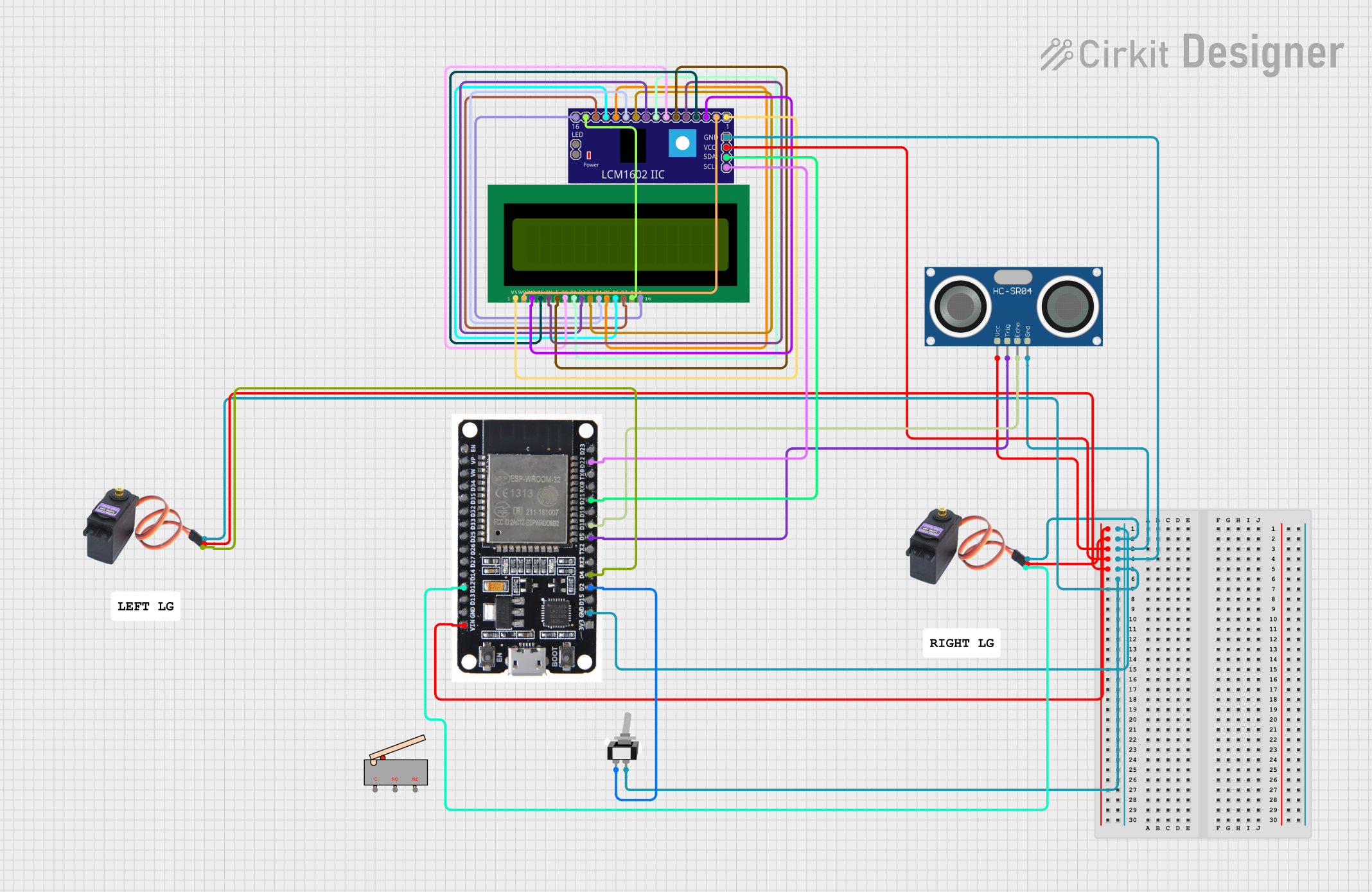

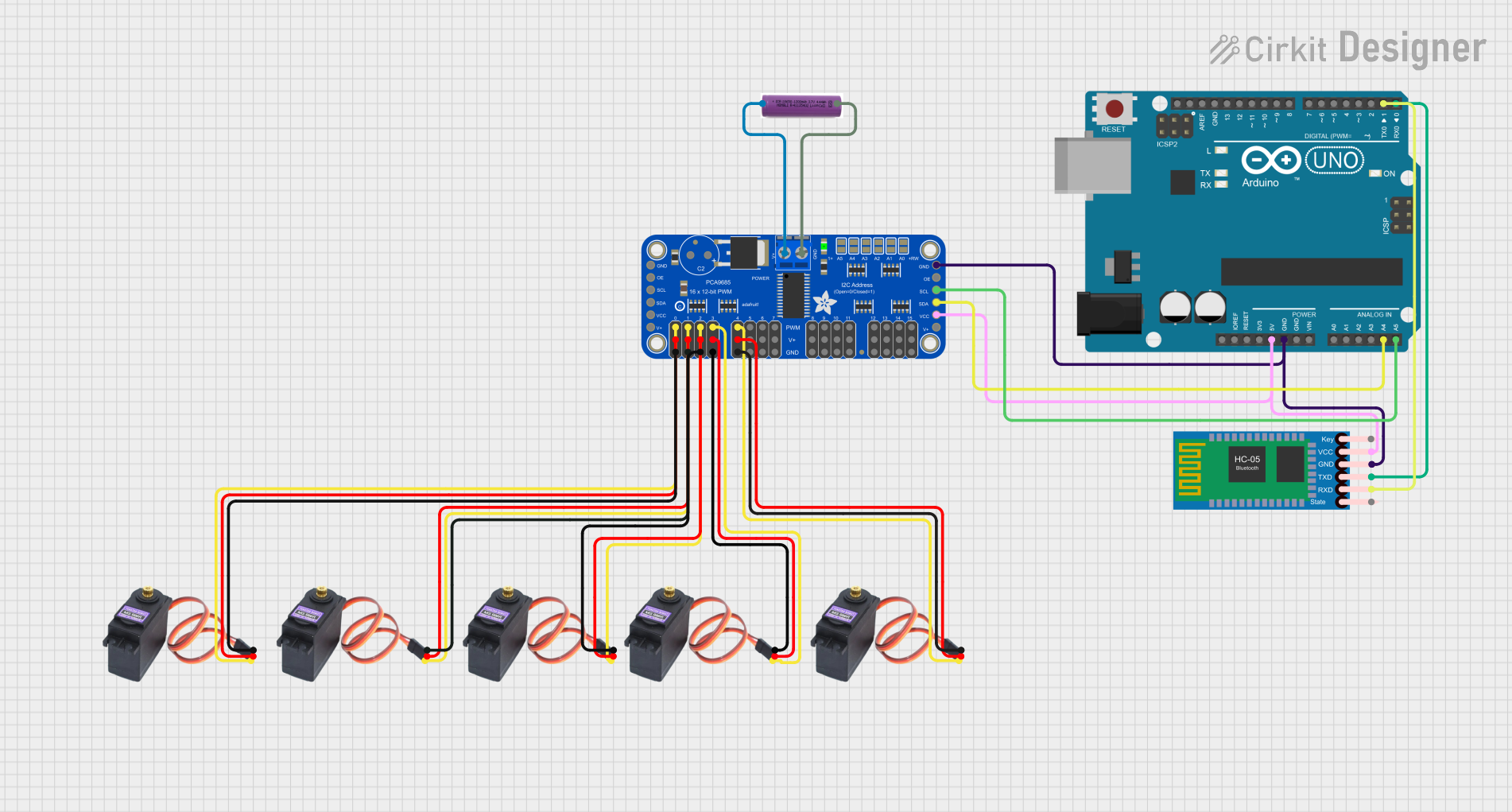

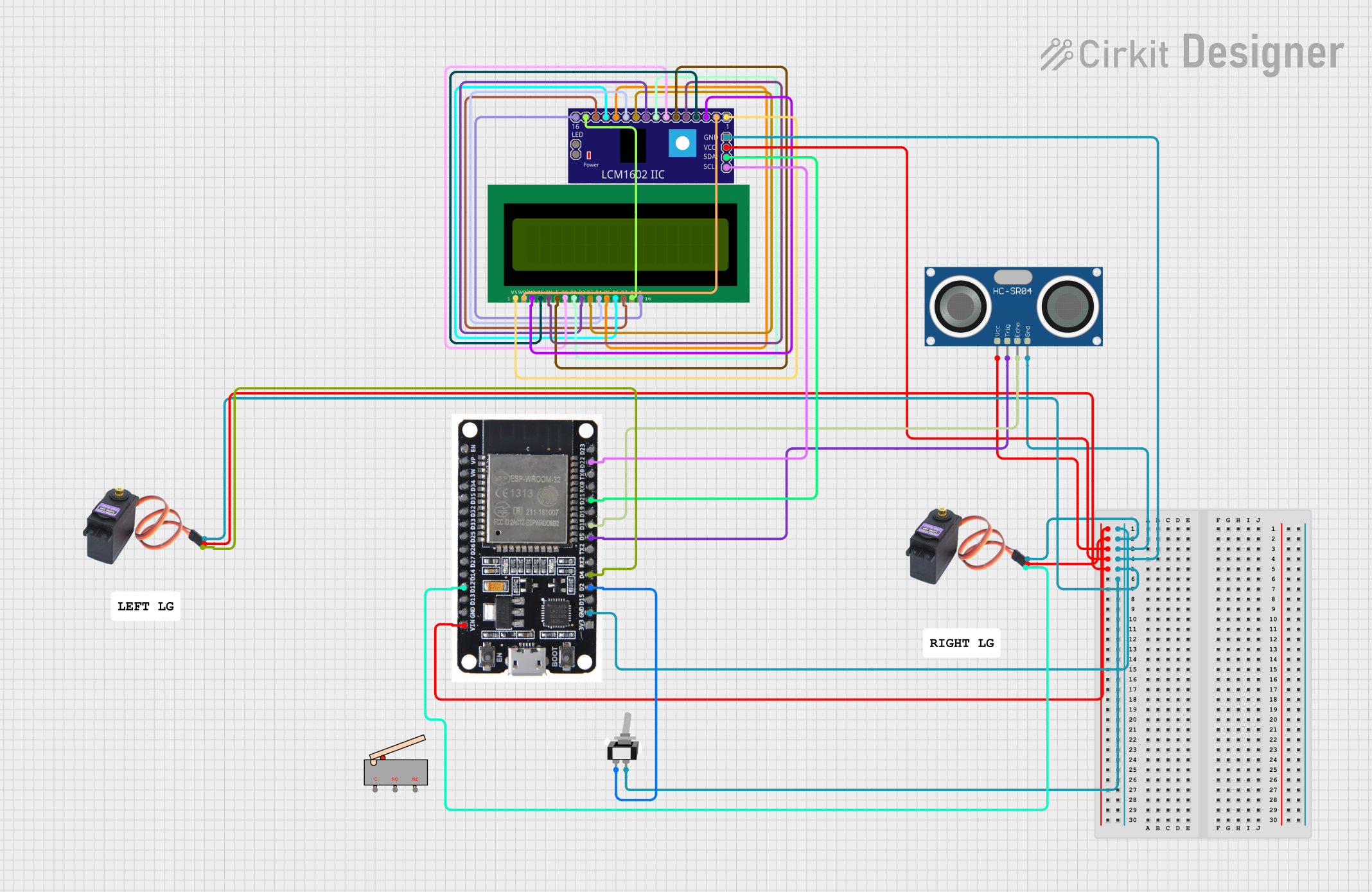

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with MG996R

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

General Features

- Type: Digital Servo

- Gear Type: Metal Gears

- Weight: 55g

- Dimension: 40.7 x 19.7 x 42.9 mm

Performance

- Operating Speed (4.8V): 0.17 sec/60°

- Operating Speed (6.0V): 0.14 sec/60°

- Stall Torque (4.8V): 9.4 kg-cm (130.5 oz-in)

- Stall Torque (6.0V): 11 kg-cm (152.8 oz-in)

Electrical Specifications

- Operating Voltage: 4.8V to 7.2V

- Running Current: 500 mA

- Stall Current: 2.5 A (at 6V)

Pin Configuration

| Pin Number | Description |

|---|---|

| 1 | Signal (PWM Input) |

| 2 | Voltage Supply (V+) |

| 3 | Ground (GND) |

Usage Instructions

Connecting to a Circuit

- Power Supply: Connect the voltage supply pin to a power source that is within the operating voltage range of the MG996R. Ensure that the power supply can handle the stall current of the servo motor.

- Ground: Connect the ground pin to the common ground in your circuit.

- Signal: Connect the signal pin to a PWM-capable pin on your microcontroller, such as an Arduino UNO.

Best Practices

- Always ensure that the power supply is disconnected before making any connections to prevent damage.

- Avoid stalling the servo motor for extended periods, as this can lead to overheating and potential damage.

- When mounting the servo, ensure that the load is within the servo's torque specifications to prevent strain and wear.

Example Code for Arduino UNO

#include <Servo.h>

Servo myservo; // Create servo object to control the MG996R

void setup() {

myservo.attach(9); // Attaches the servo on pin 9 to the servo object

}

void loop() {

myservo.write(0); // Turn servo to 0 degrees

delay(1000); // Wait for 1 second

myservo.write(90); // Turn servo to 90 degrees (neutral position)

delay(1000); // Wait for 1 second

myservo.write(180); // Turn servo to 180 degrees

delay(1000); // Wait for 1 second

}

Troubleshooting and FAQs

Common Issues

- Servo not responding: Check connections, ensure the signal pin is connected to a PWM-capable pin, and verify that the power supply is within the specified range.

- Servo jittering: This can be caused by an insufficient power supply or noise in the signal. Ensure a stable power source and check for any sources of interference.

- Overheating: If the servo is overheating, it may be stalled or overloaded. Reduce the load or duty cycle to allow the servo to cool down.

FAQs

Q: Can I power the MG996R directly from an Arduino board? A: It is not recommended to power the MG996R directly from an Arduino board, as the servo may draw more current than the board can supply, especially under load. Use an external power source that meets the servo's requirements.

Q: What is the pulse width range for controlling the MG996R? A: The typical pulse width range for controlling the MG996R is 1000µs to 2000µs, with 1500µs being the neutral position (90 degrees).

Q: How do I calibrate the MG996R to my specific application? A: Calibration involves sending different pulse widths from your microcontroller and observing the servo's response. Adjust the pulse width until you achieve the desired position or range of motion.

Q: Can the MG996R be used for continuous rotation? A: The MG996R is not designed for continuous rotation out of the box. It is a standard servo with a limited range of motion (typically 180 degrees). However, it can be modified for continuous rotation by mechanically altering the internal feedback mechanism, but this is an advanced modification and not recommended for beginners.