How to Use BTS7960: Examples, Pinouts, and Specs

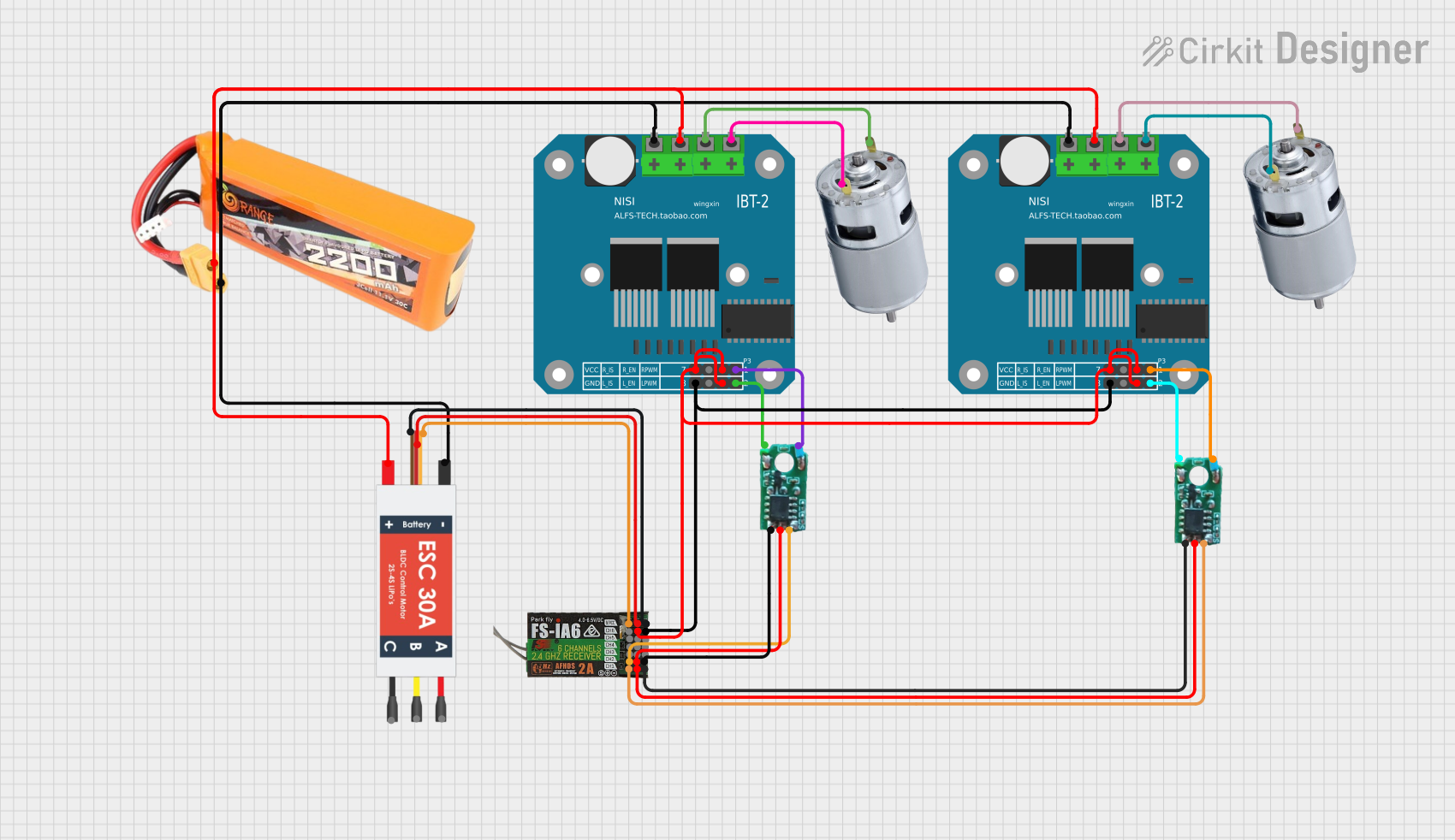

Design with BTS7960 in Cirkit Designer

Design with BTS7960 in Cirkit DesignerIntroduction

The BTS7960 is a high-current H-bridge motor driver designed to control DC motors and other inductive loads. It is capable of handling high currents, making it ideal for applications requiring robust and reliable motor control. The component integrates advanced protection features, including overcurrent, overtemperature, and undervoltage safeguards, ensuring durability and safety in demanding environments.

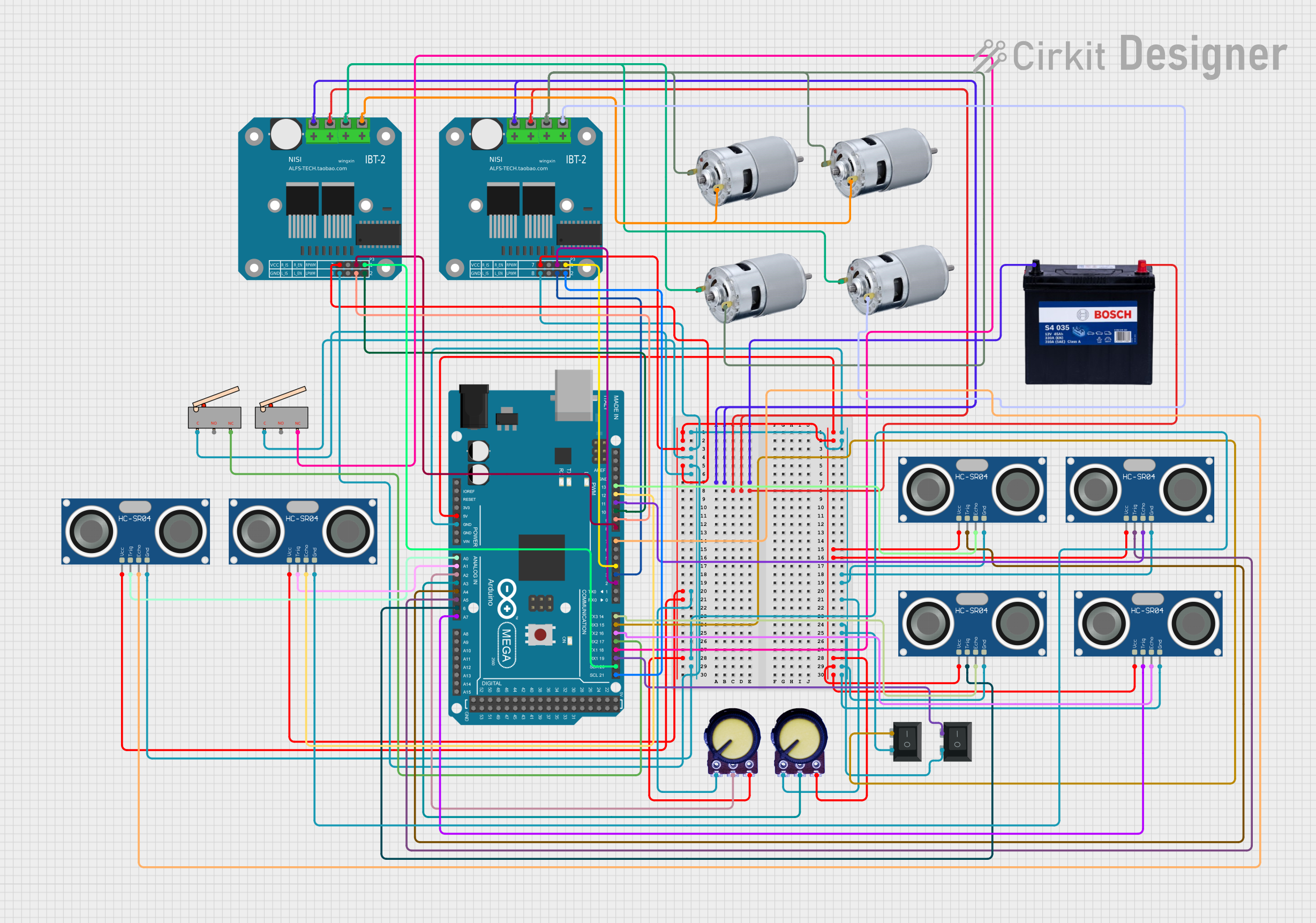

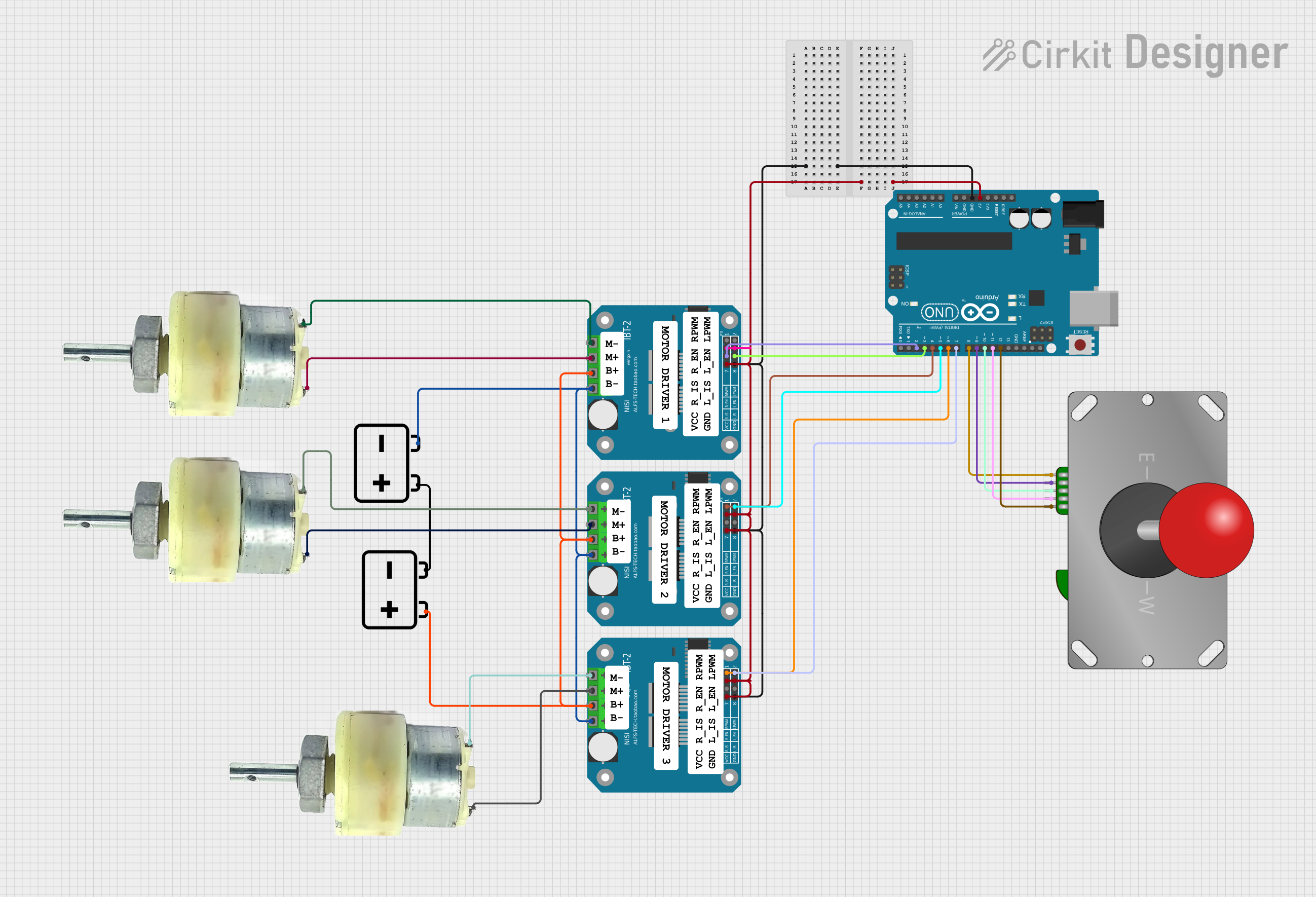

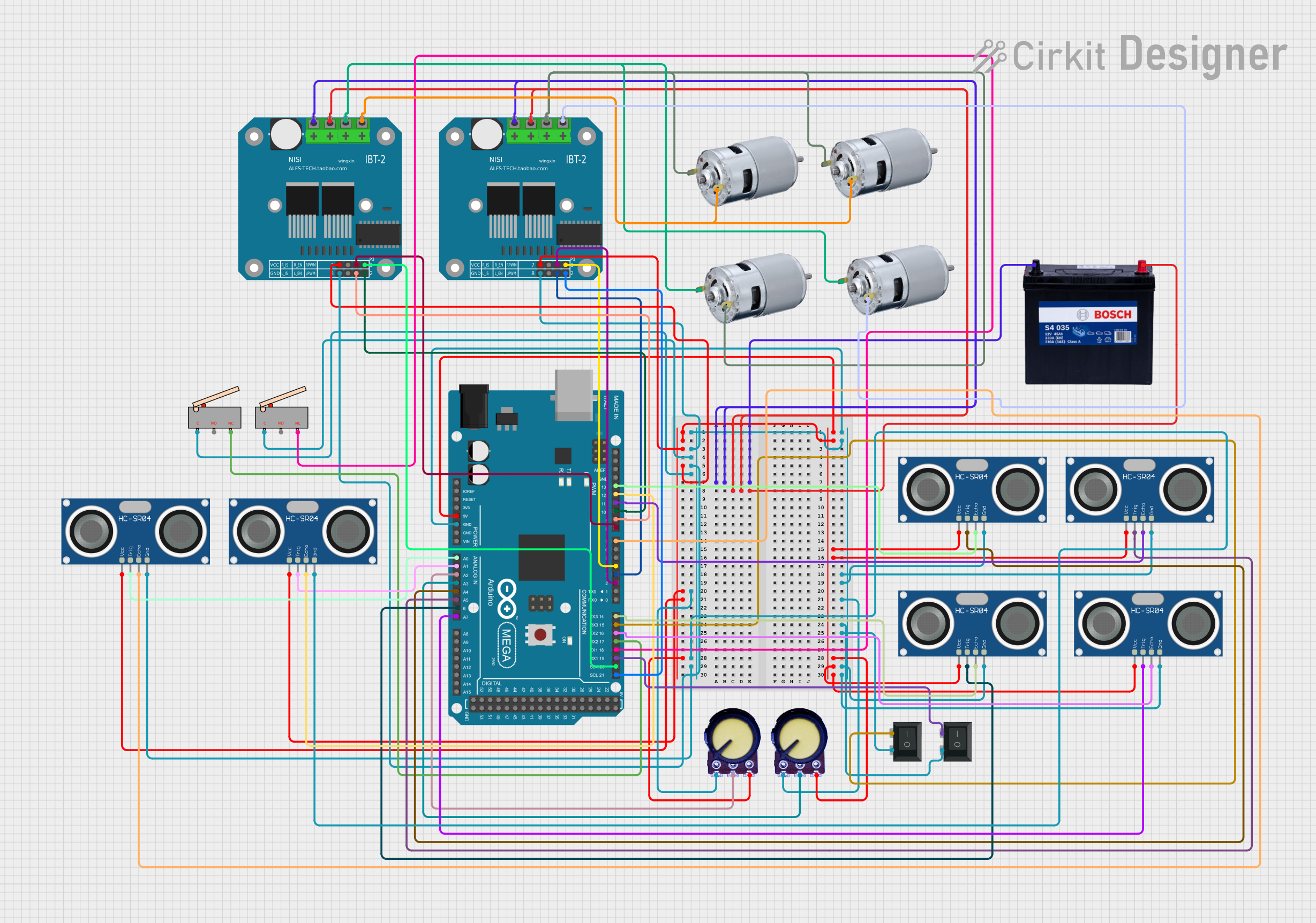

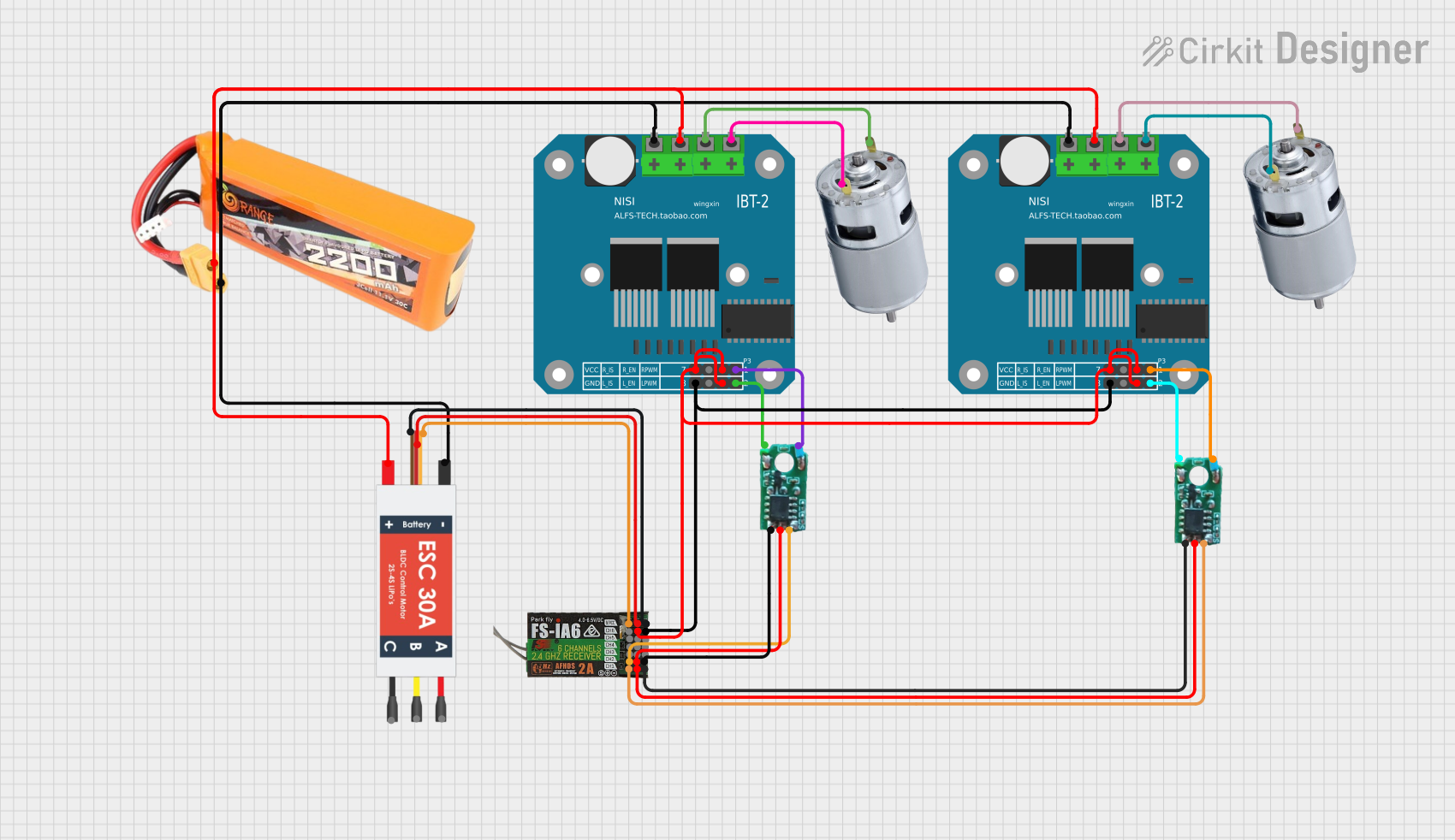

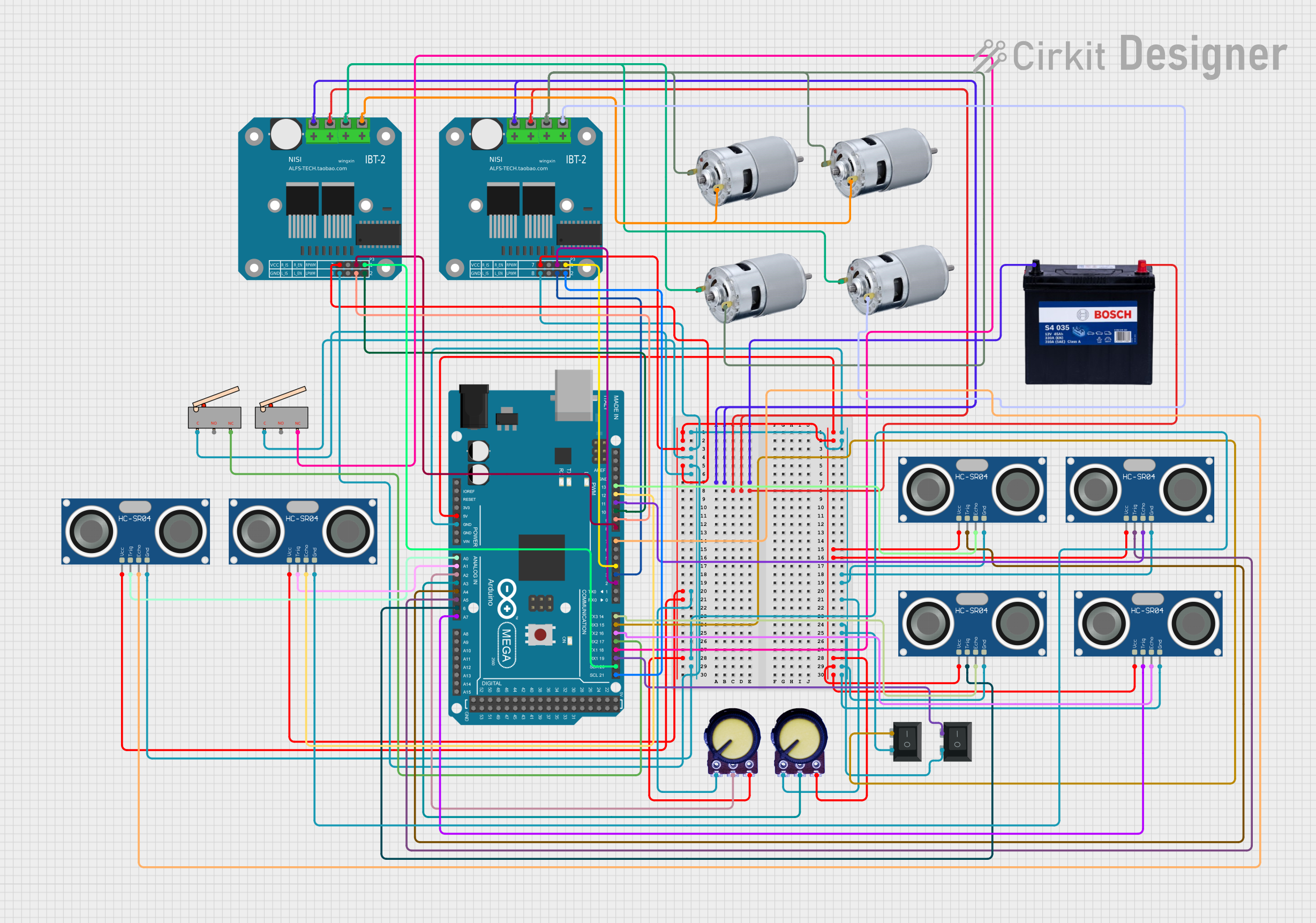

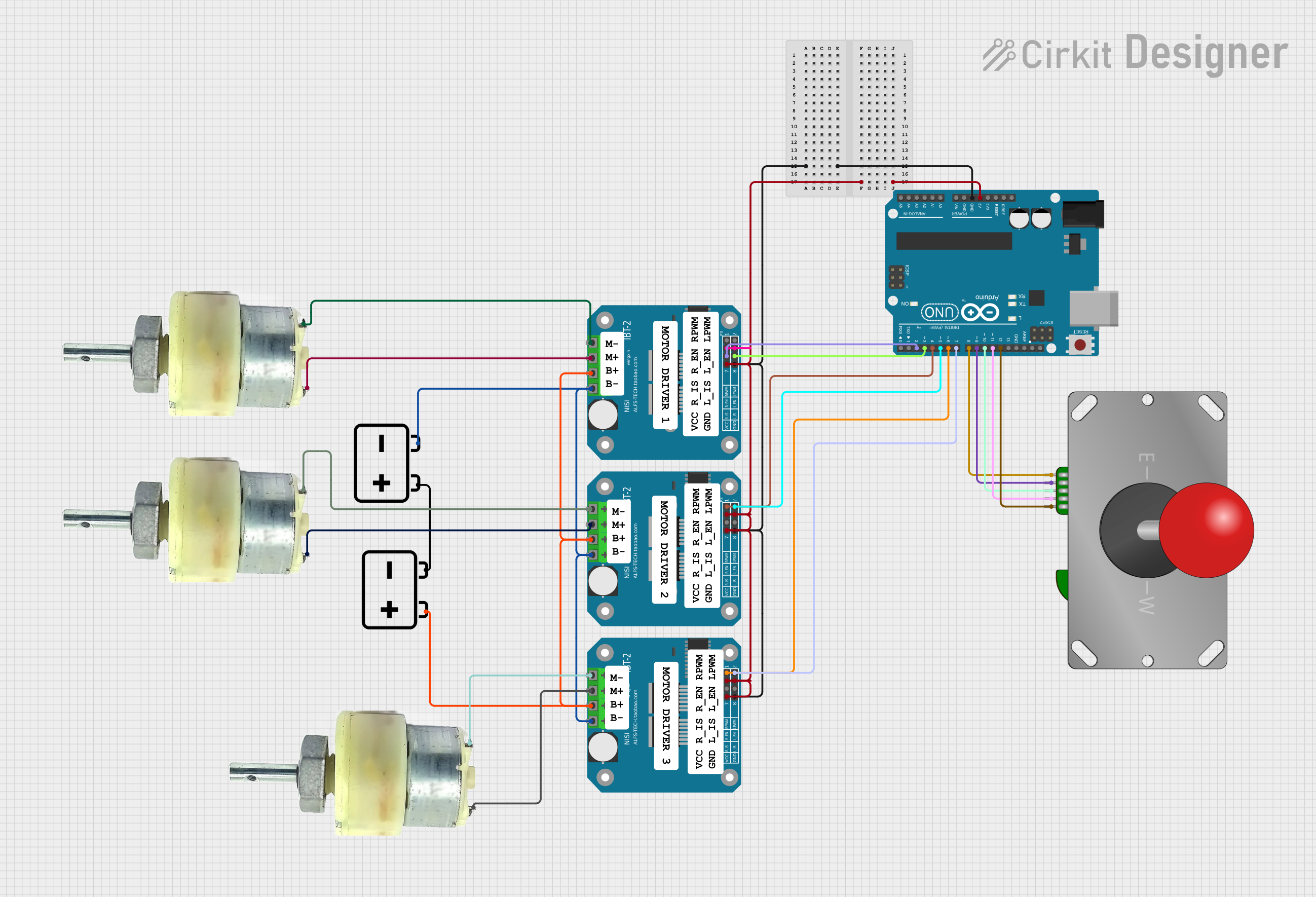

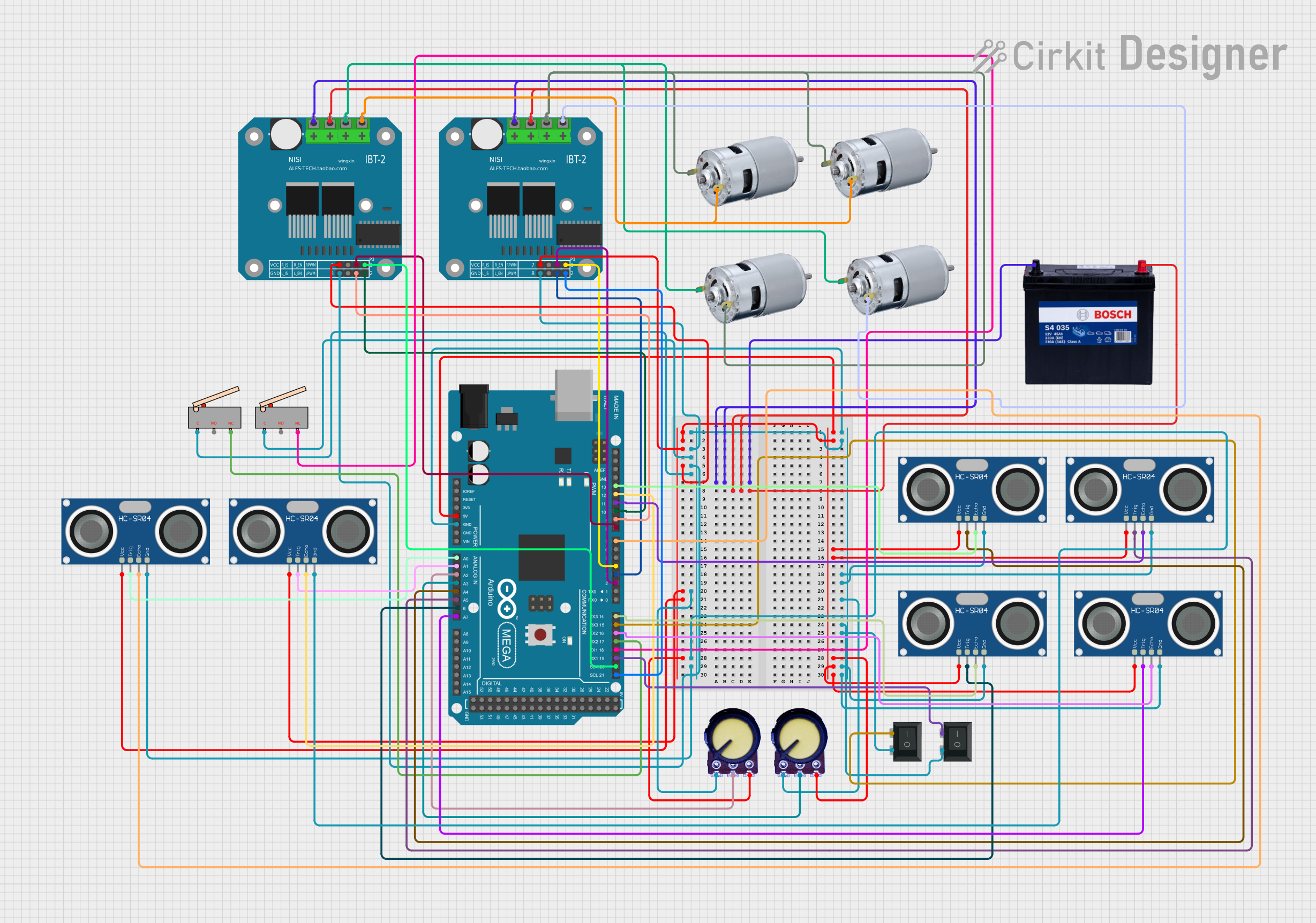

Explore Projects Built with BTS7960

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with BTS7960

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics and automation systems

- Electric vehicle motor control

- Conveyor belt systems

- Industrial machinery

- Remote-controlled vehicles

- High-power motorized projects

Technical Specifications

The BTS7960 is a versatile motor driver with the following key specifications:

| Parameter | Value |

|---|---|

| Operating Voltage Range | 5.5V to 27V |

| Maximum Continuous Current | 43A |

| Peak Current | 50A |

| PWM Frequency | Up to 25kHz |

| Logic Input Voltage | 3.3V or 5V compatible |

| Overcurrent Protection | Yes |

| Overtemperature Protection | Yes |

| Undervoltage Protection | Yes |

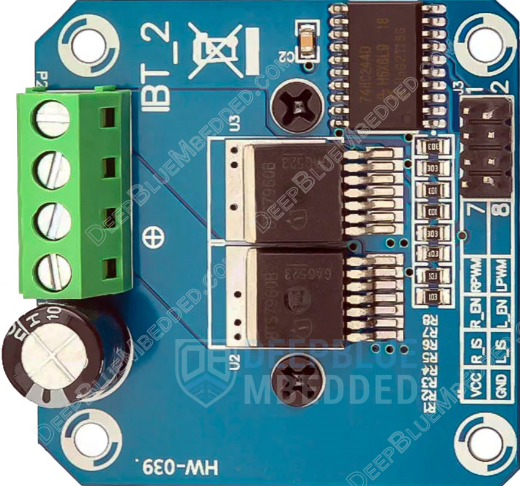

Pin Configuration and Descriptions

The BTS7960 module typically comes with the following pin layout:

| Pin Name | Description |

|---|---|

| VCC | Power supply for the logic circuit (5V). |

| GND | Ground connection for the logic circuit. |

| RPWM | PWM input for controlling motor rotation in one direction. |

| LPWM | PWM input for controlling motor rotation in the opposite direction. |

| R_EN | Enable pin for the right side of the H-bridge. |

| L_EN | Enable pin for the left side of the H-bridge. |

| IS | Current sensing output (optional, used for monitoring motor current). |

| V+ | Motor power supply (connect to the positive terminal of the motor power source). |

| OUT1 | Output terminal 1 for the motor. |

| OUT2 | Output terminal 2 for the motor. |

| GND (Power) | Ground connection for the motor power supply. |

Usage Instructions

How to Use the BTS7960 in a Circuit

Power Connections:

- Connect the motor power supply to the

V+pin and the ground of the power supply to theGND (Power)pin. - Provide 5V to the

VCCpin for the logic circuit and connect its ground to theGNDpin.

- Connect the motor power supply to the

Motor Connections:

- Connect the motor terminals to

OUT1andOUT2.

- Connect the motor terminals to

Control Connections:

- Use the

RPWMandLPWMpins to control the motor's speed and direction via PWM signals. - Enable the H-bridge by setting

R_ENandL_ENto HIGH.

- Use the

PWM Control:

- To rotate the motor in one direction, provide a PWM signal to

RPWMand setLPWMto LOW. - To rotate the motor in the opposite direction, provide a PWM signal to

LPWMand setRPWMto LOW.

- To rotate the motor in one direction, provide a PWM signal to

Important Considerations and Best Practices

- Ensure the motor power supply voltage does not exceed 27V.

- Use a heatsink or active cooling if operating at high currents for extended periods.

- Avoid connecting the motor directly to the logic power supply to prevent damage.

- Use appropriate decoupling capacitors near the power supply pins to reduce noise.

- Verify that the PWM frequency is within the supported range (up to 25kHz).

Example: Connecting BTS7960 to an Arduino UNO

Below is an example Arduino sketch to control a motor using the BTS7960:

// Define control pins for the BTS7960

const int RPWM = 5; // PWM pin for forward rotation

const int LPWM = 6; // PWM pin for reverse rotation

const int R_EN = 7; // Enable pin for right side

const int L_EN = 8; // Enable pin for left side

void setup() {

// Set control pins as outputs

pinMode(RPWM, OUTPUT);

pinMode(LPWM, OUTPUT);

pinMode(R_EN, OUTPUT);

pinMode(L_EN, OUTPUT);

// Enable both sides of the H-bridge

digitalWrite(R_EN, HIGH);

digitalWrite(L_EN, HIGH);

}

void loop() {

// Rotate motor forward at 50% speed

analogWrite(RPWM, 128); // 50% duty cycle

analogWrite(LPWM, 0); // No reverse signal

delay(2000); // Run for 2 seconds

// Stop the motor

analogWrite(RPWM, 0);

analogWrite(LPWM, 0);

delay(1000); // Pause for 1 second

// Rotate motor in reverse at 75% speed

analogWrite(RPWM, 0); // No forward signal

analogWrite(LPWM, 192); // 75% duty cycle

delay(2000); // Run for 2 seconds

// Stop the motor

analogWrite(RPWM, 0);

analogWrite(LPWM, 0);

delay(1000); // Pause for 1 second

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Does Not Rotate:

- Verify that the power supply is connected and providing the correct voltage.

- Ensure the

R_ENandL_ENpins are set to HIGH. - Check the PWM signal connections and ensure the duty cycle is not zero.

Motor Rotates in the Wrong Direction:

- Swap the connections of the motor terminals at

OUT1andOUT2. - Verify the PWM signals on

RPWMandLPWMare configured correctly.

- Swap the connections of the motor terminals at

Overheating:

- Ensure the module is not exceeding its maximum current rating.

- Use a heatsink or active cooling to dissipate heat.

No Response from the Module:

- Check all connections for loose wires or incorrect wiring.

- Verify that the logic power supply (5V) is stable and connected to

VCC.

FAQs

Q: Can the BTS7960 drive stepper motors?

A: No, the BTS7960 is designed for DC motors and other inductive loads. Stepper motors require a dedicated stepper driver.

Q: What is the purpose of the IS pin?

A: The IS pin provides a current sensing output, which can be used to monitor the motor's current draw.

Q: Can I use the BTS7960 with a 3.3V microcontroller?

A: Yes, the logic inputs are compatible with both 3.3V and 5V signals.

Q: What happens if the motor draws more than 43A?

A: The BTS7960 has built-in overcurrent protection, which will shut down the module to prevent damage.