How to Use Oil Pressure Sensor: Examples, Pinouts, and Specs

Design with Oil Pressure Sensor in Cirkit Designer

Design with Oil Pressure Sensor in Cirkit DesignerIntroduction

The Oil Pressure Sensor (Manufacturer: OIL PRESSURE, Part ID: OilPressure) is a device designed to measure the pressure of oil in an engine or hydraulic system. It provides critical data for monitoring and maintaining optimal performance, ensuring the system operates within safe parameters. This sensor is widely used in automotive, industrial, and hydraulic applications to prevent damage caused by low or high oil pressure.

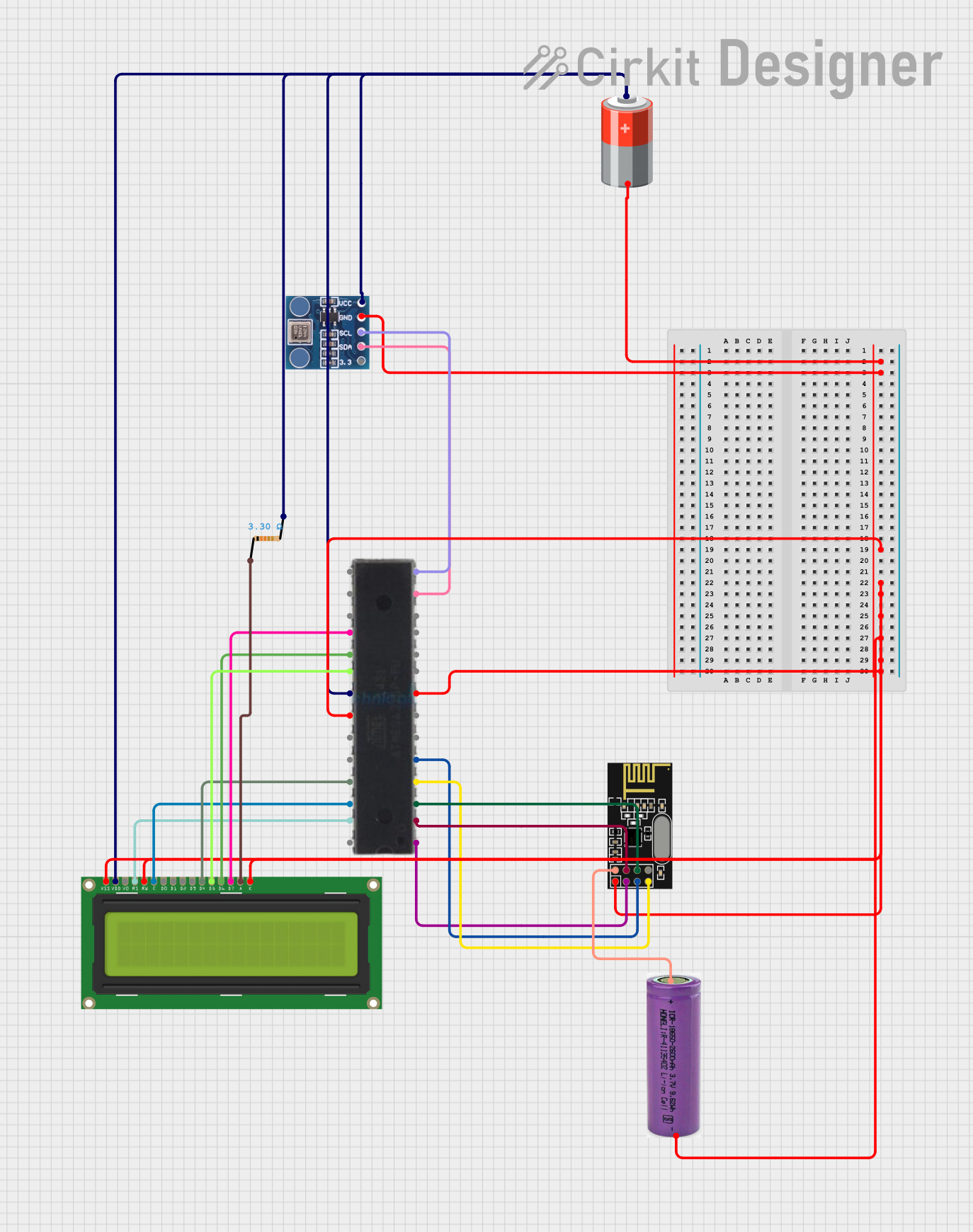

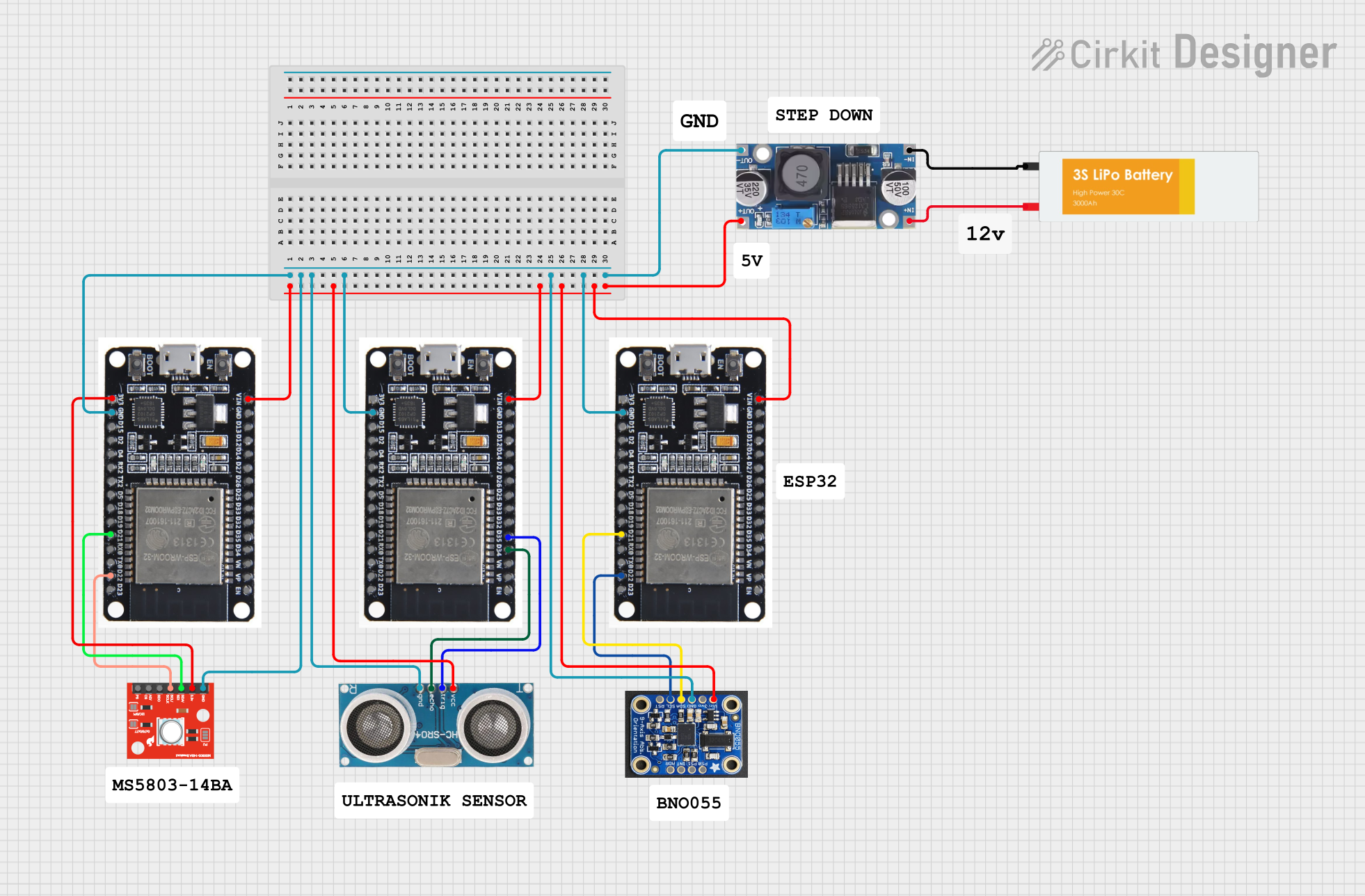

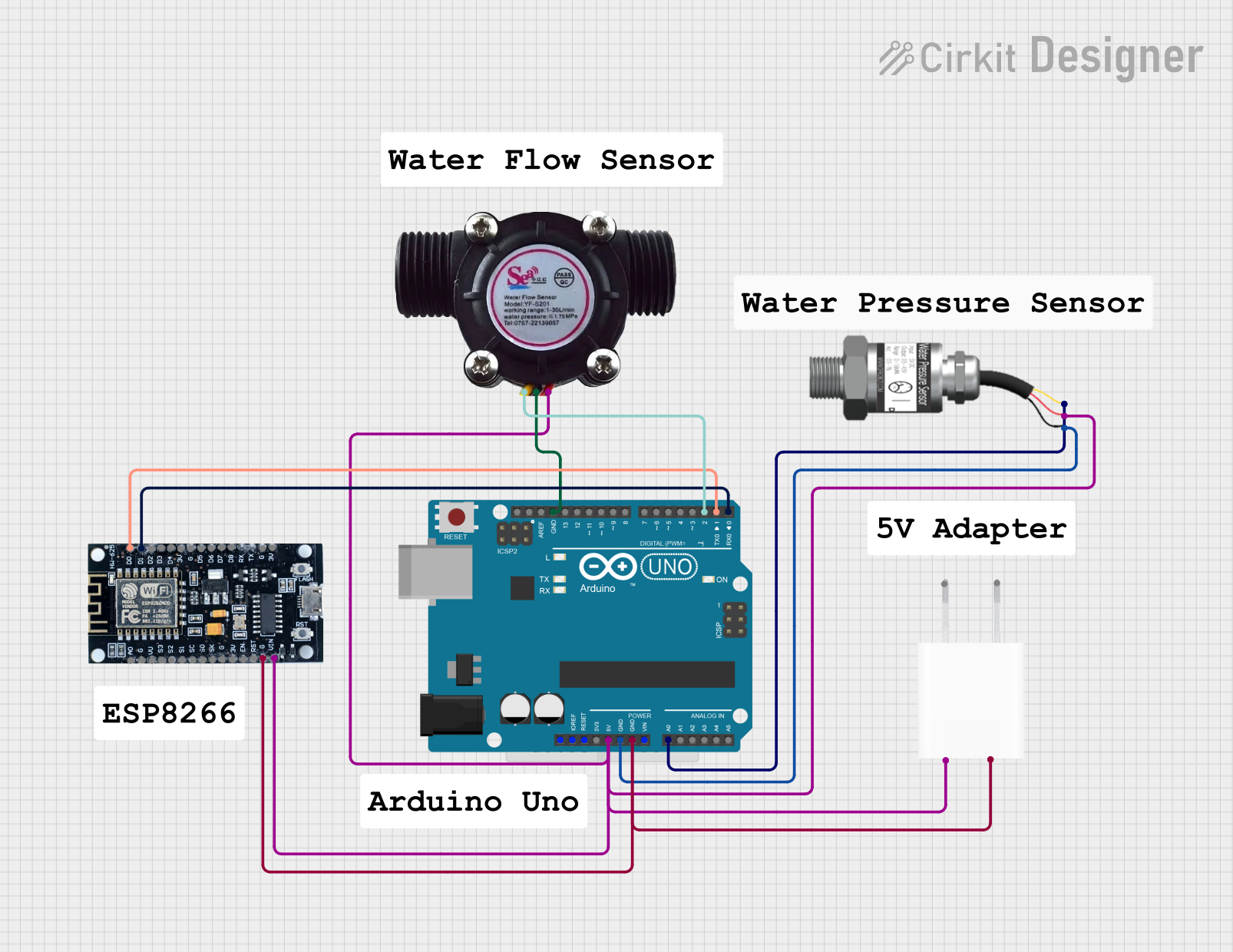

Explore Projects Built with Oil Pressure Sensor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Oil Pressure Sensor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Automotive engines for real-time oil pressure monitoring

- Hydraulic systems to ensure proper lubrication and pressure levels

- Industrial machinery for predictive maintenance

- Oil pumps and compressors for performance optimization

Technical Specifications

The following table outlines the key technical details of the Oil Pressure Sensor:

| Parameter | Value |

|---|---|

| Operating Voltage | 5V DC |

| Output Signal | Analog voltage (0.5V to 4.5V) |

| Pressure Range | 0 to 150 PSI |

| Accuracy | ±2% of full scale |

| Operating Temperature | -40°C to +125°C |

| Thread Type | 1/8"-27 NPT |

| Response Time | < 2 ms |

| Connector Type | 3-pin (VCC, GND, Signal) |

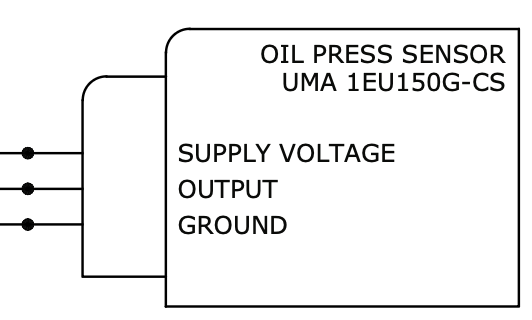

Pin Configuration and Descriptions

The Oil Pressure Sensor has a 3-pin connector. The pinout is described in the table below:

| Pin | Name | Description |

|---|---|---|

| 1 | VCC | Power supply input (5V DC) |

| 2 | GND | Ground connection |

| 3 | Signal | Analog output signal proportional to oil pressure |

Usage Instructions

How to Use the Component in a Circuit

- Power Supply: Connect the VCC pin to a regulated 5V DC power source and the GND pin to the ground of the circuit.

- Signal Output: Connect the Signal pin to an analog input pin of a microcontroller (e.g., Arduino UNO) or an analog-to-digital converter (ADC).

- Thread Installation: Securely thread the sensor into the oil system using the 1/8"-27 NPT fitting. Ensure a proper seal to prevent leaks.

- Calibration: If required, calibrate the sensor by comparing its output to a known pressure reference.

Important Considerations and Best Practices

- Power Supply: Use a stable 5V DC power source to ensure accurate readings.

- Wiring: Keep the wiring short and shielded to minimize noise interference.

- Temperature: Ensure the sensor operates within its specified temperature range (-40°C to +125°C).

- Sealing: Use thread sealant or Teflon tape to prevent oil leaks during installation.

- Testing: Verify the sensor's output using a multimeter or oscilloscope before integrating it into the system.

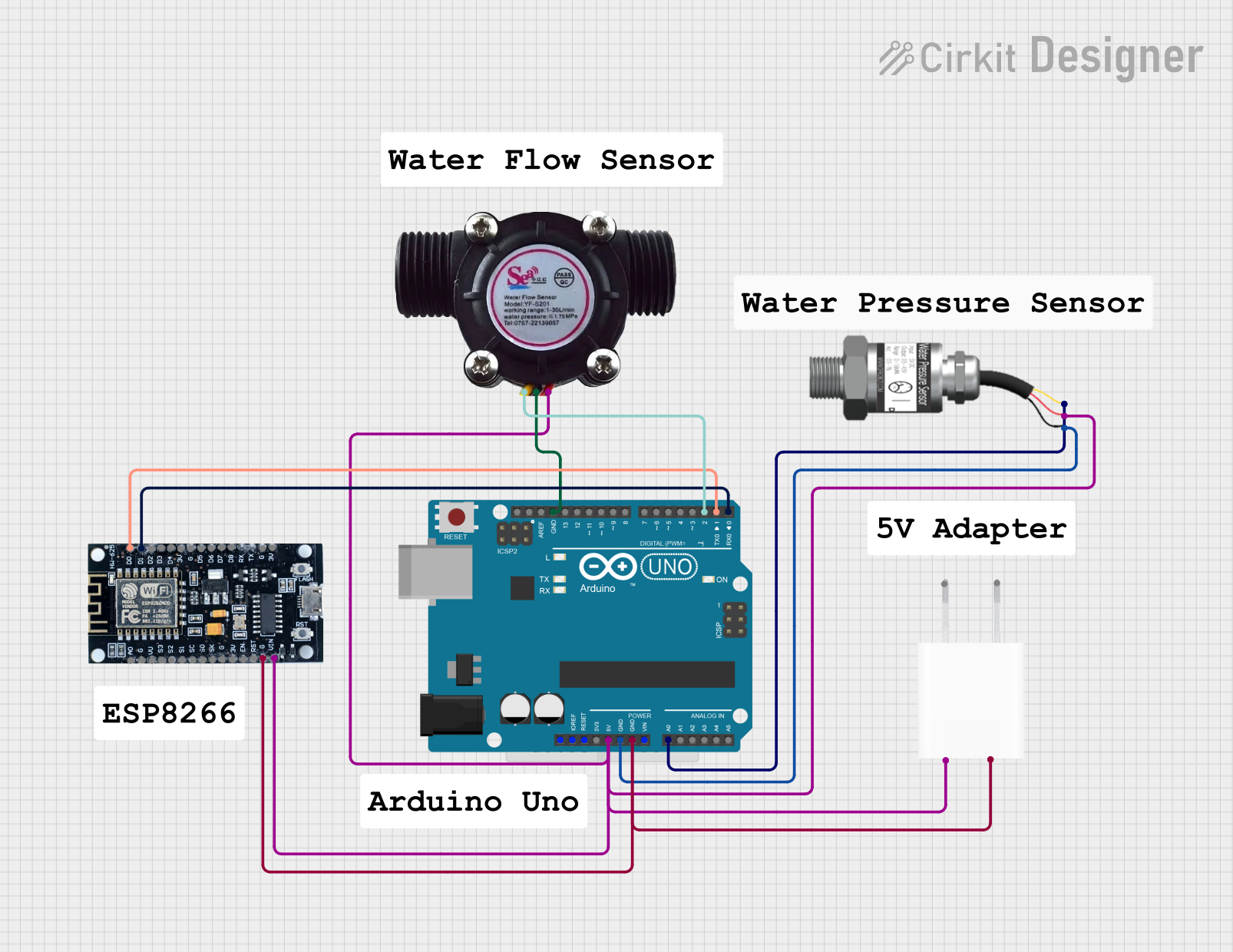

Example: Connecting to an Arduino UNO

Below is an example of how to connect the Oil Pressure Sensor to an Arduino UNO and read its output:

Circuit Diagram

- VCC: Connect to Arduino 5V pin

- GND: Connect to Arduino GND pin

- Signal: Connect to Arduino analog pin A0

Arduino Code

// Oil Pressure Sensor Example Code

// Reads the analog signal from the sensor and converts it to pressure in PSI

const int sensorPin = A0; // Analog pin connected to the sensor's Signal pin

const float voltageRef = 5.0; // Reference voltage of the Arduino (5V)

const float pressureMax = 150.0; // Maximum pressure the sensor can measure (in PSI)

const float voltageMin = 0.5; // Minimum output voltage of the sensor (in volts)

const float voltageMax = 4.5; // Maximum output voltage of the sensor (in volts)

void setup() {

Serial.begin(9600); // Initialize serial communication at 9600 baud

}

void loop() {

int sensorValue = analogRead(sensorPin); // Read the analog value (0-1023)

float voltage = (sensorValue / 1023.0) * voltageRef; // Convert to voltage

float pressure = (voltage - voltageMin) * (pressureMax / (voltageMax - voltageMin));

// Ensure pressure is within valid range

if (pressure < 0) pressure = 0;

if (pressure > pressureMax) pressure = pressureMax;

// Print the pressure value to the Serial Monitor

Serial.print("Oil Pressure: ");

Serial.print(pressure);

Serial.println(" PSI");

delay(500); // Wait for 500ms before the next reading

}

Troubleshooting and FAQs

Common Issues and Solutions

No Output Signal:

- Cause: Incorrect wiring or no power supply.

- Solution: Verify the connections and ensure the sensor is powered with 5V DC.

Inaccurate Readings:

- Cause: Electrical noise or improper calibration.

- Solution: Use shielded cables and recalibrate the sensor.

Oil Leaks:

- Cause: Improper installation or damaged threads.

- Solution: Use thread sealant or replace the sensor if threads are damaged.

Signal Stuck at Minimum/Maximum Voltage:

- Cause: Sensor failure or pressure out of range.

- Solution: Check the oil pressure system and replace the sensor if necessary.

FAQs

Q1: Can this sensor be used with a 3.3V microcontroller?

A1: No, the sensor requires a 5V power supply for proper operation. Use a level shifter if interfacing with a 3.3V system.

Q2: How do I clean the sensor?

A2: Remove the sensor from the system and clean it with a soft cloth. Avoid using harsh chemicals that may damage the sensor.

Q3: What happens if the sensor is exposed to pressure beyond 150 PSI?

A3: The sensor may become permanently damaged. Always ensure the system pressure stays within the sensor's rated range.

Q4: Can this sensor measure other fluids besides oil?

A4: This sensor is specifically designed for oil. Using it with other fluids may affect its accuracy and longevity.