How to Use OXY-LC Interface Board: Examples, Pinouts, and Specs

Design with OXY-LC Interface Board in Cirkit Designer

Design with OXY-LC Interface Board in Cirkit DesignerIntroduction

The OXY-LC Interface Board (OXY-LC-485), manufactured by SST Sensing, is a specialized circuit board designed to facilitate communication between the OXY-LC oxygen sensor and other electronic systems. It enables seamless data transfer and control functions, making it an essential component for integrating oxygen sensors into a variety of applications.

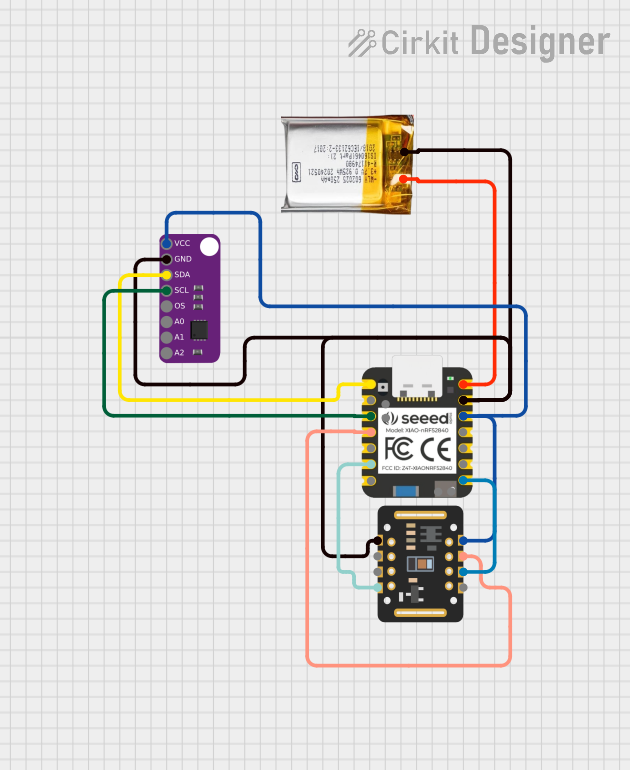

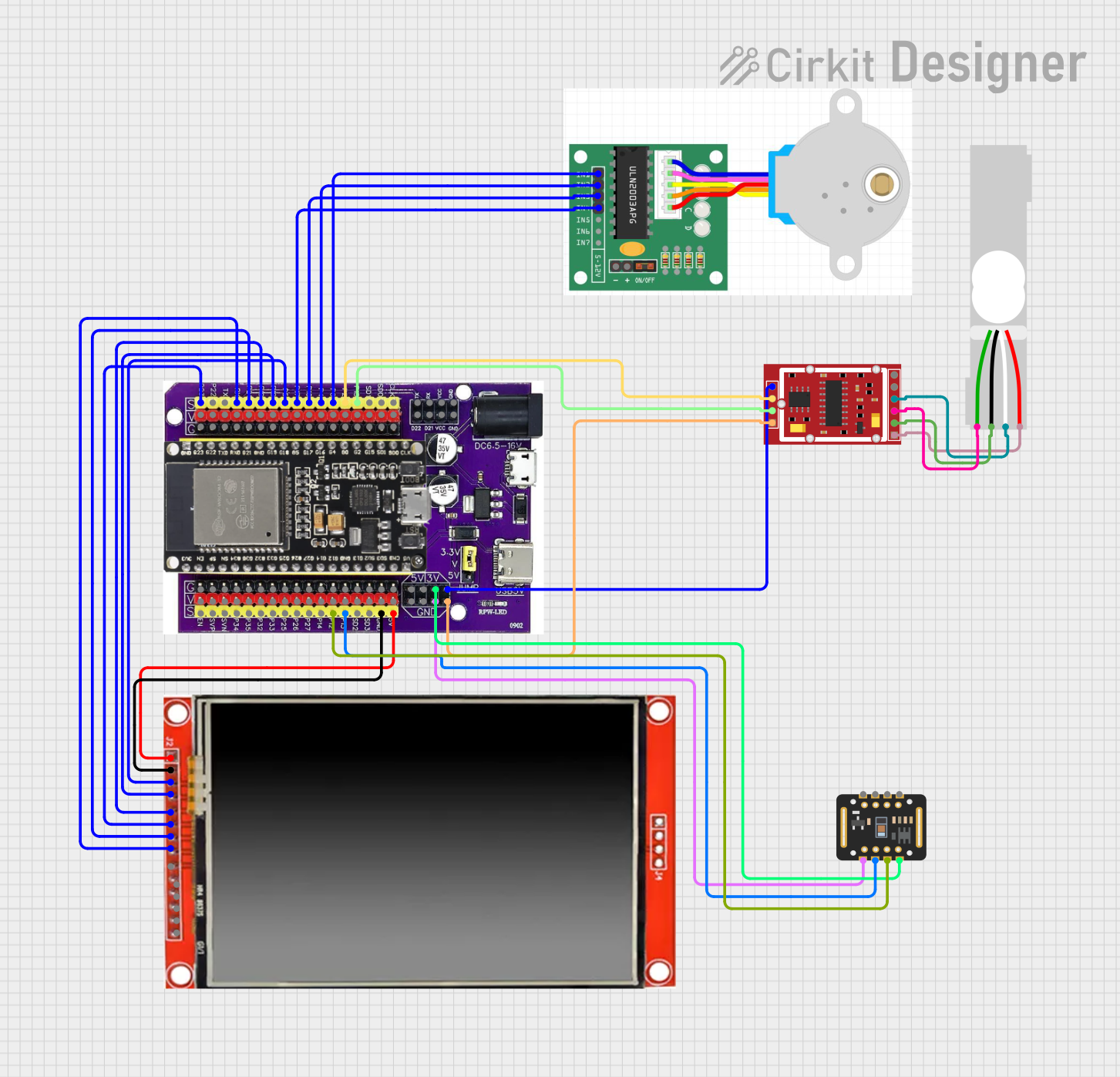

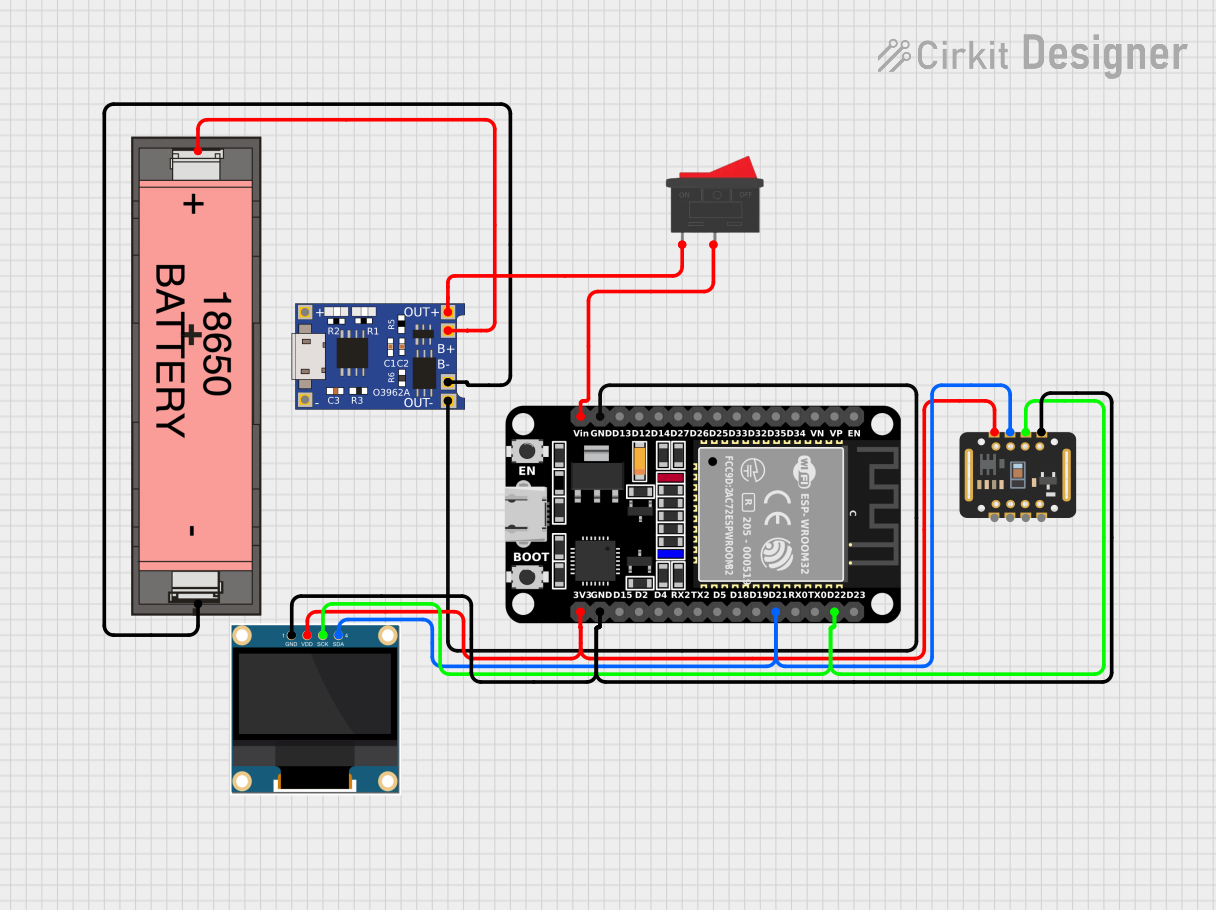

Explore Projects Built with OXY-LC Interface Board

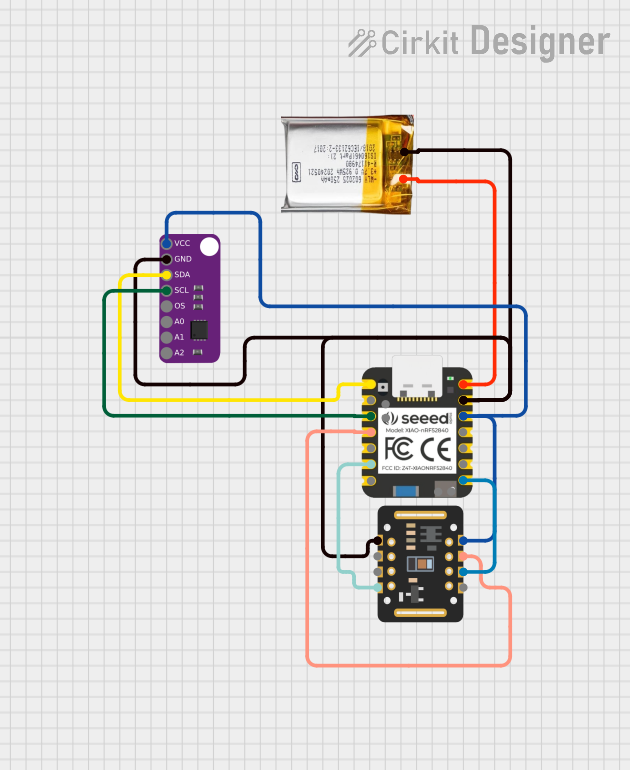

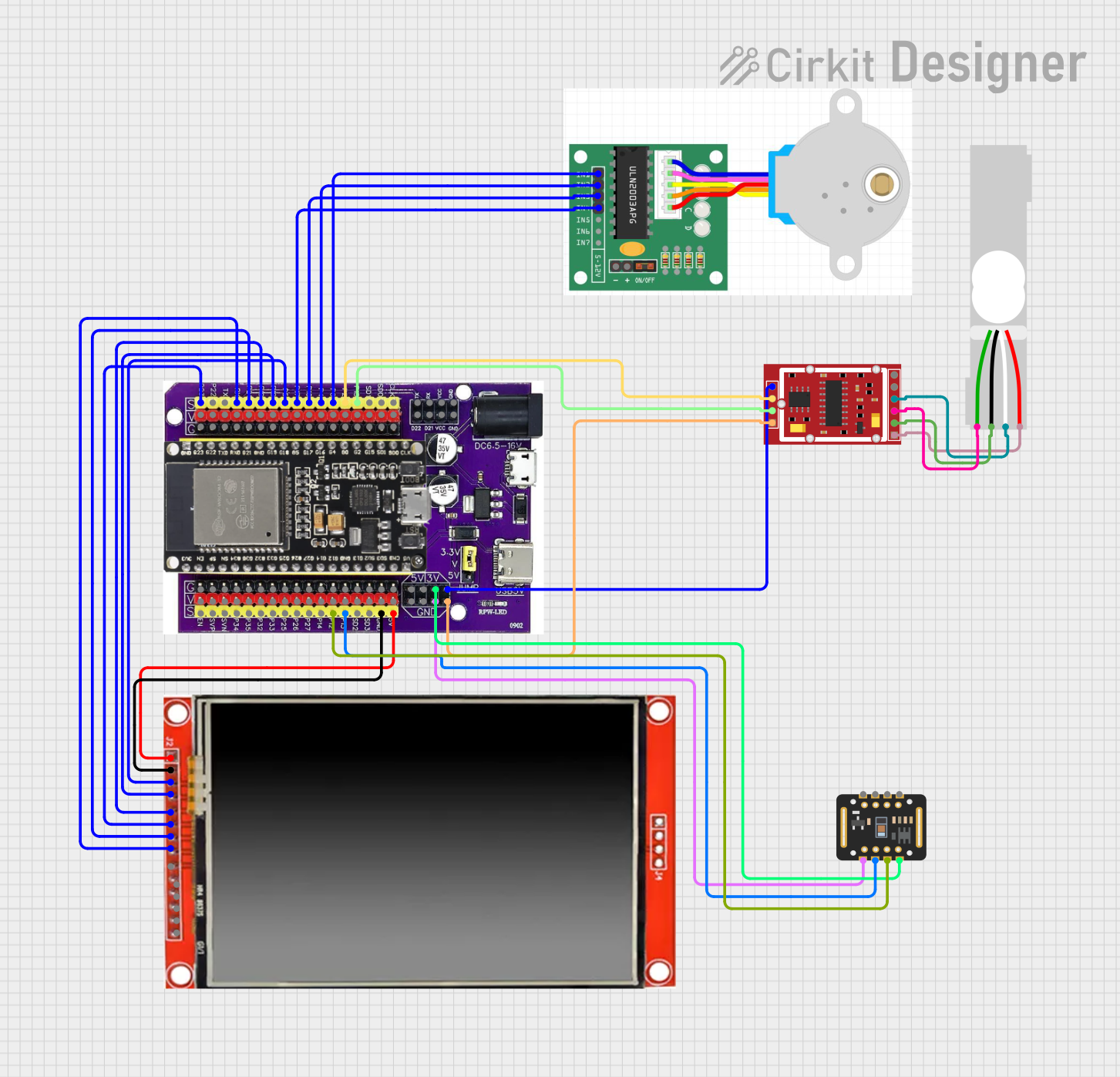

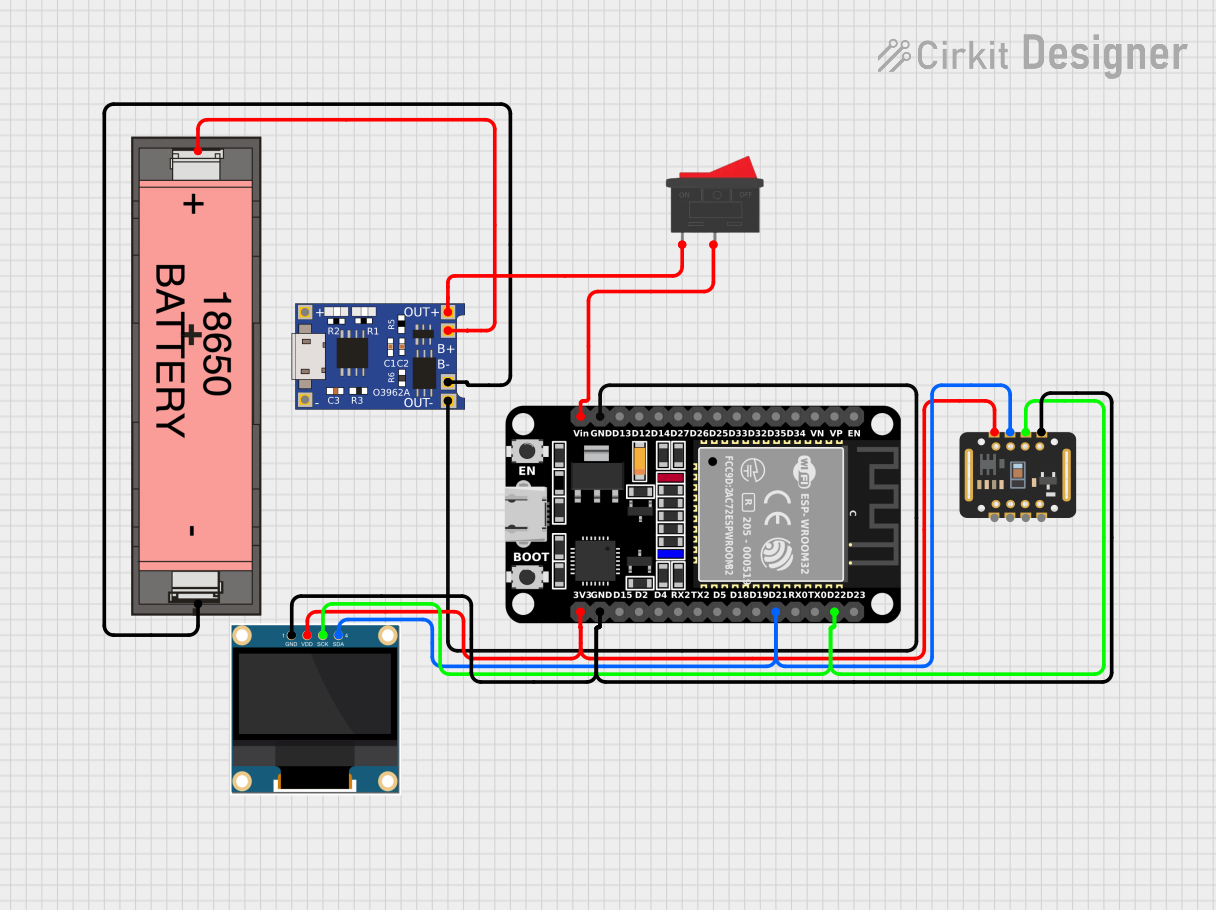

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with OXY-LC Interface Board

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Industrial process control and monitoring

- Environmental monitoring systems

- Medical equipment requiring oxygen level measurement

- Laboratory instrumentation

- Automotive and aerospace oxygen sensing

Technical Specifications

The OXY-LC Interface Board is designed to provide reliable communication and control for the OXY-LC oxygen sensor. Below are the key technical details:

General Specifications

| Parameter | Value |

|---|---|

| Manufacturer | SST Sensing |

| Part Number | OXY-LC-485 |

| Communication Protocol | RS-485 |

| Supply Voltage | 5 V DC |

| Operating Temperature | -20°C to +60°C |

| Dimensions | 50 mm x 25 mm x 10 mm |

| Mounting Type | PCB Mount |

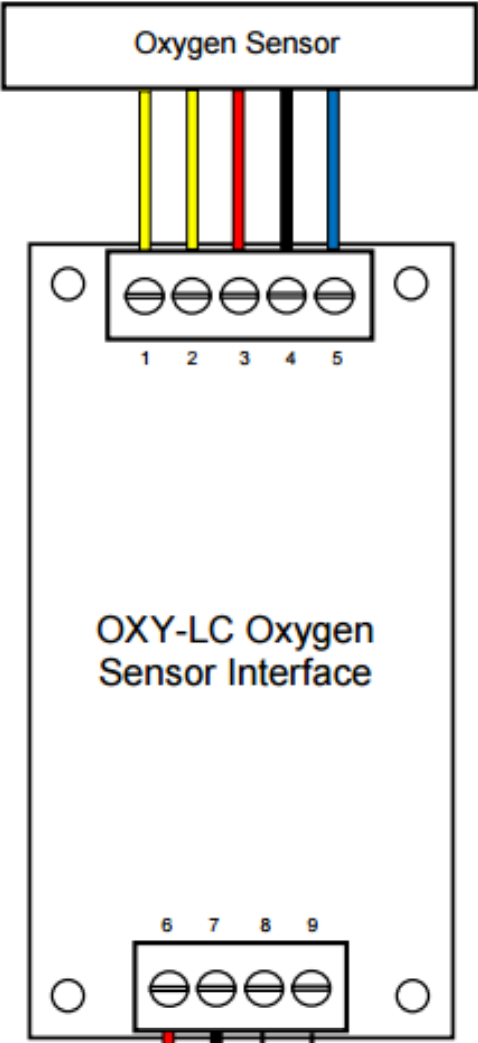

Pin Configuration and Descriptions

The OXY-LC Interface Board features a straightforward pinout for easy integration. Below is the pin configuration:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VCC | Power supply input (5 V DC) |

| 2 | GND | Ground connection |

| 3 | TX+ | RS-485 differential transmit line (positive) |

| 4 | TX- | RS-485 differential transmit line (negative) |

| 5 | RX+ | RS-485 differential receive line (positive) |

| 6 | RX- | RS-485 differential receive line (negative) |

| 7 | SENSOR_IN | Input connection for the OXY-LC oxygen sensor |

| 8 | CONFIG | Configuration pin for setting communication parameters (e.g., baud rate) |

Usage Instructions

The OXY-LC Interface Board is designed for easy integration into electronic systems. Follow the steps below to use the board effectively:

Connecting the OXY-LC Interface Board

- Power Supply: Connect the

VCCpin to a 5 V DC power source and theGNDpin to ground. - Sensor Connection: Attach the OXY-LC oxygen sensor to the

SENSOR_INpin. - RS-485 Communication:

- Connect the

TX+andTX-pins to the RS-485 transmit lines of your system. - Connect the

RX+andRX-pins to the RS-485 receive lines of your system.

- Connect the

- Configuration: Use the

CONFIGpin to set communication parameters, such as baud rate, if required.

Important Considerations and Best Practices

- Ensure the power supply voltage is stable and within the specified range (5 V DC).

- Use proper termination resistors for RS-485 communication lines to minimize signal reflections.

- Avoid exposing the board to temperatures outside the operating range (-20°C to +60°C).

- Keep the board away from sources of electromagnetic interference (EMI) to ensure reliable communication.

- Verify the sensor is securely connected to the

SENSOR_INpin to avoid data loss or inaccuracies.

Example: Connecting to an Arduino UNO

The OXY-LC Interface Board can be connected to an Arduino UNO for data acquisition and processing. Below is an example code snippet for reading data from the board:

#include <SoftwareSerial.h>

// Define RS-485 communication pins

#define RX_PIN 10 // Arduino pin connected to RX+ of OXY-LC Interface Board

#define TX_PIN 11 // Arduino pin connected to TX+ of OXY-LC Interface Board

// Initialize SoftwareSerial for RS-485 communication

SoftwareSerial rs485Serial(RX_PIN, TX_PIN);

void setup() {

// Start serial communication with the OXY-LC Interface Board

rs485Serial.begin(9600); // Set baud rate to 9600 (adjust if necessary)

Serial.begin(9600); // Start serial monitor for debugging

Serial.println("OXY-LC Interface Board Communication Initialized");

}

void loop() {

// Check if data is available from the OXY-LC Interface Board

if (rs485Serial.available()) {

String oxygenData = rs485Serial.readString(); // Read data from the board

Serial.print("Oxygen Sensor Data: ");

Serial.println(oxygenData); // Print data to the serial monitor

}

delay(1000); // Wait for 1 second before reading again

}

Note: Ensure the RS-485 transceiver module is used between the Arduino and the OXY-LC Interface Board to handle differential signaling.

Troubleshooting and FAQs

Common Issues and Solutions

No Data Received from the Board

- Cause: Incorrect wiring or loose connections.

- Solution: Verify all connections, especially the RS-485 lines and the sensor input.

Communication Errors

- Cause: Mismatched baud rate or improper termination resistors.

- Solution: Check the baud rate settings and ensure proper termination resistors are in place.

Sensor Data is Inaccurate

- Cause: Faulty sensor connection or environmental interference.

- Solution: Ensure the sensor is securely connected and shield the board from EMI.

Board Overheating

- Cause: Operating outside the specified temperature range.

- Solution: Ensure the board is used within the -20°C to +60°C range.

FAQs

Q: Can the OXY-LC Interface Board be used with other sensors?

A: No, the board is specifically designed for use with the OXY-LC oxygen sensor.

Q: What is the maximum communication distance for RS-485?

A: RS-485 supports communication distances up to 1200 meters, depending on the baud rate and cable quality.

Q: How do I change the baud rate of the board?

A: Use the CONFIG pin to set the desired baud rate. Refer to the manufacturer's documentation for detailed instructions.

Q: Is the board compatible with 3.3 V systems?

A: No, the board requires a 5 V DC power supply for proper operation. Use a level shifter if interfacing with 3.3 V systems.