How to Use FAN: Examples, Pinouts, and Specs

Design with FAN in Cirkit Designer

Design with FAN in Cirkit DesignerIntroduction

A fan is an electromechanical device designed to create airflow, primarily used for cooling or ventilation purposes. In electronic systems, fans are essential for dissipating heat generated by components such as processors, power supplies, and other heat-sensitive devices. By maintaining optimal operating temperatures, fans help ensure the reliability and longevity of electronic equipment.

Explore Projects Built with FAN

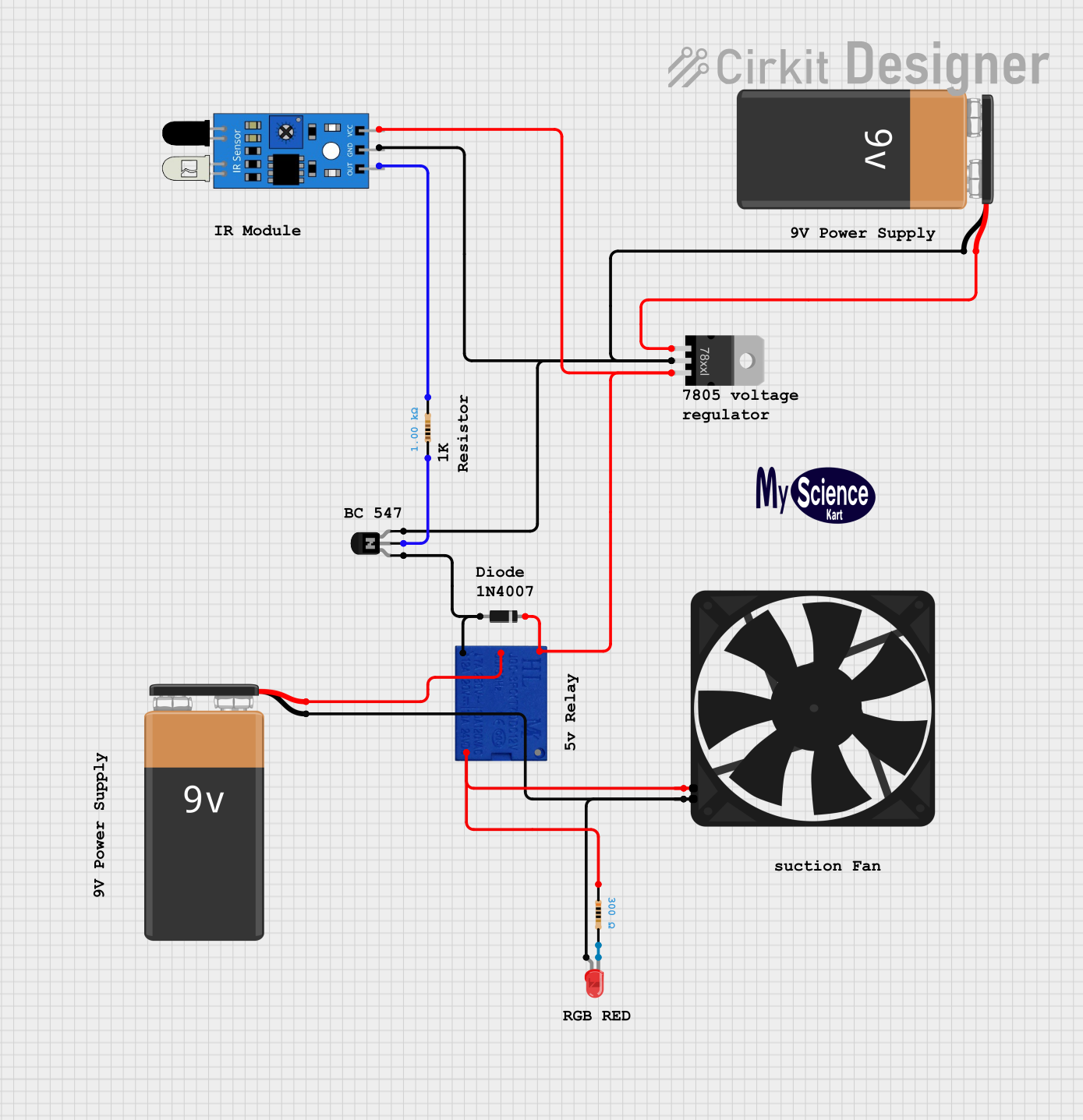

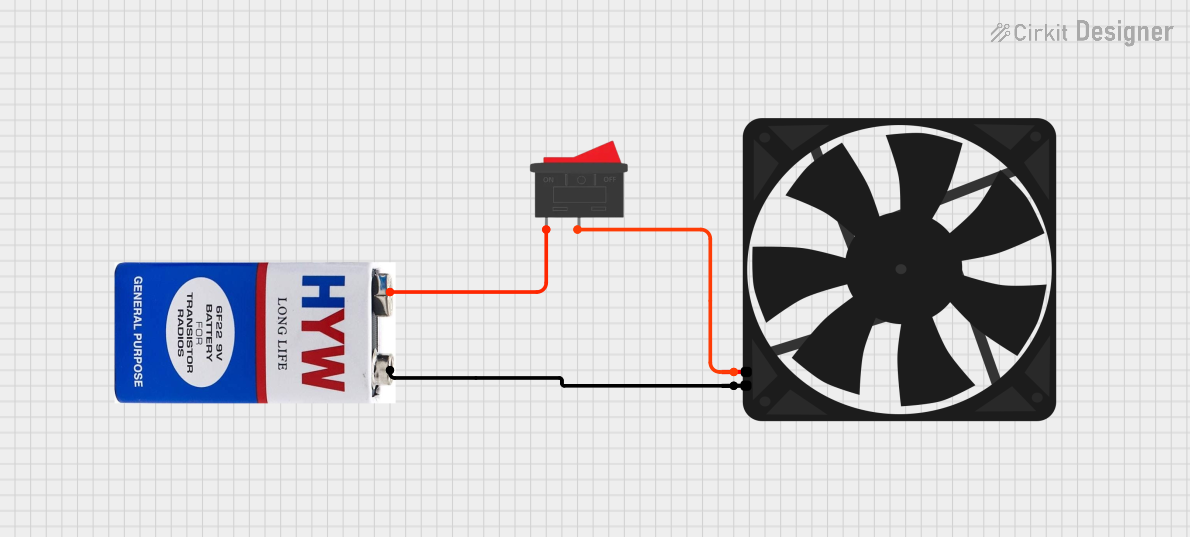

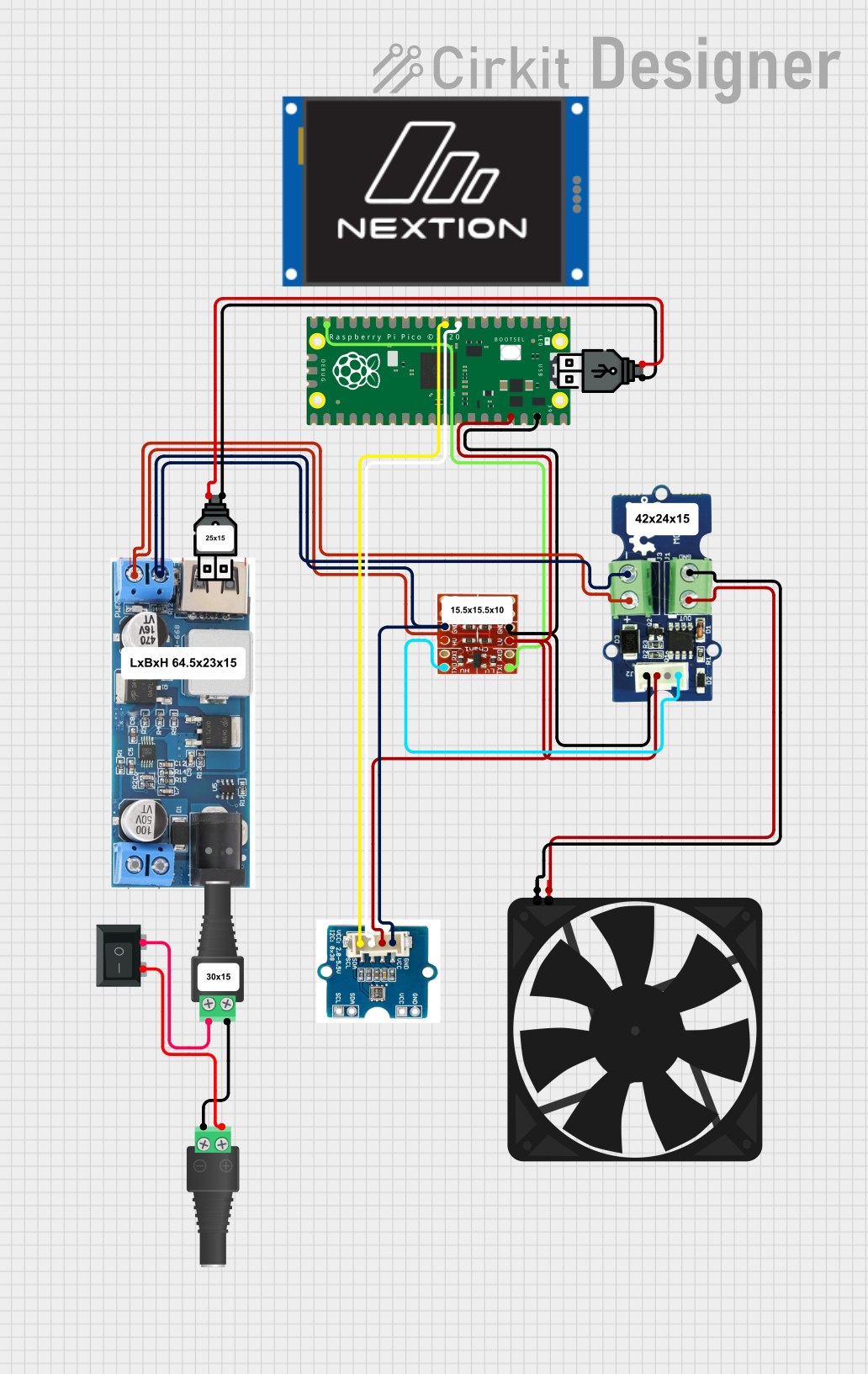

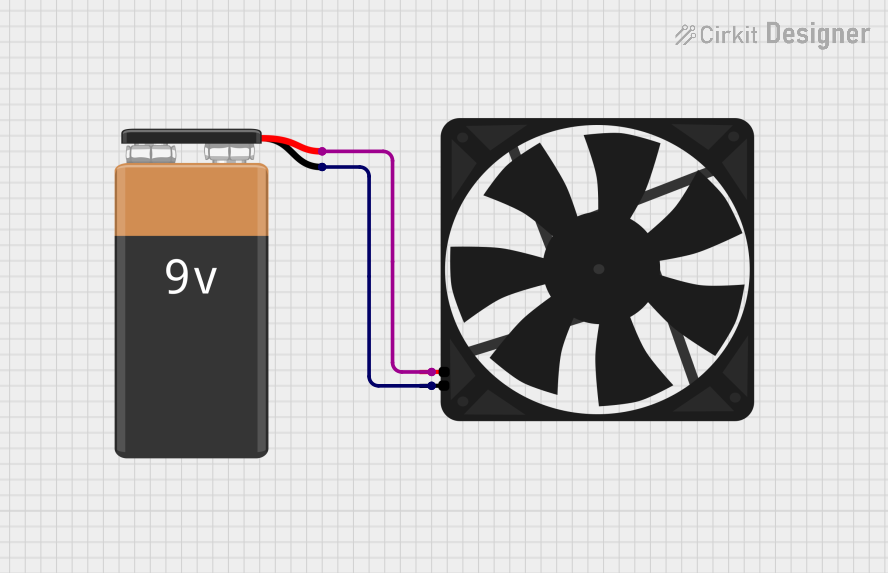

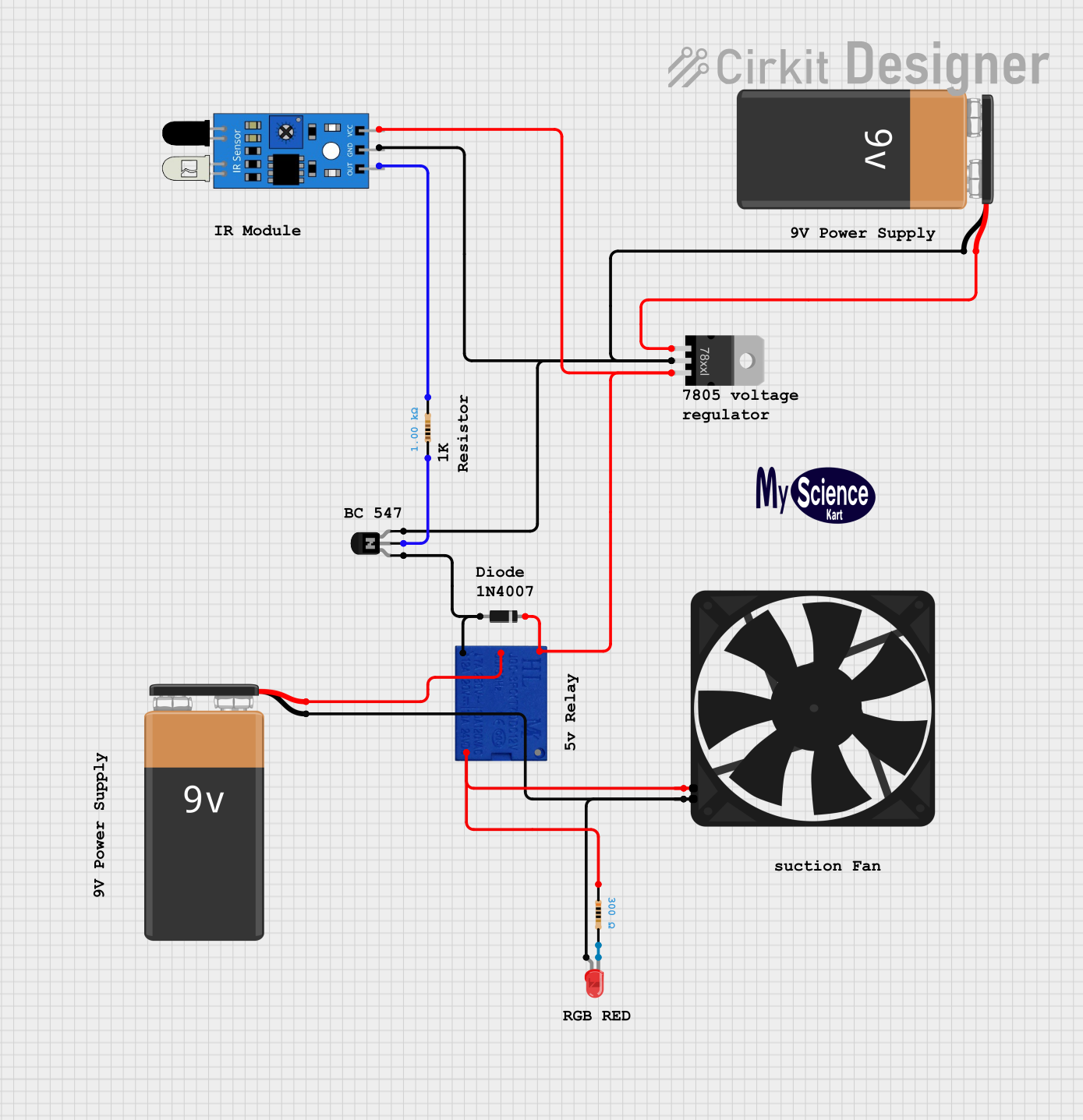

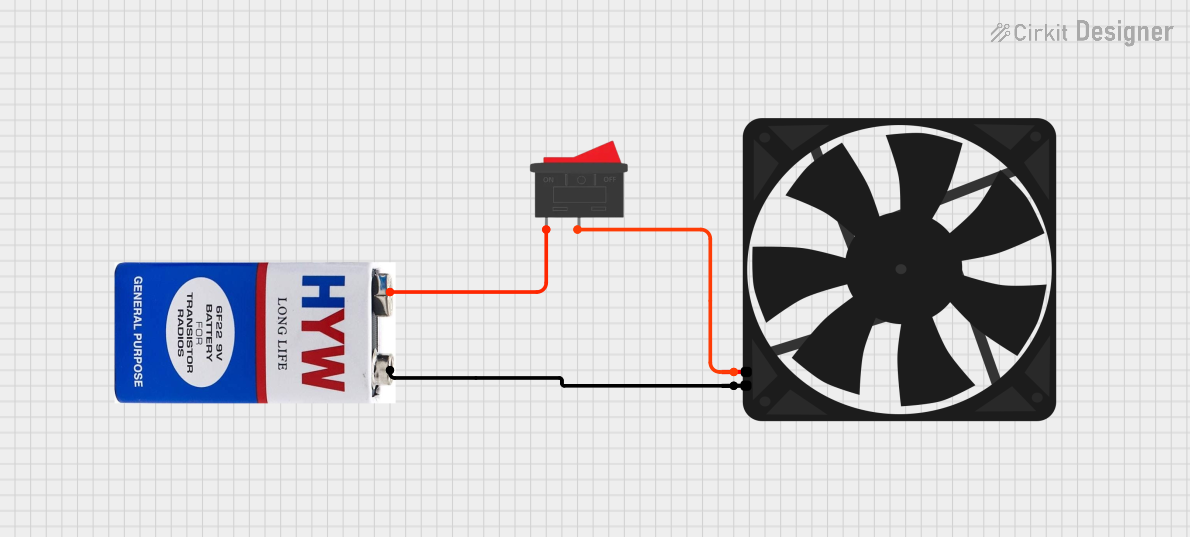

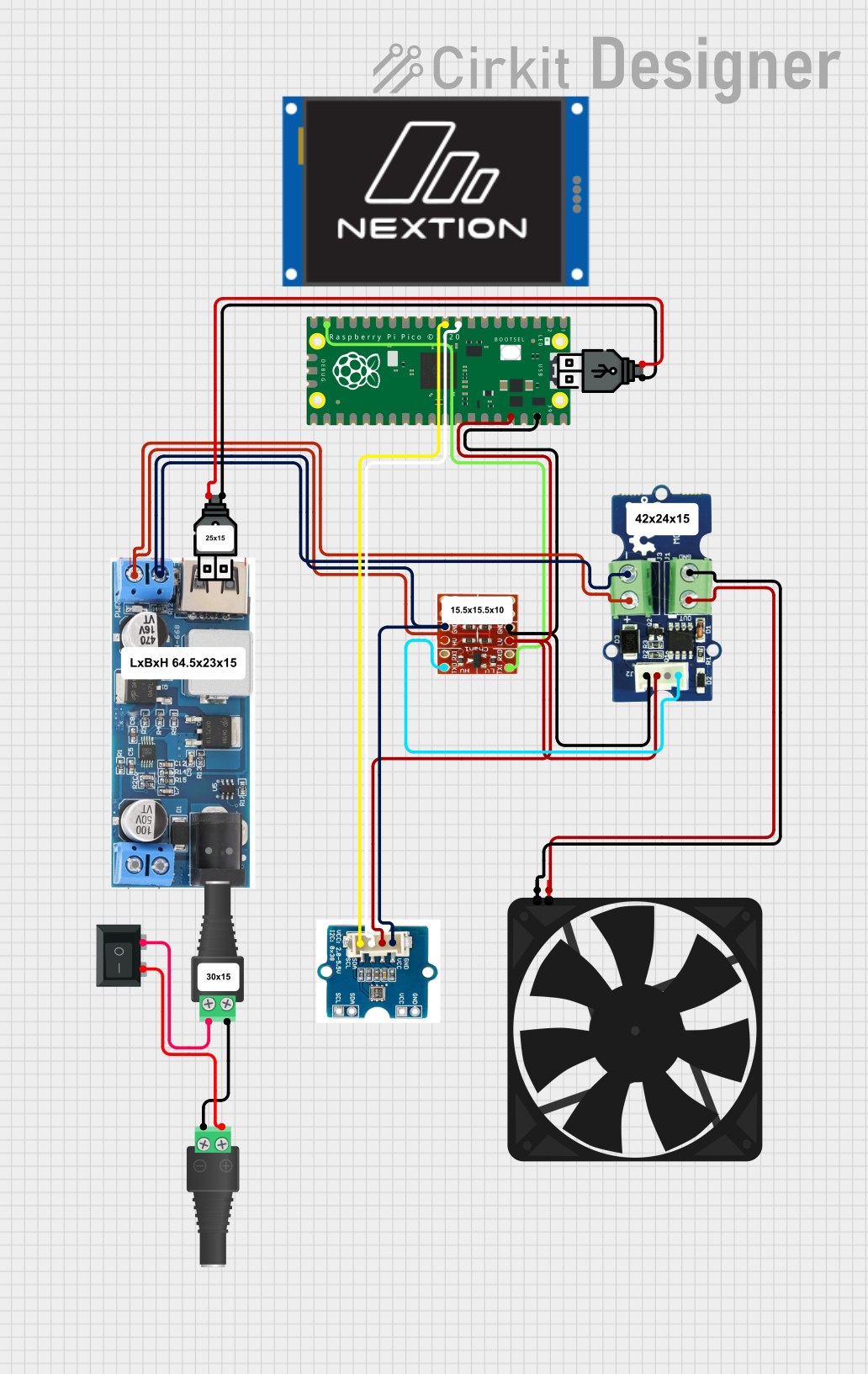

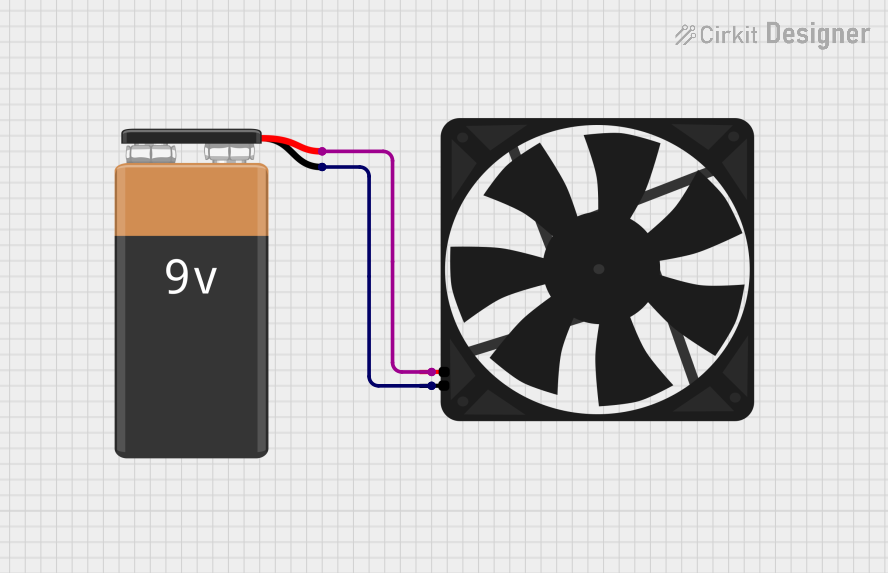

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with FAN

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Cooling computer processors, GPUs, and power supplies

- Ventilating enclosures for electronic devices

- Heat dissipation in industrial machinery

- Air circulation in HVAC systems

- Cooling 3D printers and other hobbyist projects

Technical Specifications

Below are the general technical specifications for a standard DC brushless fan commonly used in electronics:

| Parameter | Value |

|---|---|

| Operating Voltage | 5V, 12V, or 24V (varies by model) |

| Current Consumption | 0.1A to 0.5A |

| Power Rating | 0.5W to 5W |

| Speed | 1000 to 5000 RPM |

| Airflow | 10 to 100 CFM (Cubic Feet/Minute) |

| Noise Level | 20 to 40 dBA |

| Bearing Type | Sleeve or Ball Bearing |

| Connector Type | 2-pin, 3-pin, or 4-pin |

| Dimensions | 40mm x 40mm, 80mm x 80mm, etc. |

Pin Configuration and Descriptions

The pin configuration for a 3-pin and 4-pin fan is detailed below:

3-Pin Fan

| Pin | Name | Description |

|---|---|---|

| 1 | GND | Ground connection |

| 2 | VCC | Power supply (e.g., 12V or 5V) |

| 3 | Tachometer | Outputs a signal for speed monitoring (optional use) |

4-Pin Fan

| Pin | Name | Description |

|---|---|---|

| 1 | GND | Ground connection |

| 2 | VCC | Power supply (e.g., 12V or 5V) |

| 3 | Tachometer | Outputs a signal for speed monitoring (optional use) |

| 4 | PWM | Pulse Width Modulation input for speed control |

Usage Instructions

How to Use the Fan in a Circuit

- Power Connection: Connect the VCC pin to the appropriate voltage source (e.g., 12V or 5V) and the GND pin to the ground of the circuit.

- Speed Monitoring (Optional): If using a 3-pin or 4-pin fan, connect the Tachometer pin to a microcontroller or monitoring circuit to measure the fan's speed.

- Speed Control (4-Pin Fans): For 4-pin fans, connect the PWM pin to a microcontroller or PWM signal generator to control the fan's speed dynamically.

Important Considerations and Best Practices

- Voltage Compatibility: Ensure the fan's operating voltage matches the power supply to avoid damage.

- Current Rating: Verify that the power source can supply sufficient current for the fan.

- Orientation: Install the fan in the correct orientation to direct airflow as needed.

- Noise Reduction: Use rubber mounts or grommets to minimize vibration and noise.

- PWM Signal: For 4-pin fans, use a PWM signal with a frequency of 25 kHz for optimal speed control.

Example: Connecting a 4-Pin Fan to an Arduino UNO

Below is an example of how to control a 4-pin fan using an Arduino UNO:

// Example: Controlling a 4-pin fan with PWM using Arduino UNO

// Connect the fan's PWM pin to Arduino pin 9

// Ensure the fan's VCC and GND are connected to a suitable power source

const int fanPWM = 9; // PWM pin connected to the fan's PWM input

void setup() {

pinMode(fanPWM, OUTPUT); // Set the PWM pin as an output

}

void loop() {

// Set fan speed to 50% duty cycle (128 out of 255)

analogWrite(fanPWM, 128);

delay(5000); // Run at 50% speed for 5 seconds

// Set fan speed to 100% duty cycle (255 out of 255)

analogWrite(fanPWM, 255);

delay(5000); // Run at full speed for 5 seconds

}

Troubleshooting and FAQs

Common Issues and Solutions

Fan Does Not Spin

- Cause: Incorrect power supply voltage or loose connections.

- Solution: Verify the voltage and current ratings of the power supply and ensure all connections are secure.

Fan Spins but No Airflow

- Cause: Fan installed in the wrong orientation.

- Solution: Reinstall the fan to ensure airflow is directed as intended.

Excessive Noise

- Cause: Vibration or worn-out bearings.

- Solution: Use rubber mounts to reduce vibration or replace the fan if bearings are damaged.

Fan Speed Not Controllable

- Cause: PWM signal not configured correctly.

- Solution: Ensure the PWM signal frequency is set to 25 kHz and the duty cycle is adjusted properly.

FAQs

Q: Can I use a 3-pin fan with a 4-pin connector?

A: Yes, you can connect a 3-pin fan to a 4-pin connector. The PWM pin will remain unused, and the fan will run at full speed.

Q: How do I measure the fan's speed using the Tachometer pin?

A: Connect the Tachometer pin to a microcontroller's input pin and use an interrupt or frequency measurement function to calculate the RPM.

Q: What is the lifespan of a typical fan?

A: The lifespan depends on the bearing type. Sleeve bearings typically last 30,000 hours, while ball bearings can last up to 50,000 hours or more.

Q: Can I run a 12V fan on a 5V power supply?

A: While the fan may spin at a reduced speed, it is not recommended as it may not provide sufficient airflow and could damage the fan over time. Always use the correct voltage.