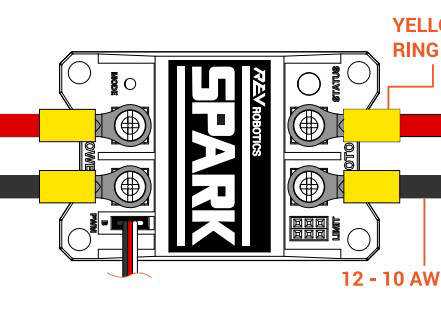

How to Use Spark: Examples, Pinouts, and Specs

Design with Spark in Cirkit Designer

Design with Spark in Cirkit DesignerIntroduction

The Spark Gap module, manufactured by Rev Robotics, is an essential safety device used in various electronic circuits. It is designed to protect sensitive components from voltage spikes by providing a controlled path for excess voltage to discharge, preventing damage to the circuit. Common applications include surge protection in power supply units, as part of ignition systems in internal combustion engines, and in high-voltage circuits where voltage regulation is crucial.

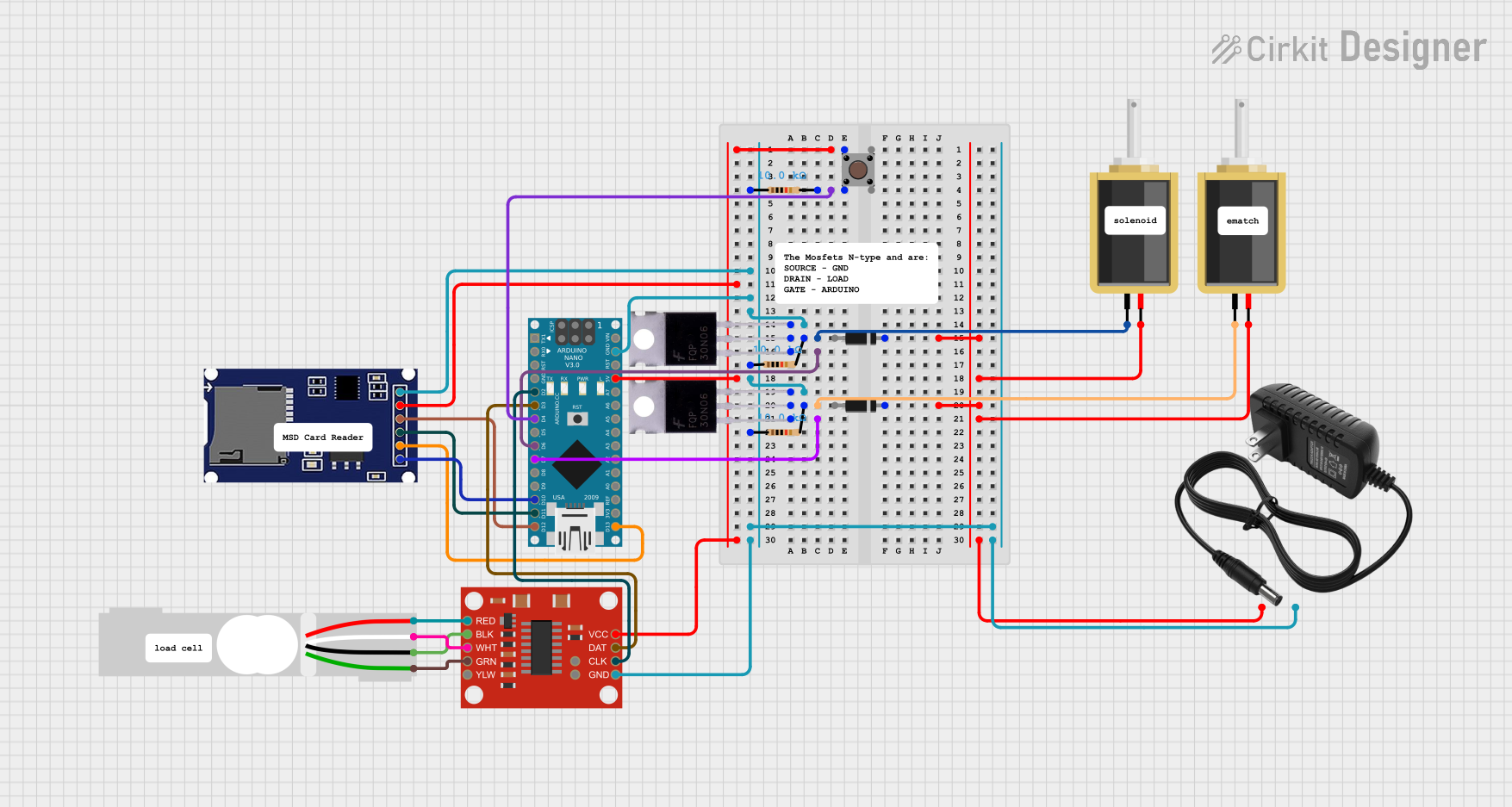

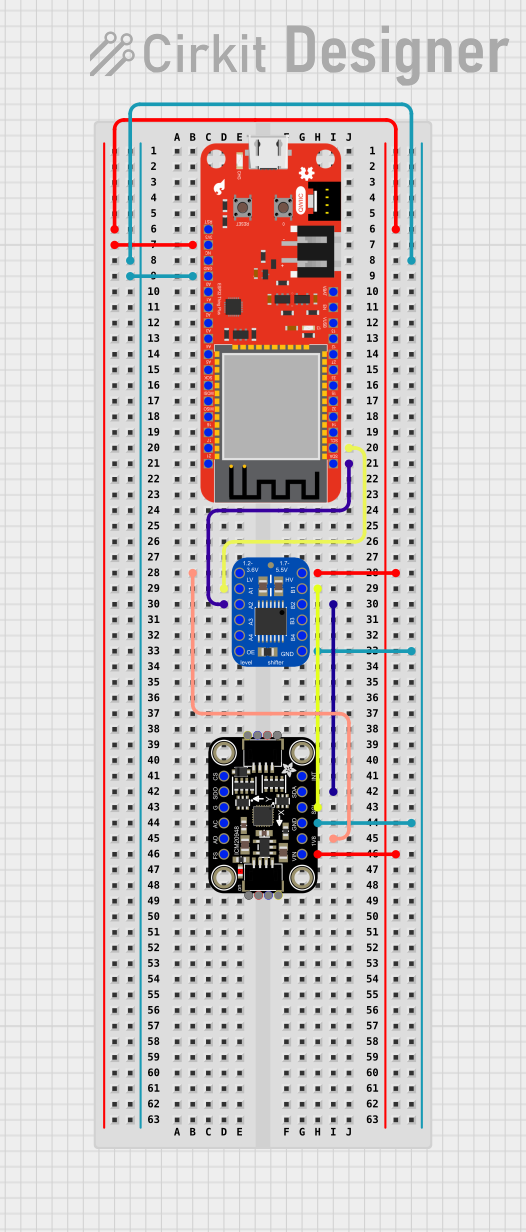

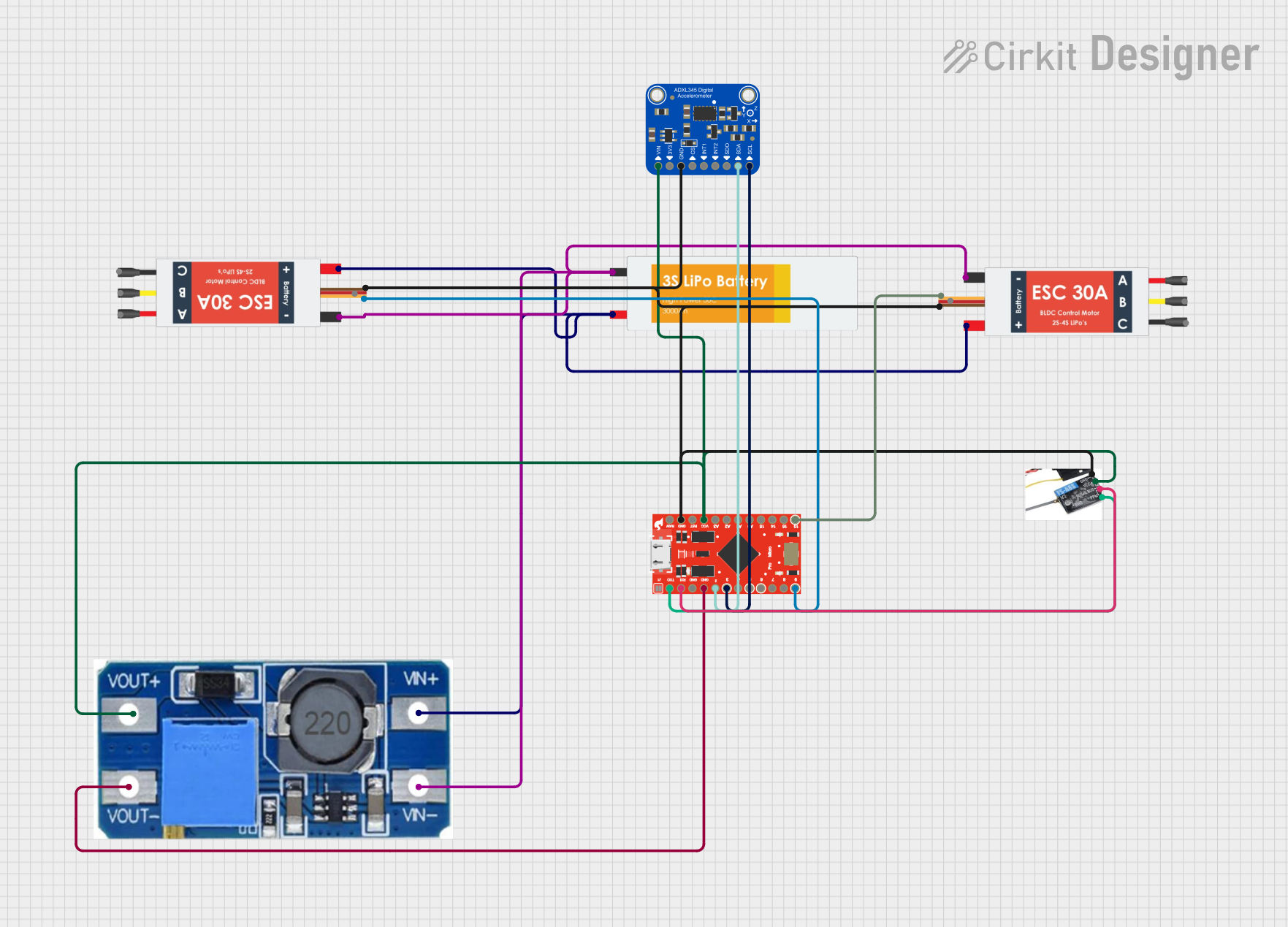

Explore Projects Built with Spark

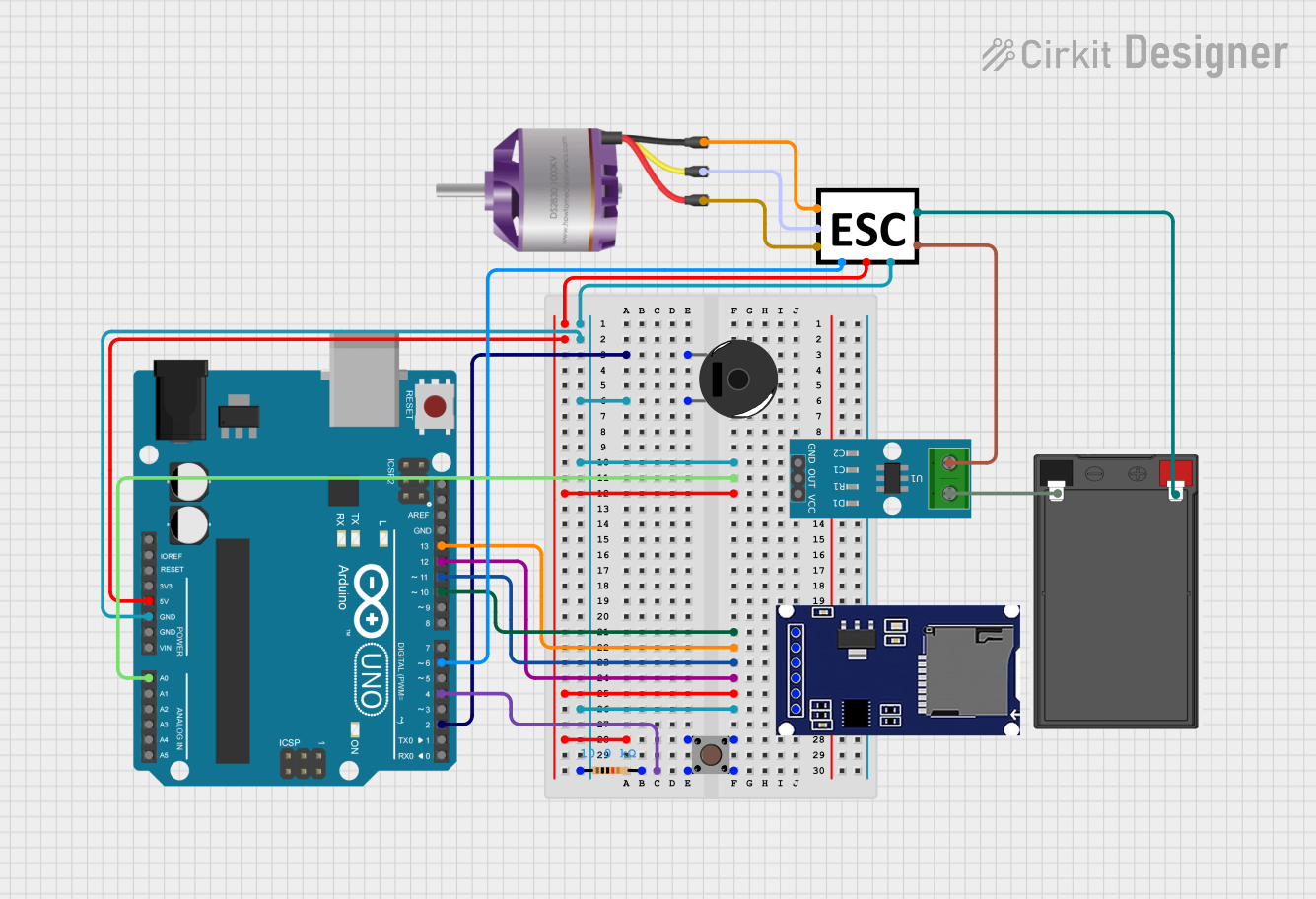

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

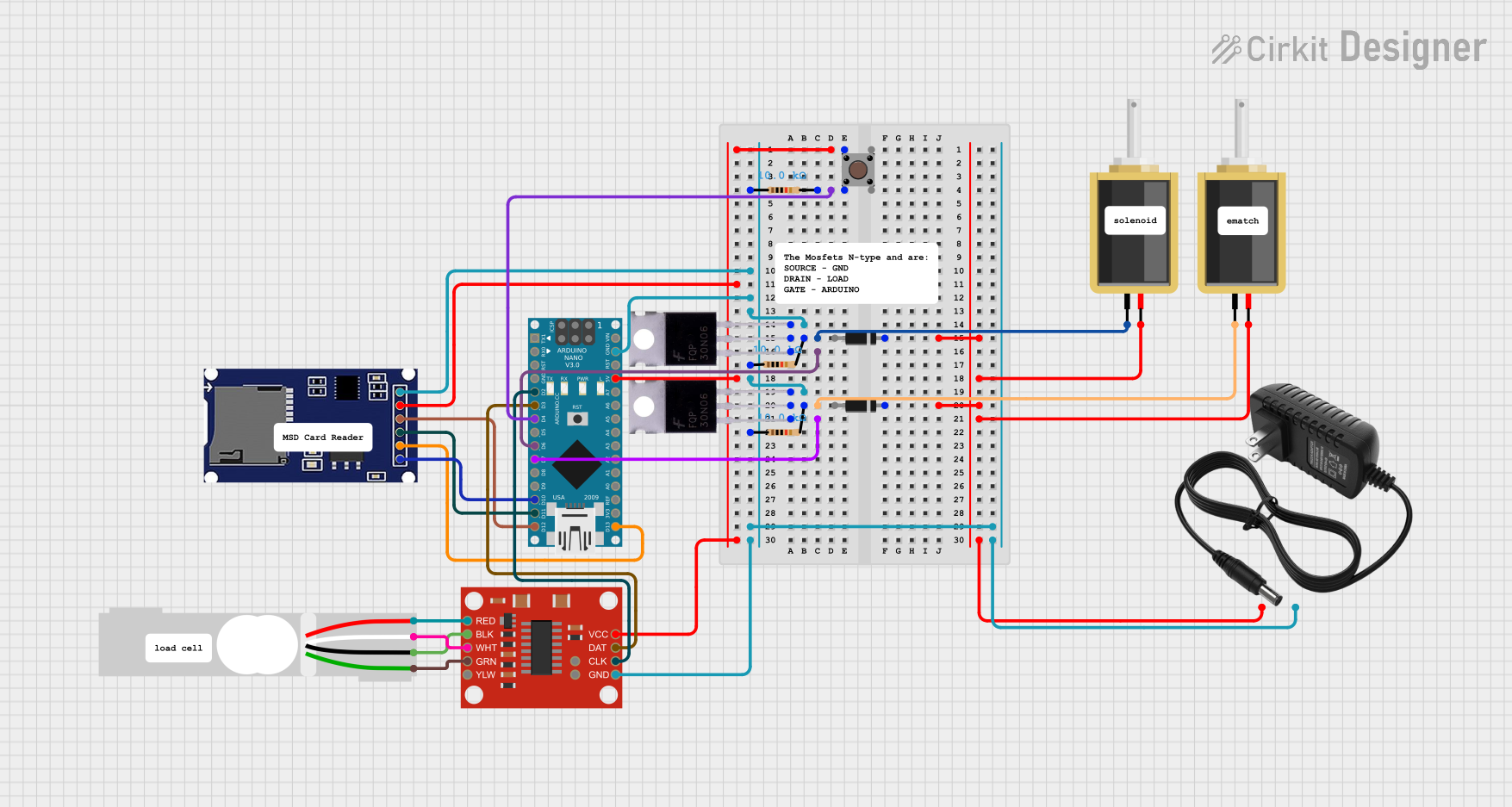

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with Spark

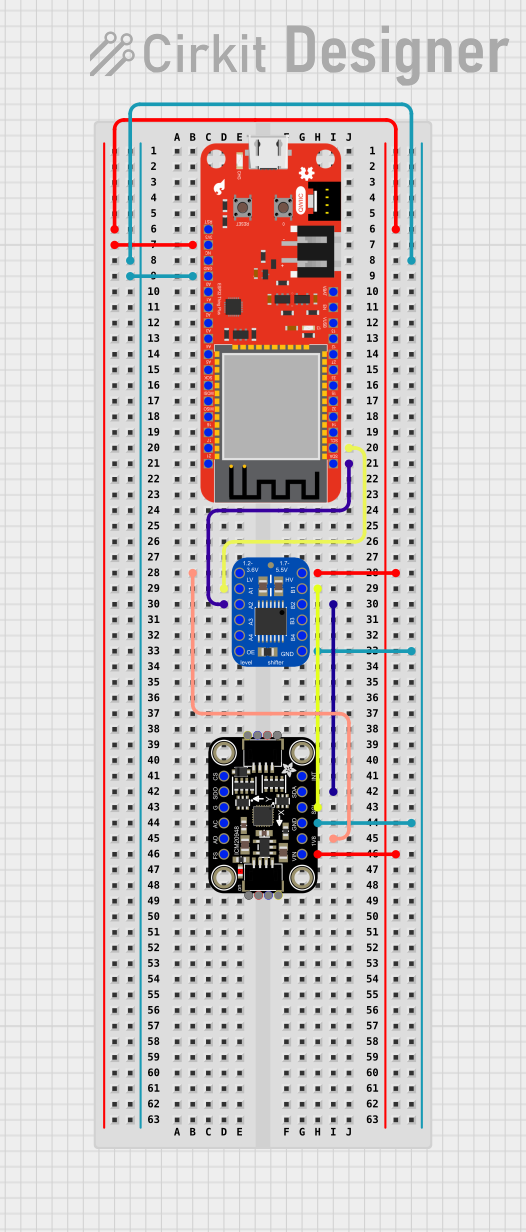

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

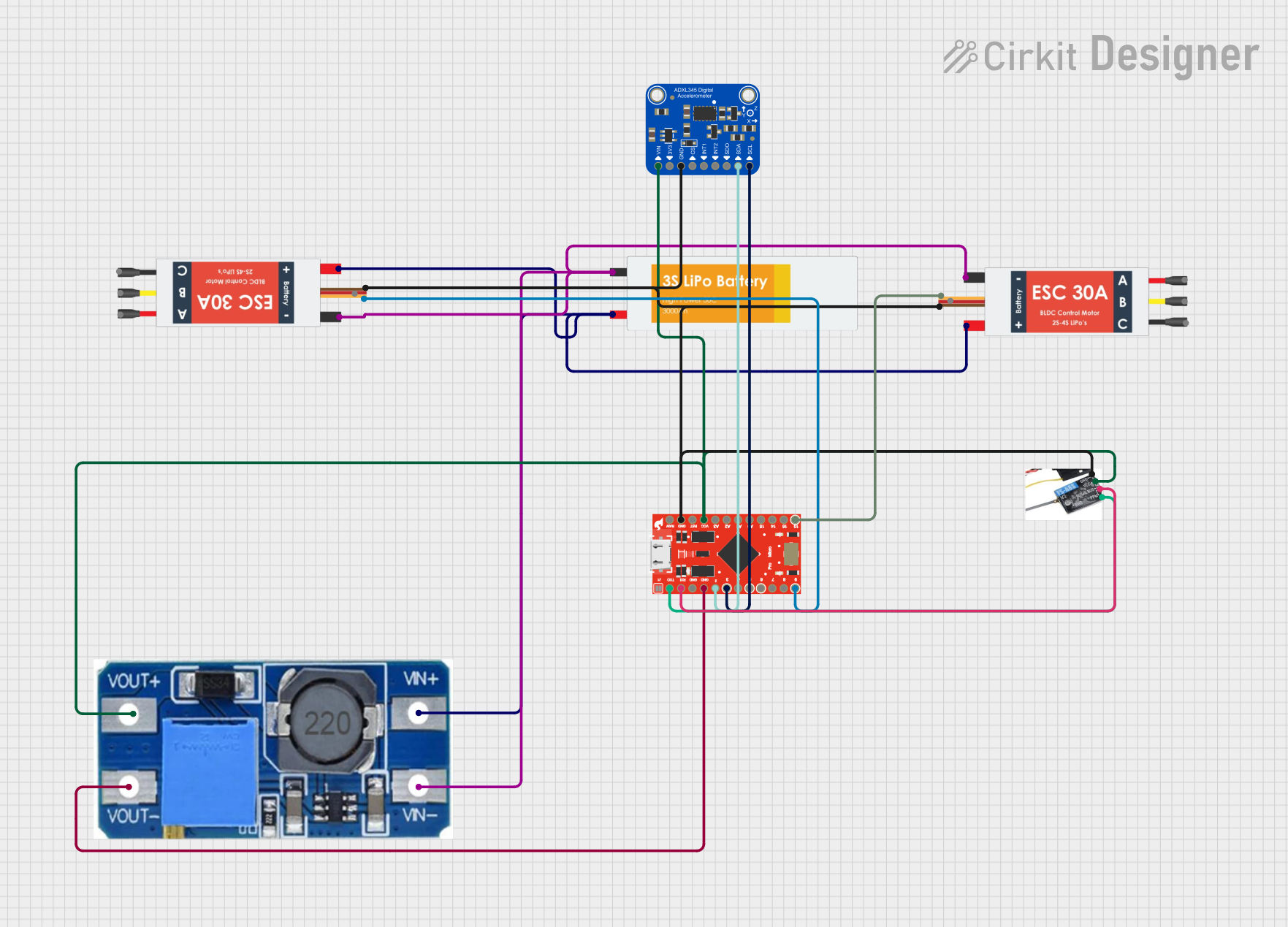

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

General Specifications

| Parameter | Value | Description |

|---|---|---|

| Operating Voltage | 5V - 24V | The range of voltages the spark gap can handle |

| Discharge Voltage | Typically 500V - 1kV | Voltage at which the spark will jump the gap |

| Peak Current | Up to 10A | Maximum current the spark gap can handle |

| Gap Distance | Adjustable | Distance between electrodes can be set |

| Electrode Material | Tungsten or similar | Material used for the electrodes |

Pin Configuration

| Pin Number | Name | Description |

|---|---|---|

| 1 | GND | Ground connection for the spark gap module |

| 2 | HV | High voltage input for the spark gap module |

| 3 | NC | No connection; reserved for future use |

Usage Instructions

Integration into a Circuit

- Power Supply Connection: Connect the HV pin to the high voltage line that requires protection. Ensure that the voltage does not exceed the module's maximum operating voltage.

- Grounding: Connect the GND pin to the common ground in your circuit to provide a discharge path for the excess voltage.

- Adjusting the Gap: Carefully adjust the gap distance between the electrodes based on the desired discharge voltage. A smaller gap will discharge at lower voltages, while a larger gap requires higher voltages.

Best Practices

- Mounting: Secure the Spark Gap module away from sensitive components to prevent electromagnetic interference when a discharge occurs.

- Inspection: Regularly inspect the gap distance and condition of the electrodes, as arcing can cause wear over time.

- Safety Precautions: Always power down the circuit before making adjustments to the spark gap to avoid electric shock.

Troubleshooting and FAQs

Common Issues

- No Discharge: If the spark gap is not discharging when expected, check the gap distance and ensure it is set correctly for the desired voltage. Also, inspect the electrodes for wear or contamination.

- Unexpected Discharge: If the spark gap is discharging at lower voltages than expected, verify that the gap distance has not changed and that there are no conductive contaminants bridging the gap.

FAQs

Q: Can the Spark Gap module be used for AC applications? A: Yes, the Spark Gap module can be used in AC circuits, but ensure that the specifications match the requirements of the application.

Q: How often should the gap distance be adjusted? A: The gap distance should be set during the initial installation and checked periodically, especially if the module is subject to mechanical vibrations or thermal expansion.

Q: Is there a risk of fire with the Spark Gap module? A: While the spark gap can generate a small arc, it is contained and should not pose a fire risk if used within its specifications and with proper mounting.

Example Code for Arduino UNO

Below is an example code snippet for monitoring the operation of the Spark Gap module with an Arduino UNO. This example assumes the use of an additional sensor to detect when the spark gap has discharged.

// Define the pin connected to the discharge sensor

const int dischargeSensorPin = 2;

void setup() {

// Initialize the discharge sensor pin as an input

pinMode(dischargeSensorPin, INPUT);

// Begin serial communication at 9600 baud rate

Serial.begin(9600);

}

void loop() {

// Read the state of the discharge sensor pin

int sensorState = digitalRead(dischargeSensorPin);

// Check if a discharge has been detected

if (sensorState == HIGH) {

// Print a message to the serial monitor

Serial.println("Discharge detected!");

}

// Small delay to debounce the sensor and prevent multiple detections

delay(50);

}

Please note that this code is for illustrative purposes and assumes the use of a hypothetical discharge sensor. In practice, the Spark Gap module does not require any active control or monitoring and functions passively within the circuit.