How to Use sensor_fluxo: Examples, Pinouts, and Specs

Design with sensor_fluxo in Cirkit Designer

Design with sensor_fluxo in Cirkit DesignerIntroduction

The Sensor Fluxo is a versatile electronic component designed to measure the flow rate of liquids or gases in a system. It is widely used in various applications, including industrial automation, water management systems, HVAC systems, and medical devices. By providing accurate flow rate measurements, the Sensor Fluxo helps in monitoring and controlling fluid dynamics, ensuring efficient and safe operation of systems.

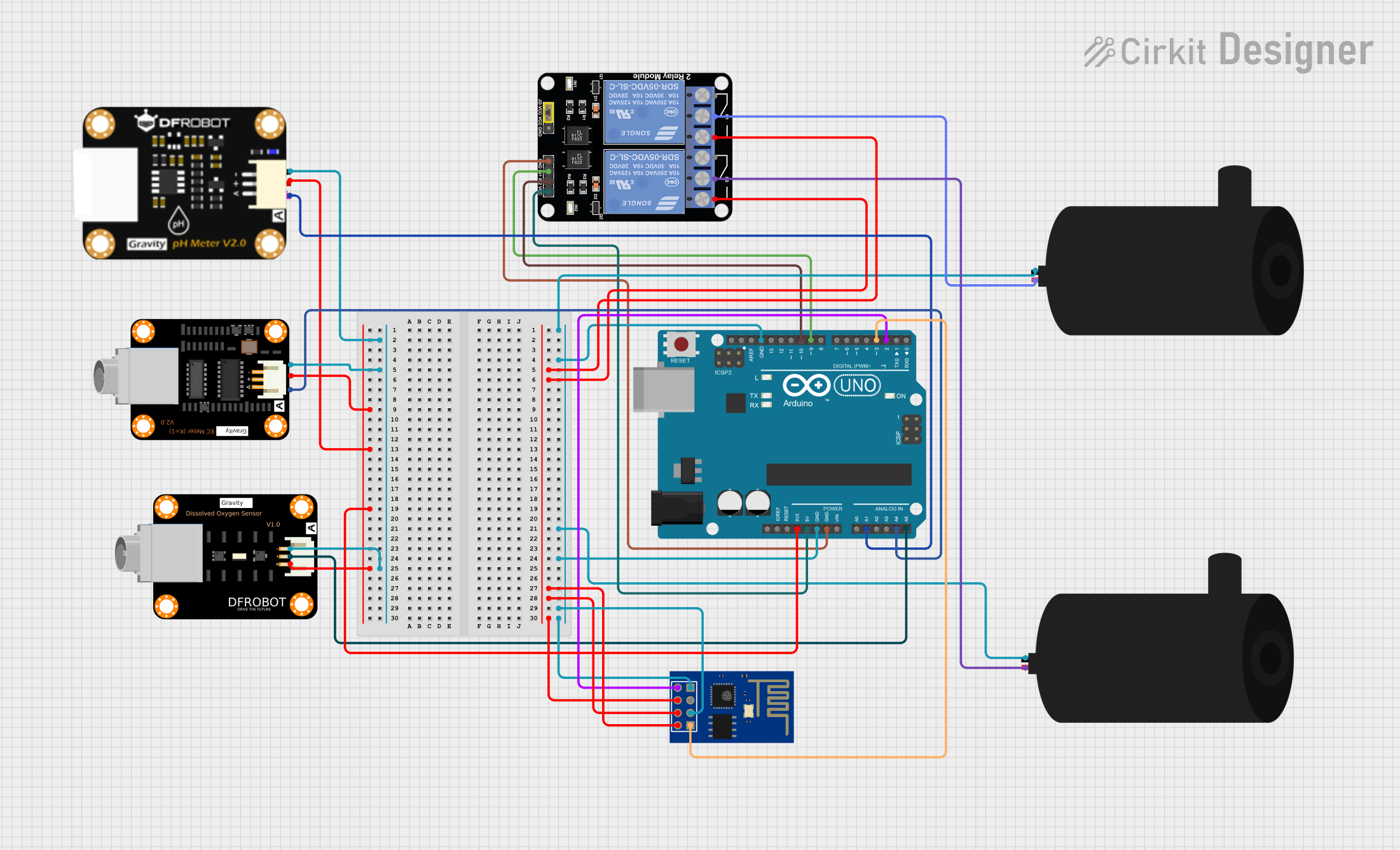

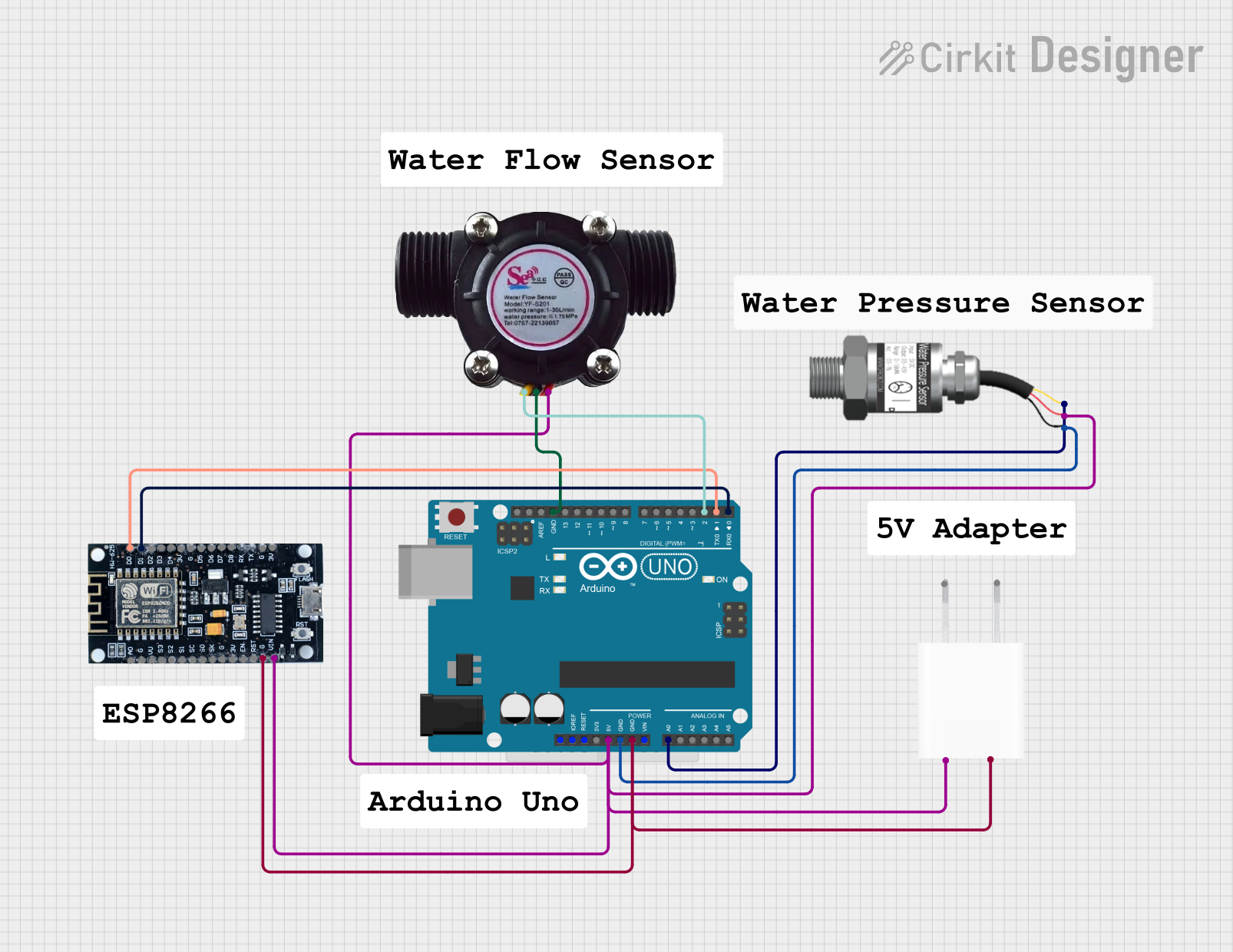

Explore Projects Built with sensor_fluxo

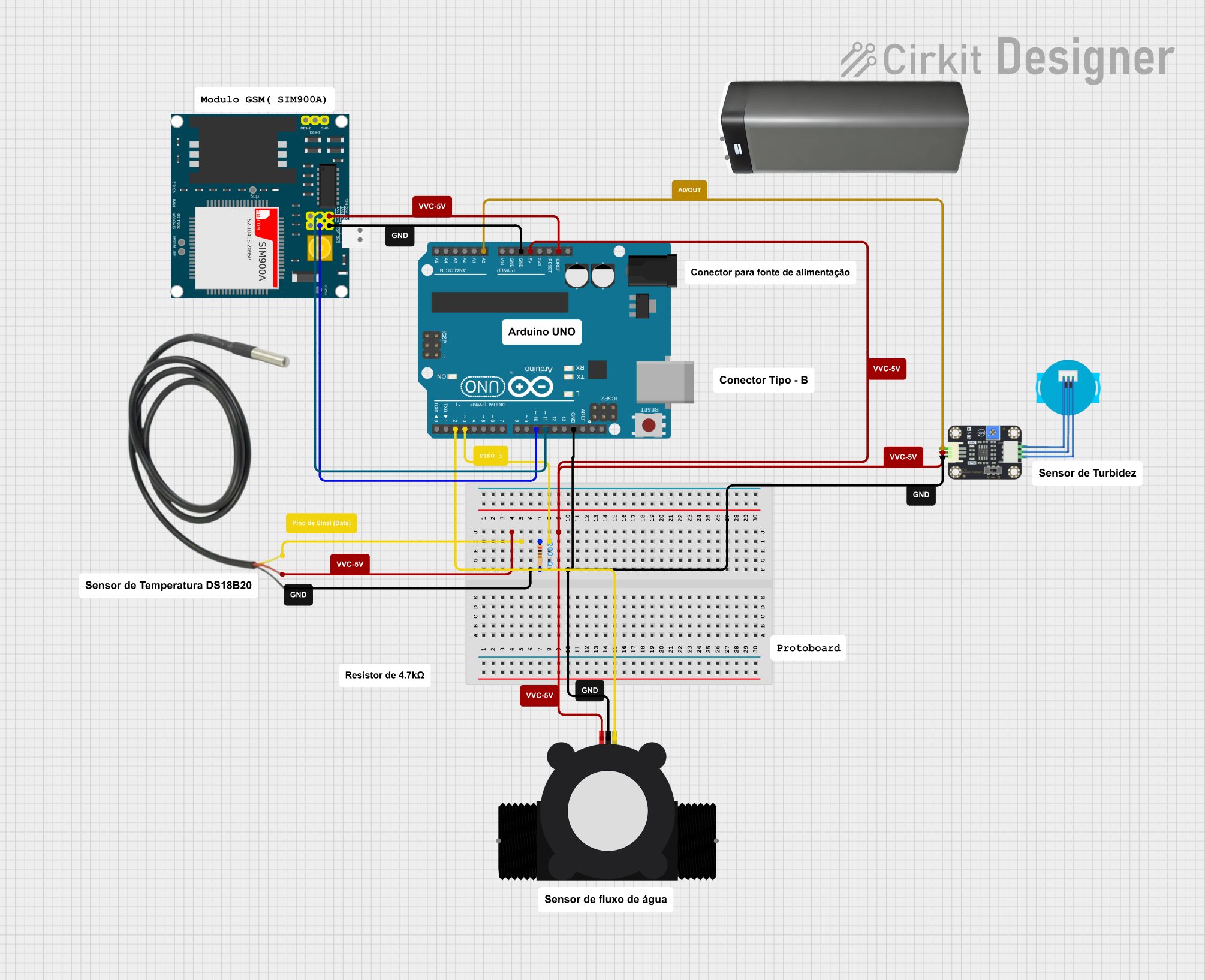

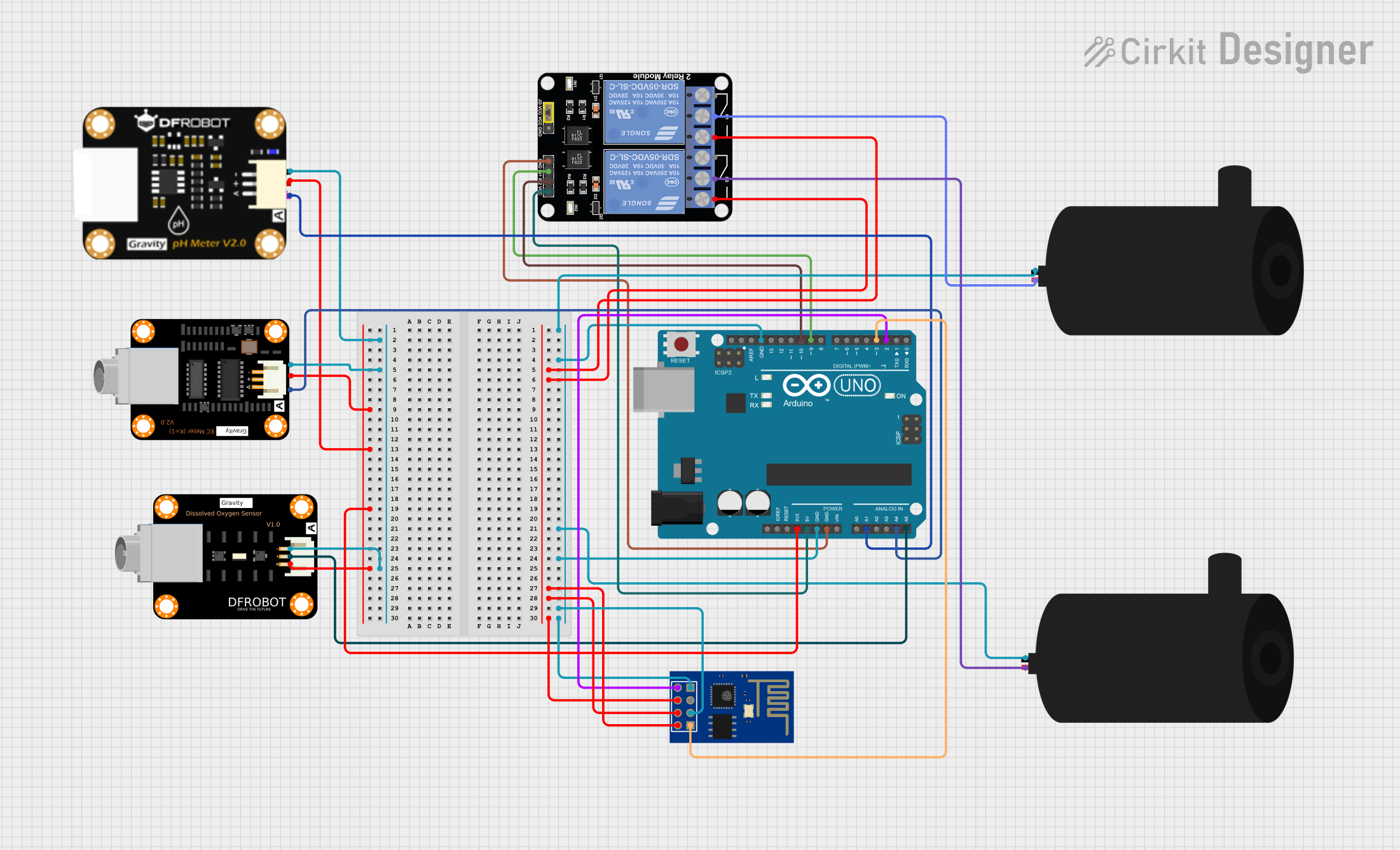

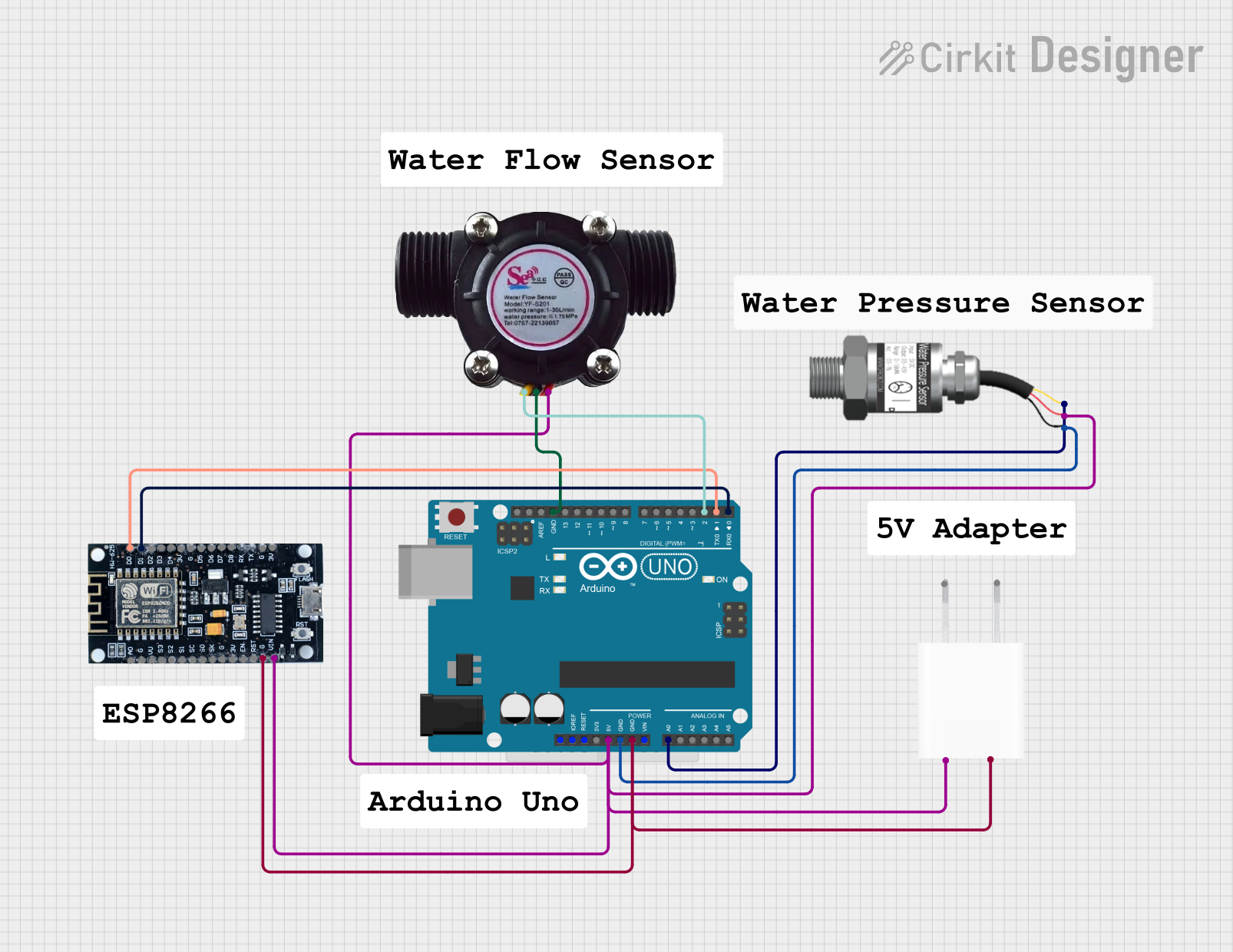

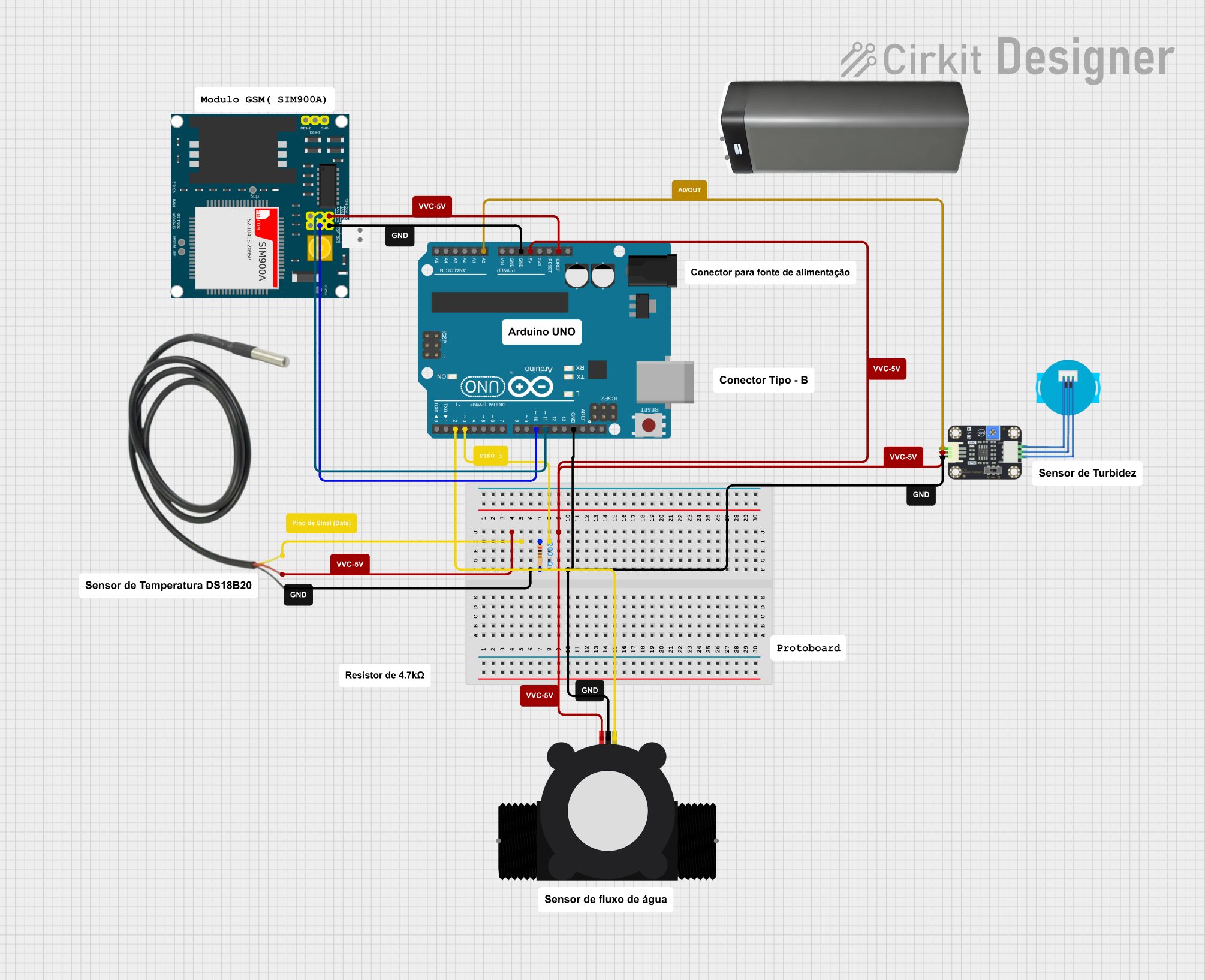

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with sensor_fluxo

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Operating Voltage | 5V DC |

| Operating Current | 10-15 mA |

| Flow Rate Range | 1-30 L/min |

| Output Type | Pulse signal |

| Pulse Frequency | 45 Hz (at 1 L/min) |

| Accuracy | ±1.5% |

| Operating Temperature | -25°C to 80°C |

| Material | Plastic (food-grade) |

| Connector Type | 3-pin (VCC, GND, Signal) |

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | VCC | Power supply (5V DC) |

| 2 | GND | Ground |

| 3 | Signal | Pulse output signal proportional to flow rate |

Usage Instructions

How to Use the Sensor Fluxo in a Circuit

- Power Supply: Connect the VCC pin to a 5V DC power supply.

- Ground Connection: Connect the GND pin to the ground of the circuit.

- Signal Output: Connect the Signal pin to a digital input pin of a microcontroller (e.g., Arduino UNO).

Example Circuit Diagram

+5V (Arduino) ----> VCC (Sensor Fluxo)

GND (Arduino) ----> GND (Sensor Fluxo)

Digital Pin 2 (Arduino) ----> Signal (Sensor Fluxo)

Arduino UNO Example Code

// Define the pin where the sensor is connected

const int sensorPin = 2;

// Variables to store pulse count and flow rate

volatile int pulseCount = 0;

float flowRate = 0.0;

void setup() {

// Initialize serial communication

Serial.begin(9600);

// Set the sensor pin as input

pinMode(sensorPin, INPUT);

// Attach an interrupt to the sensor pin

attachInterrupt(digitalPinToInterrupt(sensorPin), pulseCounter, RISING);

}

void loop() {

// Calculate flow rate (L/min)

flowRate = (pulseCount / 45.0); // 45 pulses per liter

// Print the flow rate to the serial monitor

Serial.print("Flow Rate: ");

Serial.print(flowRate);

Serial.println(" L/min");

// Reset pulse count for the next measurement

pulseCount = 0;

// Wait for 1 second before the next measurement

delay(1000);

}

// Interrupt service routine to count pulses

void pulseCounter() {

pulseCount++;

}

Important Considerations and Best Practices

- Power Supply: Ensure a stable 5V DC power supply to avoid inaccurate readings.

- Mounting: Install the sensor in a straight section of the pipe to minimize turbulence.

- Orientation: Follow the manufacturer's guidelines for the correct orientation of the sensor.

- Calibration: Periodically calibrate the sensor to maintain accuracy.

Troubleshooting and FAQs

Common Issues and Solutions

No Output Signal:

- Check Connections: Ensure all connections are secure and correct.

- Power Supply: Verify that the sensor is receiving the correct voltage.

Inaccurate Readings:

- Calibration: Recalibrate the sensor.

- Flow Disturbances: Ensure the sensor is installed in a straight section of the pipe.

Intermittent Signal:

- Electrical Noise: Use shielded cables to reduce electrical noise.

- Loose Connections: Check for any loose or corroded connections.

FAQs

Q1: Can the Sensor Fluxo be used with liquids other than water? A1: Yes, the Sensor Fluxo can measure the flow rate of various liquids and gases, but ensure the material compatibility with the fluid.

Q2: How often should the sensor be calibrated? A2: Calibration frequency depends on the application and usage. For critical applications, calibrate the sensor every 6 months.

Q3: Can the sensor be used in high-pressure systems? A3: The Sensor Fluxo is designed for standard pressure systems. For high-pressure applications, consult the manufacturer for suitable models.

By following this documentation, users can effectively integrate and utilize the Sensor Fluxo in their projects, ensuring accurate and reliable flow rate measurements.