How to Use 28BYJ-48 Stepper Motor: Examples, Pinouts, and Specs

Design with 28BYJ-48 Stepper Motor in Cirkit Designer

Design with 28BYJ-48 Stepper Motor in Cirkit DesignerIntroduction

The 28BYJ-48 is a small, low-cost stepper motor widely used in robotics, automation, and DIY electronics projects. It features a 5-phase design and is capable of precise control of rotation and position. This motor is ideal for applications requiring accurate angular movement, such as robotic arms, camera sliders, and automated mechanisms. Its compact size and affordability make it a popular choice for hobbyists and professionals alike.

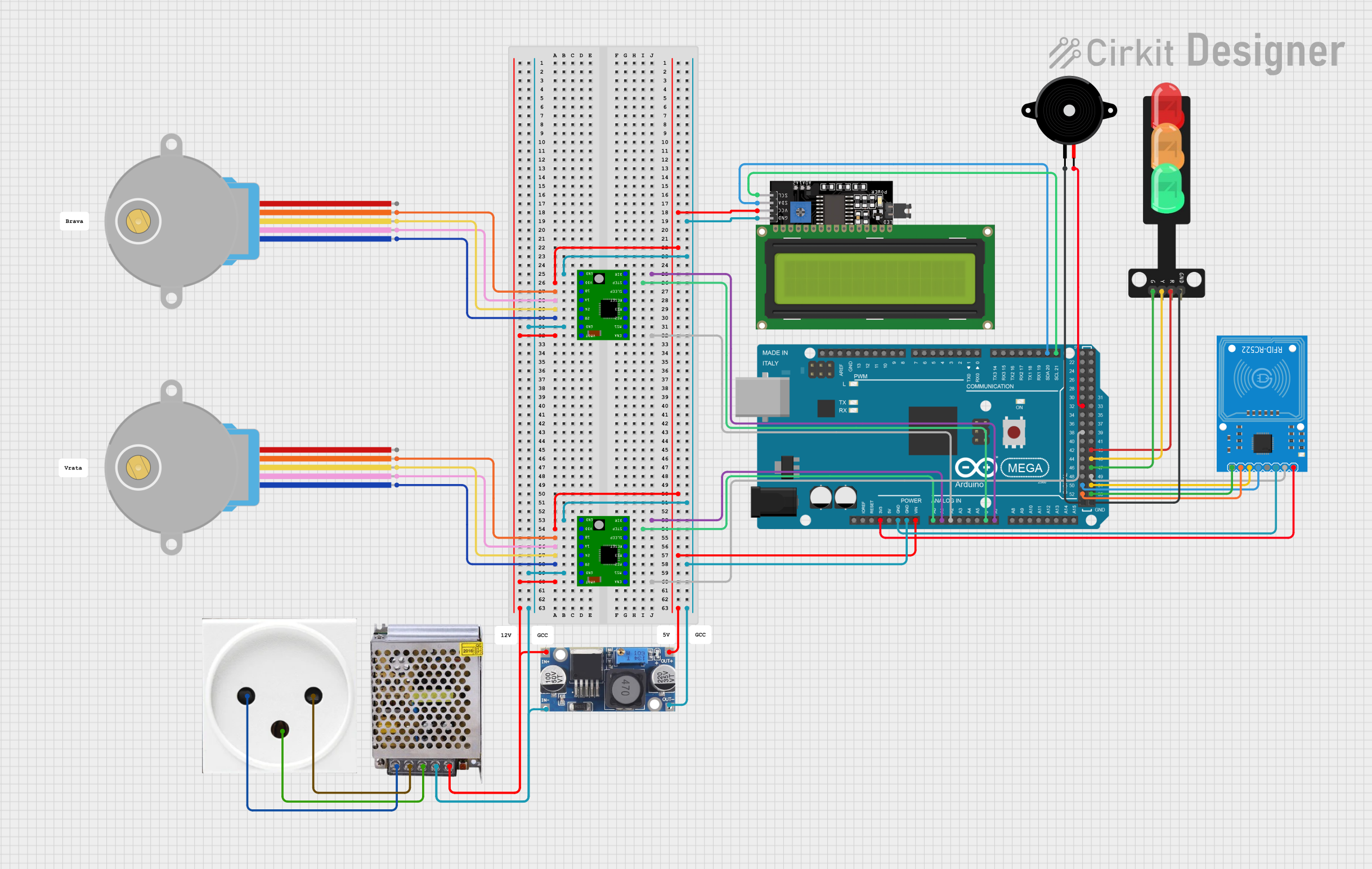

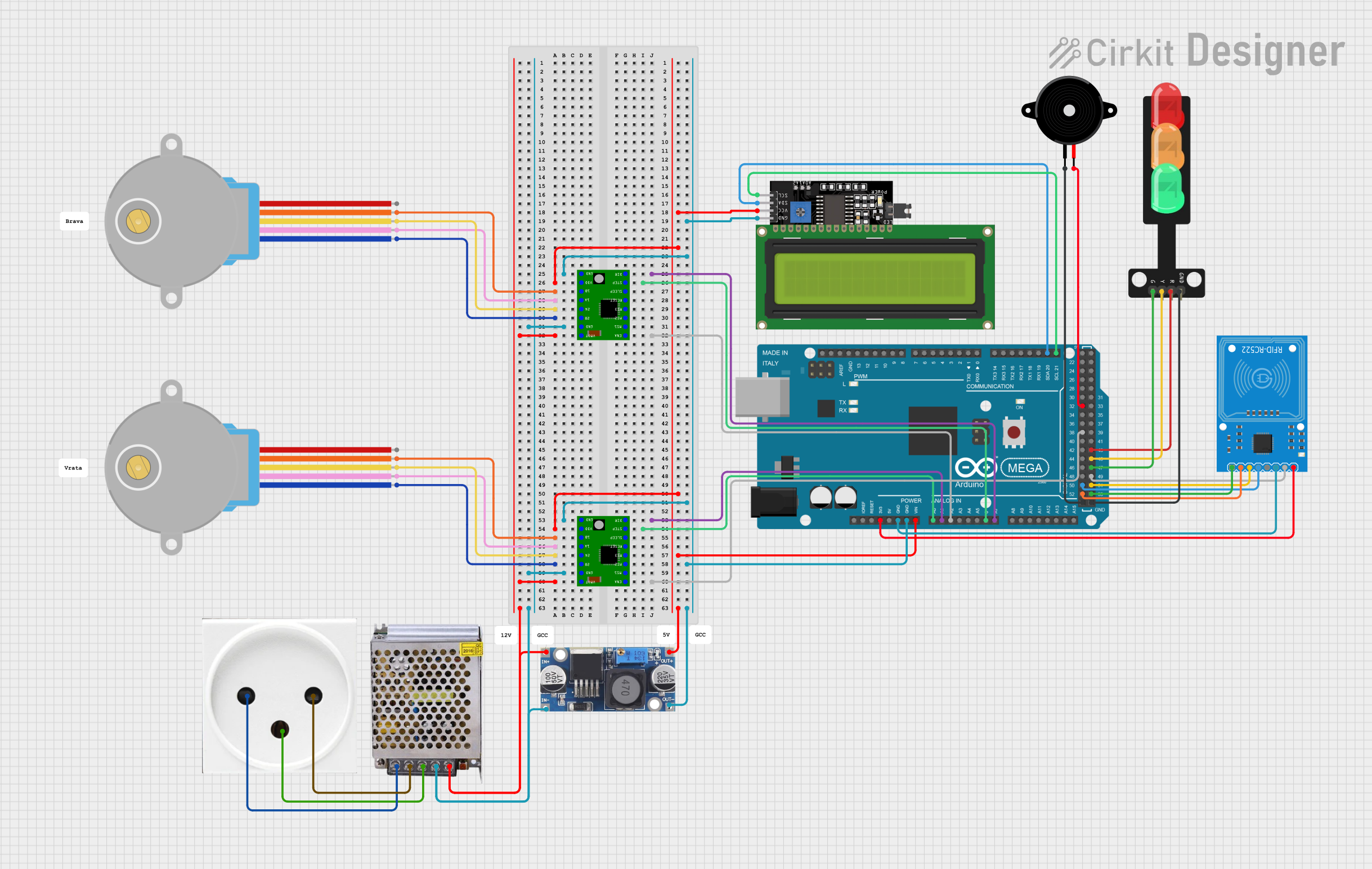

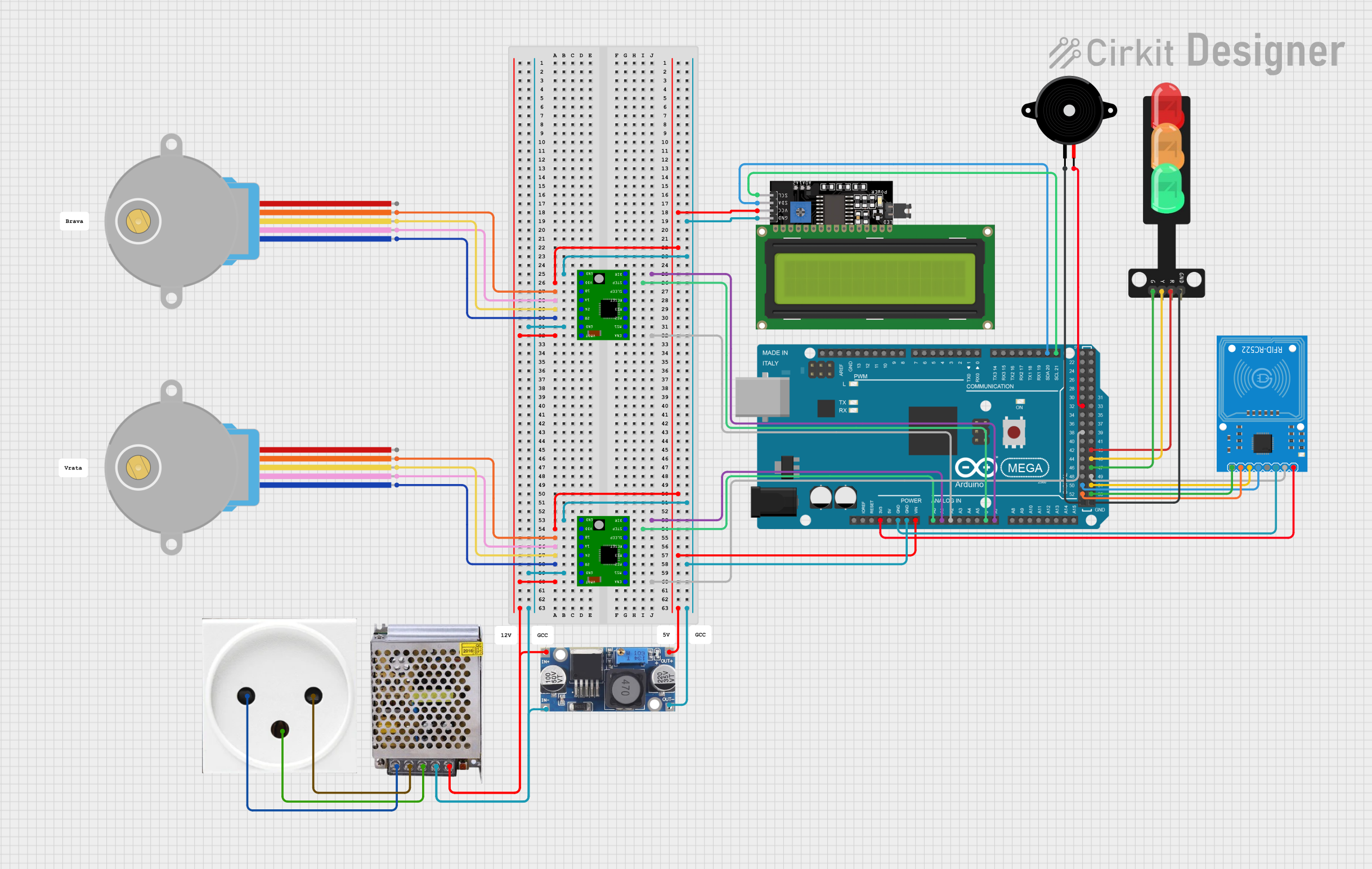

Explore Projects Built with 28BYJ-48 Stepper Motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 28BYJ-48 Stepper Motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

The 28BYJ-48 stepper motor is designed for low-power applications and offers reliable performance. Below are its key technical details:

General Specifications

- Type: Unipolar Stepper Motor

- Operating Voltage: 5V DC

- Step Angle: 5.625°/step (64 steps per revolution in full-step mode)

- Gear Ratio: 1:64 (final resolution: 4096 steps per revolution)

- Coil Resistance: ~50Ω per coil

- Max Current: ~240mA

- Holding Torque: ~300 gf.cm

- Weight: ~30g

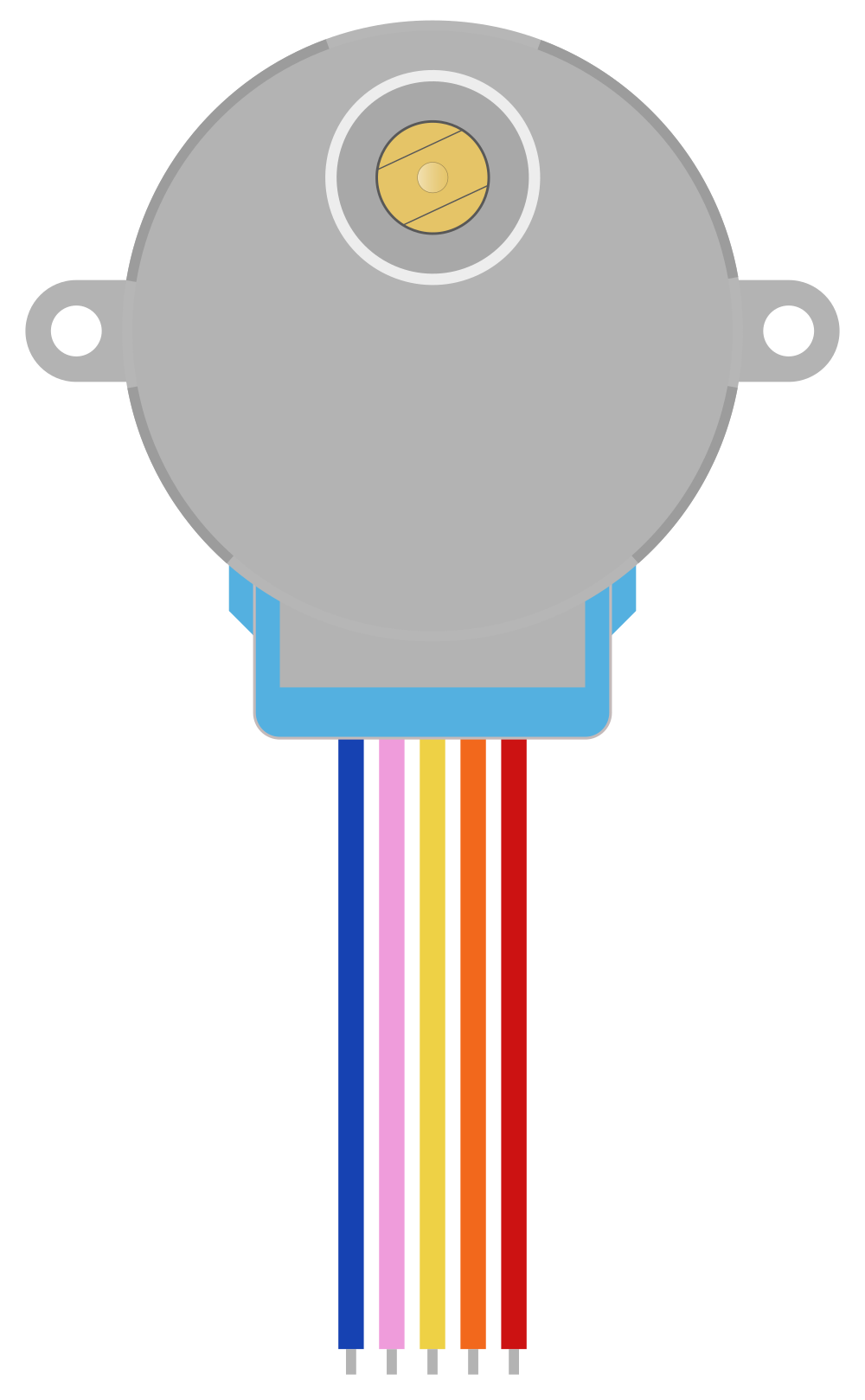

Pin Configuration

The 28BYJ-48 stepper motor is typically used with a ULN2003 driver board, which provides an easy interface for controlling the motor. Below is the pin configuration for the motor and the driver board:

Motor Pinout

| Pin Number | Wire Color | Description |

|---|---|---|

| 1 | Orange | Coil A |

| 2 | Yellow | Coil B |

| 3 | Pink | Coil C |

| 4 | Blue | Coil D |

| 5 | Red | VCC (5V Power Input) |

ULN2003 Driver Board Pinout

| Pin Label | Description |

|---|---|

| IN1 | Input for Coil A |

| IN2 | Input for Coil B |

| IN3 | Input for Coil C |

| IN4 | Input for Coil D |

| VCC | Power Input (5V) |

| GND | Ground |

| OUT1-OUT4 | Outputs to Motor Coils (A-D) |

Usage Instructions

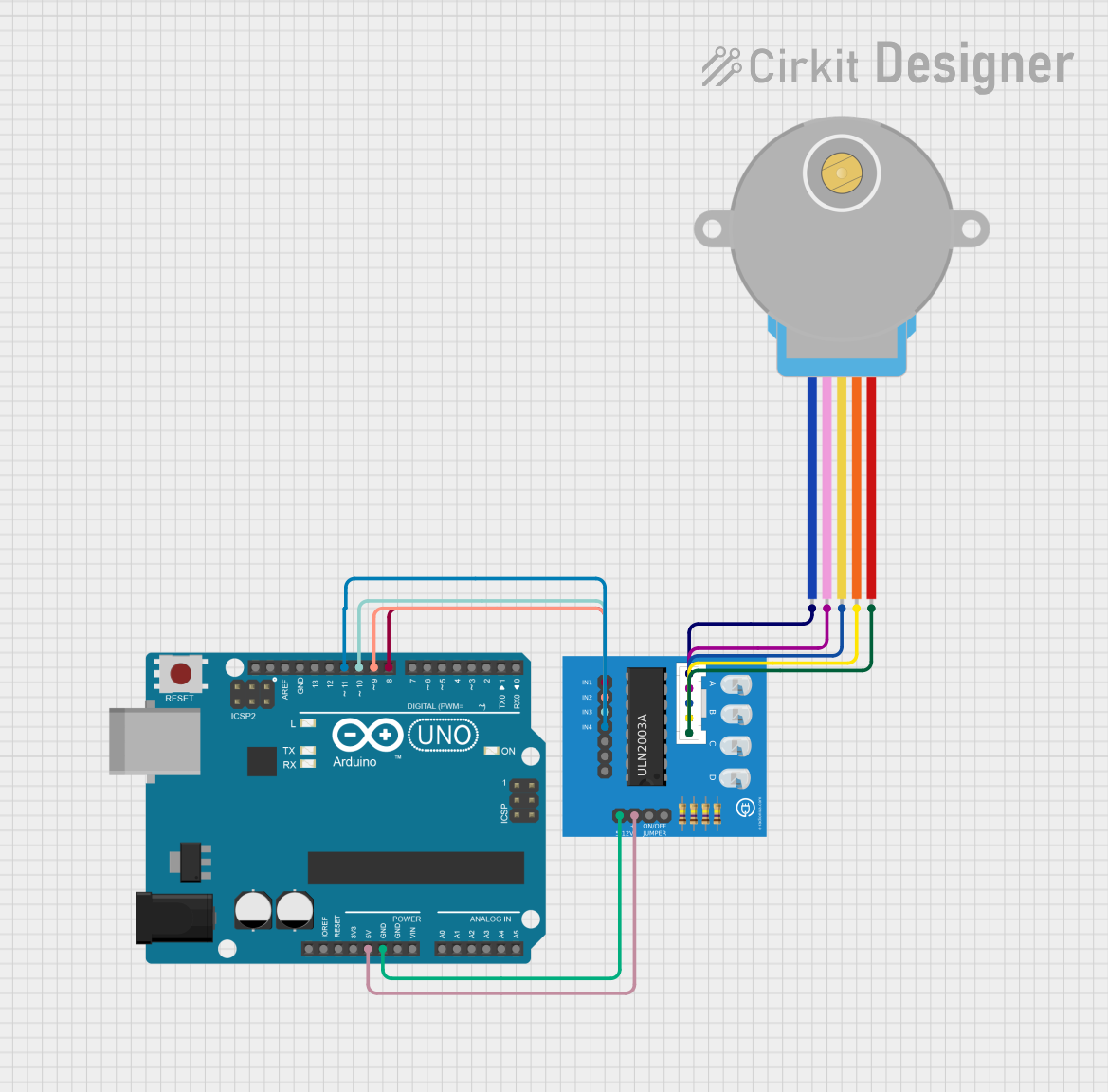

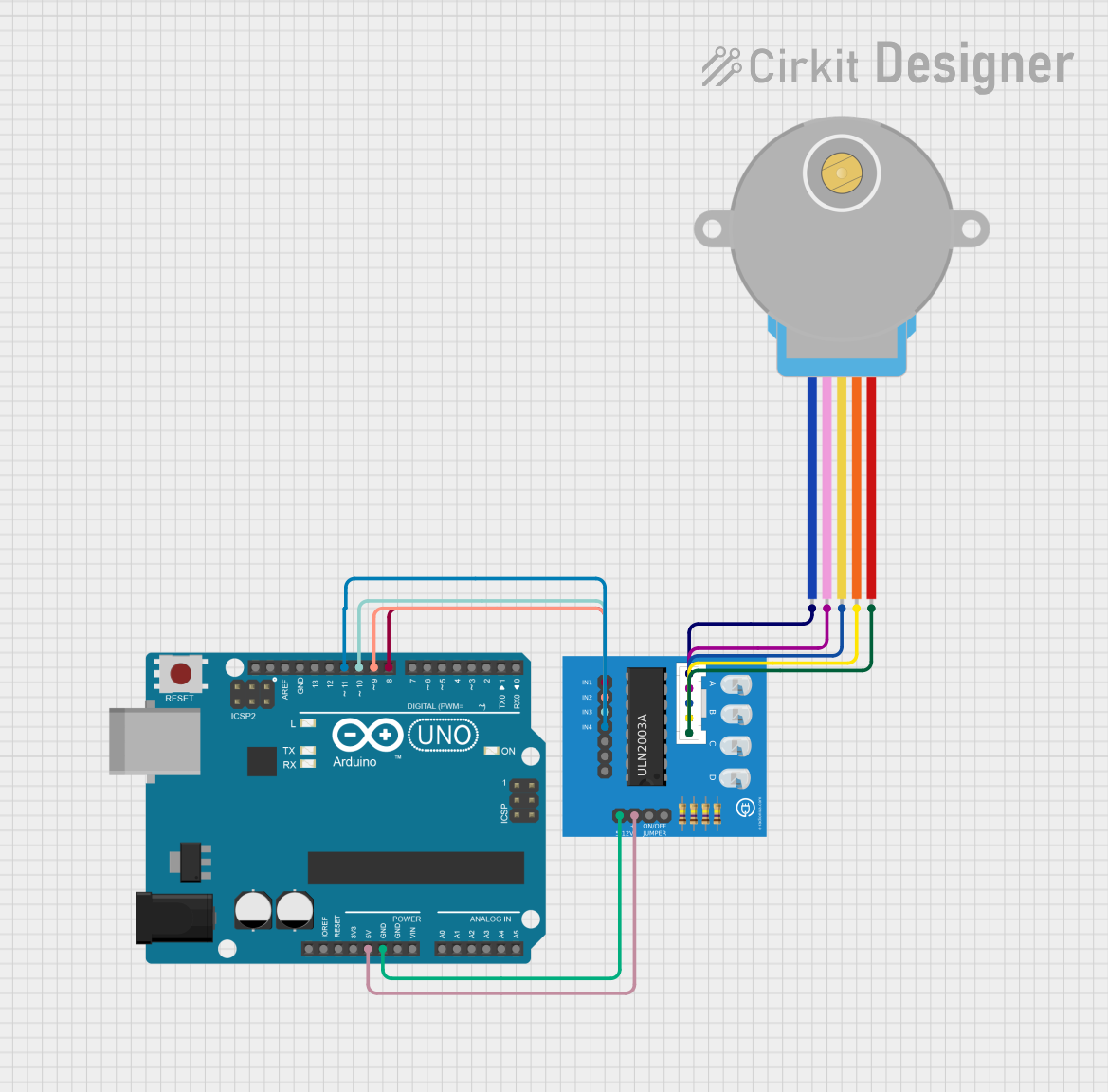

The 28BYJ-48 stepper motor is typically controlled using a driver board like the ULN2003 and a microcontroller such as an Arduino UNO. Below are the steps to use the motor in a circuit:

Circuit Connection

- Connect the 28BYJ-48 motor to the ULN2003 driver board:

- Match the motor's 5-pin connector to the driver board's socket.

- Connect the ULN2003 driver board to the Arduino UNO:

- IN1 → Arduino Digital Pin 8

- IN2 → Arduino Digital Pin 9

- IN3 → Arduino Digital Pin 10

- IN4 → Arduino Digital Pin 11

- VCC → Arduino 5V

- GND → Arduino GND

- Power the Arduino UNO using a USB cable or an external power source.

Arduino Code Example

Below is an example Arduino sketch to control the 28BYJ-48 stepper motor using the ULN2003 driver board:

#include <Stepper.h>

// Define the number of steps per revolution for the motor

#define STEPS_PER_REV 2048 // 4096 steps per revolution (half-step mode)

// Initialize the Stepper library with the motor's pin connections

Stepper stepper(STEPS_PER_REV, 8, 10, 9, 11);

void setup() {

// Set the motor speed (in RPM)

stepper.setSpeed(10); // Adjust speed as needed

Serial.begin(9600);

Serial.println("28BYJ-48 Stepper Motor Test");

}

void loop() {

// Rotate the motor 1 full revolution clockwise

Serial.println("Rotating clockwise...");

stepper.step(STEPS_PER_REV);

delay(1000); // Wait for 1 second

// Rotate the motor 1 full revolution counterclockwise

Serial.println("Rotating counterclockwise...");

stepper.step(-STEPS_PER_REV);

delay(1000); // Wait for 1 second

}

Important Considerations

- Power Supply: Ensure the motor is powered with a stable 5V DC supply. Using higher voltages may damage the motor.

- Current Limitation: Avoid exceeding the motor's maximum current rating (~240mA) to prevent overheating.

- Speed and Torque: Higher speeds may reduce torque. Adjust the speed in the code to balance performance.

- Gearbox: The motor's internal gearbox provides high torque but limits speed. Avoid applying excessive force to the motor shaft to prevent damage.

Troubleshooting and FAQs

Common Issues

Motor Not Rotating:

- Check all connections between the motor, driver board, and microcontroller.

- Ensure the power supply is providing 5V DC.

- Verify the Arduino code is correctly uploaded and running.

Motor Vibrates but Doesn't Rotate:

- Ensure the step sequence in the code matches the motor's wiring.

- Check for loose or incorrect connections.

Motor Overheating:

- Reduce the operating speed or duty cycle.

- Verify the current does not exceed the motor's rating.

Inconsistent Movement:

- Ensure the power supply is stable and not fluctuating.

- Check for mechanical obstructions in the motor or connected load.

FAQs

Q: Can I power the motor directly from the Arduino?

A: While the motor can be powered from the Arduino's 5V pin, it is recommended to use an external 5V power supply for better performance and to avoid overloading the Arduino.

Q: How do I increase the motor's speed?

A: Increase the speed in the stepper.setSpeed() function in the Arduino code. Note that higher speeds may reduce torque.

Q: Can I use the motor without a driver board?

A: It is possible but not recommended. The ULN2003 driver board simplifies control and protects the microcontroller from high currents.

Q: What is the maximum load the motor can handle?

A: The motor's holding torque is approximately 300 gf.cm. Ensure the load does not exceed this value to avoid stalling or damage.

By following this documentation, you can effectively use the 28BYJ-48 stepper motor in your projects.