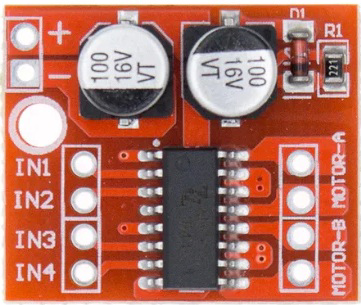

How to Use L298N: Examples, Pinouts, and Specs

Design with L298N in Cirkit Designer

Design with L298N in Cirkit DesignerIntroduction

The L298N is a dual H-bridge motor driver IC manufactured by Custon (Part ID: L298N). It is designed to control the direction and speed of DC motors and stepper motors. With the ability to drive two motors simultaneously and handle up to 2A per channel, the L298N is widely used in robotics, automation, and other motor control applications.

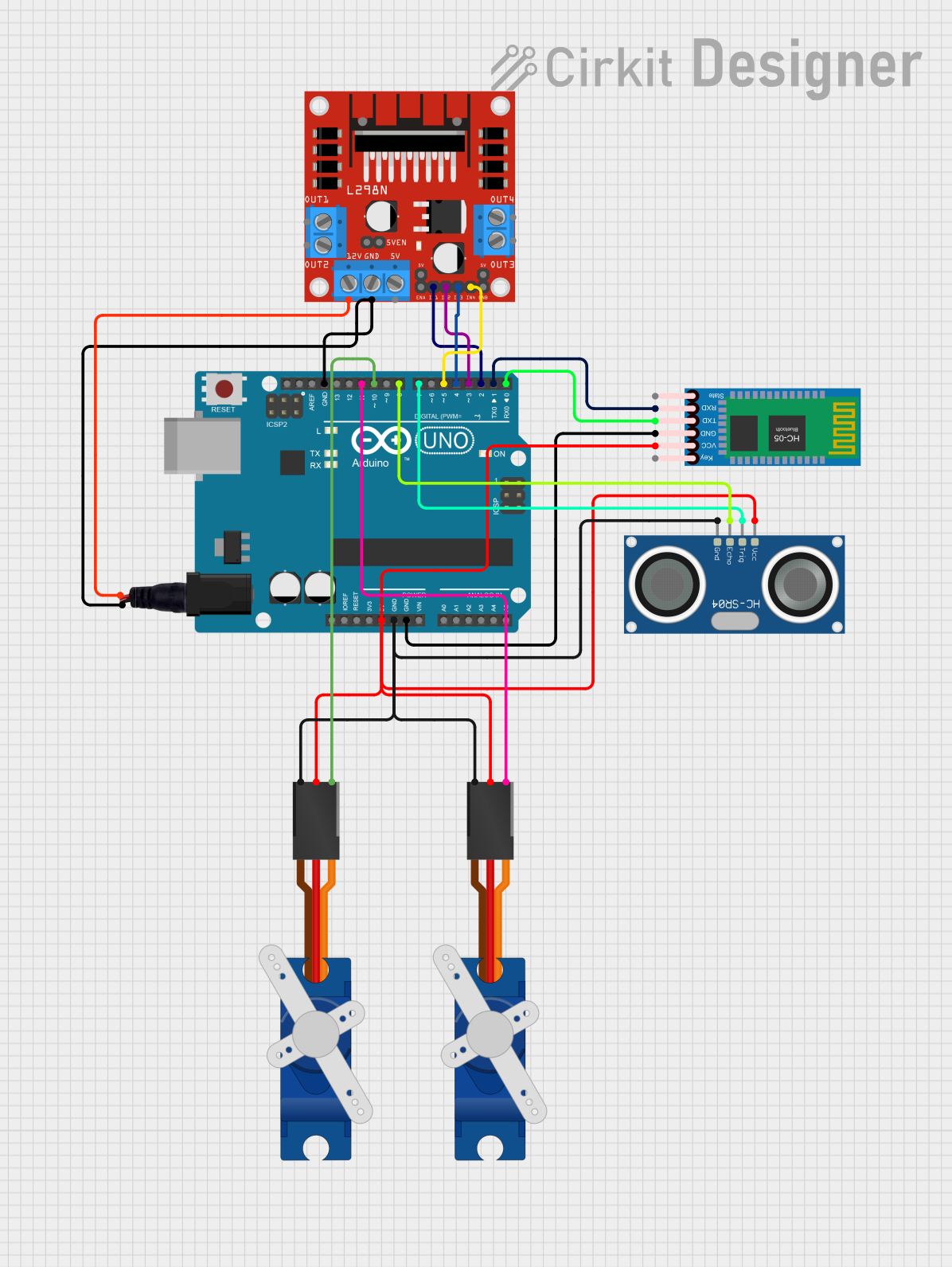

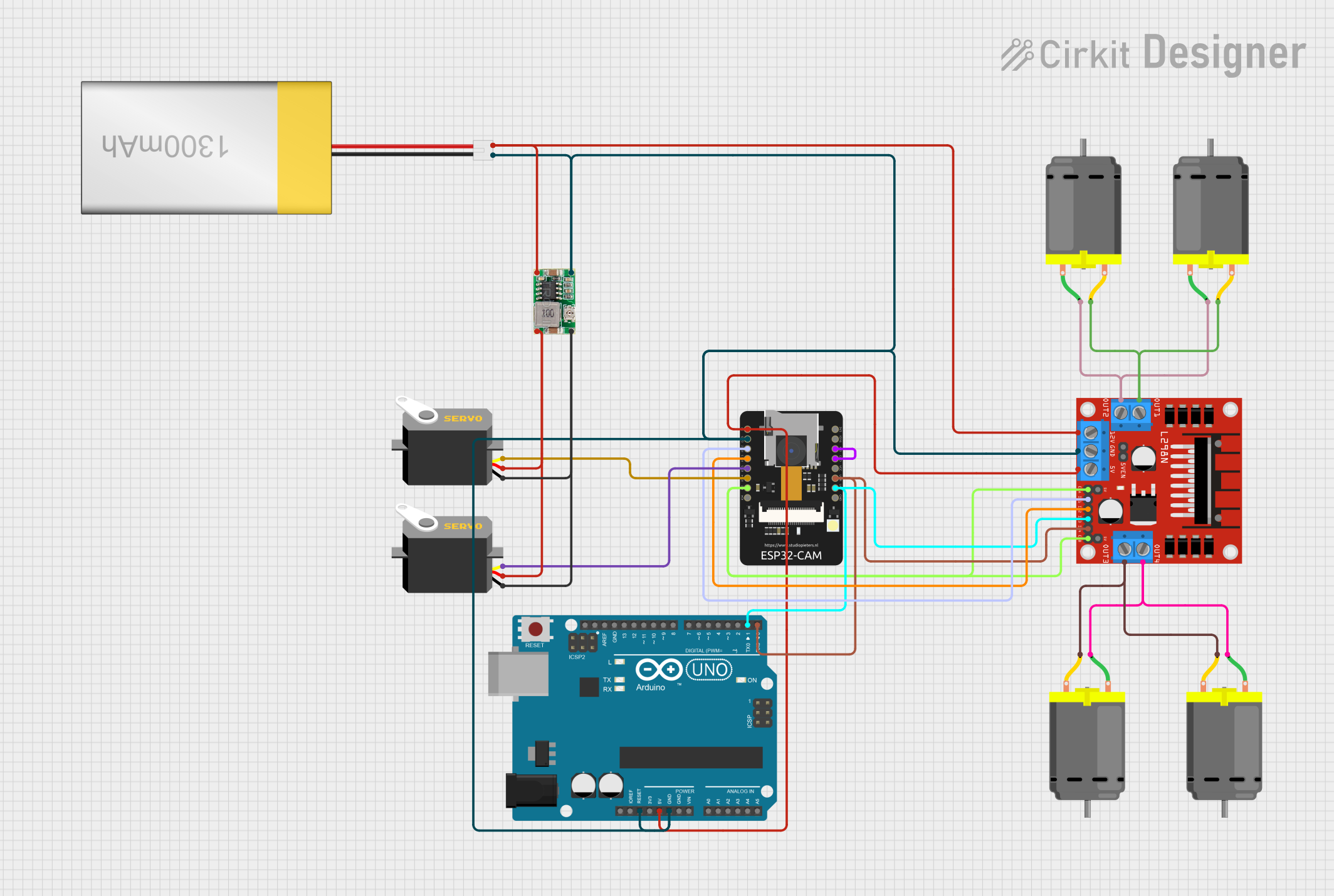

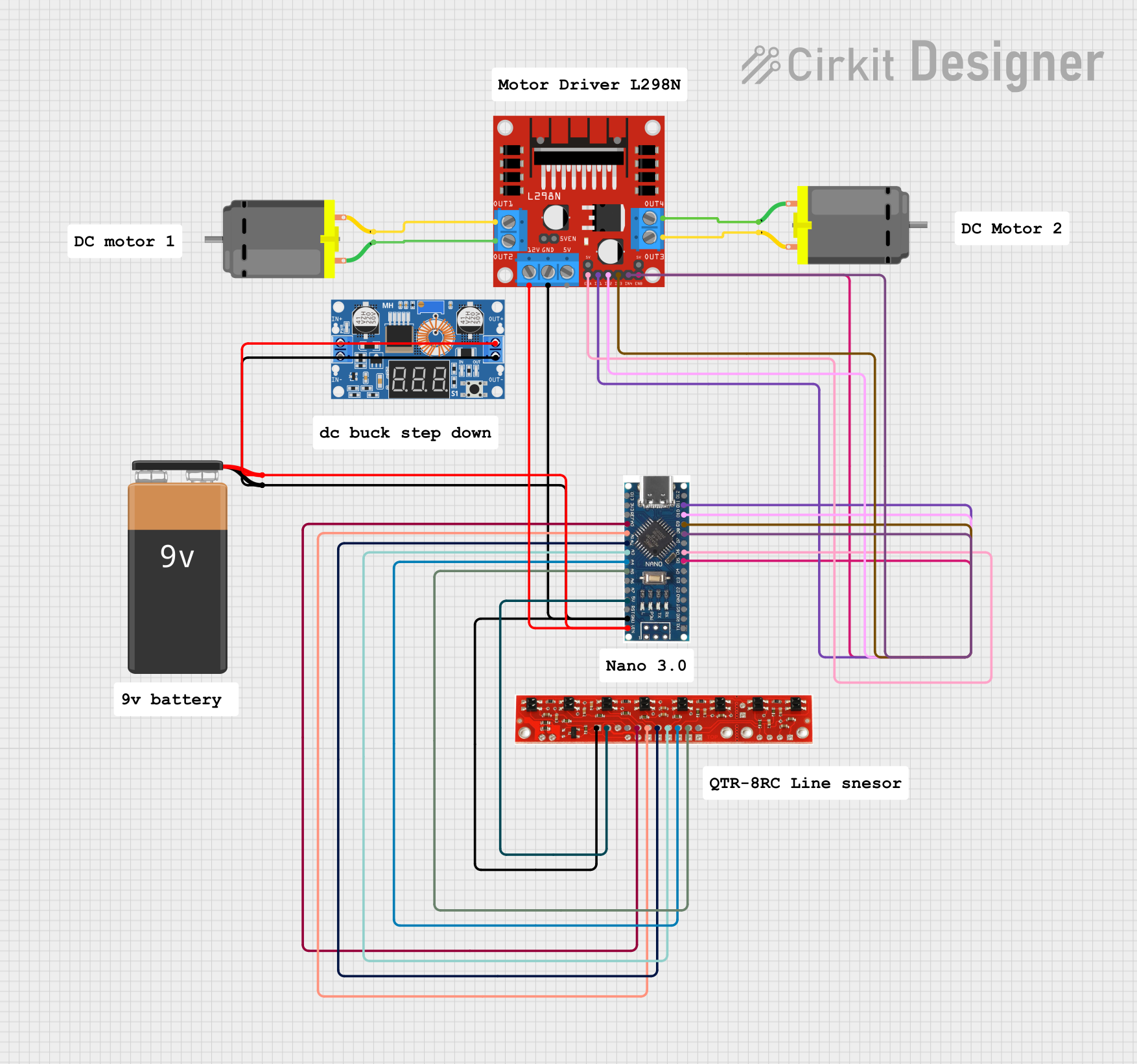

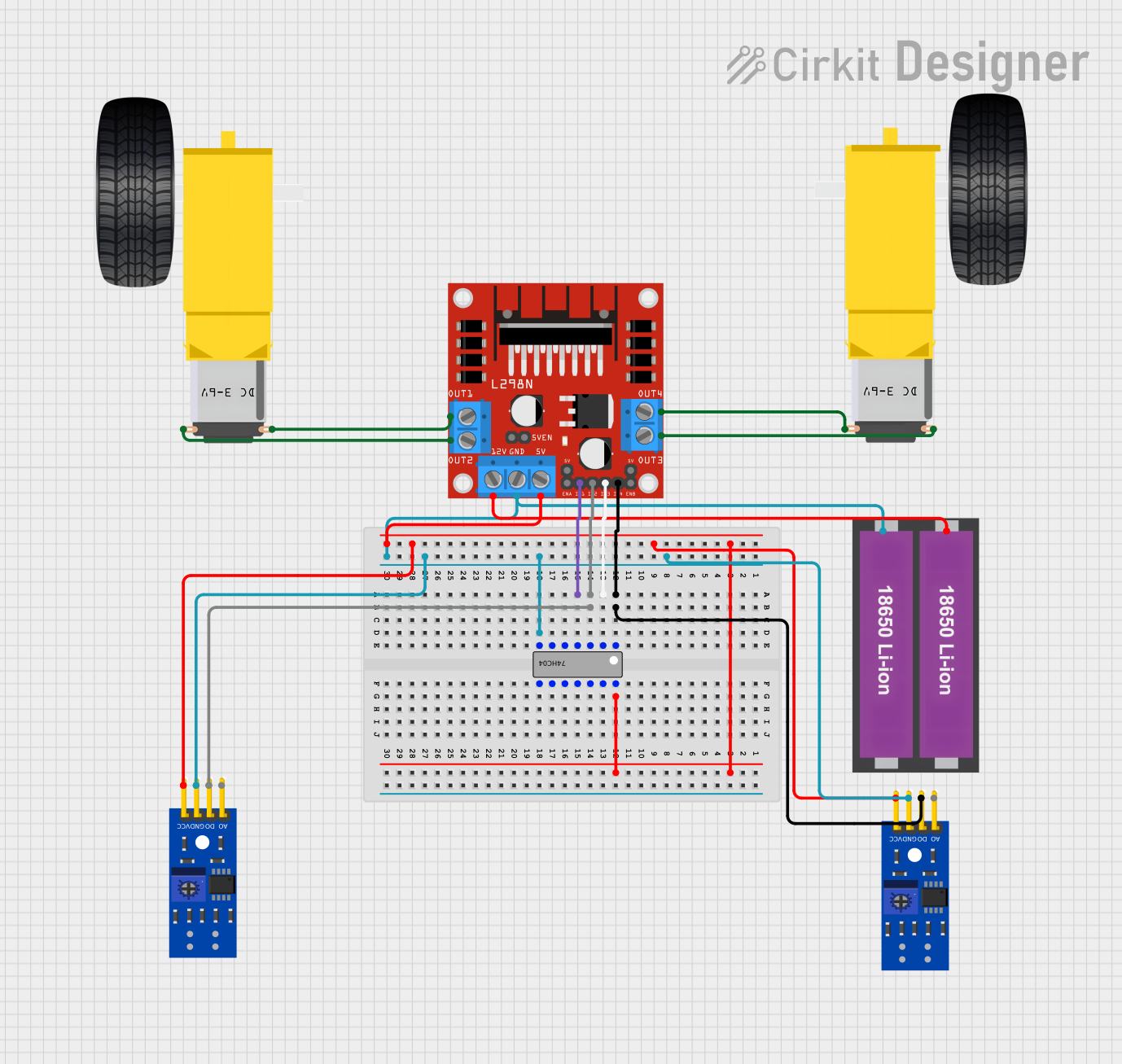

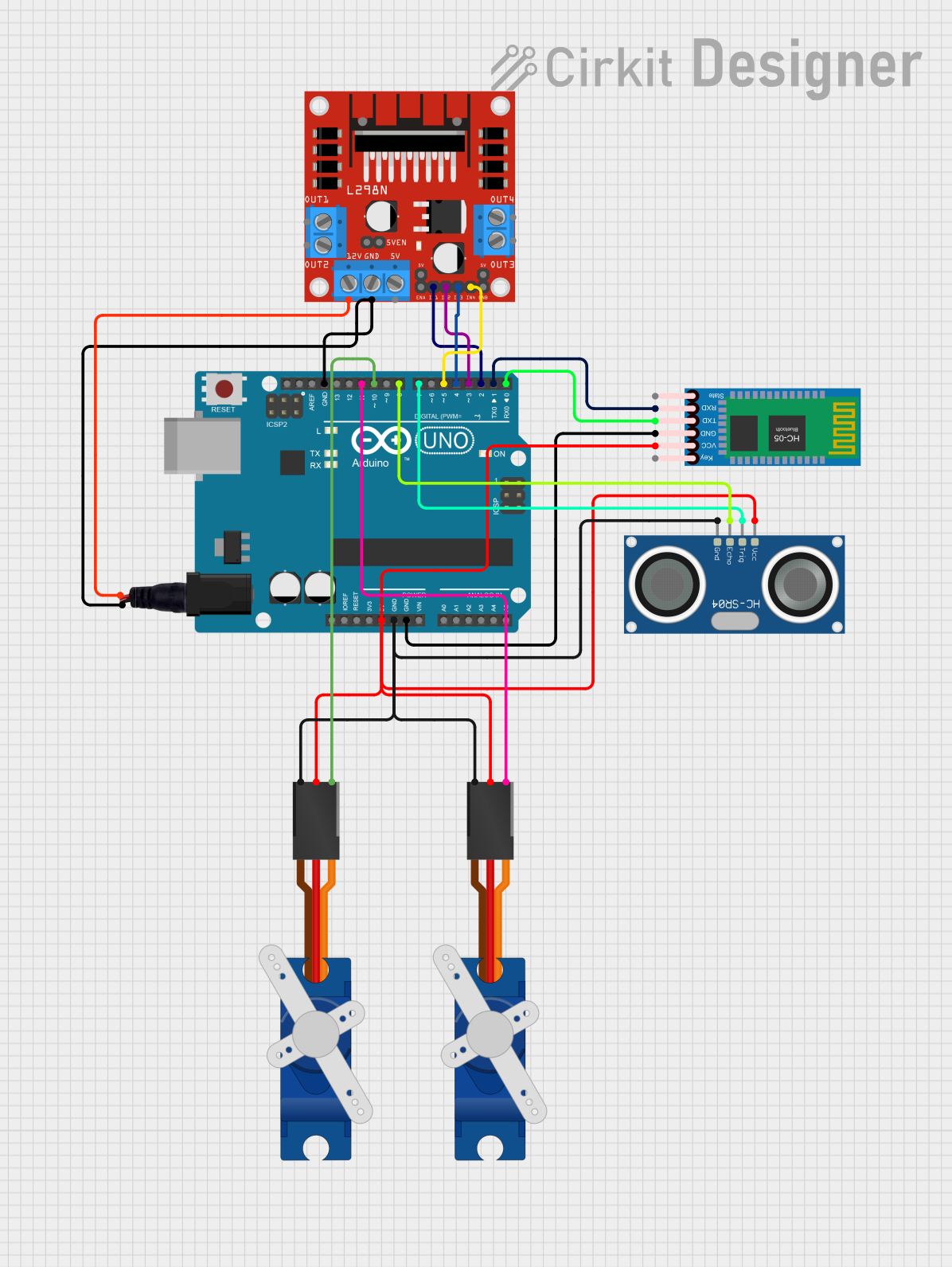

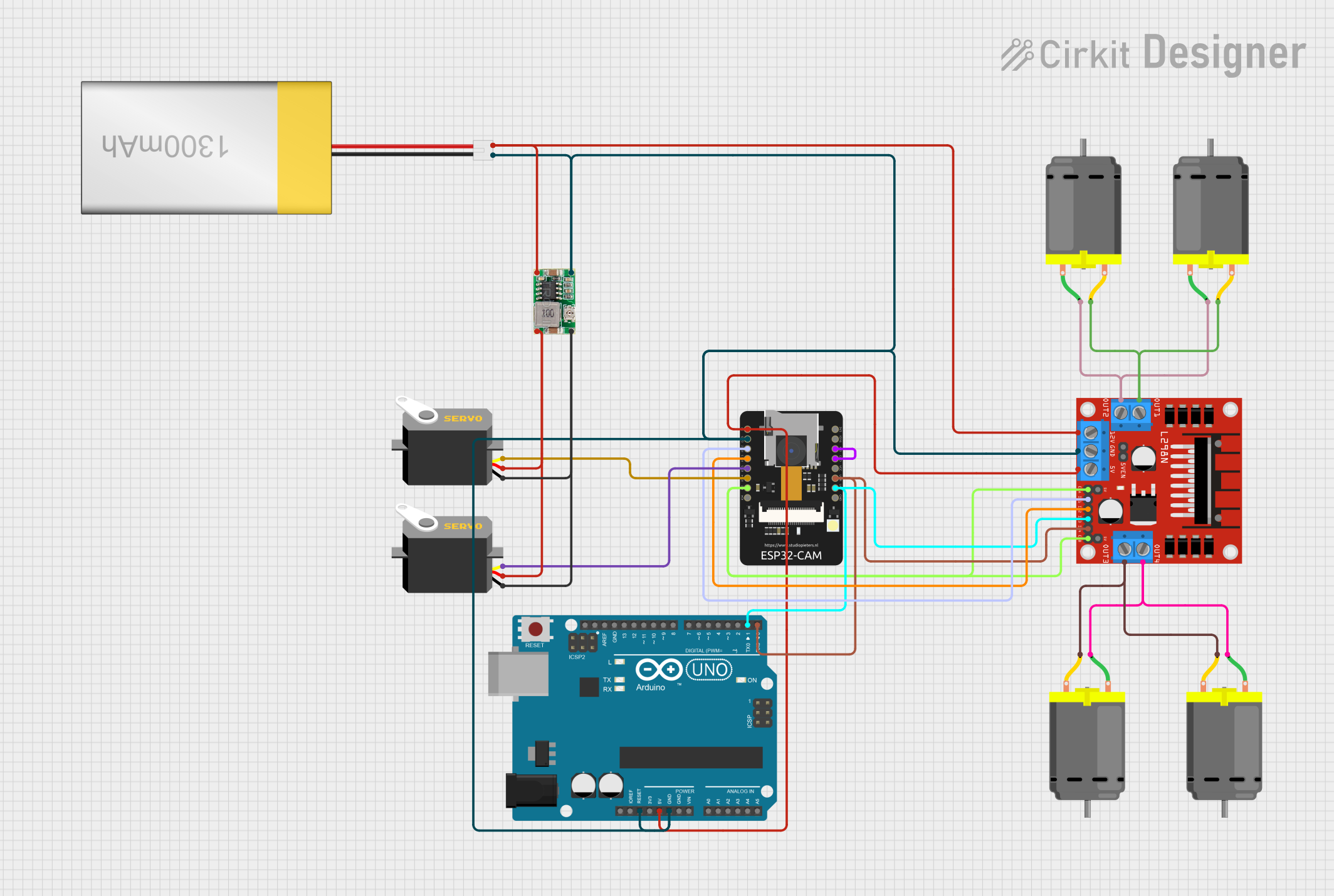

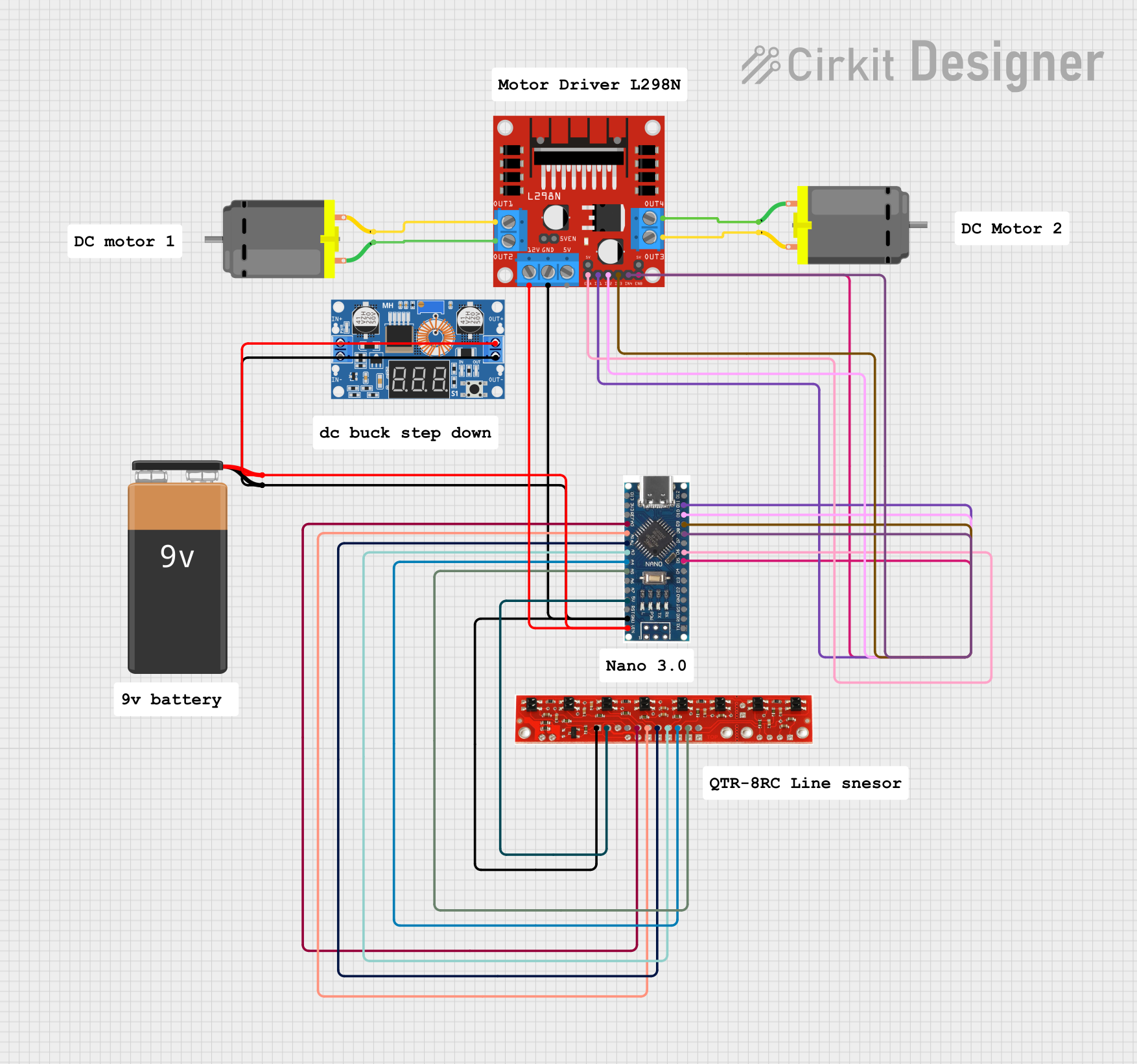

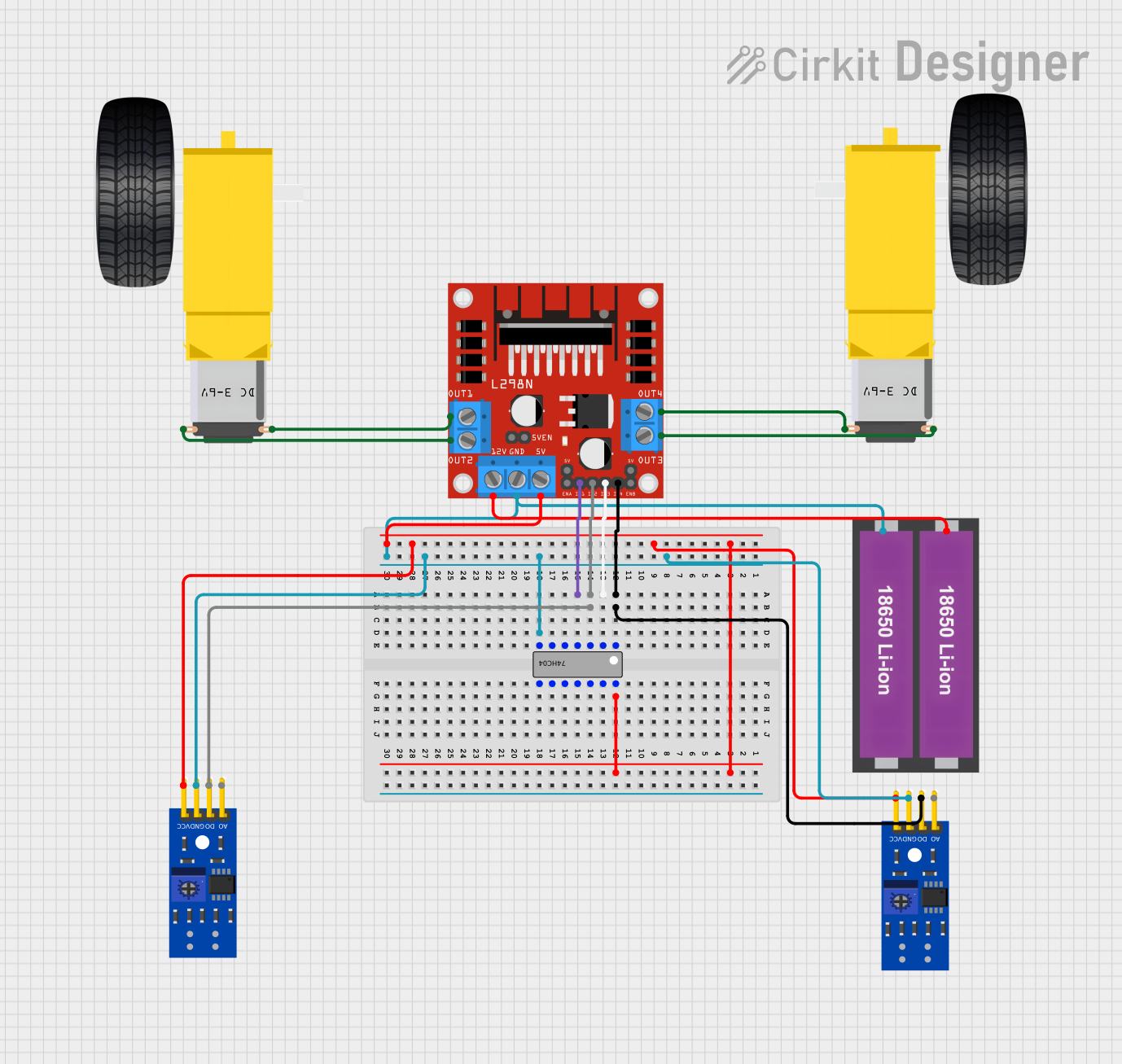

Explore Projects Built with L298N

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with L298N

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Robotics: Driving wheels or tracks of robots

- Automation: Controlling conveyor belts or actuators

- DIY Projects: Building motorized vehicles or robotic arms

- Stepper Motor Control: Driving stepper motors for precise positioning

Technical Specifications

Below are the key technical details of the L298N motor driver IC:

| Parameter | Value |

|---|---|

| Supply Voltage (Vcc) | 4.5V to 46V |

| Logic Voltage (Vss) | 5V to 7V |

| Maximum Output Current | 2A per channel (continuous) |

| Peak Output Current | 3A per channel (short duration) |

| Power Dissipation | 25W (with proper heat sinking) |

| Operating Temperature | -25°C to +130°C |

| Motor Channels | 2 (independent control) |

| Control Logic | TTL-compatible |

Pin Configuration and Descriptions

The L298N IC has 15 pins, each serving a specific function. Below is the pinout and description:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | Enable A | Enables or disables motor channel A (active HIGH) |

| 2 | Input 1 | Logic input to control motor A direction (HIGH/LOW) |

| 3 | Output 1 | Output to motor A terminal 1 |

| 4 | Ground | Ground connection |

| 5 | Ground | Ground connection |

| 6 | Output 2 | Output to motor A terminal 2 |

| 7 | Vss | Logic voltage supply (5V to 7V) |

| 8 | Vcc | Motor power supply (4.5V to 46V) |

| 9 | Output 3 | Output to motor B terminal 1 |

| 10 | Ground | Ground connection |

| 11 | Ground | Ground connection |

| 12 | Output 4 | Output to motor B terminal 2 |

| 13 | Input 2 | Logic input to control motor B direction (HIGH/LOW) |

| 14 | Enable B | Enables or disables motor channel B (active HIGH) |

| 15 | Sense A/B | Current sensing pins for motor A and B (optional, connect to ground if unused) |

Usage Instructions

The L298N is straightforward to use in motor control circuits. Below are the steps and best practices for using the component:

Connecting the L298N to a DC Motor

Power Supply:

- Connect the motor power supply (4.5V to 46V) to the Vcc pin.

- Connect the logic power supply (5V) to the Vss pin.

- Ensure all ground pins are connected to a common ground.

Motor Connections:

- Connect the motor terminals to the Output 1 and Output 2 pins for motor A.

- For motor B, use Output 3 and Output 4.

Control Logic:

- Use the Input 1 and Input 2 pins to control the direction of motor A.

- Similarly, use Input 3 and Input 4 for motor B.

- Set the Enable A and Enable B pins HIGH to activate the respective motor channels.

Optional Features:

- Use the Sense A/B pins for current sensing if required. Otherwise, connect them to ground.

Example: Controlling a DC Motor with Arduino UNO

Below is an example Arduino sketch to control a single DC motor using the L298N:

// Define L298N control pins

const int enableA = 9; // Enable pin for motor A

const int input1 = 8; // Input 1 for motor A

const int input2 = 7; // Input 2 for motor A

void setup() {

// Set pin modes

pinMode(enableA, OUTPUT);

pinMode(input1, OUTPUT);

pinMode(input2, OUTPUT);

// Initialize motor in stopped state

digitalWrite(enableA, LOW); // Disable motor

digitalWrite(input1, LOW); // Set direction to LOW

digitalWrite(input2, LOW); // Set direction to LOW

}

void loop() {

// Example: Rotate motor forward

digitalWrite(enableA, HIGH); // Enable motor

digitalWrite(input1, HIGH); // Set direction to forward

digitalWrite(input2, LOW); // Set direction to forward

delay(2000); // Run motor for 2 seconds

// Example: Rotate motor backward

digitalWrite(input1, LOW); // Set direction to backward

digitalWrite(input2, HIGH); // Set direction to backward

delay(2000); // Run motor for 2 seconds

// Stop motor

digitalWrite(enableA, LOW); // Disable motor

delay(2000); // Wait for 2 seconds

}

Best Practices

- Use a heat sink with the L298N to prevent overheating during high-current operation.

- Ensure the motor power supply voltage matches the motor's rated voltage.

- Use decoupling capacitors near the power supply pins to reduce noise.

- Avoid exceeding the maximum current rating (2A per channel) to prevent damage.

Troubleshooting and FAQs

Common Issues

Motor Not Running:

- Check if the Enable pin is HIGH.

- Verify the power supply connections to Vcc and Vss.

- Ensure the motor connections are correct.

Overheating:

- Use a heat sink or active cooling to dissipate heat.

- Reduce the motor load or current draw.

Erratic Motor Behavior:

- Check for loose connections or faulty wiring.

- Add decoupling capacitors to the power supply.

Low Motor Speed:

- Verify the motor power supply voltage.

- Check if the PWM signal (if used) is configured correctly.

FAQs

Q: Can the L298N drive stepper motors?

A: Yes, the L298N can drive stepper motors by controlling the sequence of inputs to the motor windings.

Q: What is the purpose of the Sense A/B pins?

A: The Sense A/B pins are used for current sensing. They can be connected to a resistor to measure the current flowing through the motors.

Q: Can I use the L298N with a 3.3V microcontroller?

A: The L298N requires a logic voltage of 5V to 7V. You may need a level shifter to interface it with a 3.3V microcontroller.

Q: How do I protect the L298N from voltage spikes?

A: Use flyback diodes across the motor terminals to protect the IC from voltage spikes caused by inductive loads.