How to Use HBV 1716WA: Examples, Pinouts, and Specs

Design with HBV 1716WA in Cirkit Designer

Design with HBV 1716WA in Cirkit DesignerIntroduction

The HBV 1716WA is a high-performance hydraulic valve designed for precise control of fluid flow in hydraulic systems. Its robust construction ensures durability and reliability, making it suitable for demanding industrial and commercial applications. This component is widely used in hydraulic machinery, automotive systems, and industrial automation where accurate fluid control is critical.

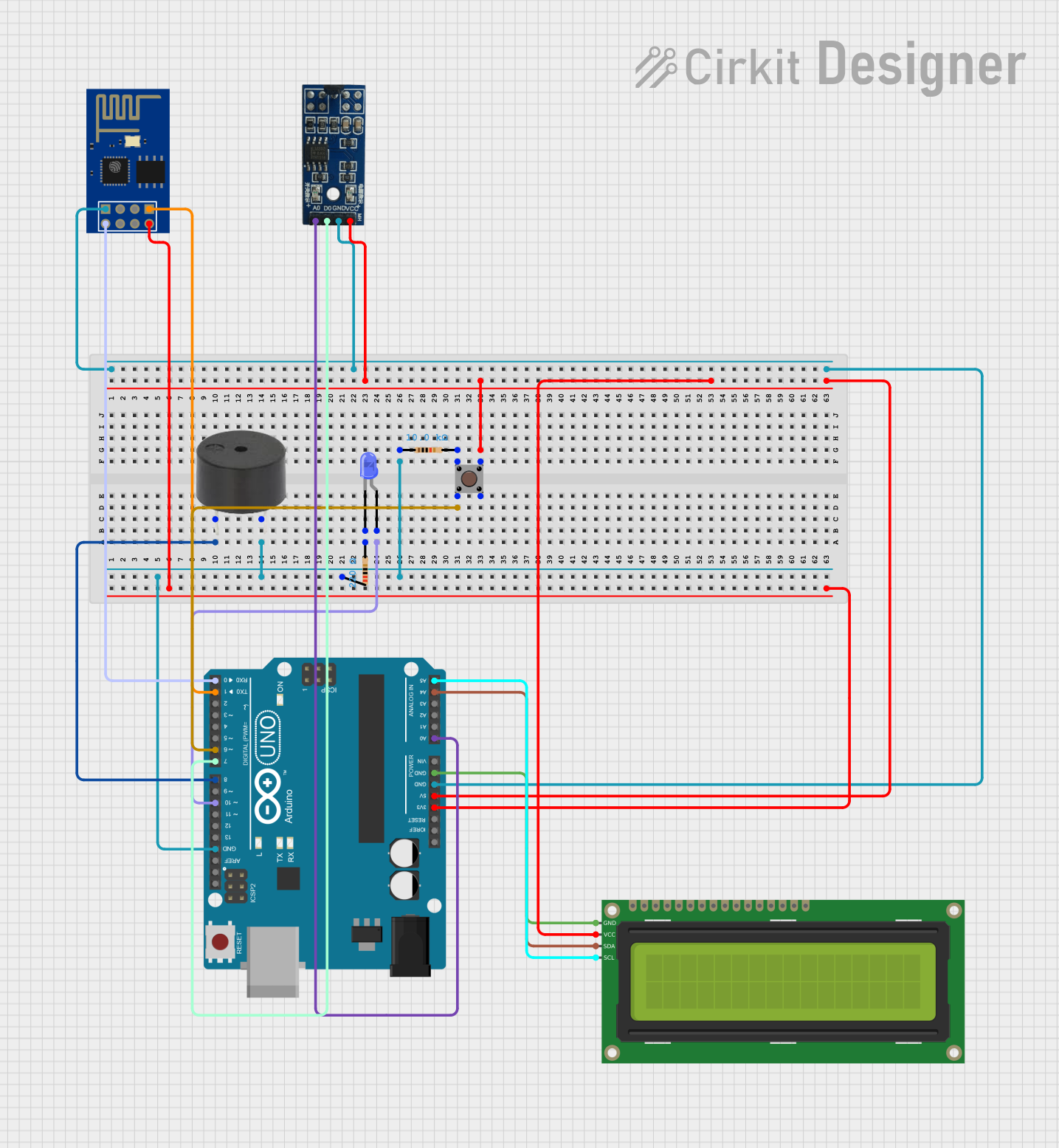

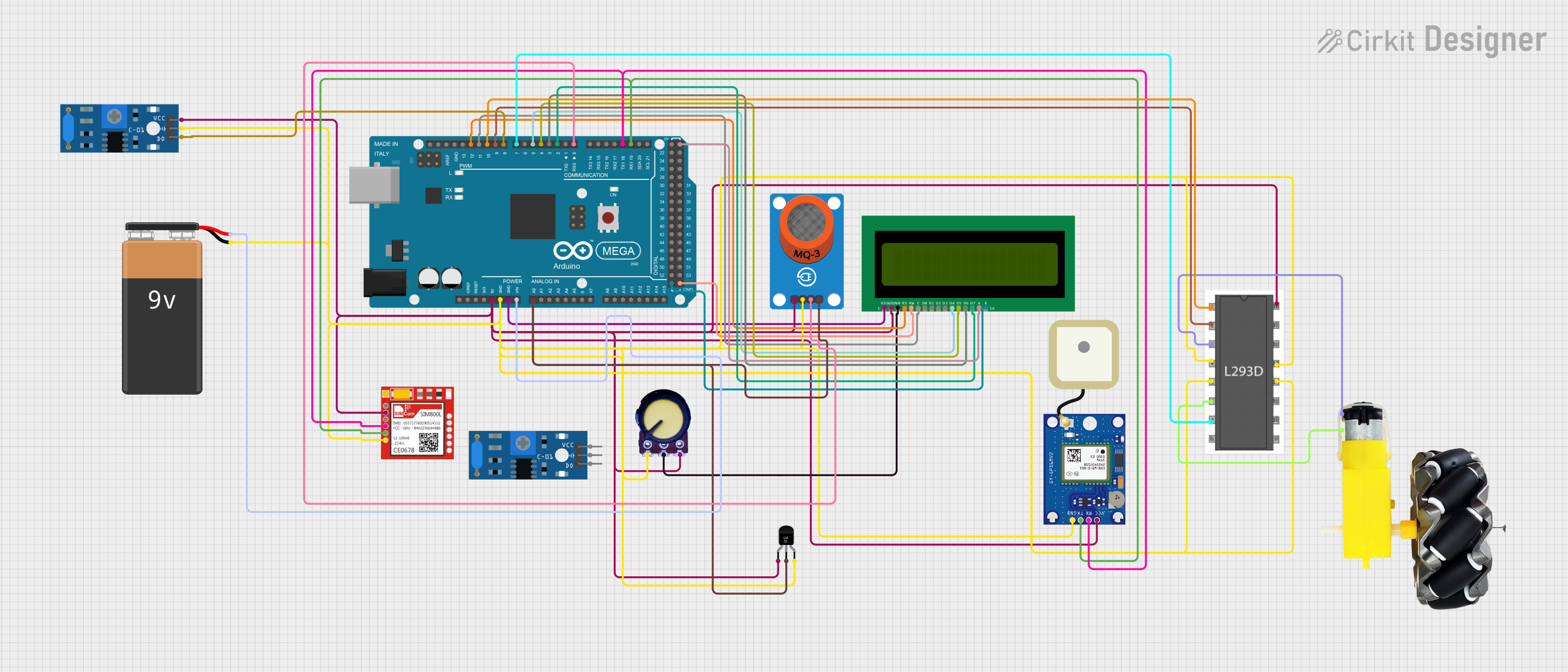

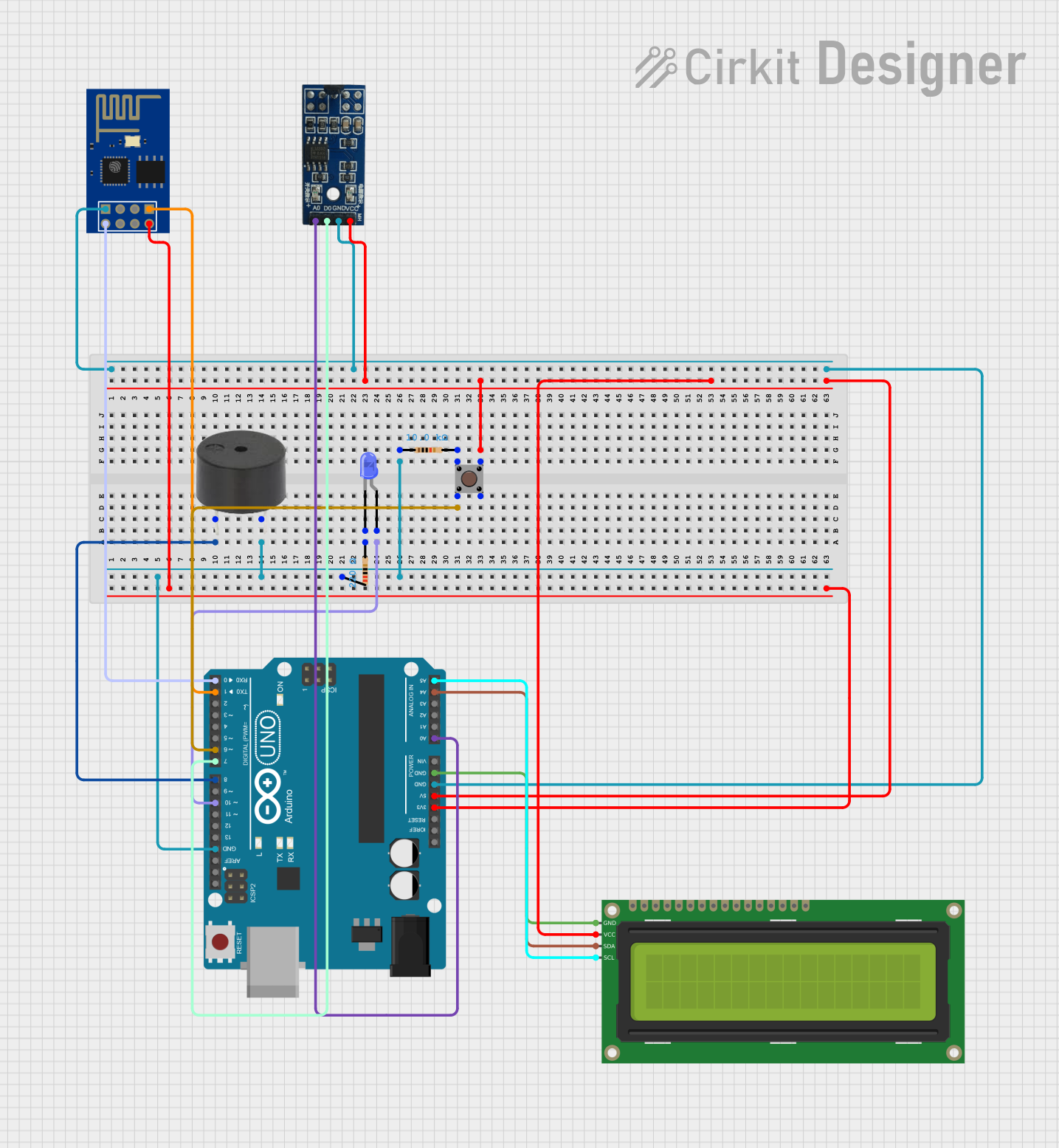

Explore Projects Built with HBV 1716WA

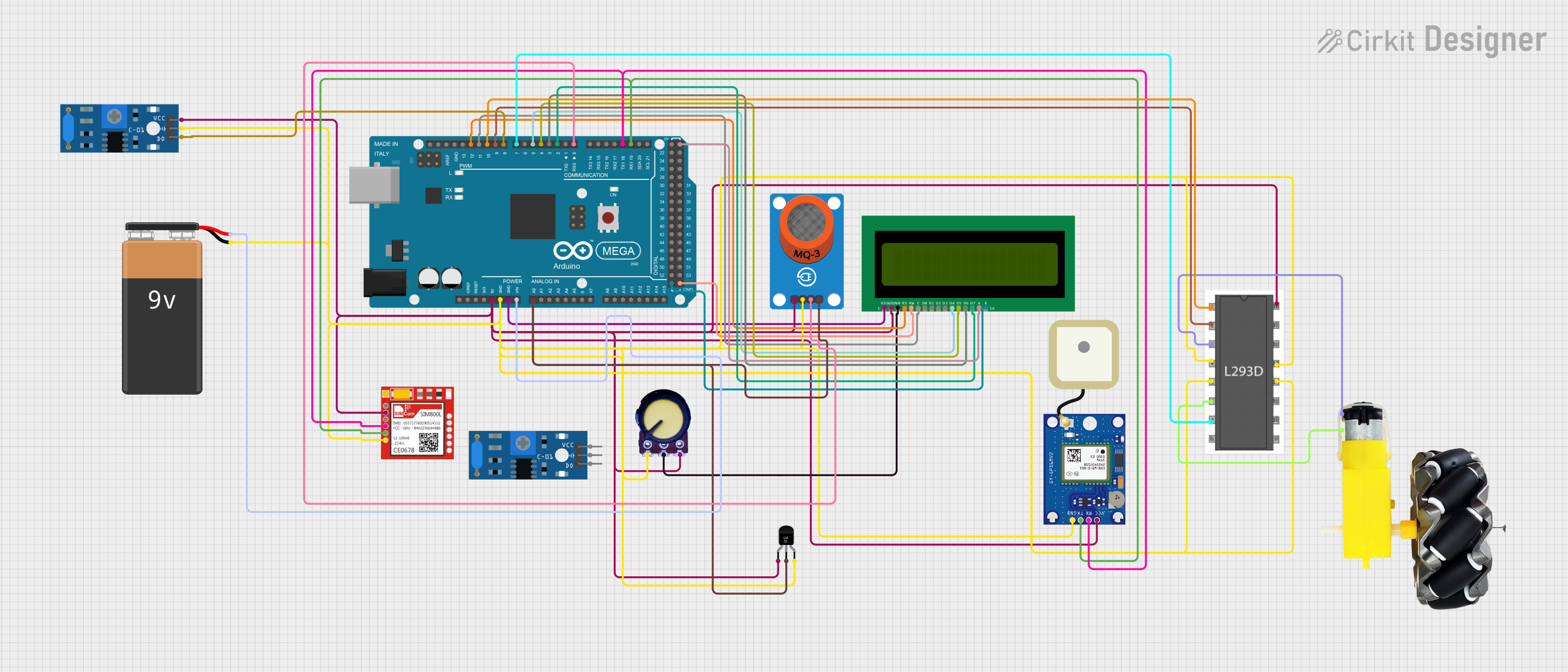

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with HBV 1716WA

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Hydraulic machinery for manufacturing and construction

- Automotive hydraulic systems (e.g., braking and steering systems)

- Industrial automation and robotics

- Agricultural equipment with hydraulic controls

- Fluid flow regulation in heavy-duty machinery

Technical Specifications

The HBV 1716WA is engineered to meet the needs of high-performance hydraulic systems. Below are its key technical details:

Key Technical Details

- Operating Pressure Range: 0 to 350 bar (0 to 5075 psi)

- Flow Rate: Up to 60 liters per minute (L/min)

- Temperature Range: -20°C to 80°C (-4°F to 176°F)

- Material: High-strength steel with corrosion-resistant coating

- Seal Type: Nitrile (NBR) or Fluorocarbon (FKM) options

- Port Size: G 3/8" (BSPP thread)

- Control Type: Manual lever or solenoid-actuated

- Weight: 1.2 kg (2.65 lbs)

Pin Configuration and Descriptions

For solenoid-actuated versions of the HBV 1716WA, the electrical connections are as follows:

| Pin Number | Description | Details |

|---|---|---|

| 1 | Solenoid Positive Terminal | Connect to the positive voltage supply (12V or 24V DC). |

| 2 | Solenoid Negative Terminal | Connect to ground or negative terminal of the power supply. |

| 3 | Optional Feedback Signal Pin | Provides a signal for valve position monitoring (if equipped). |

Usage Instructions

The HBV 1716WA can be integrated into hydraulic systems for precise fluid control. Follow the steps below to ensure proper installation and operation:

Installation

- Mounting: Secure the valve to a stable surface using the provided mounting holes. Ensure the valve is aligned with the hydraulic system's flow direction.

- Hydraulic Connections: Connect the inlet and outlet ports to the hydraulic lines using compatible fittings. Ensure all connections are tight to prevent leaks.

- Electrical Connections (for solenoid-actuated models):

- Connect the solenoid terminals to the appropriate power supply (12V or 24V DC).

- If the valve includes a feedback signal pin, connect it to the monitoring system.

Operation

- For manual models, use the lever to adjust the flow rate as needed.

- For solenoid-actuated models, apply the appropriate voltage to the solenoid terminals to open or close the valve.

Important Considerations and Best Practices

- Pressure Rating: Do not exceed the maximum operating pressure of 350 bar to avoid damage.

- Temperature Range: Ensure the operating environment is within the specified temperature range.

- Fluid Compatibility: Use only compatible hydraulic fluids to prevent seal degradation.

- Maintenance: Regularly inspect the valve for wear, leaks, or debris buildup. Replace seals as needed.

Arduino Integration (for Solenoid Models)

The HBV 1716WA solenoid-actuated valve can be controlled using an Arduino UNO. Below is an example code snippet to operate the valve:

// Example code to control the HBV 1716WA solenoid valve using Arduino UNO

const int solenoidPin = 9; // Pin connected to the solenoid positive terminal

void setup() {

pinMode(solenoidPin, OUTPUT); // Set the solenoid pin as an output

}

void loop() {

digitalWrite(solenoidPin, HIGH); // Open the valve

delay(5000); // Keep the valve open for 5 seconds

digitalWrite(solenoidPin, LOW); // Close the valve

delay(5000); // Keep the valve closed for 5 seconds

}

Note: Use a relay module or MOSFET driver circuit to handle the solenoid's current requirements, as the Arduino's GPIO pins cannot directly drive high-current loads.

Troubleshooting and FAQs

Common Issues and Solutions

Valve Not Operating (Solenoid Models):

- Cause: No power to the solenoid.

- Solution: Check the power supply and ensure proper electrical connections.

Fluid Leaks:

- Cause: Loose fittings or damaged seals.

- Solution: Tighten fittings and replace seals if necessary.

Erratic Flow Control:

- Cause: Debris in the valve or hydraulic fluid contamination.

- Solution: Clean the valve and replace the hydraulic fluid.

Overheating:

- Cause: Operating outside the specified temperature range.

- Solution: Ensure the system operates within the recommended temperature range.

FAQs

Q: Can the HBV 1716WA handle high-viscosity fluids?

A: Yes, but ensure the fluid's viscosity is within the manufacturer's recommended range.Q: Is the valve compatible with biodegradable hydraulic fluids?

A: Yes, as long as the fluid is compatible with the valve's seals (NBR or FKM).Q: Can I use the valve in a high-vibration environment?

A: Yes, the HBV 1716WA is designed for durability in demanding conditions, including high-vibration environments.Q: How often should I perform maintenance?

A: Inspect the valve every 6 months or as recommended by your hydraulic system's maintenance schedule.

This concludes the documentation for the HBV 1716WA. For further assistance, refer to the manufacturer's technical support.