Cirkit Designer

Your all-in-one circuit design IDE

Home /

Component Documentation

How to Use DC motor RC 7.4V: Examples, Pinouts, and Specs

Design with DC motor RC 7.4V in Cirkit Designer

Design with DC motor RC 7.4V in Cirkit DesignerIntroduction

The DC Motor RC 7.4V is a direct current motor designed for remote control applications, typically operating at 7.4 volts. Manufactured in China, this motor is widely used in various RC (remote control) vehicles, including cars, boats, and drones. Its robust design and reliable performance make it a popular choice for hobbyists and professionals alike.

Explore Projects Built with DC motor RC 7.4V

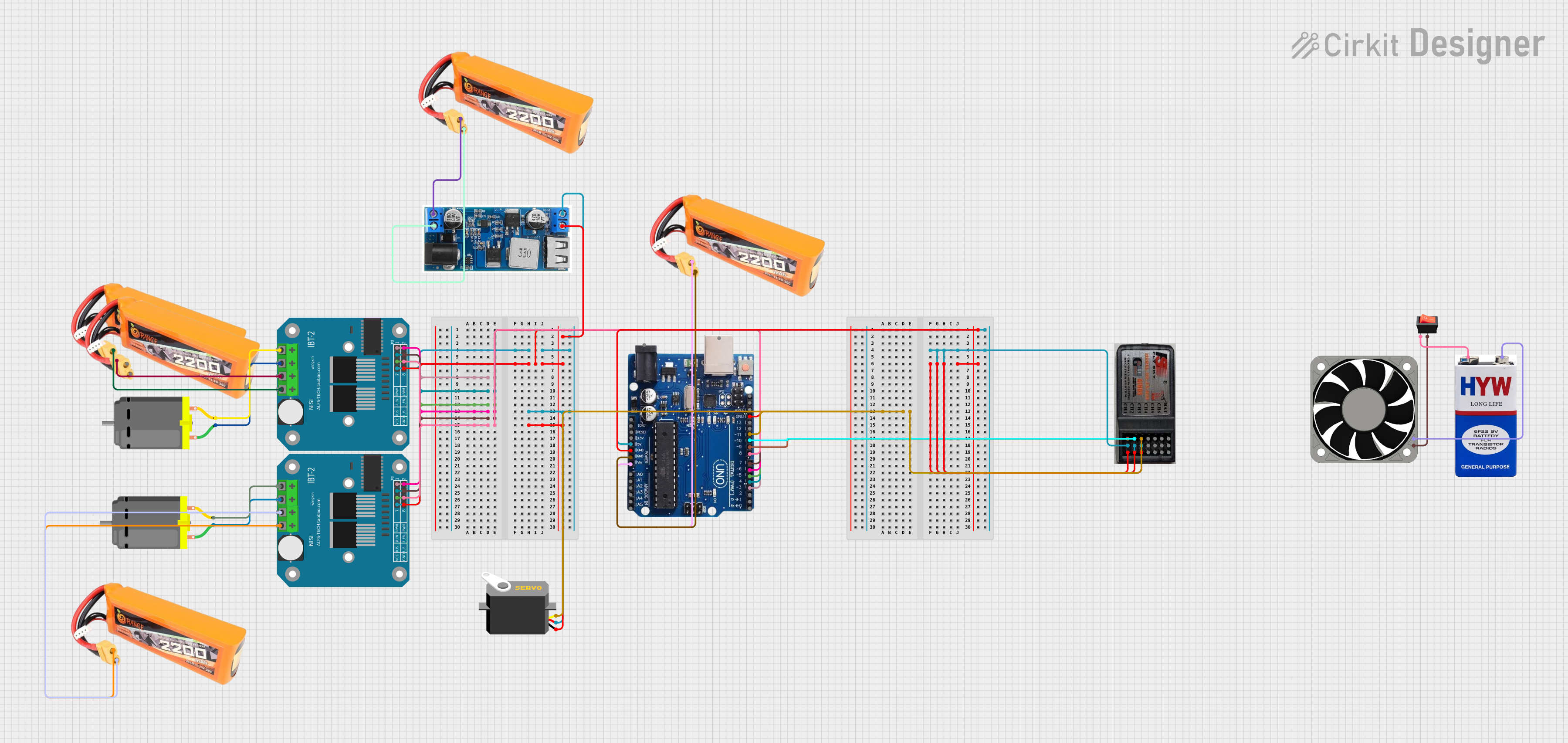

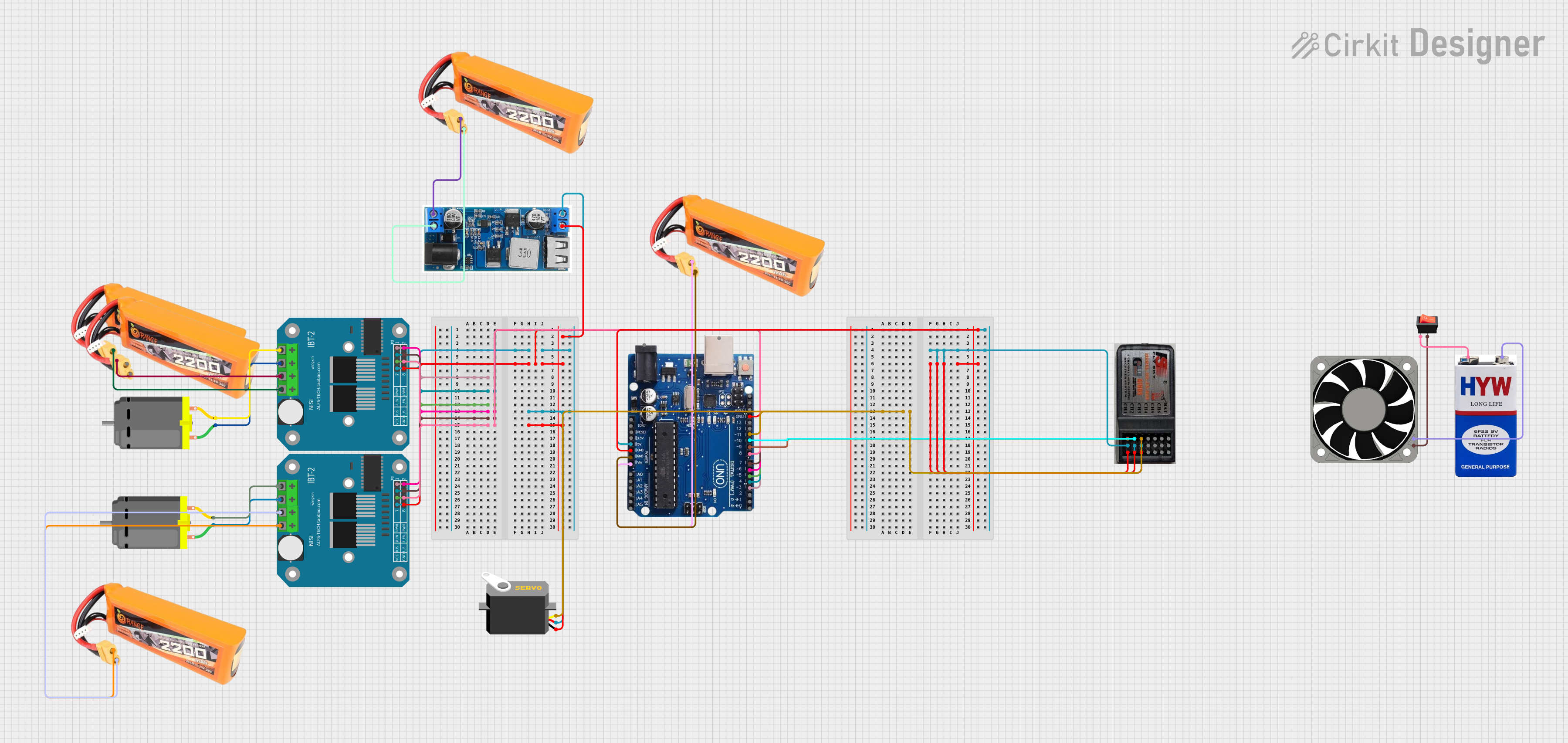

Arduino-Controlled Dual Motor Driver with RC Servo and Power Management

This is a remote-controlled vehicle circuit with an Arduino Uno R3 microcontroller interfacing with an RC receiver to drive two DC motors via BTS7960 motor drivers and control a servo motor. It includes a 12V cooling fan operated by a rocker switch and multiple LiPo batteries for power, with a buck converter for voltage regulation.

Open Project in Cirkit Designer

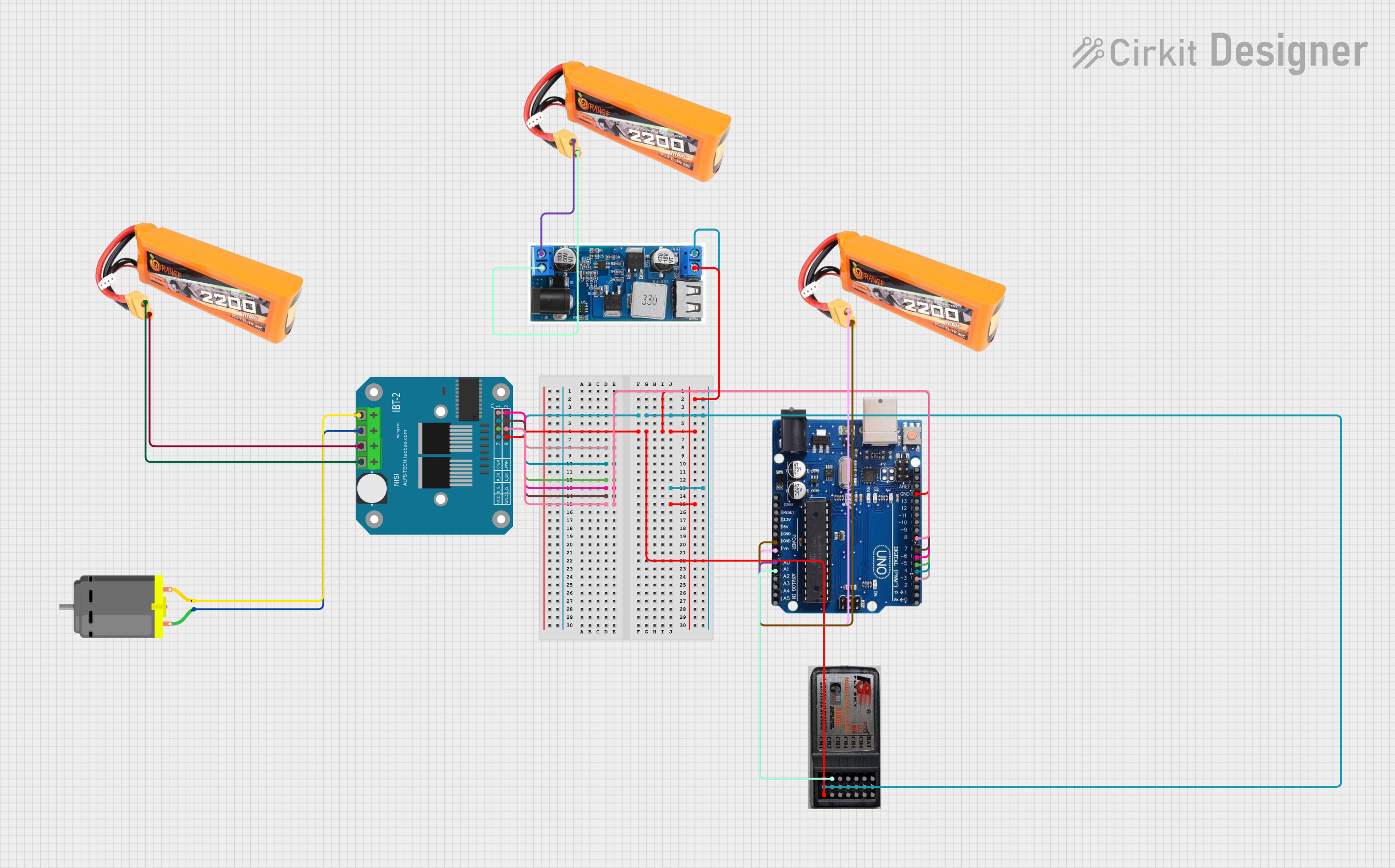

Open Project in Cirkit DesignerBattery-Powered Remote-Controlled Dual Motor System with Cytron URC10

This circuit is a remote-controlled dual DC motor driver system powered by a 3S LiPo battery. It uses a Cytron URC10 motor driver to control two GM25 DC motors based on signals received from an R6FG receiver, with a rocker switch for power control and a 7-segment panel voltmeter for monitoring the battery voltage.

Open Project in Cirkit Designer

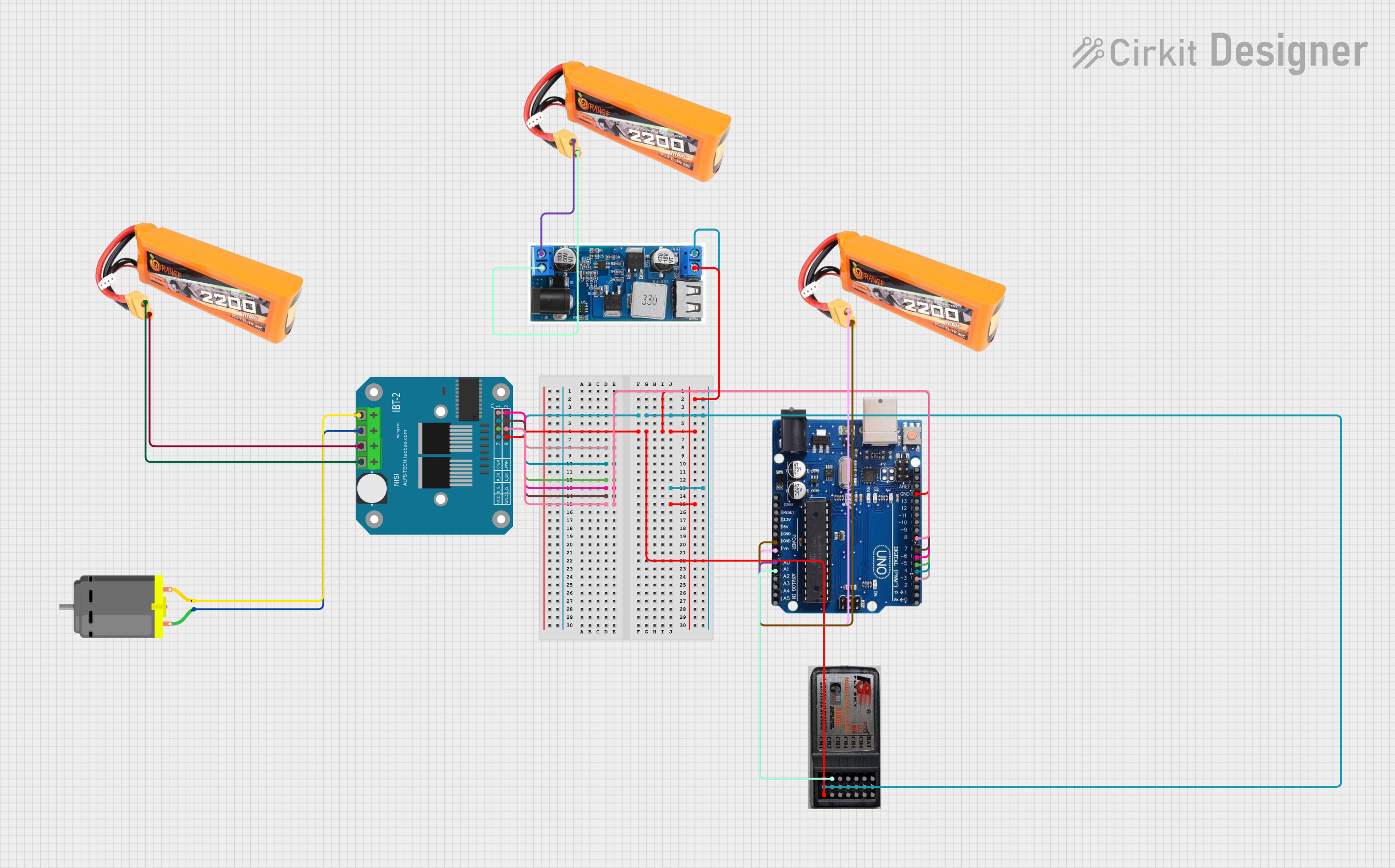

Open Project in Cirkit DesignerArduino-Based RC Controlled DC Motor System with Battery Power

This circuit is designed to control a DC motor using an Arduino Uno, an RC receiver, and a BTS7960 motor driver. The Arduino receives signals from the RC receiver and sends control signals to the motor driver, which in turn drives the DC motor. Power is supplied by multiple LiPo batteries, with a buck converter providing regulated voltage to the RC receiver and other components.

Open Project in Cirkit Designer

Open Project in Cirkit DesignerBattery-Powered DC Motor Control with LED Indicator

This circuit consists of a DC motor powered by a 12V battery, with a diode for protection against reverse voltage and an LED indicator. The LED is connected in parallel with the motor to indicate when the motor is powered.

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with DC motor RC 7.4V

Arduino-Controlled Dual Motor Driver with RC Servo and Power Management

This is a remote-controlled vehicle circuit with an Arduino Uno R3 microcontroller interfacing with an RC receiver to drive two DC motors via BTS7960 motor drivers and control a servo motor. It includes a 12V cooling fan operated by a rocker switch and multiple LiPo batteries for power, with a buck converter for voltage regulation.

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Battery-Powered Remote-Controlled Dual Motor System with Cytron URC10

This circuit is a remote-controlled dual DC motor driver system powered by a 3S LiPo battery. It uses a Cytron URC10 motor driver to control two GM25 DC motors based on signals received from an R6FG receiver, with a rocker switch for power control and a 7-segment panel voltmeter for monitoring the battery voltage.

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Arduino-Based RC Controlled DC Motor System with Battery Power

This circuit is designed to control a DC motor using an Arduino Uno, an RC receiver, and a BTS7960 motor driver. The Arduino receives signals from the RC receiver and sends control signals to the motor driver, which in turn drives the DC motor. Power is supplied by multiple LiPo batteries, with a buck converter providing regulated voltage to the RC receiver and other components.

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Battery-Powered DC Motor Control with LED Indicator

This circuit consists of a DC motor powered by a 12V battery, with a diode for protection against reverse voltage and an LED indicator. The LED is connected in parallel with the motor to indicate when the motor is powered.

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

| Specification | Value |

|---|---|

| Operating Voltage | 7.4V |

| No-load Current | 0.5A |

| Stall Current | 5A |

| No-load Speed | 12000 RPM |

| Stall Torque | 1.2 kg.cm |

| Shaft Diameter | 3.17 mm |

| Motor Dimensions | 36mm x 50mm |

| Weight | 100g |

Pin Configuration and Descriptions

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | V+ | Positive terminal for power supply |

| 2 | V- | Negative terminal for power supply |

Usage Instructions

How to Use the Component in a Circuit

To use the DC Motor RC 7.4V in a circuit, follow these steps:

- Power Supply: Connect the V+ pin to the positive terminal of a 7.4V power supply and the V- pin to the negative terminal.

- Motor Driver: Use a motor driver (e.g., L298N) to control the motor's speed and direction. Connect the motor driver to a microcontroller (e.g., Arduino UNO) for precise control.

- Connections: Ensure all connections are secure and insulated to prevent short circuits.

Important Considerations and Best Practices

- Current Rating: Ensure the power supply can provide sufficient current, especially during stall conditions.

- Heat Dissipation: The motor may heat up during operation. Ensure proper ventilation or use a heat sink if necessary.

- Polarity: Double-check the polarity of the connections to avoid damaging the motor.

- PWM Control: Use Pulse Width Modulation (PWM) for speed control to achieve smooth and efficient operation.

Example Code for Arduino UNO

Below is an example code to control the DC Motor RC 7.4V using an Arduino UNO and an L298N motor driver:

// Define motor control pins

const int enA = 9; // PWM pin for speed control

const int in1 = 8; // Control pin 1

const int in2 = 7; // Control pin 2

void setup() {

// Set all the motor control pins to output

pinMode(enA, OUTPUT);

pinMode(in1, OUTPUT);

pinMode(in2, OUTPUT);

// Initialize motor to stop

digitalWrite(in1, LOW);

digitalWrite(in2, LOW);

analogWrite(enA, 0);

}

void loop() {

// Set motor direction to forward

digitalWrite(in1, HIGH);

digitalWrite(in2, LOW);

// Set motor speed to 50% (128 out of 255)

analogWrite(enA, 128);

// Run motor for 5 seconds

delay(5000);

// Stop the motor

digitalWrite(in1, LOW);

digitalWrite(in2, LOW);

analogWrite(enA, 0);

// Wait for 2 seconds

delay(2000);

// Set motor direction to reverse

digitalWrite(in1, LOW);

digitalWrite(in2, HIGH);

// Set motor speed to 50% (128 out of 255)

analogWrite(enA, 128);

// Run motor for 5 seconds

delay(5000);

// Stop the motor

digitalWrite(in1, LOW);

digitalWrite(in2, LOW);

analogWrite(enA, 0);

// Wait for 2 seconds

delay(2000);

}

Troubleshooting and FAQs

Common Issues Users Might Face

Motor Not Spinning:

- Solution: Check the power supply connections and ensure the voltage is 7.4V. Verify that the motor driver is functioning correctly and that the control signals from the microcontroller are being sent properly.

Motor Overheating:

- Solution: Ensure proper ventilation and consider using a heat sink. Check for any obstructions in the motor's movement and reduce the load if necessary.

Inconsistent Speed:

- Solution: Use PWM for speed control and ensure the power supply is stable. Check for any loose connections or damaged wires.

Solutions and Tips for Troubleshooting

- Check Connections: Ensure all connections are secure and correctly oriented.

- Use Proper Tools: Use a multimeter to check voltage and current levels.

- Consult Datasheets: Refer to the motor and motor driver datasheets for detailed information and specifications.

- Test Components Individually: Isolate and test each component (motor, driver, microcontroller) to identify the source of the issue.

By following this documentation, users can effectively utilize the DC Motor RC 7.4V in their projects, ensuring reliable performance and longevity.