How to Use L293D: Examples, Pinouts, and Specs

Design with L293D in Cirkit Designer

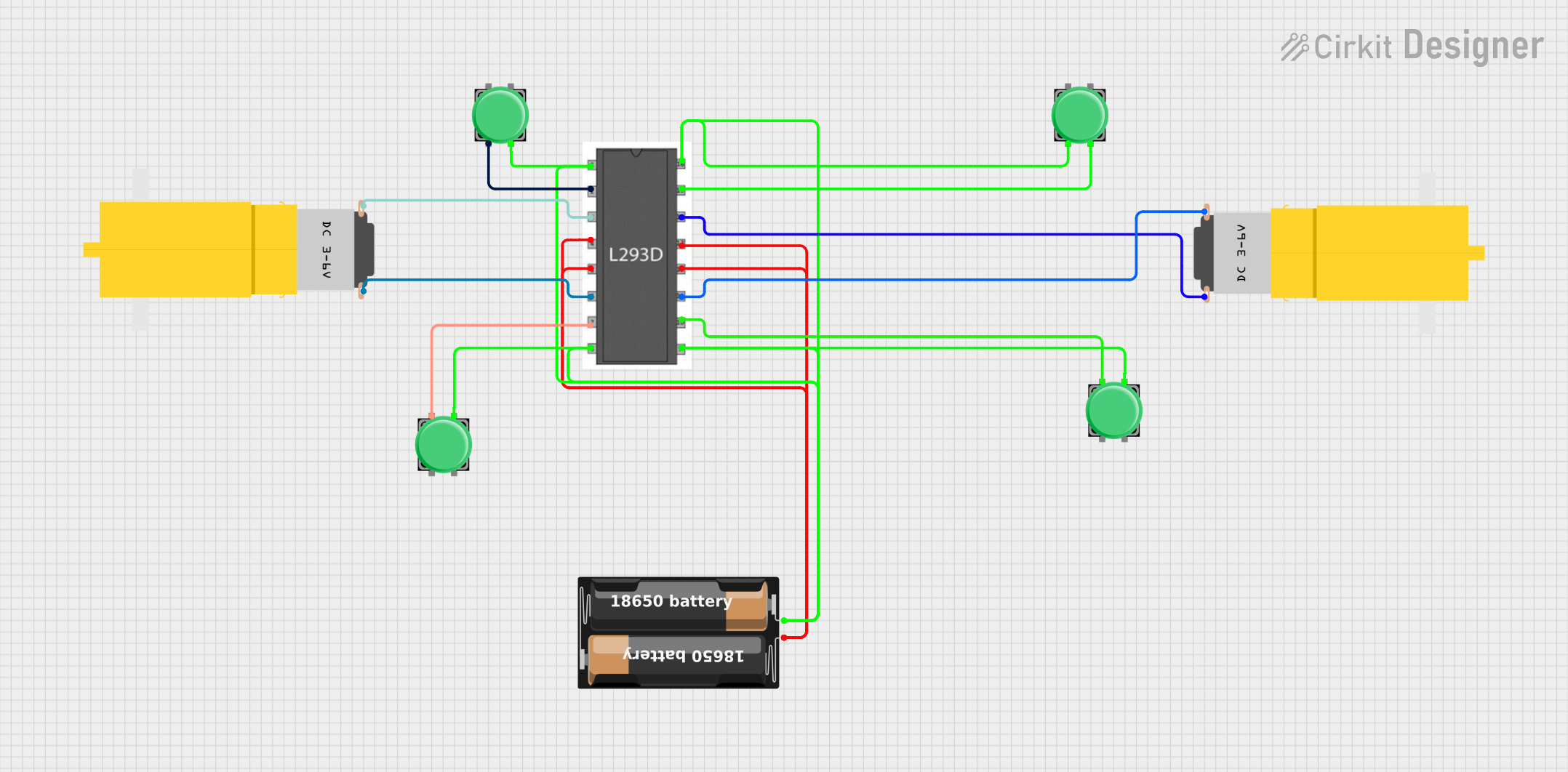

Design with L293D in Cirkit DesignerIntroduction

The L293D is a quadruple high-current half-H driver designed to control the direction and speed of DC motors and stepper motors. It is a versatile motor driver IC that can drive two motors simultaneously, making it ideal for robotics and automation projects. The L293D can handle up to 600 mA of continuous current per channel, with a peak current of 1.2 A. Additionally, it features built-in diodes for back EMF protection, ensuring safe operation when driving inductive loads like motors.

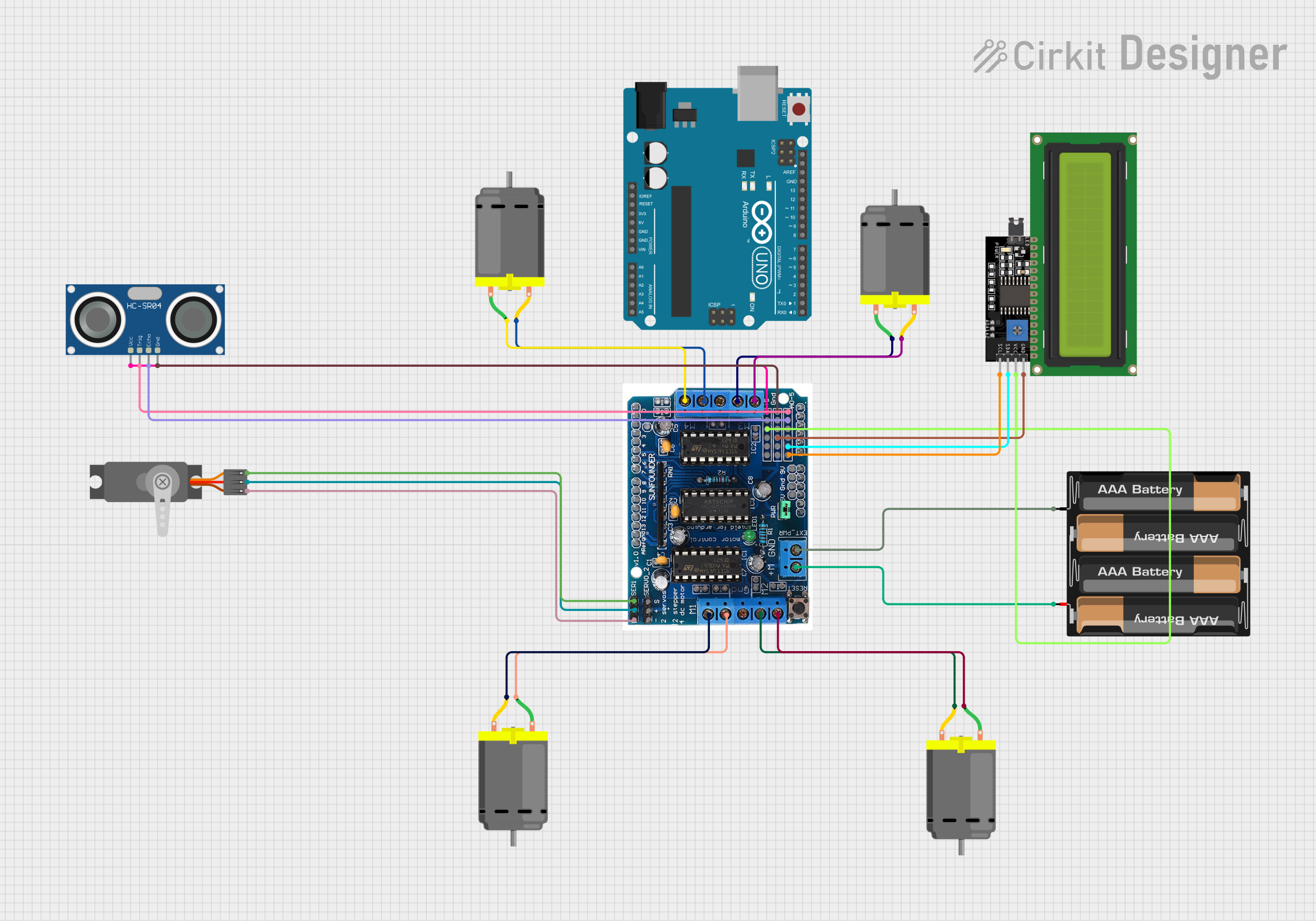

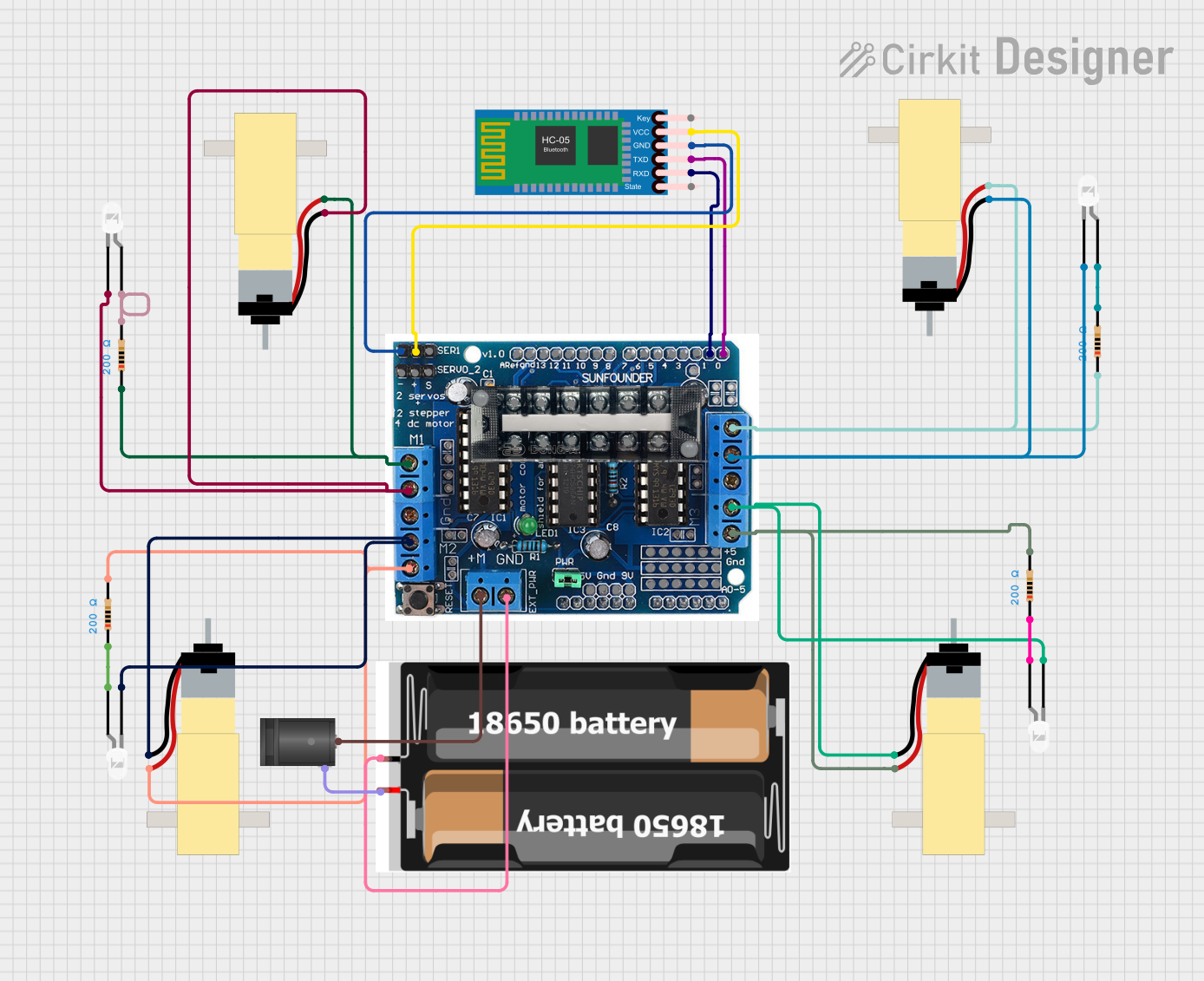

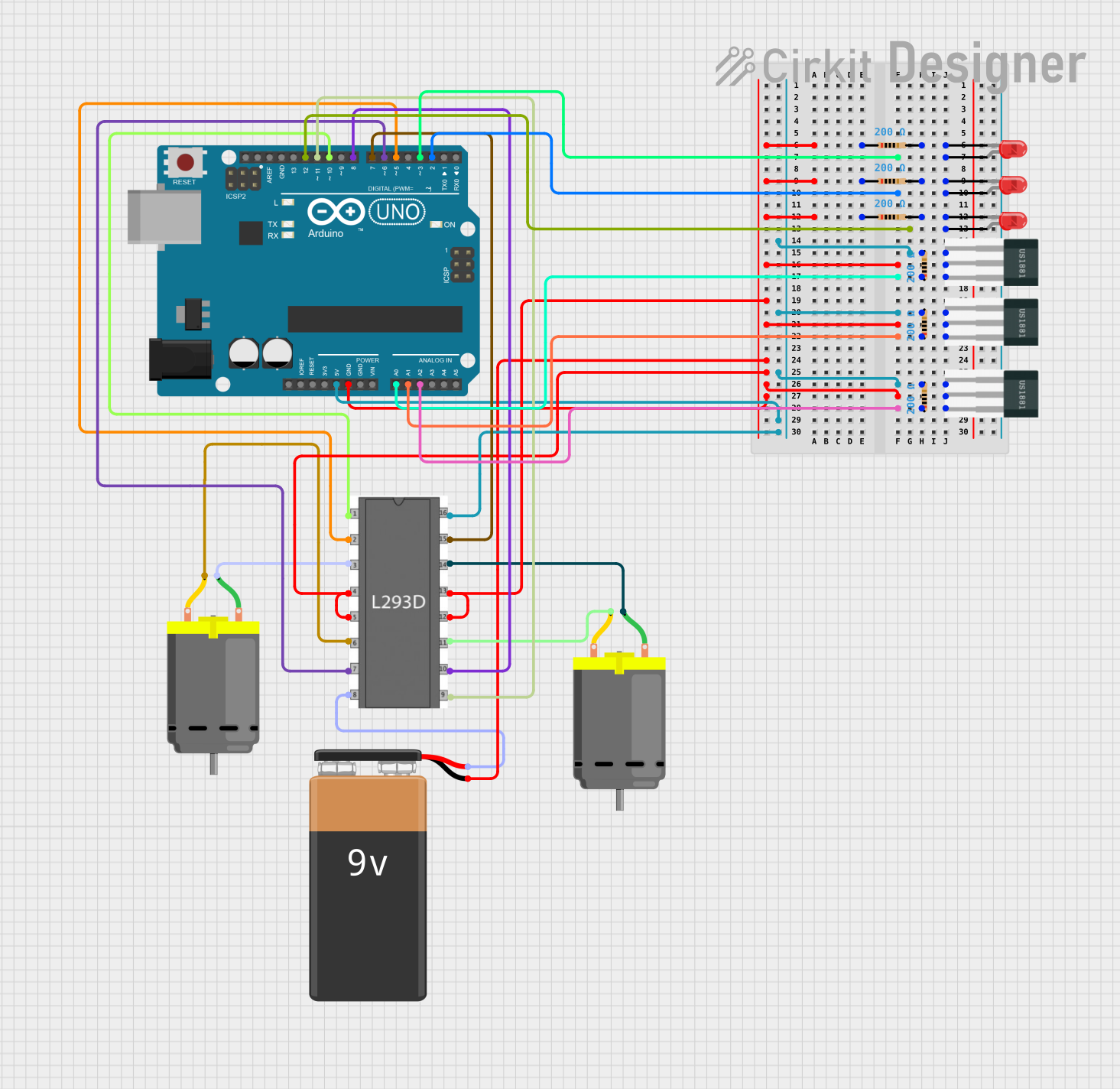

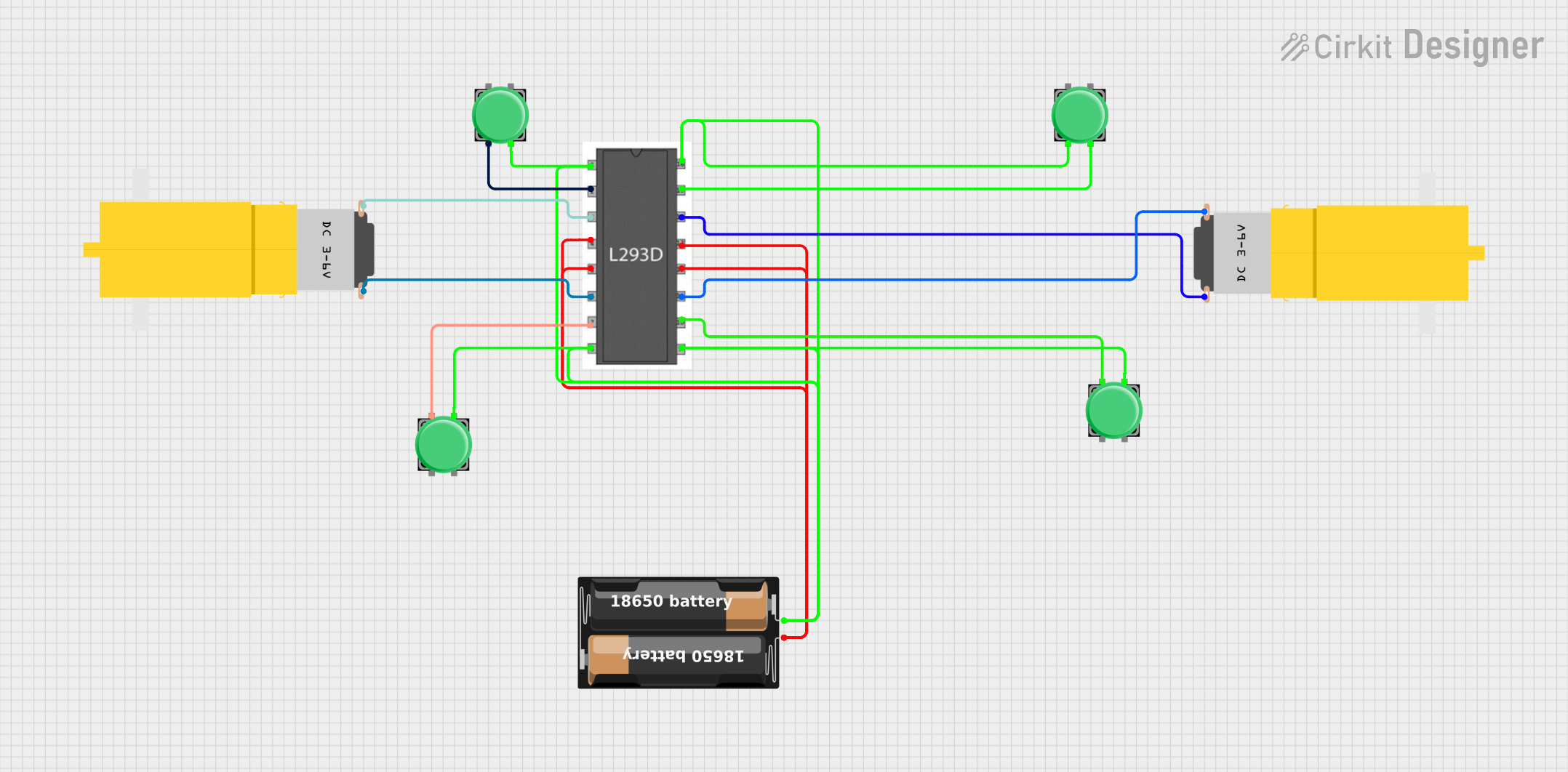

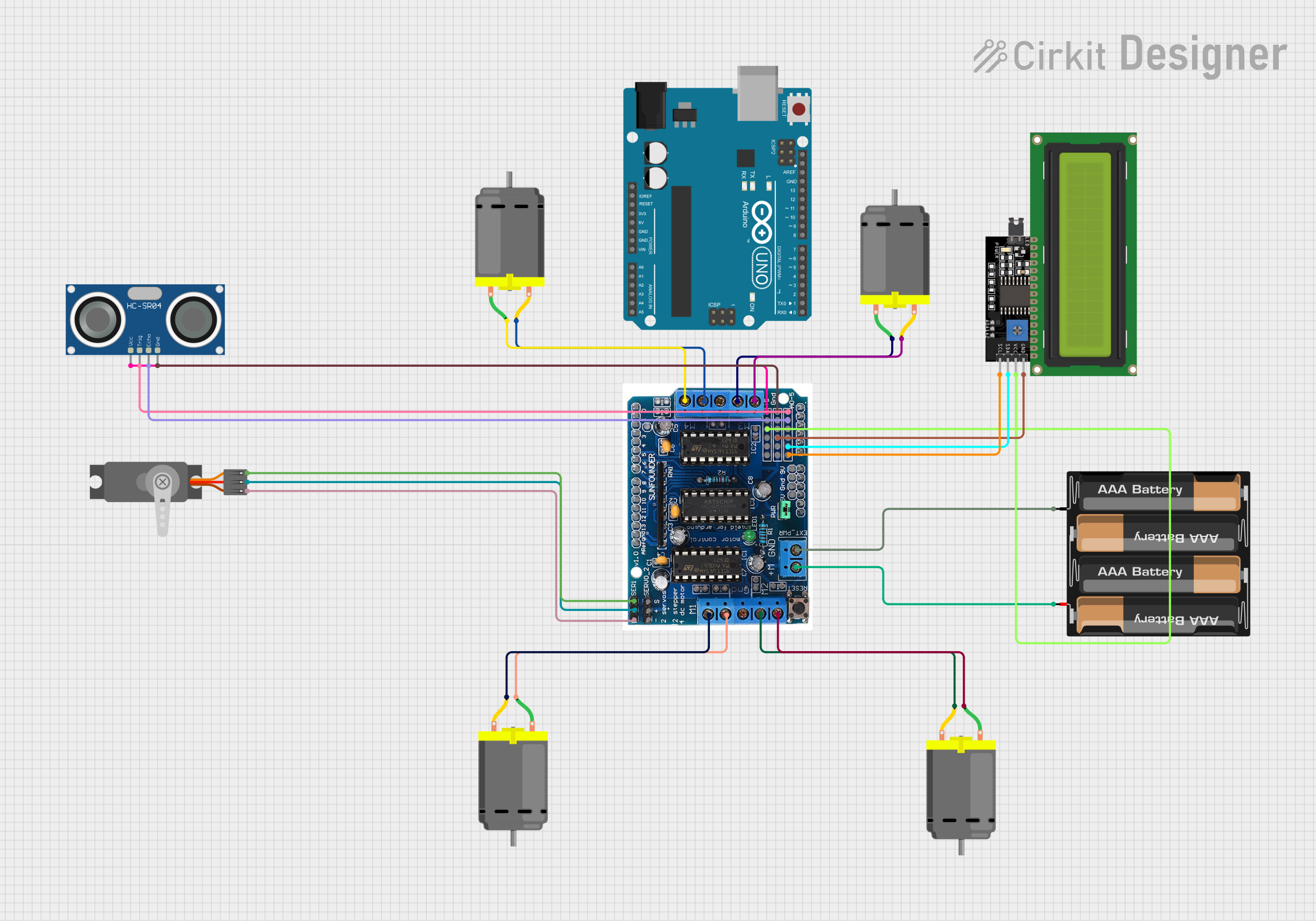

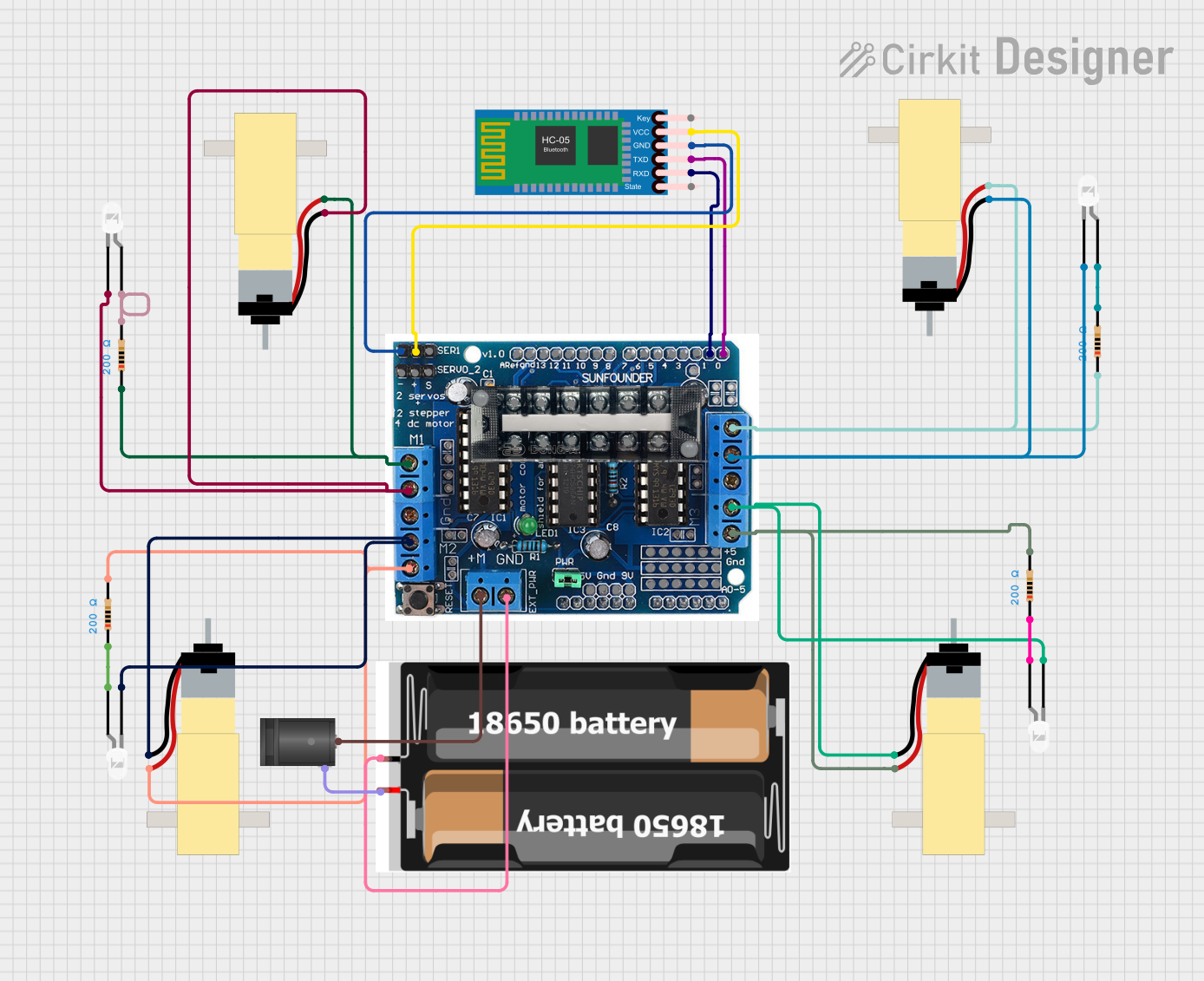

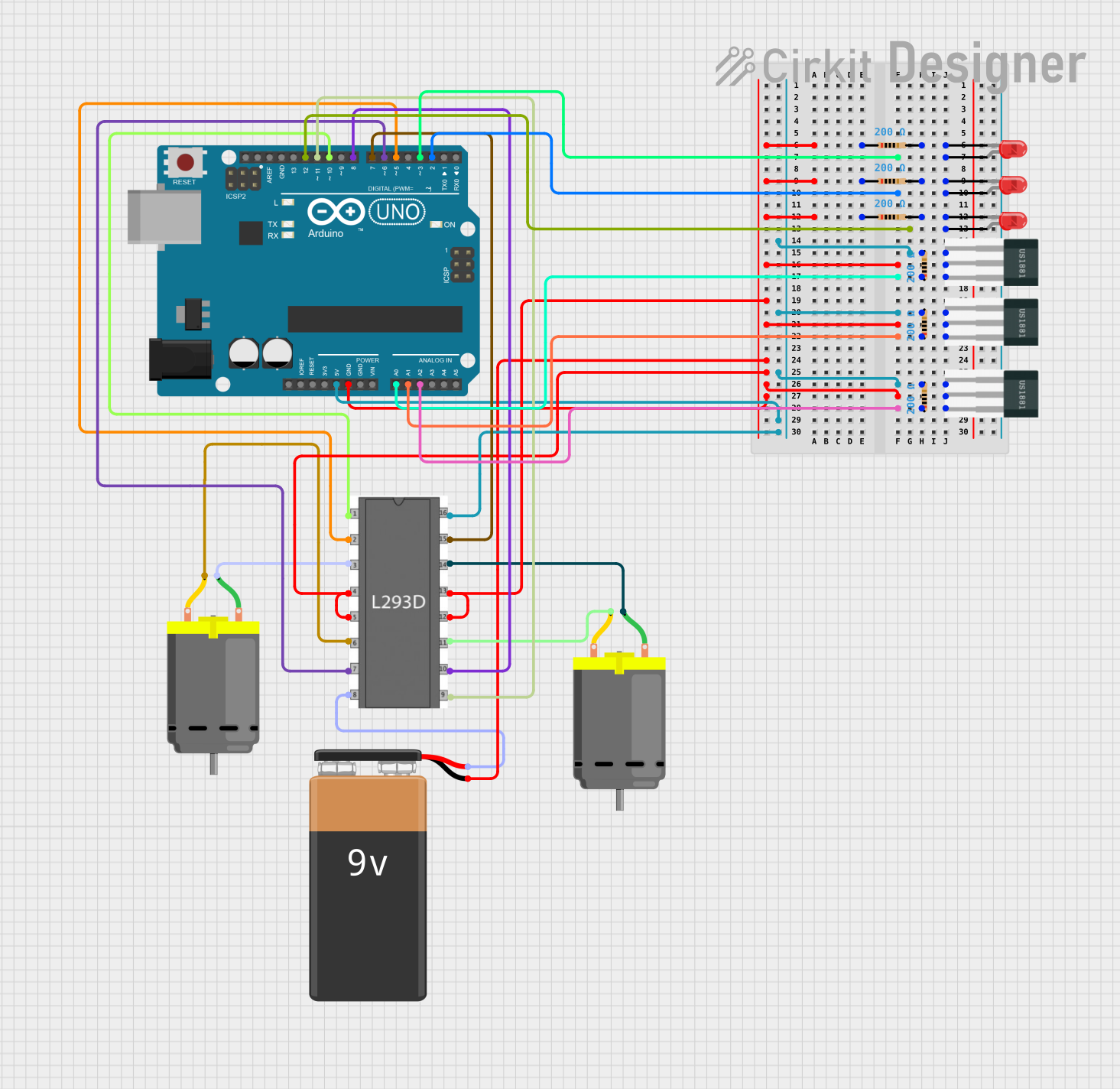

Explore Projects Built with L293D

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with L293D

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Robotics: Controlling DC motors for wheels or arms

- Automation: Driving stepper motors in CNC machines or 3D printers

- DIY Projects: Motorized toys, conveyor belts, and small vehicles

- Educational Projects: Learning motor control with microcontrollers like Arduino or Raspberry Pi

Technical Specifications

Key Technical Details

- Operating Voltage: 4.5 V to 36 V

- Output Current: 600 mA per channel (continuous), 1.2 A (peak)

- Logic Input Voltage: 0 V to 7 V

- Enable Input Voltage: High (2.3 V to 7 V), Low (0 V to 1.5 V)

- Power Dissipation: 5 W (maximum)

- Built-in Protection: Back EMF diodes for inductive loads

- Temperature Range: 0°C to 70°C

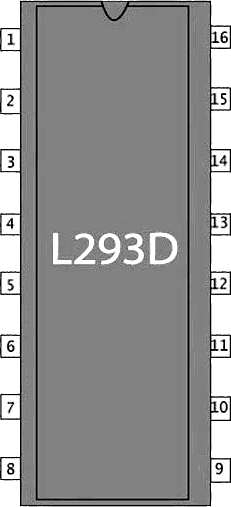

Pin Configuration and Descriptions

The L293D is a 16-pin IC. Below is the pin configuration:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | Enable 1,2 | Enables and disables the first motor (High = Enabled, Low = Disabled) |

| 2 | Input 1 | Logic input to control the direction of Motor 1 |

| 3 | Output 1 | Output connected to one terminal of Motor 1 |

| 4 | GND | Ground (common ground for logic and motor power supply) |

| 5 | GND | Ground (common ground for logic and motor power supply) |

| 6 | Output 2 | Output connected to the other terminal of Motor 1 |

| 7 | Input 2 | Logic input to control the direction of Motor 1 |

| 8 | Vcc2 (Motor) | Motor power supply (4.5 V to 36 V) |

| 9 | Enable 3,4 | Enables and disables the second motor (High = Enabled, Low = Disabled) |

| 10 | Input 3 | Logic input to control the direction of Motor 2 |

| 11 | Output 3 | Output connected to one terminal of Motor 2 |

| 12 | GND | Ground (common ground for logic and motor power supply) |

| 13 | GND | Ground (common ground for logic and motor power supply) |

| 14 | Output 4 | Output connected to the other terminal of Motor 2 |

| 15 | Input 4 | Logic input to control the direction of Motor 2 |

| 16 | Vcc1 (Logic) | Logic power supply (5 V) |

Usage Instructions

How to Use the L293D in a Circuit

- Power Supply: Connect the motor power supply to

Vcc2(Pin 8) and the logic power supply toVcc1(Pin 16). Ensure that the ground pins (Pins 4, 5, 12, and 13) are connected to the common ground. - Motor Connections: Connect the motor terminals to the output pins (

Output 1andOutput 2for Motor 1,Output 3andOutput 4for Motor 2). - Control Inputs: Use the input pins (

Input 1,Input 2,Input 3, andInput 4) to control the direction of the motors. A HIGH signal on one input and a LOW signal on the other will determine the motor's rotation direction. - Enable Pins: Set the enable pins (

Enable 1,2andEnable 3,4) HIGH to activate the corresponding motor channels.

Important Considerations and Best Practices

- Heat Dissipation: The L293D can get hot during operation. Use a heat sink if driving motors at high currents for extended periods.

- Back EMF Protection: The built-in diodes protect against back EMF, but ensure proper wiring to avoid damage.

- Power Supply: Use separate power supplies for the logic and motor circuits if the motor's power requirements exceed the logic circuit's capacity.

- Decoupling Capacitors: Add decoupling capacitors near the power supply pins to reduce noise and improve stability.

Example: Using L293D with Arduino UNO

Below is an example of controlling a DC motor using the L293D and Arduino UNO:

// Define motor control pins

const int enablePin = 9; // Enable pin for Motor 1

const int input1 = 2; // Input 1 for Motor 1

const int input2 = 3; // Input 2 for Motor 1

void setup() {

// Set motor control pins as outputs

pinMode(enablePin, OUTPUT);

pinMode(input1, OUTPUT);

pinMode(input2, OUTPUT);

// Initialize motor in stopped state

digitalWrite(enablePin, LOW); // Disable motor

digitalWrite(input1, LOW); // Set Input 1 to LOW

digitalWrite(input2, LOW); // Set Input 2 to LOW

}

void loop() {

// Rotate motor clockwise

digitalWrite(enablePin, HIGH); // Enable motor

digitalWrite(input1, HIGH); // Set Input 1 to HIGH

digitalWrite(input2, LOW); // Set Input 2 to LOW

delay(2000); // Run motor for 2 seconds

// Stop motor

digitalWrite(enablePin, LOW); // Disable motor

delay(1000); // Wait for 1 second

// Rotate motor counterclockwise

digitalWrite(enablePin, HIGH); // Enable motor

digitalWrite(input1, LOW); // Set Input 1 to LOW

digitalWrite(input2, HIGH); // Set Input 2 to HIGH

delay(2000); // Run motor for 2 seconds

// Stop motor

digitalWrite(enablePin, LOW); // Disable motor

delay(1000); // Wait for 1 second

}

Troubleshooting and FAQs

Common Issues and Solutions

Motor Not Running:

- Ensure the enable pin is set HIGH.

- Verify the power supply connections to

Vcc1andVcc2. - Check the input pin logic levels.

Motor Running in the Wrong Direction:

- Swap the HIGH and LOW signals on the input pins for the motor.

Overheating:

- Reduce the motor load or add a heat sink to the L293D.

- Ensure the motor's current does not exceed the IC's maximum ratings.

Noisy Operation:

- Add decoupling capacitors near the power supply pins.

- Check for loose connections in the circuit.

FAQs

Q: Can the L293D drive stepper motors?

A: Yes, the L293D can drive stepper motors by controlling the sequence of inputs to the motor coils.

Q: Can I use the L293D with a 3.3 V microcontroller?

A: The L293D requires a minimum logic voltage of 4.5 V. Use a level shifter or a 5 V microcontroller for compatibility.

Q: How many motors can the L293D control?

A: The L293D can control up to two DC motors or one stepper motor.

Q: Do I need external diodes for back EMF protection?

A: No, the L293D has built-in diodes for back EMF protection.