How to Use TB6612FNG Motor Driver: Examples, Pinouts, and Specs

Design with TB6612FNG Motor Driver in Cirkit Designer

Design with TB6612FNG Motor Driver in Cirkit DesignerIntroduction

The TB6612FNG is a dual H-bridge motor driver IC designed to control two DC motors or one stepper motor. It supports PWM (Pulse Width Modulation) for precise speed control and direction management. With built-in thermal shutdown protection, overcurrent protection, and low standby current, the TB6612FNG is a reliable choice for robotics, automation, and other motor control applications.

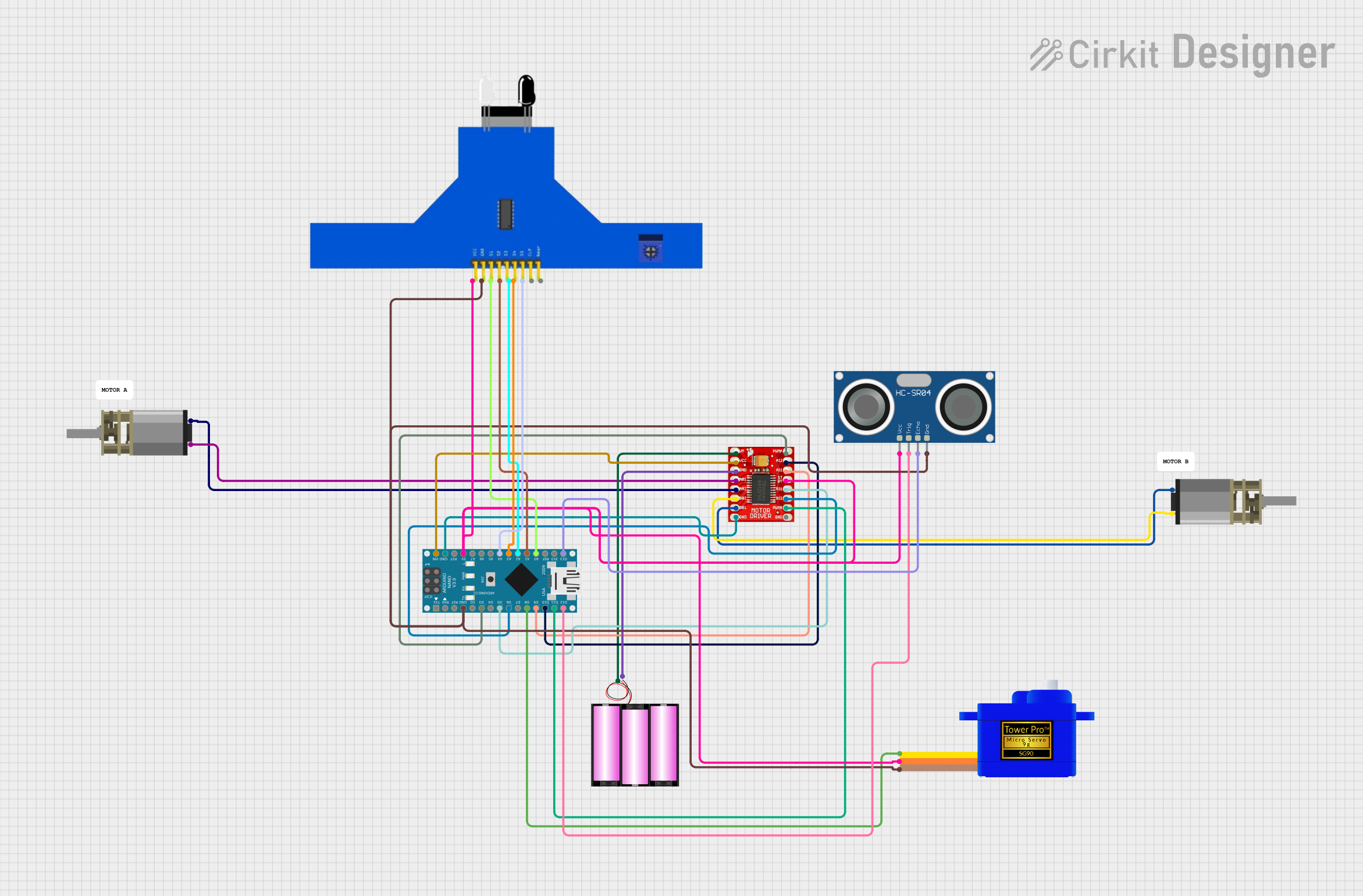

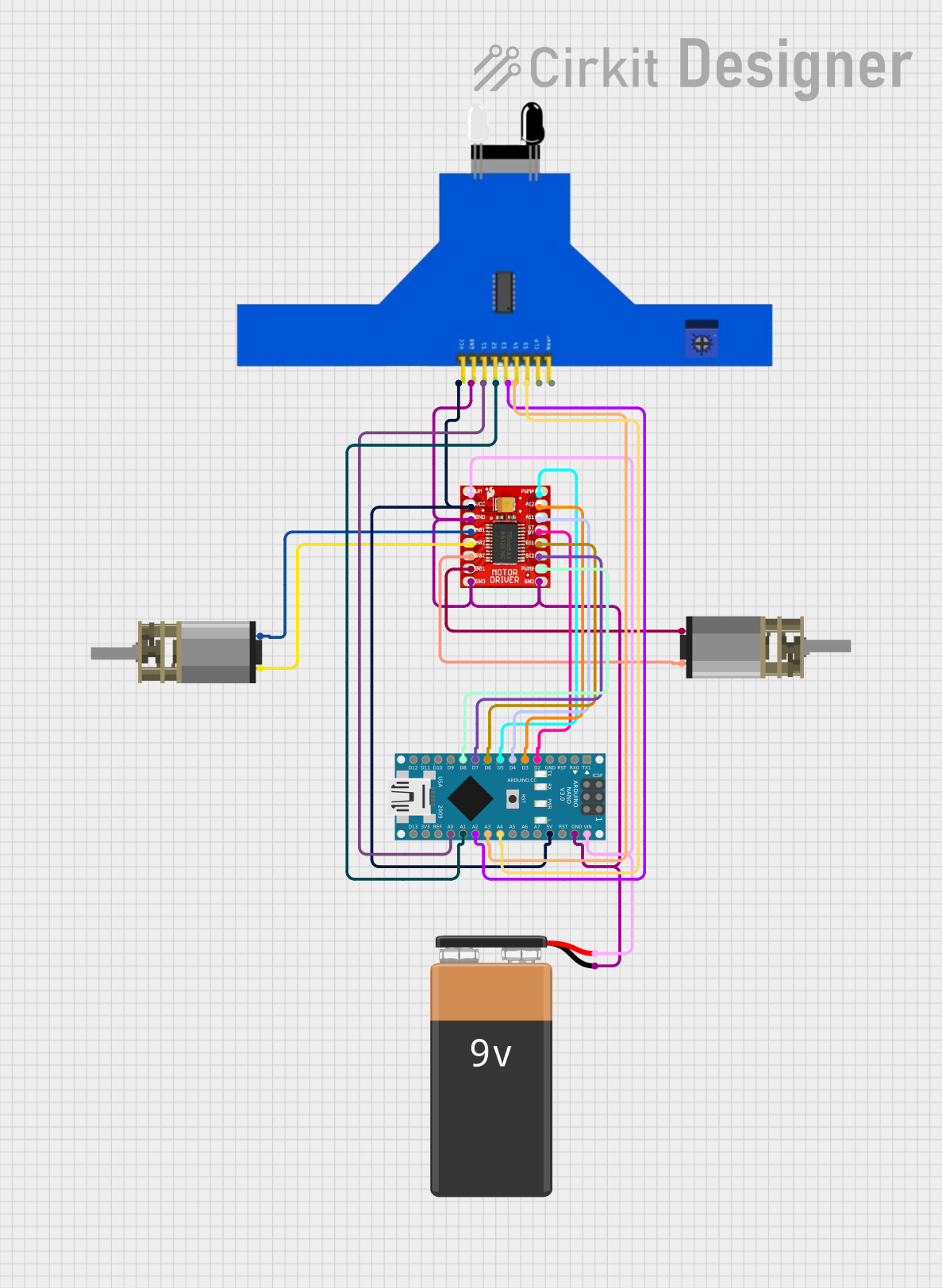

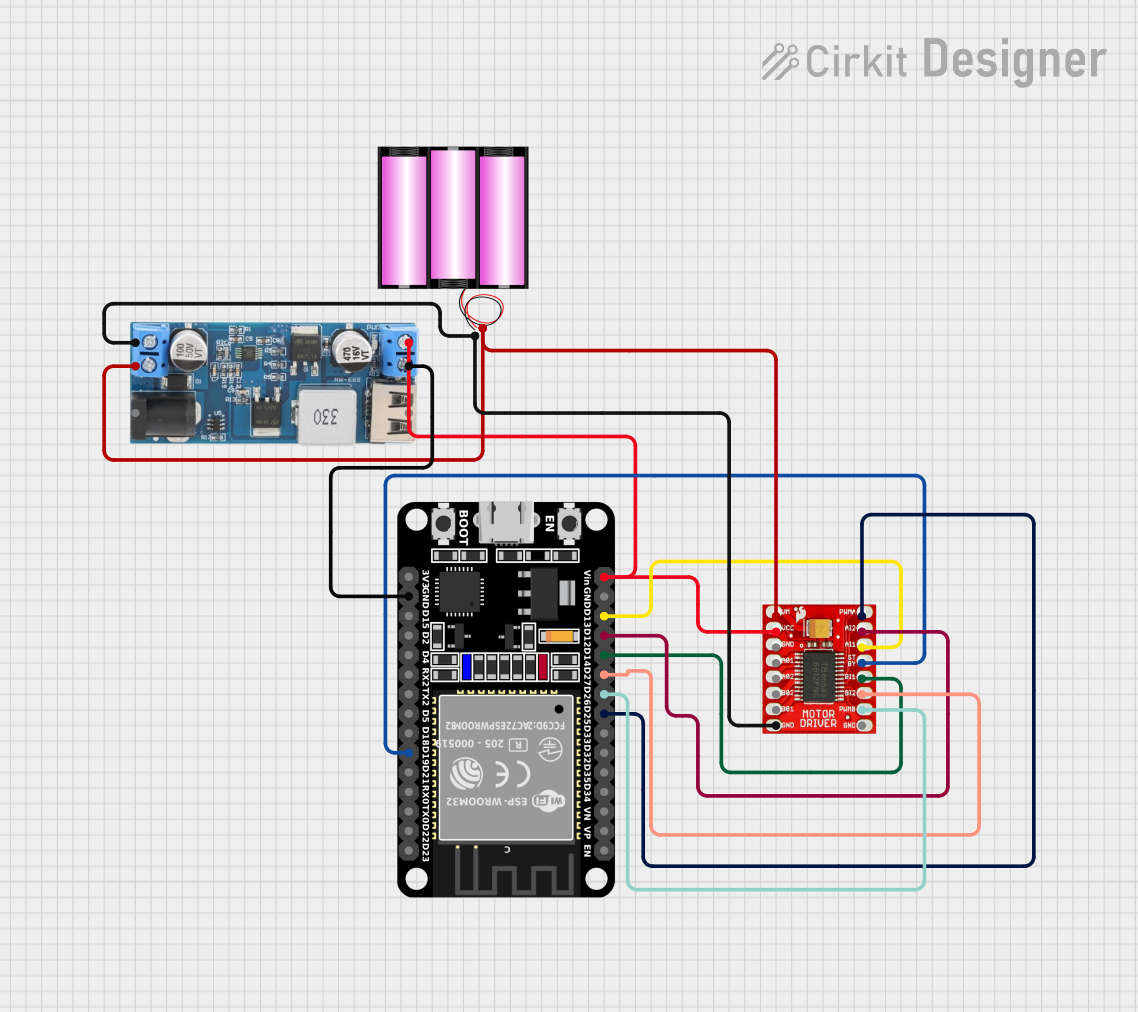

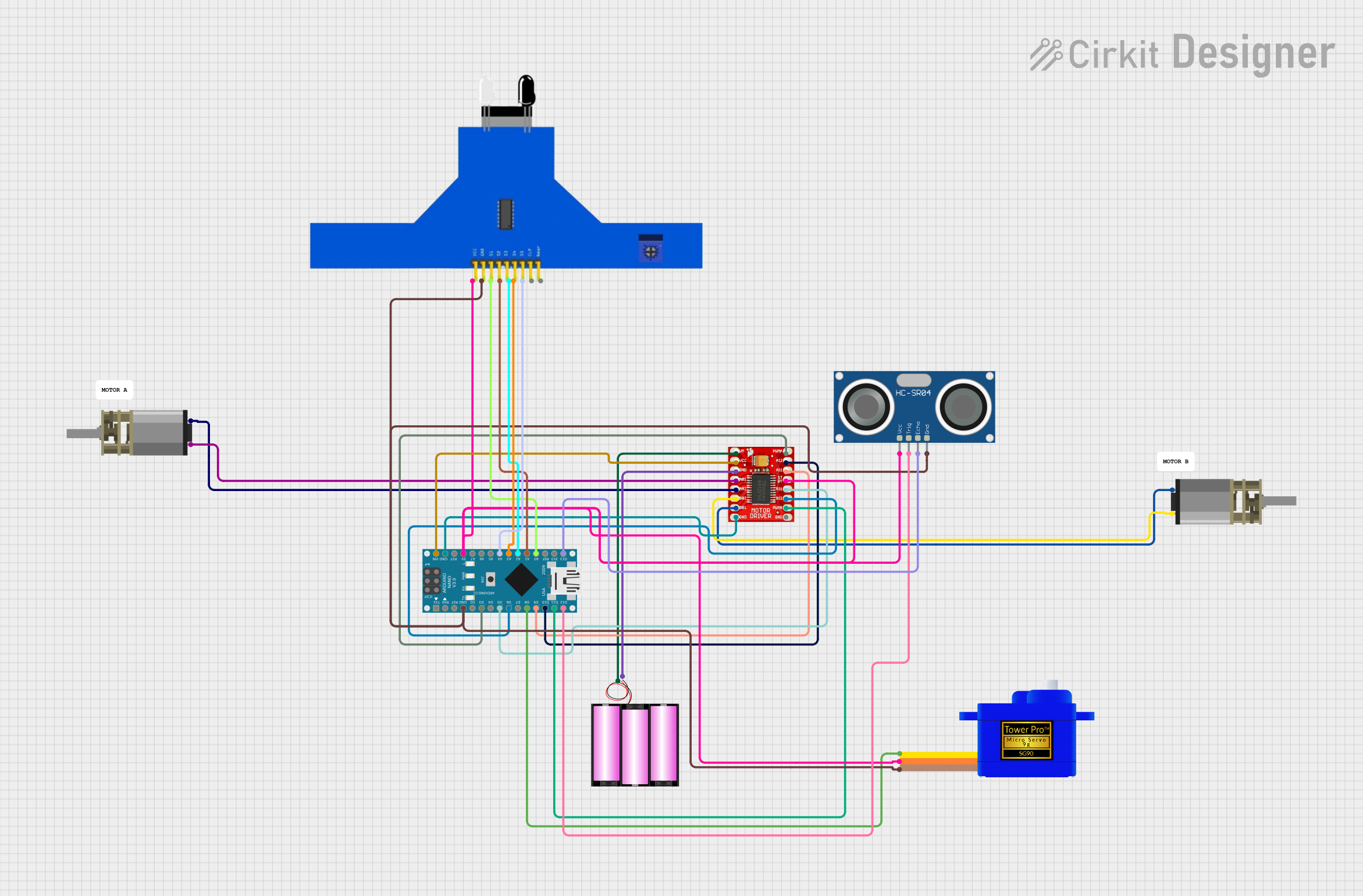

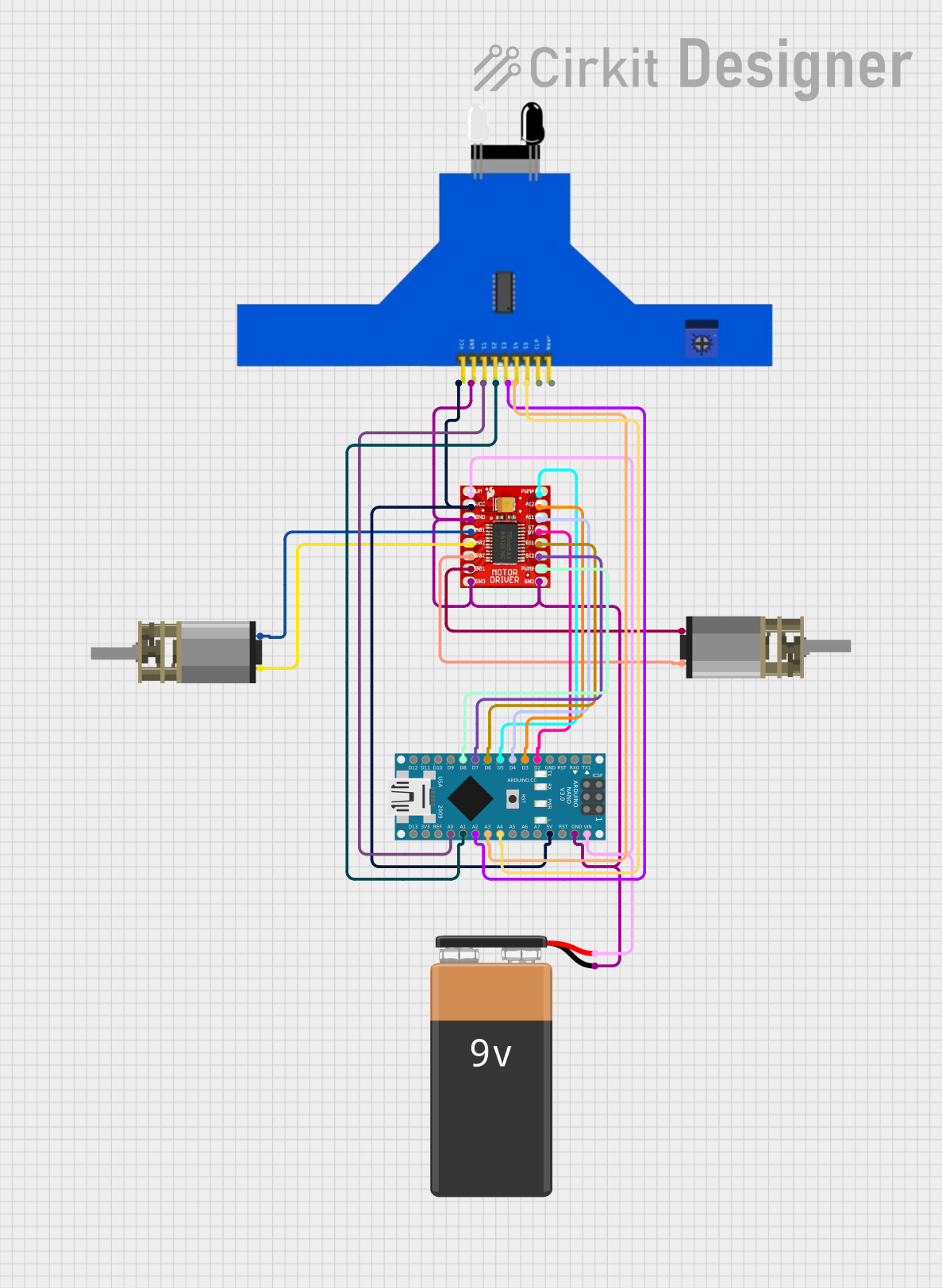

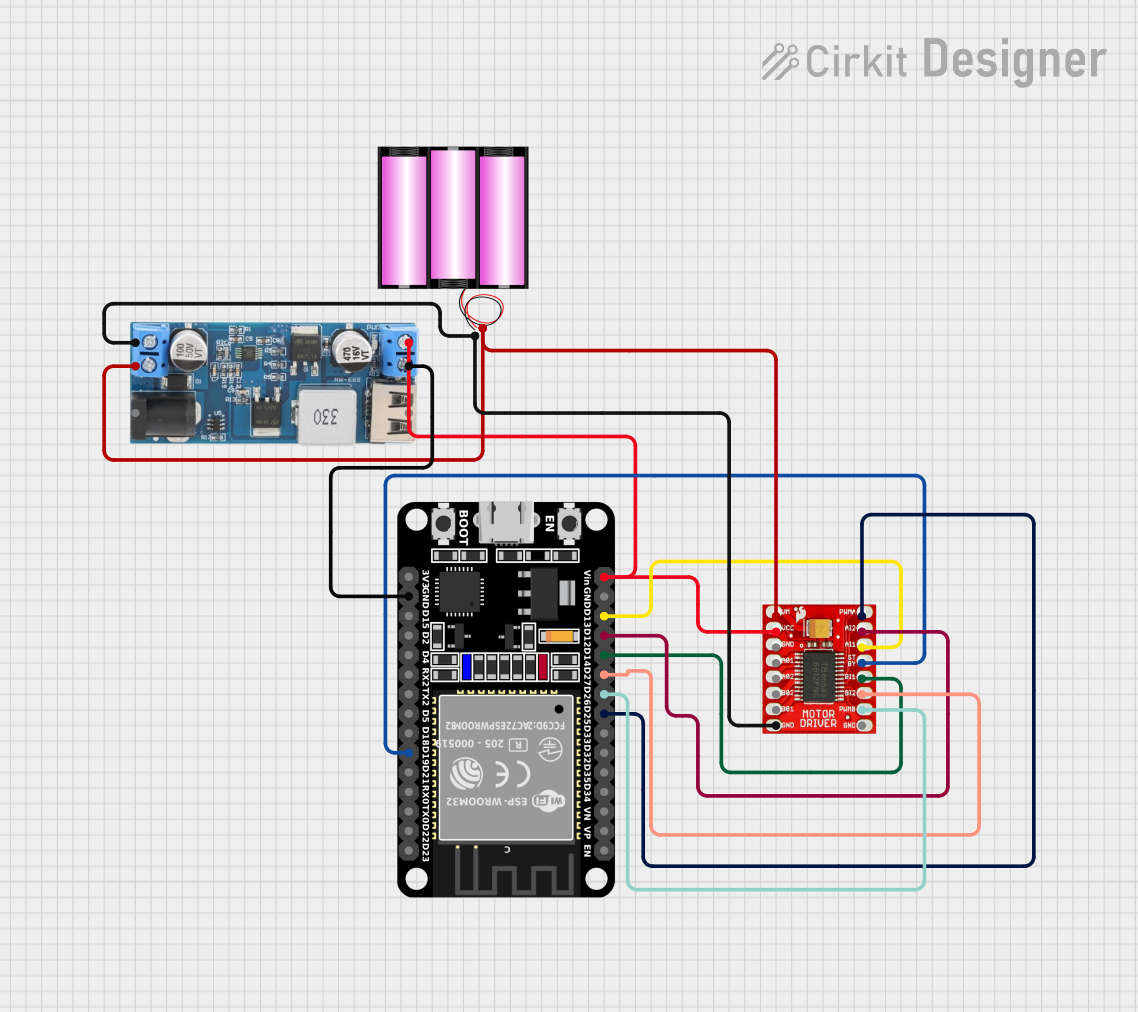

Explore Projects Built with TB6612FNG Motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with TB6612FNG Motor Driver

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications

- Robotics (e.g., controlling wheels or arms)

- Automated conveyor systems

- DIY projects involving DC or stepper motors

- Educational electronics kits

- Small-scale industrial automation

Technical Specifications

Key Technical Details

| Parameter | Value |

|---|---|

| Operating Voltage (Vcc) | 2.7V to 5.5V |

| Motor Voltage (VM) | 4.5V to 13.5V |

| Output Current (per channel) | 1.2A (continuous), 3.2A (peak) |

| Control Interface | PWM and digital signals |

| Standby Current | 1 µA (typical) |

| Built-in Protections | Thermal shutdown, overcurrent |

| Operating Temperature Range | -20°C to +85°C |

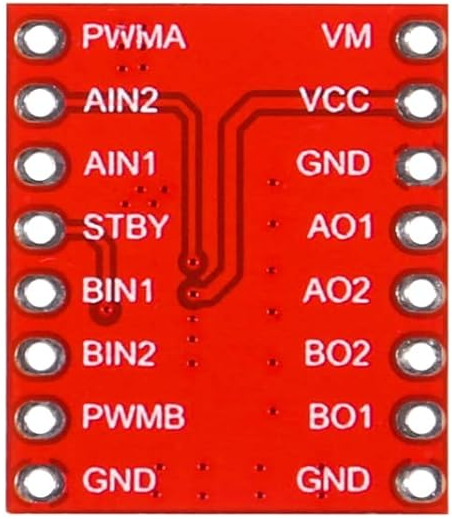

Pin Configuration and Descriptions

The TB6612FNG comes in a 16-pin package. Below is the pinout and description:

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | PWMA | PWM input for Motor A |

| 2 | AIN1 | Input 1 for Motor A (direction control) |

| 3 | AIN2 | Input 2 for Motor A (direction control) |

| 4 | STBY | Standby control (active HIGH to enable the IC) |

| 5 | Vcc | Logic power supply (2.7V to 5.5V) |

| 6 | AO1 | Output 1 for Motor A |

| 7 | AO2 | Output 2 for Motor A |

| 8 | VM | Motor power supply (4.5V to 13.5V) |

| 9 | BO2 | Output 2 for Motor B |

| 10 | BO1 | Output 1 for Motor B |

| 11 | GND | Ground |

| 12 | Vcc | Logic power supply (connected internally to Pin 5) |

| 13 | BIN2 | Input 2 for Motor B (direction control) |

| 14 | BIN1 | Input 1 for Motor B (direction control) |

| 15 | PWMB | PWM input for Motor B |

| 16 | NC | No connection |

Usage Instructions

How to Use the TB6612FNG in a Circuit

Power Connections:

- Connect

Vccto a 3.3V or 5V logic power supply. - Connect

VMto the motor power supply (4.5V to 13.5V). - Connect

GNDto the ground of the power supply.

- Connect

Motor Connections:

- Connect the motor terminals to

AO1andAO2for Motor A, andBO1andBO2for Motor B.

- Connect the motor terminals to

Control Signals:

- Use

AIN1andAIN2to control the direction of Motor A, andBIN1andBIN2for Motor B. - Provide PWM signals to

PWMAandPWMBto control the speed of Motor A and Motor B, respectively. - Set

STBYHIGH to enable the IC. Pull it LOW to put the IC in standby mode.

- Use

Direction Control:

- Set

AIN1HIGH andAIN2LOW to rotate Motor A in one direction. - Set

AIN1LOW andAIN2HIGH to rotate Motor A in the opposite direction. - Similarly, use

BIN1andBIN2for Motor B.

- Set

PWM Speed Control:

- Apply a PWM signal (0-100% duty cycle) to

PWMAorPWMBto control the speed of the motors.

- Apply a PWM signal (0-100% duty cycle) to

Example: Using TB6612FNG with Arduino UNO

Below is an example code to control two DC motors using the TB6612FNG and an Arduino UNO:

// Pin definitions for Motor A

const int AIN1 = 7; // Direction control pin 1 for Motor A

const int AIN2 = 8; // Direction control pin 2 for Motor A

const int PWMA = 9; // PWM speed control pin for Motor A

// Pin definitions for Motor B

const int BIN1 = 4; // Direction control pin 1 for Motor B

const int BIN2 = 5; // Direction control pin 2 for Motor B

const int PWMB = 6; // PWM speed control pin for Motor B

// Standby pin

const int STBY = 10; // Standby control pin

void setup() {

// Set all pins as outputs

pinMode(AIN1, OUTPUT);

pinMode(AIN2, OUTPUT);

pinMode(PWMA, OUTPUT);

pinMode(BIN1, OUTPUT);

pinMode(BIN2, OUTPUT);

pinMode(PWMB, OUTPUT);

pinMode(STBY, OUTPUT);

// Enable the motor driver by setting STBY HIGH

digitalWrite(STBY, HIGH);

}

void loop() {

// Example: Rotate Motor A forward at 50% speed

digitalWrite(AIN1, HIGH);

digitalWrite(AIN2, LOW);

analogWrite(PWMA, 128); // 50% duty cycle (128 out of 255)

// Example: Rotate Motor B backward at 75% speed

digitalWrite(BIN1, LOW);

digitalWrite(BIN2, HIGH);

analogWrite(PWMB, 192); // 75% duty cycle (192 out of 255)

delay(2000); // Run motors for 2 seconds

// Stop both motors

analogWrite(PWMA, 0);

analogWrite(PWMB, 0);

delay(2000); // Wait for 2 seconds before repeating

}

Important Considerations

- Ensure that the motor power supply voltage (

VM) matches the motor's rated voltage. - Do not exceed the maximum continuous current rating of 1.2A per channel.

- Use appropriate decoupling capacitors between

VMandGNDto reduce noise. - Avoid running the IC at high currents for extended periods to prevent overheating.

Troubleshooting and FAQs

Common Issues and Solutions

Motors Not Running:

- Ensure

STBYis set HIGH to enable the IC. - Check the power supply connections for

VccandVM. - Verify that the PWM signals are being generated correctly.

- Ensure

Motor Running in the Wrong Direction:

- Swap the logic levels of

AIN1andAIN2(orBIN1andBIN2) to reverse the direction.

- Swap the logic levels of

Overheating:

- Ensure the current draw of the motors does not exceed 1.2A per channel.

- Add a heatsink or improve ventilation if the IC gets too hot.

No Response to PWM Signals:

- Verify that the PWM frequency is within the recommended range (typically 20kHz or lower).

- Check the connections to the

PWMAandPWMBpins.

FAQs

Q: Can the TB6612FNG drive stepper motors?

A: Yes, the TB6612FNG can drive a bipolar stepper motor by controlling the two H-bridges with appropriate step sequences.

Q: What happens if the IC overheats?

A: The TB6612FNG has built-in thermal shutdown protection. It will automatically disable the outputs if the temperature exceeds safe limits.

Q: Can I use the TB6612FNG with a 3.3V microcontroller?

A: Yes, the TB6612FNG supports logic levels as low as 2.7V, making it compatible with 3.3V microcontrollers.