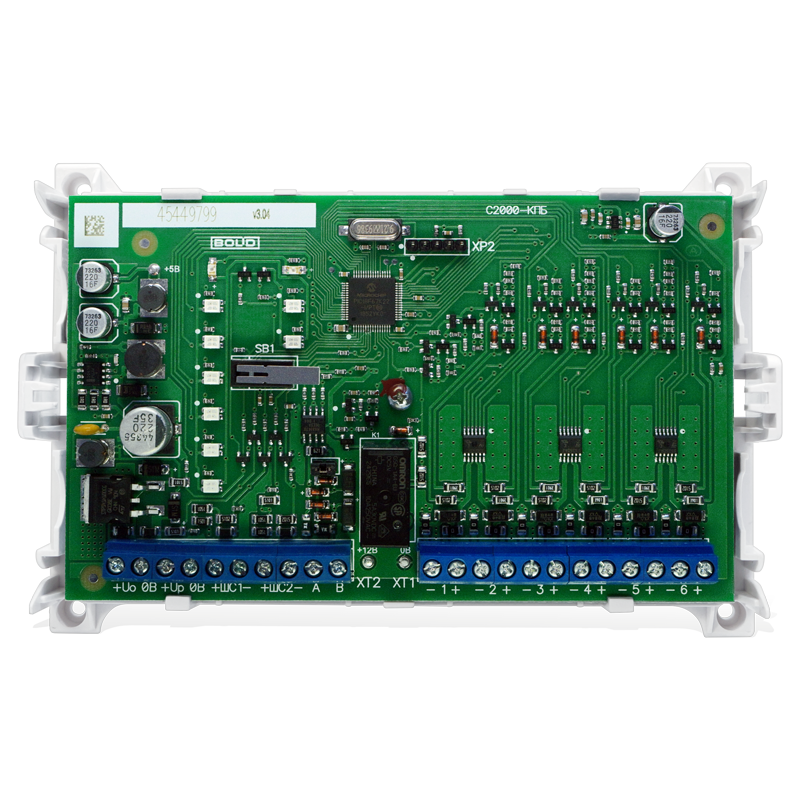

How to Use С2000-КПБ: Examples, Pinouts, and Specs

Design with С2000-КПБ in Cirkit Designer

Design with С2000-КПБ in Cirkit DesignerIntroduction

The С2000-КПБ, manufactured by Bolid, is a versatile programmable logic controller (PLC) designed for industrial automation applications. It provides a robust platform for controlling machinery, processes, and systems in a wide range of industries. With its flexible input/output (I/O) options and communication interfaces, the С2000-КПБ is ideal for tasks such as process automation, equipment monitoring, and system integration.

Explore Projects Built with С2000-КПБ

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with С2000-КПБ

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Industrial process control and automation

- Monitoring and controlling machinery in manufacturing plants

- Integration with SCADA (Supervisory Control and Data Acquisition) systems

- Building automation systems (e.g., HVAC, lighting control)

- Remote monitoring and diagnostics of industrial equipment

Technical Specifications

Key Technical Details

| Parameter | Specification |

|---|---|

| Power Supply | 24V DC ±10% |

| Power Consumption | ≤ 5W |

| Digital Inputs | 8 channels (optically isolated) |

| Digital Outputs | 6 channels (relay-based) |

| Analog Inputs | 2 channels (0-10V or 4-20mA) |

| Communication Interfaces | RS-485, Ethernet |

| Protocols Supported | Modbus RTU, Modbus TCP |

| Operating Temperature Range | -10°C to +50°C |

| Dimensions | 120mm x 90mm x 60mm |

| Mounting | DIN rail |

Pin Configuration and Descriptions

Power and Communication Terminals

| Pin Number | Label | Description |

|---|---|---|

| 1 | +24V | Positive terminal for 24V DC power |

| 2 | GND | Ground terminal |

| 3 | A (RS-485) | RS-485 communication line (A) |

| 4 | B (RS-485) | RS-485 communication line (B) |

| 5 | ETH_TX+ | Ethernet transmit positive |

| 6 | ETH_TX- | Ethernet transmit negative |

| 7 | ETH_RX+ | Ethernet receive positive |

| 8 | ETH_RX- | Ethernet receive negative |

Input/Output Terminals

| Pin Number | Label | Description |

|---|---|---|

| 9-16 | DI1-DI8 | Digital input channels 1 to 8 |

| 17-22 | DO1-DO6 | Digital output channels 1 to 6 |

| 23-24 | AI1, AI2 | Analog input channels 1 and 2 |

Usage Instructions

How to Use the С2000-КПБ in a Circuit

- Power Connection: Connect a 24V DC power supply to the +24V and GND terminals.

- Input Connections:

- For digital inputs, connect sensors or switches to the DI1-DI8 terminals.

- For analog inputs, connect devices providing 0-10V or 4-20mA signals to AI1 and AI2.

- Output Connections:

- Connect actuators, relays, or other devices to the DO1-DO6 terminals.

- Communication Setup:

- Use the RS-485 terminals (A and B) for Modbus RTU communication.

- For Ethernet-based communication, connect the Ethernet cable to the appropriate terminals (ETH_TX+, ETH_TX-, ETH_RX+, ETH_RX-).

- Programming:

- Use the Bolid-provided software to program the PLC according to your application requirements.

- Configure I/O channels, communication settings, and logic sequences.

Important Considerations and Best Practices

- Ensure the power supply voltage is within the specified range (24V DC ±10%).

- Use shielded cables for RS-485 and Ethernet connections to minimize interference.

- Properly terminate the RS-485 bus with a 120-ohm resistor at both ends.

- Avoid exceeding the maximum current ratings for digital outputs to prevent damage.

- Regularly update the firmware to ensure compatibility with the latest features and protocols.

Example Code for Arduino UNO Integration

The С2000-КПБ can communicate with an Arduino UNO via the Modbus RTU protocol over RS-485. Below is an example of how to read a digital input from the PLC using the Arduino Modbus library.

#include <ModbusMaster.h>

// Instantiate ModbusMaster object

ModbusMaster node;

// Define RS-485 communication pins

#define RS485_TX 2 // Arduino TX pin

#define RS485_RX 3 // Arduino RX pin

#define RS485_DE 4 // Driver Enable pin

void setup() {

// Initialize serial communication for debugging

Serial.begin(9600);

// Initialize RS-485 communication

pinMode(RS485_DE, OUTPUT);

digitalWrite(RS485_DE, LOW); // Set to receive mode

Serial1.begin(9600, SERIAL_8N1, RS485_RX, RS485_TX);

// Configure Modbus communication

node.begin(1, Serial1); // Set Modbus ID to 1

}

void loop() {

uint8_t result;

uint16_t data;

// Read digital input status from С2000-КПБ (address 0x0000)

result = node.readDiscreteInputs(0x0000, 1);

if (result == node.ku8MBSuccess) {

data = node.getResponseBuffer(0);

Serial.print("Digital Input Status: ");

Serial.println(data);

} else {

Serial.print("Error: ");

Serial.println(result);

}

delay(1000); // Wait 1 second before next read

}

Notes:

- Use an RS-485 transceiver module (e.g., MAX485) to interface the Arduino with the С2000-КПБ.

- Ensure the Modbus ID and baud rate match the PLC's configuration.

Troubleshooting and FAQs

Common Issues and Solutions

PLC Not Powering On:

- Verify the power supply voltage is within the specified range (24V DC ±10%).

- Check for loose or incorrect wiring at the power terminals.

No Communication via RS-485:

- Ensure the A and B lines are correctly connected.

- Verify the Modbus ID, baud rate, and other communication settings.

- Check for proper termination of the RS-485 bus with a 120-ohm resistor.

Digital Outputs Not Working:

- Confirm the connected load does not exceed the output's current rating.

- Check the program logic to ensure the output is being activated.

Analog Input Readings Are Incorrect:

- Verify the input signal type (0-10V or 4-20mA) matches the PLC configuration.

- Check for proper wiring and ensure the signal source is functioning correctly.

FAQs

Q: Can the С2000-КПБ be used in outdoor environments?

A: The PLC is designed for indoor use. If outdoor installation is required, ensure it is housed in a weatherproof enclosure.

Q: What software is used to program the С2000-КПБ?

A: Bolid provides proprietary software for programming and configuring the PLC. Refer to the manufacturer's website for downloads and documentation.

Q: How many devices can be connected to the RS-485 bus?

A: Up to 32 devices can be connected to the RS-485 bus, including the С2000-КПБ, depending on the network configuration.

Q: Is the С2000-КПБ compatible with third-party SCADA systems?

A: Yes, the PLC supports Modbus RTU and Modbus TCP protocols, making it compatible with most SCADA systems.