How to Use 28BYJ-48 Stepper Motor: Examples, Pinouts, and Specs

Design with 28BYJ-48 Stepper Motor in Cirkit Designer

Design with 28BYJ-48 Stepper Motor in Cirkit DesignerIntroduction

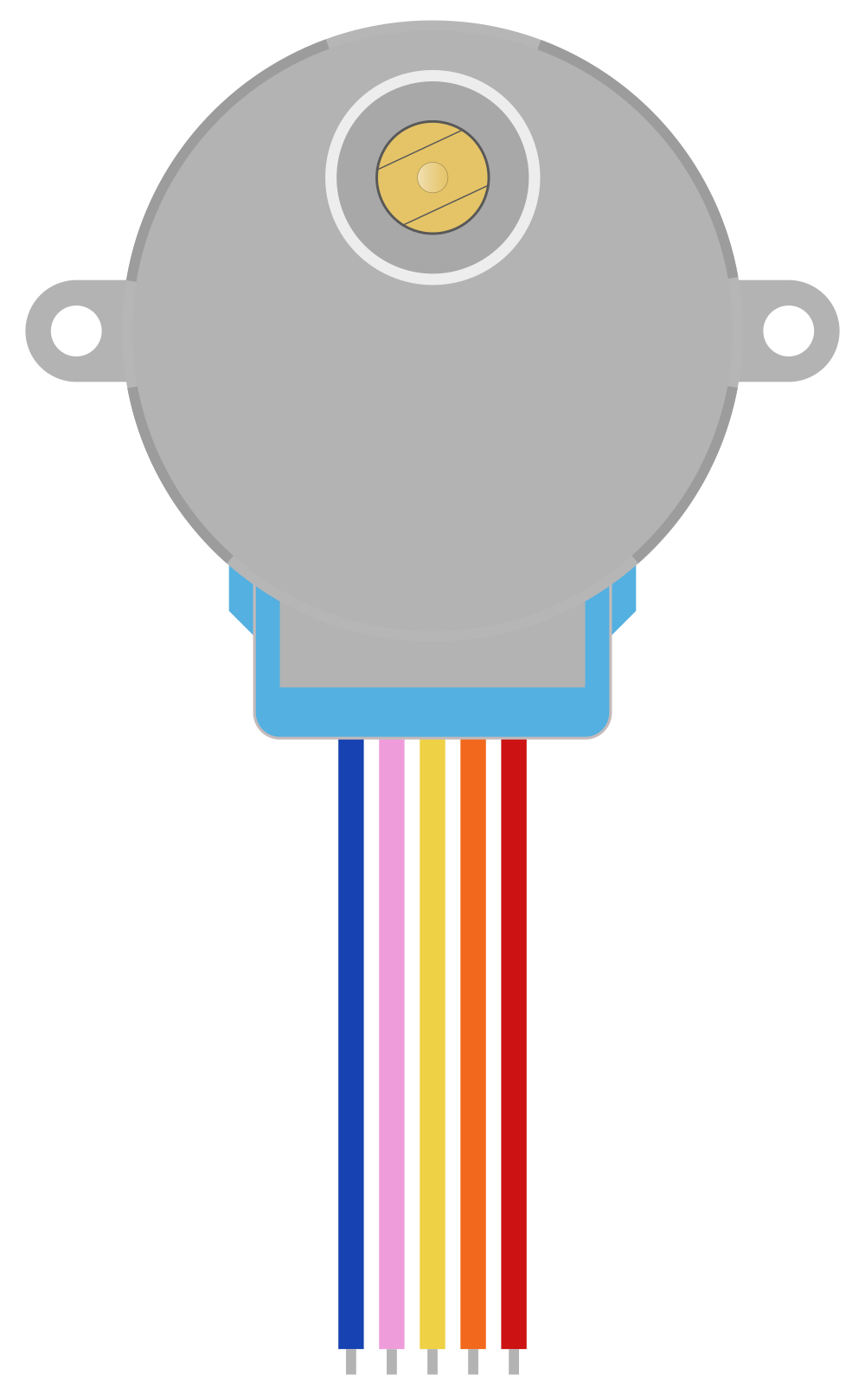

The 28BYJ-48 stepper motor is a small, lightweight, and cost-effective unipolar stepper motor commonly used in DIY projects, robotics, and automation systems. It is designed for applications requiring precise rotational movement and control. With its 4-phase coil arrangement and 5-wire connection, it offers a high degree of control and is suitable for a wide range of applications.

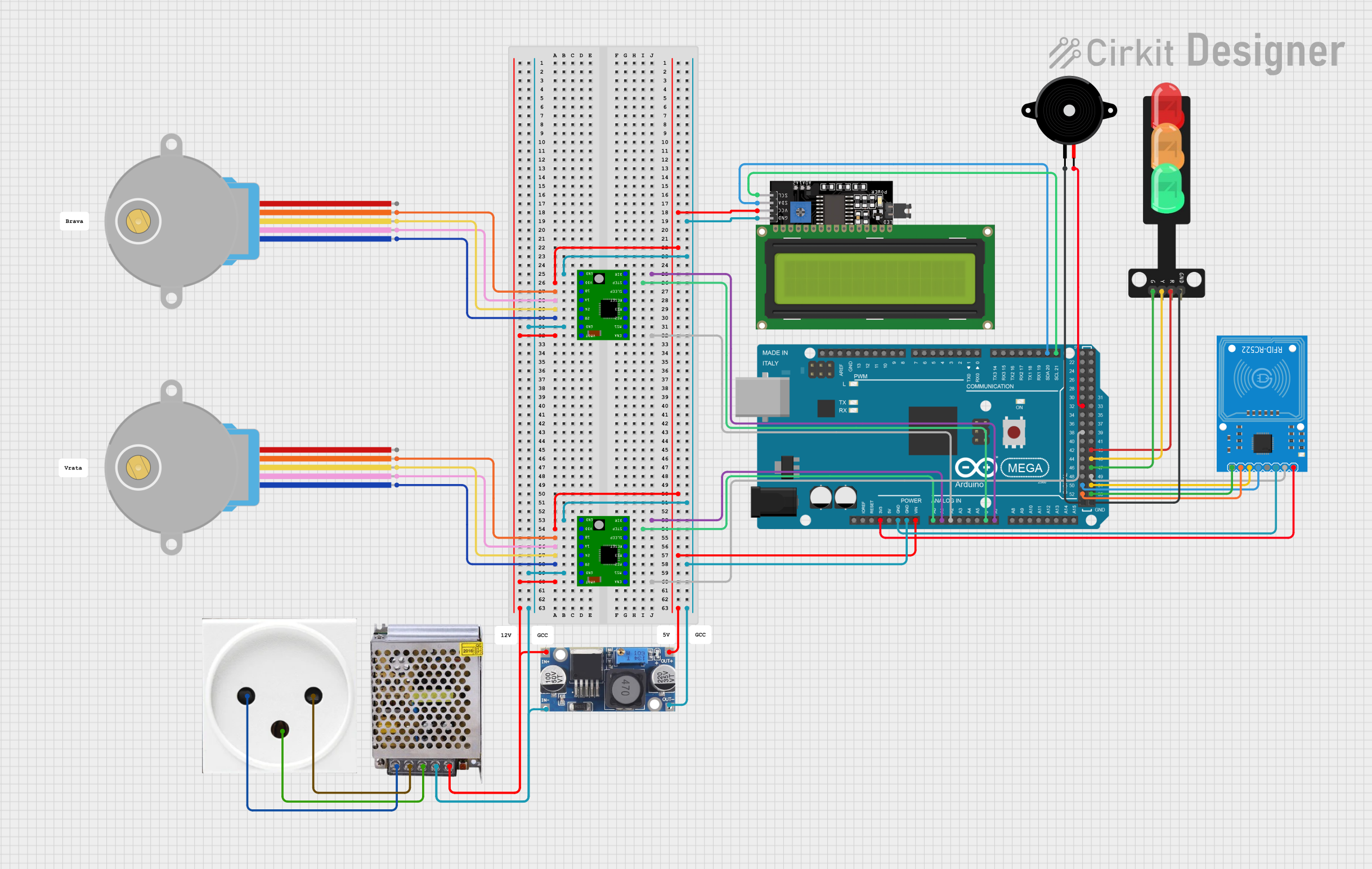

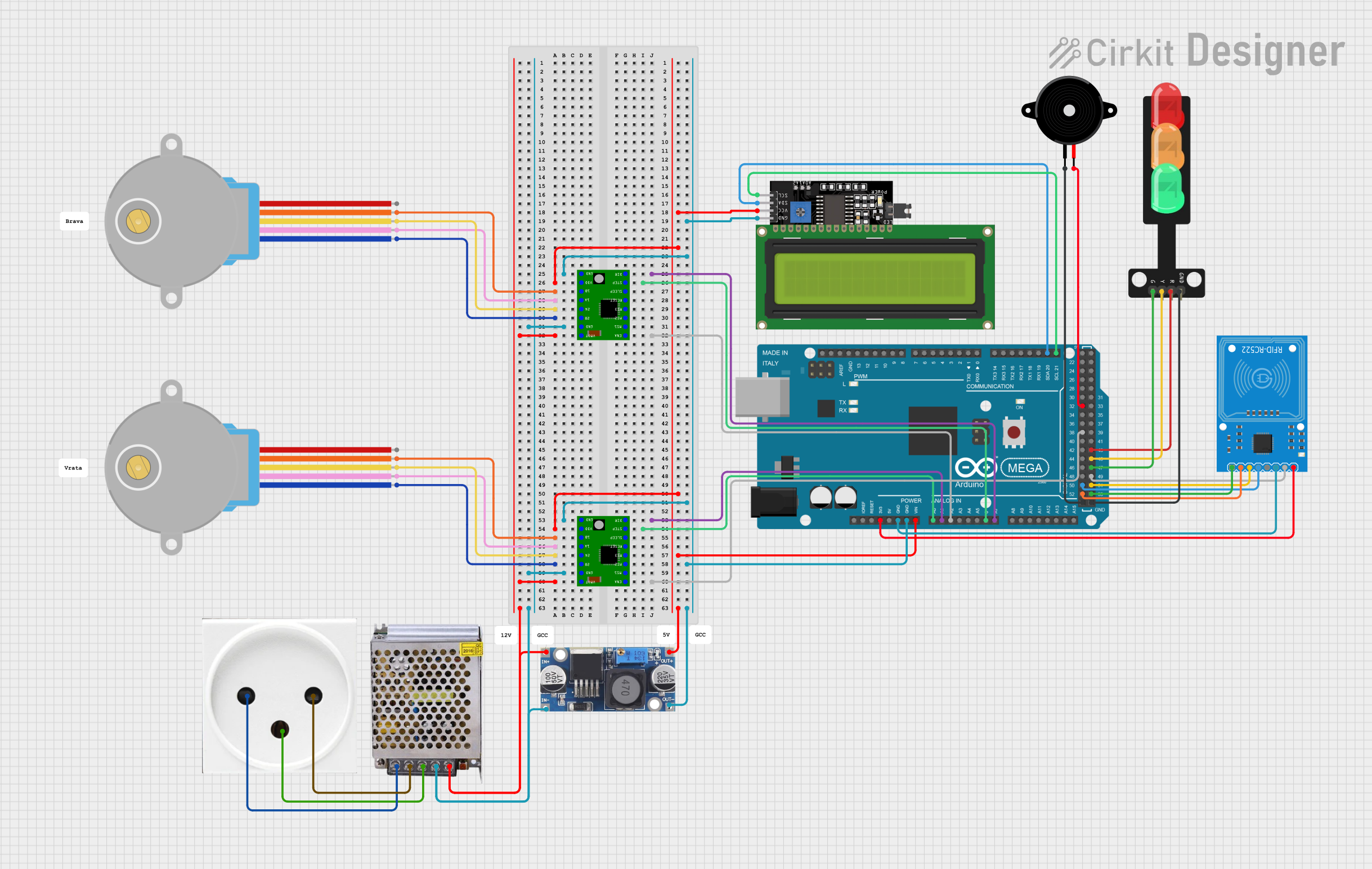

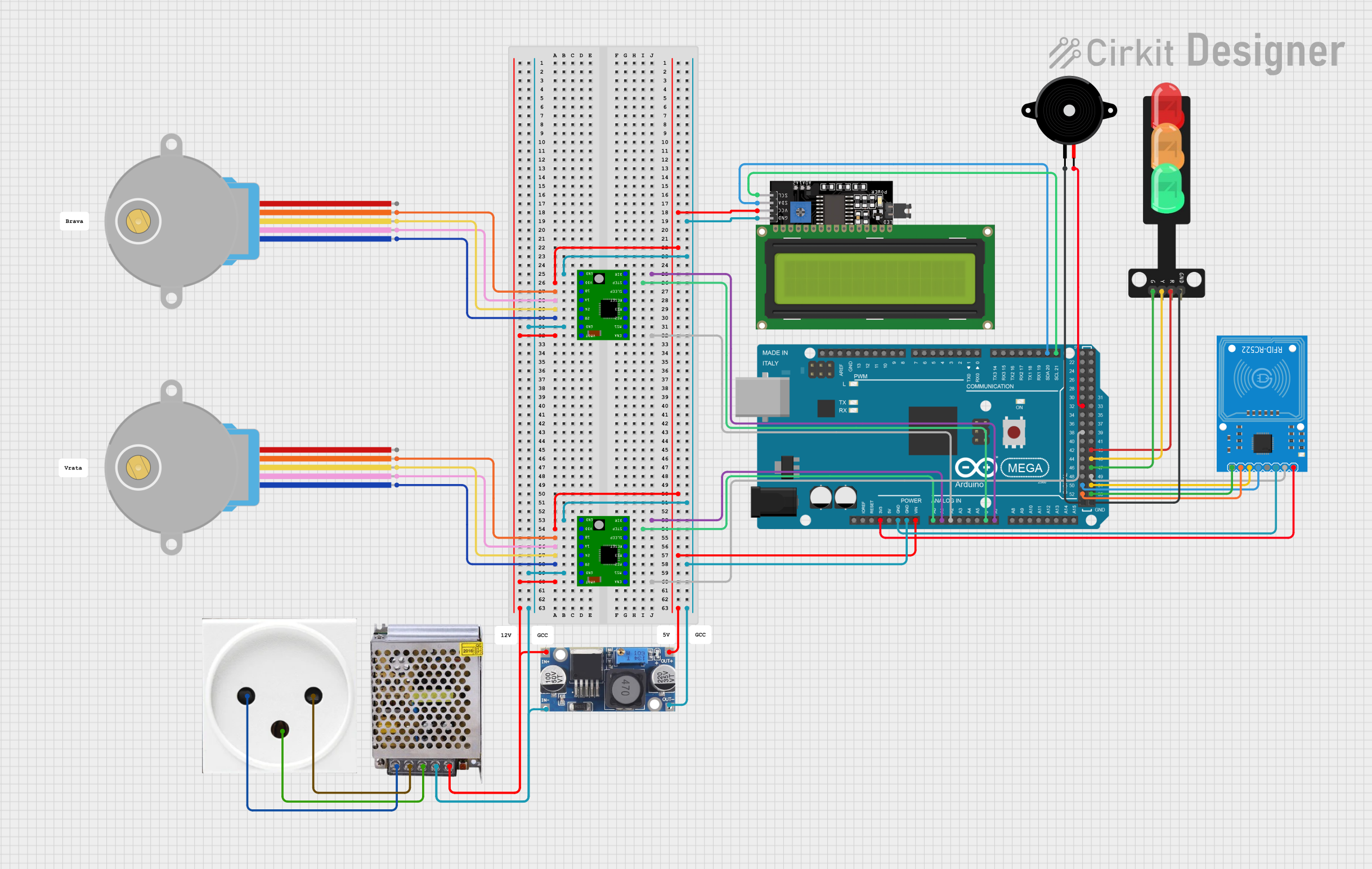

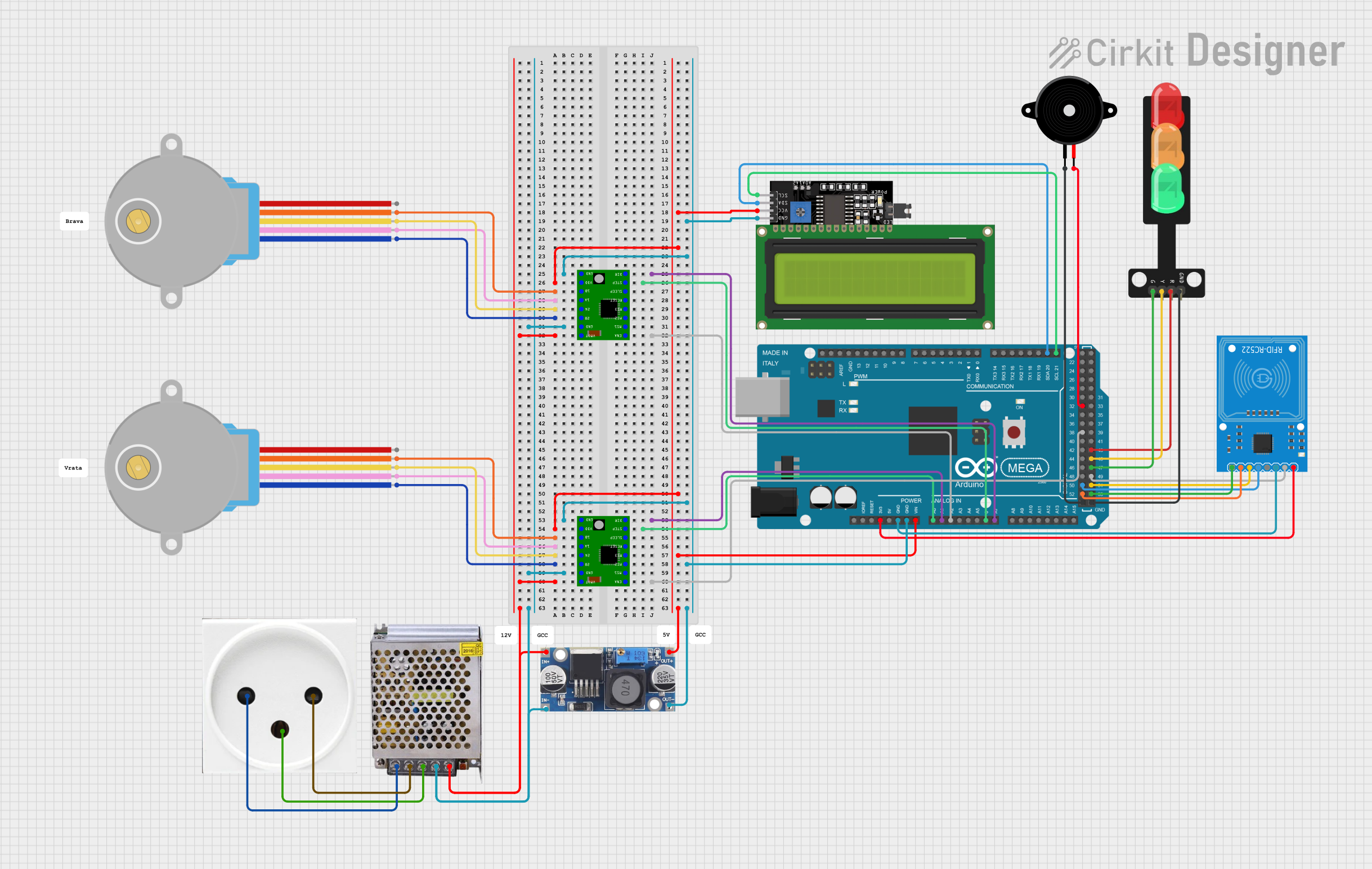

Explore Projects Built with 28BYJ-48 Stepper Motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with 28BYJ-48 Stepper Motor

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerCommon Applications and Use Cases

- Precision movement control in robotics

- Automated equipment such as 3D printers and CNC machines

- Camera pan and tilt mechanisms

- Time-lapse photography rigs

- Small positioning devices

Technical Specifications

Key Technical Details

- Voltage: 5V DC

- Current: 92 mA (no-load)

- Step Angle: 5.625°/64 (0.0879° per step)

- Resistance: 50 ohms per phase

- Insulation Resistance: >10M ohms at 500V DC

- Dielectric Strength: 600V AC for 1 sec

- Pull-in Torque: 300 gf-cm

Pin Configuration and Descriptions

| Pin Number | Wire Color | Description |

|---|---|---|

| 1 | Red | Common VCC (5V) |

| 2 | Blue | Coil 1 |

| 3 | Pink | Coil 2 |

| 4 | Yellow | Coil 3 |

| 5 | Orange | Coil 4 |

Usage Instructions

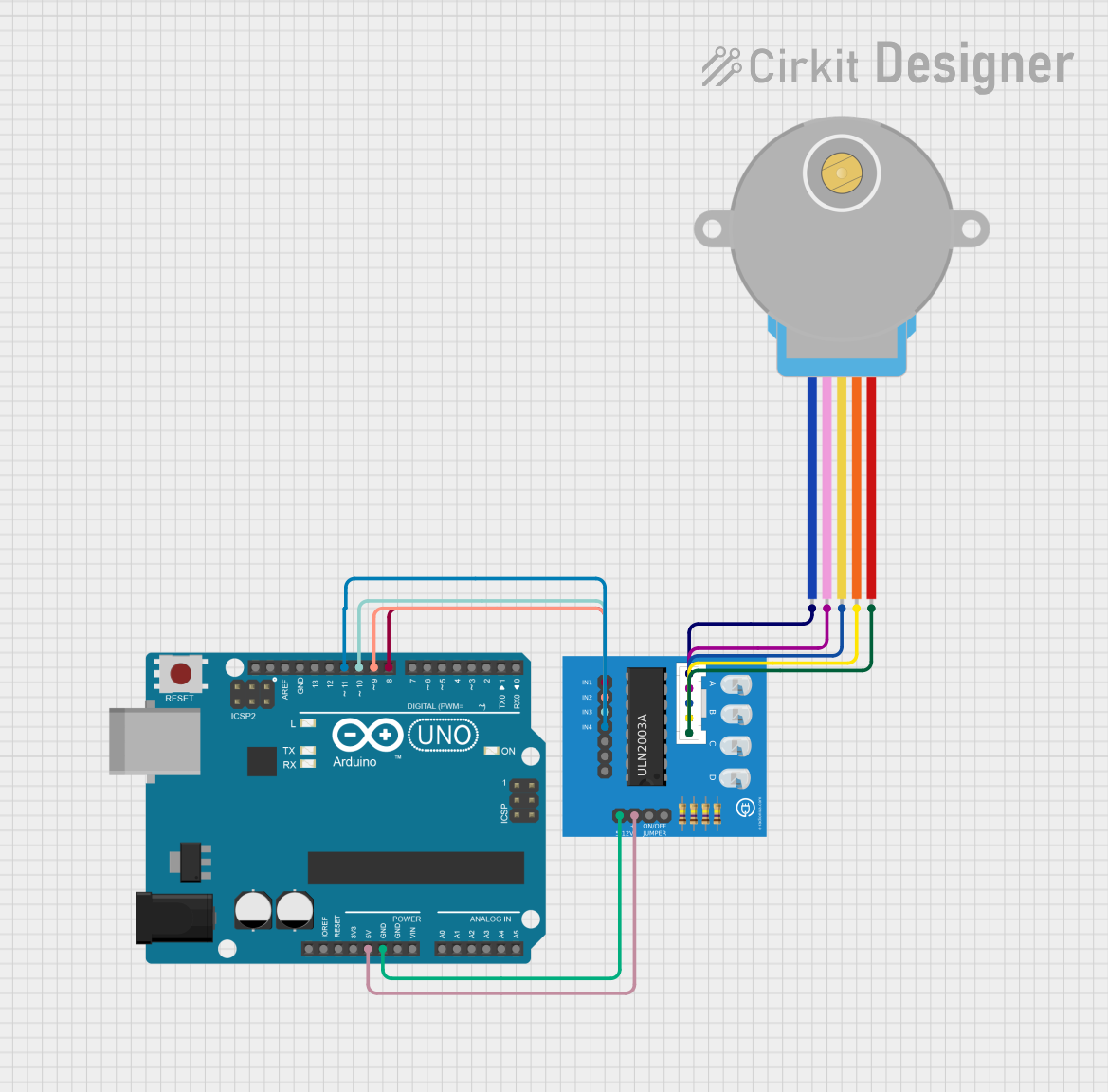

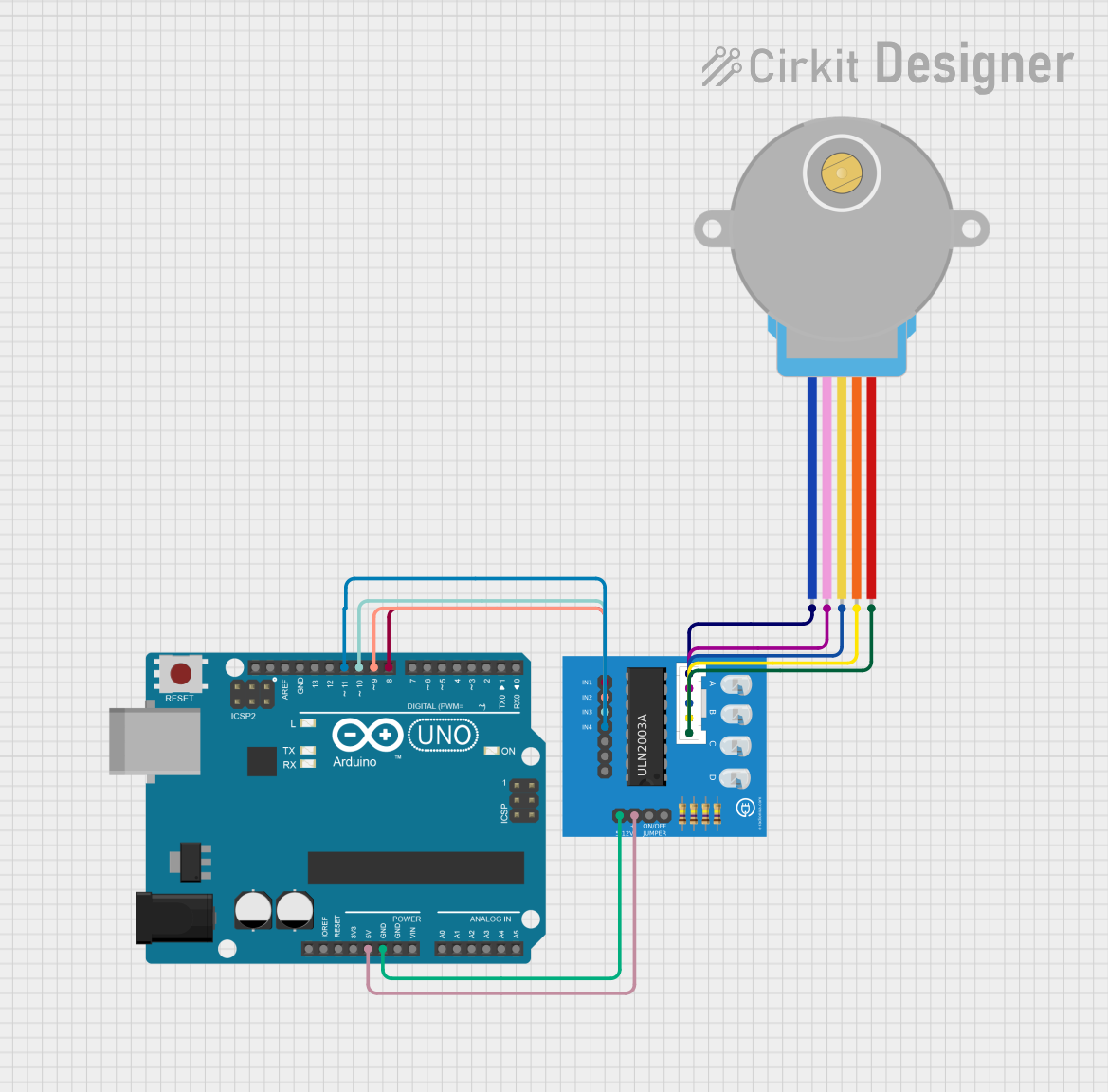

How to Use the Component in a Circuit

- Power Supply: Connect the red wire to a 5V power supply.

- Control Wires: Connect the blue, pink, yellow, and orange wires to the control pins of a stepper motor driver or directly to a microcontroller if you are using one that can handle the required current.

- Microcontroller Connection: If using an Arduino UNO, you can connect the control wires to digital pins 8 through 11, for example.

Important Considerations and Best Practices

- Always use a suitable driver circuit or a microcontroller with enough current capacity to drive the motor.

- Avoid stalling or overloading the motor as it may lead to overheating and damage.

- Use a decoupling capacitor across the power supply to minimize electrical noise.

- Start with slow step rates and gradually increase as needed to avoid missing steps.

Example Code for Arduino UNO

#include <Stepper.h>

// Define the number of steps per revolution

const int stepsPerRevolution = 2048;

// Initialize the stepper library on pins 8 through 11

Stepper myStepper(stepsPerRevolution, 8, 10, 9, 11);

void setup() {

// Set the speed (rpm) of the motor

myStepper.setSpeed(15);

}

void loop() {

// Step one revolution in one direction:

myStepper.step(stepsPerRevolution);

delay(1000);

// Step one revolution in the other direction:

myStepper.step(-stepsPerRevolution);

delay(1000);

}

Note: The Stepper library is used for controlling the stepper motor with an Arduino. The stepsPerRevolution value is set to 2048, which corresponds to the number of steps the motor needs to make a full revolution.

Troubleshooting and FAQs

Common Issues Users Might Face

- Motor not rotating: Check the wiring and ensure that the power supply is adequate and correctly connected.

- Motor skipping steps or stalling: This could be due to running the motor too fast or overloading it. Reduce the speed or the load on the motor.

- Motor getting hot: Ensure that the current supplied to the motor does not exceed the recommended rating.

Solutions and Tips for Troubleshooting

- Double-check all connections and wire colors to ensure they match the pin configuration.

- Start with a low speed to test the motor and gradually increase as needed.

- If the motor is not functioning correctly, try reducing the load or changing the step sequence.

FAQs

Q: Can I run the 28BYJ-48 motor at a higher voltage? A: Running the motor at a higher voltage than recommended may increase its speed and torque but can also lead to overheating and reduced lifespan. It is best to use the motor within its specified voltage range.

Q: How can I reverse the direction of the motor?

A: To reverse the direction, you can reverse the sequence of the control signals or simply call the step() function with a negative number of steps.

Q: What is the maximum speed of the 28BYJ-48 stepper motor? A: The maximum speed depends on the voltage and the load but is typically around 15-20 rotations per minute (rpm) when driven at 5V.

Q: Can I control the 28BYJ-48 stepper motor without a driver? A: While it is possible to control the motor directly from a microcontroller, using a dedicated stepper motor driver is recommended for better performance and to protect the microcontroller from excessive current draw.