How to Use SIMATIC S7-300: Examples, Pinouts, and Specs

Design with SIMATIC S7-300 in Cirkit Designer

Design with SIMATIC S7-300 in Cirkit DesignerIntroduction

The SIMATIC S7-300 is a modular Programmable Logic Controller (PLC) system manufactured by Siemens. It is designed for automation tasks in industrial environments, offering a range of CPUs, I/O modules, and communication options for flexible and scalable control solutions. The S7-300 is widely used in various industries, including manufacturing, process control, and building automation, due to its reliability, versatility, and ease of integration.

Explore Projects Built with SIMATIC S7-300

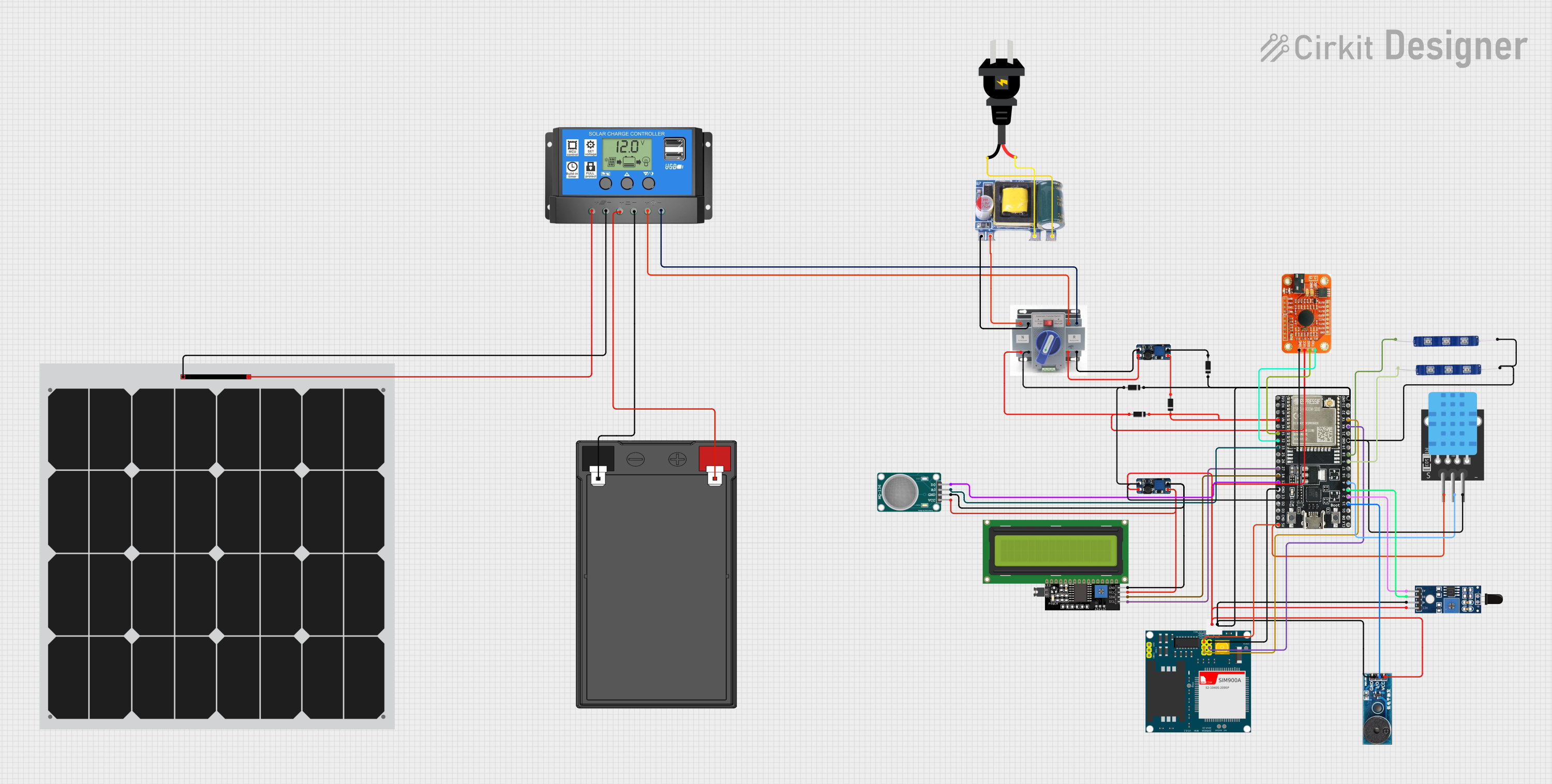

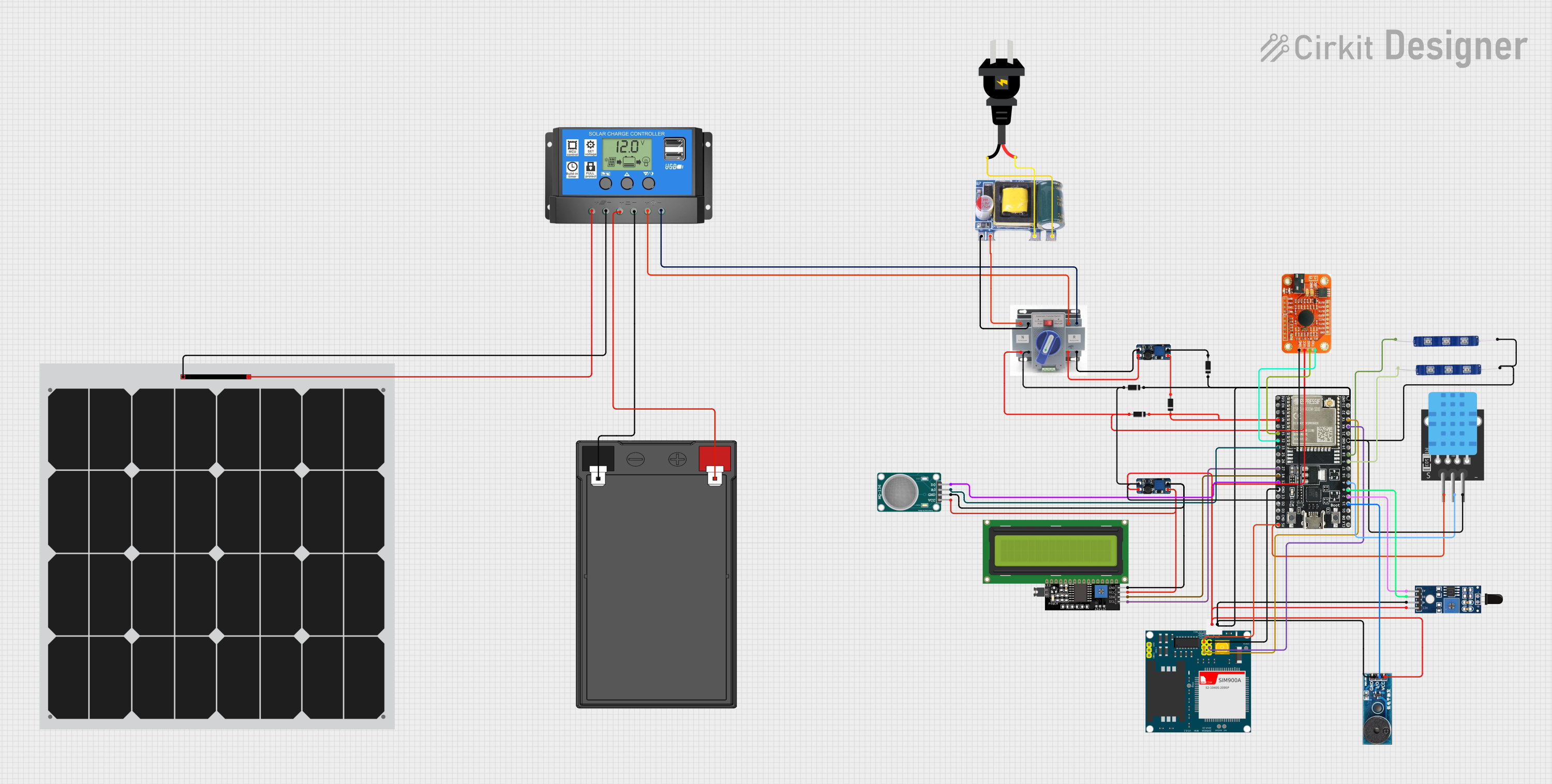

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with SIMATIC S7-300

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

| Parameter | Specification |

|---|---|

| Manufacturer | Siemens |

| Part ID | SIMATIC S7-300 |

| Power Supply Voltage | 24V DC or 120/230V AC (depending on the power module) |

| CPU Processing Speed | Varies by model (e.g., 0.1 ms per 1,000 instructions) |

| Memory | Varies by model (e.g., 32 KB to 512 KB) |

| Communication Interfaces | MPI, Profibus, Industrial Ethernet, Profinet |

| I/O Modules | Digital and Analog I/O, Specialty Modules |

| Operating Temperature | 0°C to 60°C |

| Storage Temperature | -40°C to 70°C |

Pin Configuration and Descriptions

The pin configuration varies depending on the specific CPU and I/O modules used. Below is an example of a typical digital input module (SM 321) and its pin configuration:

Digital Input Module (SM 321)

| Pin Number | Description |

|---|---|

| 1 | Input 0 |

| 2 | Input 1 |

| 3 | Input 2 |

| 4 | Input 3 |

| 5 | Input 4 |

| 6 | Input 5 |

| 7 | Input 6 |

| 8 | Input 7 |

| 9 | Common (0V) |

| 10 | +24V DC |

Usage Instructions

How to Use the Component in a Circuit

Power Supply Connection: Connect the power supply to the power module of the S7-300. Ensure the voltage matches the specifications (24V DC or 120/230V AC).

CPU Installation: Install the CPU module into the S7-300 rack. Secure it properly to ensure stable operation.

I/O Module Installation: Install the required I/O modules (digital, analog, or specialty) into the rack. Connect the field devices (sensors, actuators) to the corresponding I/O module pins.

Communication Setup: Connect the communication cables (MPI, Profibus, Ethernet) to the appropriate ports on the CPU module for network integration.

Programming: Use Siemens' STEP 7 software to program the S7-300. Create a new project, configure the hardware, and write the control logic using ladder logic, function block diagrams, or structured text.

Download and Test: Download the program to the CPU module and test the system. Monitor the inputs and outputs to ensure proper operation.

Important Considerations and Best Practices

- Proper Ventilation: Ensure adequate ventilation around the S7-300 to prevent overheating.

- Surge Protection: Use surge protection devices to safeguard the PLC from voltage spikes.

- Regular Maintenance: Perform regular maintenance checks to ensure the system's reliability.

- Backup Programs: Always keep a backup of the PLC programs to prevent data loss.

Troubleshooting and FAQs

Common Issues and Solutions

PLC Not Powering On

- Solution: Check the power supply connections and ensure the correct voltage is supplied. Verify that the power module is functioning properly.

Communication Failure

- Solution: Check the communication cable connections and ensure they are secure. Verify the network settings in the STEP 7 software.

I/O Modules Not Responding

- Solution: Ensure the I/O modules are properly installed and connected. Check the wiring to the field devices and verify the module configuration in the software.

Program Not Executing

- Solution: Verify that the program is correctly downloaded to the CPU. Check for any errors in the program logic and correct them.

FAQs

Q1: Can the S7-300 be used in hazardous environments?

- A1: The S7-300 is not designed for hazardous environments. Use appropriate protective enclosures and follow safety guidelines for such applications.

Q2: How can I expand the I/O capacity of the S7-300?

- A2: You can expand the I/O capacity by adding additional I/O modules to the rack. Ensure the total power consumption does not exceed the power supply capacity.

Q3: Is it possible to integrate the S7-300 with other PLC systems?

- A3: Yes, the S7-300 can be integrated with other PLC systems using communication protocols like Profibus, Profinet, or Industrial Ethernet.

Q4: How do I update the firmware of the S7-300 CPU?

- A4: Use the STEP 7 software to update the firmware. Follow the instructions provided by Siemens for the specific CPU model.

Conclusion

The SIMATIC S7-300 is a versatile and reliable PLC system suitable for a wide range of industrial automation tasks. By following the usage instructions and best practices outlined in this documentation, users can effectively implement and maintain the S7-300 in their automation projects. For further assistance, refer to the Siemens support resources and user manuals.