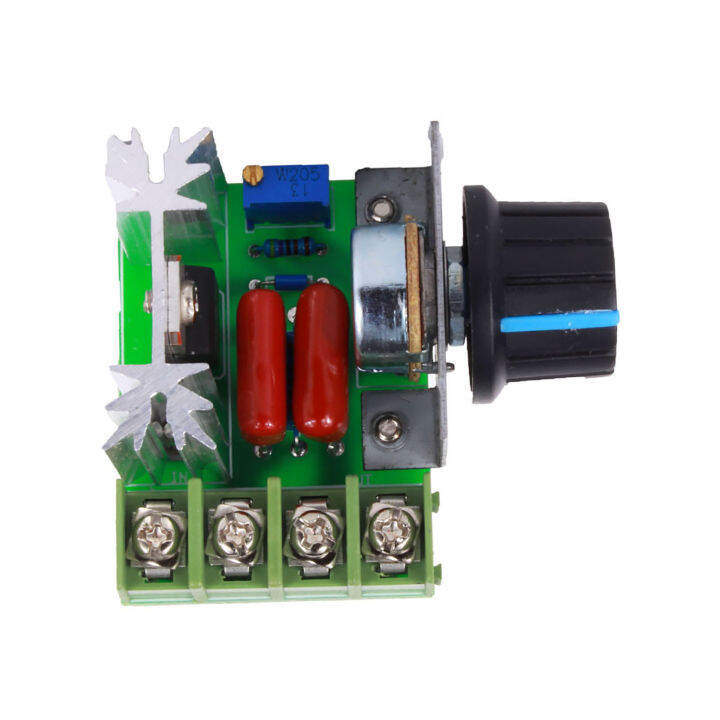

How to Use HiLetgo 2000W PWM AC Motor Speed Control Module Dimmer Speed Regulator 50-220V Adjustable Voltage Regulator: Examples, Pinouts, and Specs

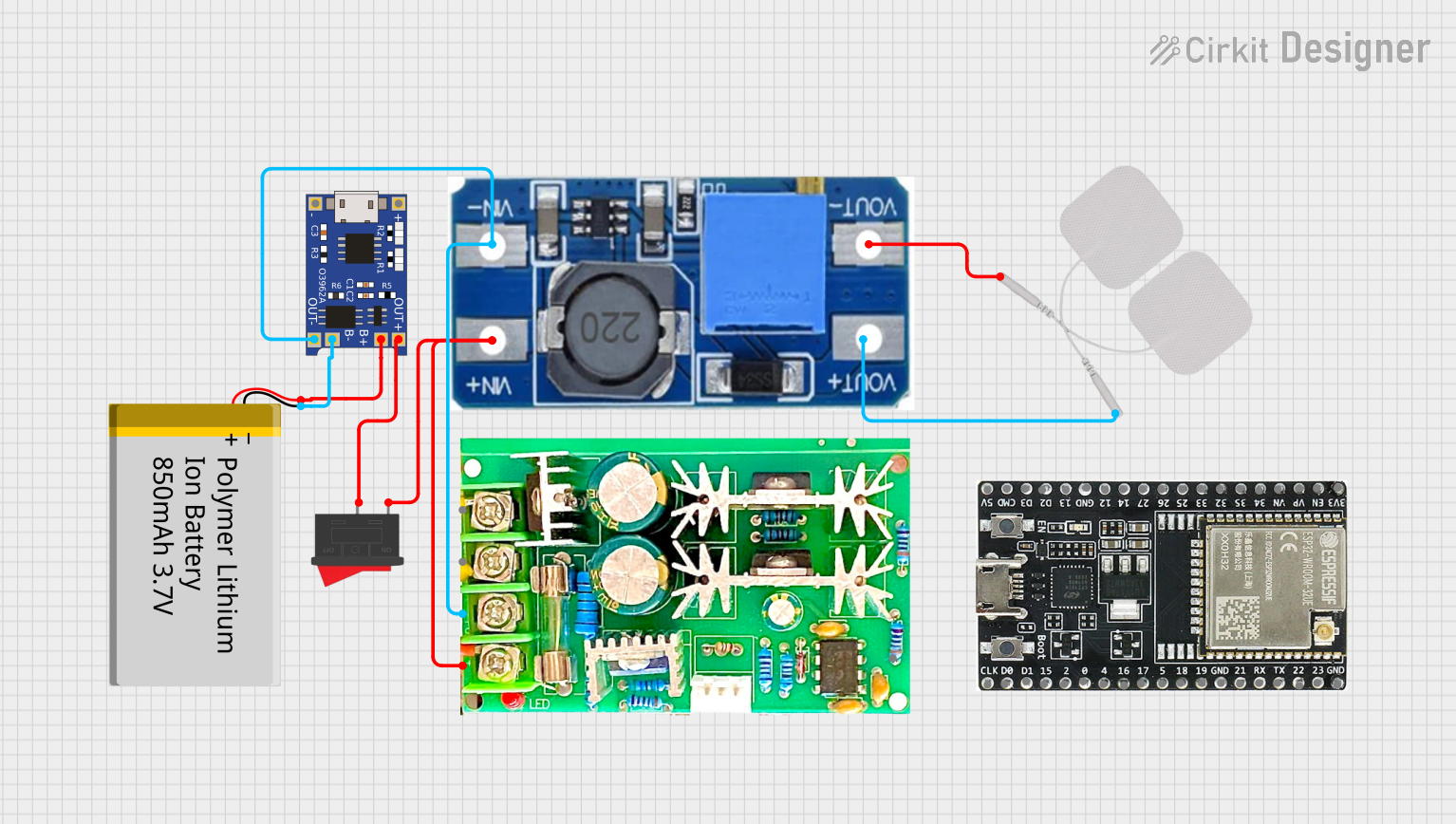

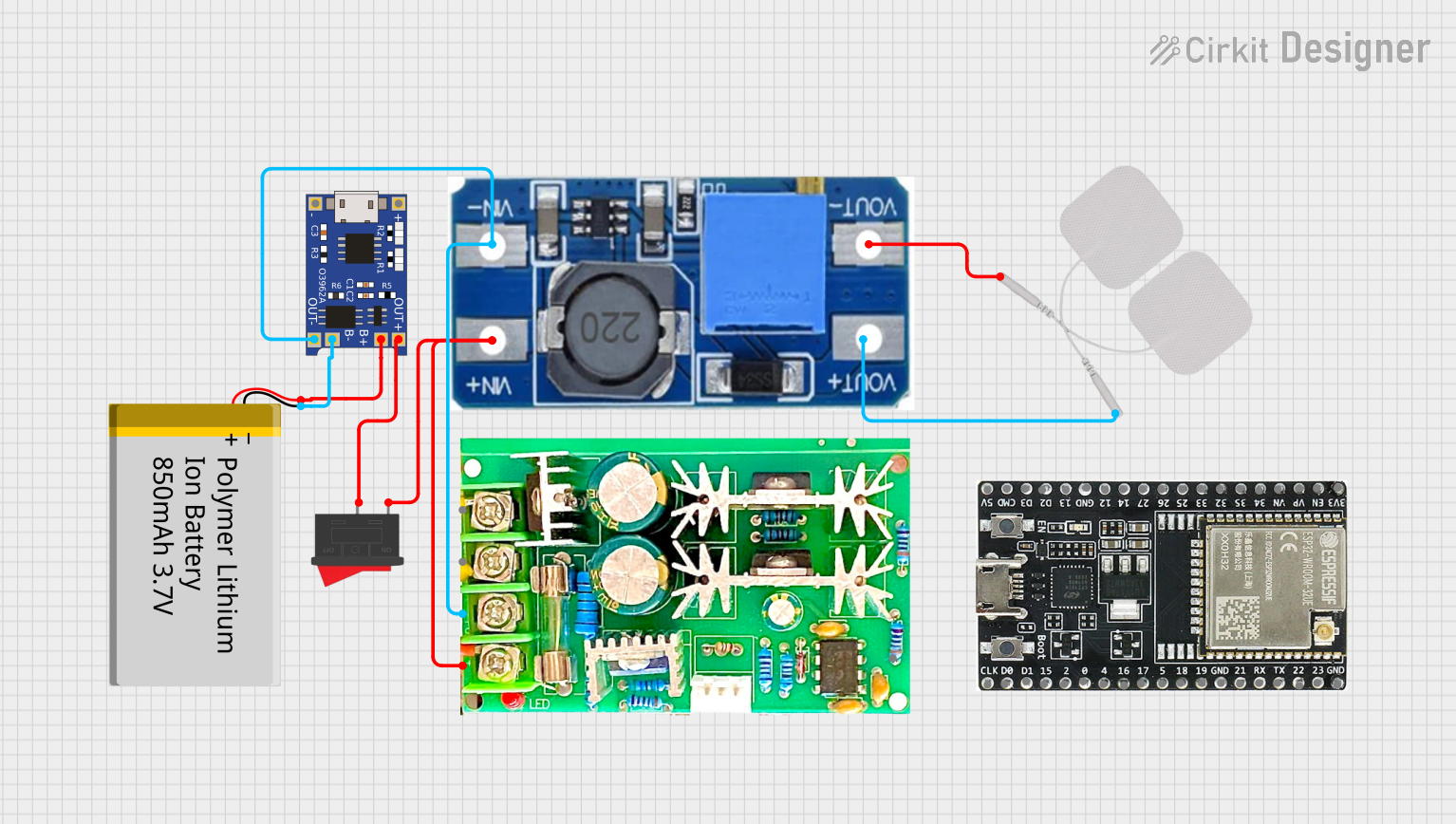

Design with HiLetgo 2000W PWM AC Motor Speed Control Module Dimmer Speed Regulator 50-220V Adjustable Voltage Regulator in Cirkit Designer

Design with HiLetgo 2000W PWM AC Motor Speed Control Module Dimmer Speed Regulator 50-220V Adjustable Voltage Regulator in Cirkit DesignerIntroduction

The HiLetgo 2000W PWM AC Motor Speed Control Module is an electronic device designed to control the speed of an AC motor by adjusting the voltage supplied to the motor using Pulse Width Modulation (PWM) technology. This module is capable of handling power loads up to 2000 watts and allows for adjustable voltage regulation within the range of 50-220 volts AC. It is commonly used in applications such as fan speed control, light dimming, and speed regulation for small AC motors in tools and appliances.

Explore Projects Built with HiLetgo 2000W PWM AC Motor Speed Control Module Dimmer Speed Regulator 50-220V Adjustable Voltage Regulator

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with HiLetgo 2000W PWM AC Motor Speed Control Module Dimmer Speed Regulator 50-220V Adjustable Voltage Regulator

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Key Technical Details

- Input Voltage: 110V/220V AC

- Output Voltage: 50-220V AC (adjustable)

- Maximum Power: 2000W

- PWM Frequency: 25kHz

- Operating Temperature: -20°C to 40°C

Pin Configuration and Descriptions

| Pin Number | Description | Notes |

|---|---|---|

| 1 | AC Input Line (Live) | Connect to AC live wire |

| 2 | AC Input Neutral | Connect to AC neutral wire |

| 3 | AC Output Line (Live) | Connect to motor or load live wire |

| 4 | Potentiometer (Speed Control) | Rotate to adjust output voltage |

| 5 | Heat Sink | Dissipates heat during operation |

Usage Instructions

How to Use the Component in a Circuit

Wiring:

- Connect the AC input line (live) and neutral to pins 1 and 2, respectively.

- Connect the AC output line (live) to pin 3, which will go to the AC motor or load.

- Ensure that the connections are secure and insulated to prevent electrical hazards.

Adjusting Speed:

- Rotate the potentiometer knob (pin 4) to adjust the output voltage and, consequently, the speed of the AC motor.

- Turning the knob clockwise typically increases the voltage and speed, while turning it counterclockwise decreases them.

Mounting:

- Secure the module to a non-conductive surface.

- Ensure the heat sink (pin 5) has adequate airflow for cooling.

Important Considerations and Best Practices

- Load Capacity: Do not exceed the maximum power rating of 2000W to prevent damage to the module or the connected load.

- Heat Management: Ensure proper ventilation around the module to prevent overheating.

- Safety: Always disconnect power before making any adjustments or wiring changes.

- Compatibility: This module is designed for resistive loads and may not be suitable for inductive loads without additional components such as snubber circuits.

Troubleshooting and FAQs

Common Issues

- Motor Not Starting: Ensure that the AC input is correctly connected and that the potentiometer is not set to the minimum position.

- Overheating: Check for adequate ventilation around the heat sink and verify that the load does not exceed the module's power rating.

- Inconsistent Speed Control: Confirm that the load is resistive and within the power rating of the module. Inductive loads may require additional components.

Solutions and Tips

- Motor Hums but Does Not Turn: This may indicate that the voltage is too low. Gradually increase the voltage using the potentiometer.

- Module Cuts Out: If the module overheats, it may temporarily cut out to protect itself. Allow it to cool before resuming operation.

- Flickering Lights (if used for dimming): This can be caused by incompatibility with certain types of bulbs or incorrect wiring. Ensure that the bulbs are dimmable and correctly connected.

FAQs

Q: Can this module be used with an Arduino UNO? A: While the module is primarily designed for direct AC control, it is possible to use an Arduino UNO to control the potentiometer for automated adjustments. However, this requires additional circuitry and is not covered in this documentation.

Q: Is this module suitable for all types of AC motors? A: This module works best with universal motors or motors that are designed for variable speed operation. It is not recommended for motors that require a constant frequency, such as synchronous motors.

Q: Can I use this module to control the speed of a ceiling fan? A: Yes, as long as the ceiling fan's power rating is within the module's capacity and it is designed to operate with variable voltage input.

For further assistance or inquiries, please refer to the manufacturer's support resources or contact a professional electrician.