How to Use MOTOR ENCODER: Examples, Pinouts, and Specs

Design with MOTOR ENCODER in Cirkit Designer

Design with MOTOR ENCODER in Cirkit DesignerIntroduction

A motor encoder is a device that measures the rotational position and speed of a motor's shaft. It provides feedback to control systems, enabling precise motor control in various applications. Motor encoders are essential in automation, robotics, and other systems requiring accurate motion control. They are commonly used in servo motors, CNC machines, robotic arms, and conveyor systems to ensure precise positioning and speed regulation.

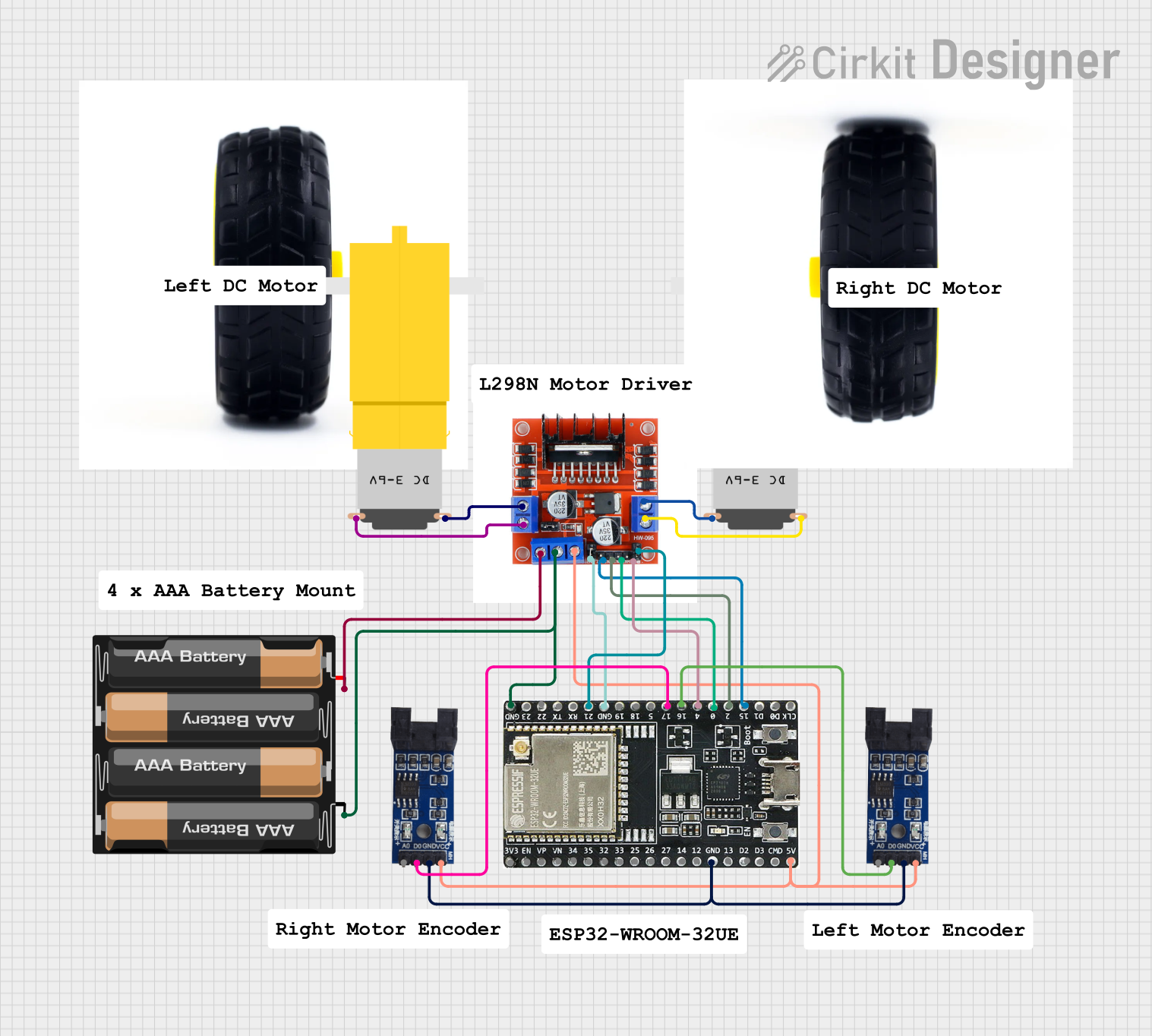

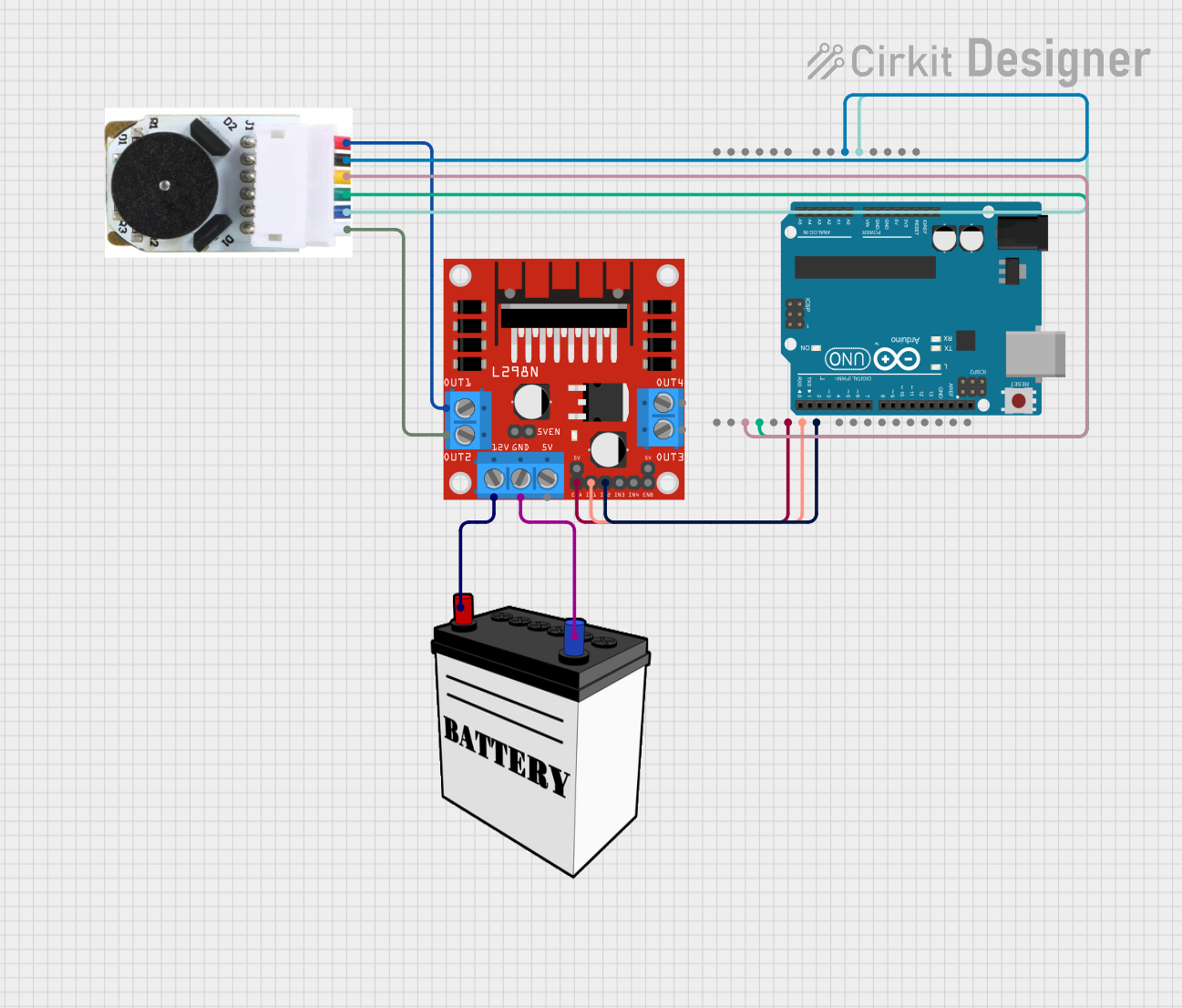

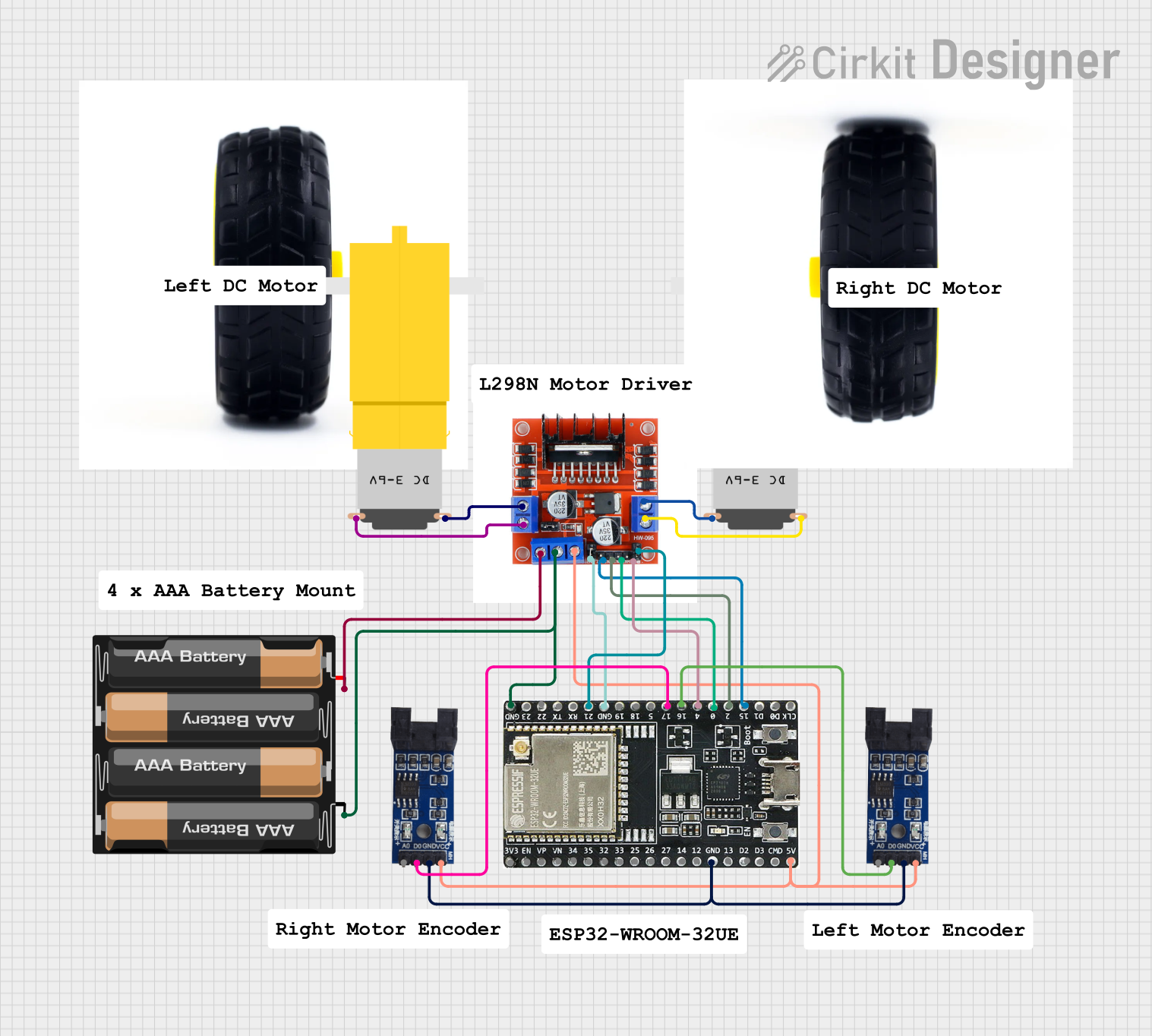

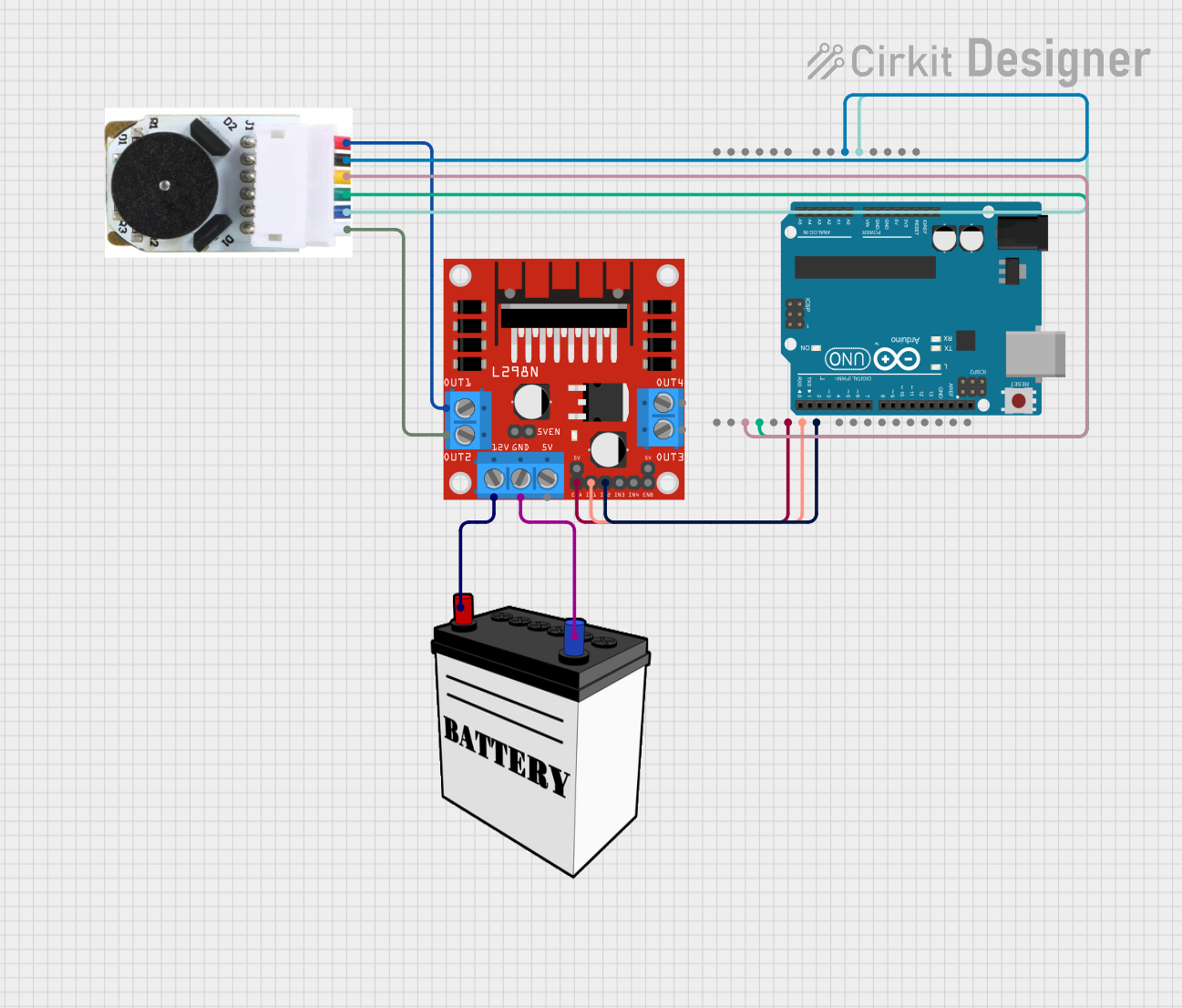

Explore Projects Built with MOTOR ENCODER

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerExplore Projects Built with MOTOR ENCODER

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit Designer

Open Project in Cirkit DesignerTechnical Specifications

Below are the general technical specifications for a typical motor encoder. Specific values may vary depending on the model and manufacturer.

Key Specifications

- Type: Incremental or Absolute Encoder

- Supply Voltage: 5V to 24V DC (varies by model)

- Output Signal: Quadrature (A, B) or Absolute Position

- Resolution: 100 to 10,000 pulses per revolution (PPR)

- Operating Temperature: -20°C to 85°C

- Maximum Rotational Speed: Up to 10,000 RPM

- Output Format: Digital (TTL or Open Collector)

Pin Configuration and Descriptions

The pinout of a motor encoder depends on its type and design. Below is a typical pin configuration for an incremental encoder with quadrature output.

| Pin | Name | Description |

|---|---|---|

| 1 | VCC | Power supply input (e.g., 5V or 12V DC). |

| 2 | GND | Ground connection. |

| 3 | A (Channel A) | Quadrature output signal A. Indicates position and direction of rotation. |

| 4 | B (Channel B) | Quadrature output signal B. Used in conjunction with Channel A for direction. |

| 5 | Z (Index) | Optional index pulse for absolute position reference (one pulse per revolution). |

For absolute encoders, additional pins may be present for communication protocols like SPI, I2C, or RS-485.

Usage Instructions

How to Use the Motor Encoder in a Circuit

- Power the Encoder: Connect the VCC pin to a regulated power supply (e.g., 5V or 12V) and the GND pin to the ground of your circuit.

- Connect Output Signals:

- For incremental encoders, connect the A and B output pins to the input pins of a microcontroller or motor driver.

- If using the Z (index) pin, connect it to an additional input pin for absolute position reference.

- Read the Signals: Use a microcontroller to read the quadrature signals (A and B) and calculate the motor's position and speed. The direction of rotation can be determined by the phase difference between A and B signals.

Important Considerations and Best Practices

- Debouncing: Use hardware or software debouncing to filter noise from the encoder signals.

- Shielded Cables: Use shielded cables for long-distance connections to reduce electromagnetic interference (EMI).

- Pull-Up Resistors: If the encoder outputs are open-collector, add pull-up resistors to the signal lines.

- Mounting: Ensure the encoder is securely mounted to the motor shaft to avoid misalignment or slippage.

- Power Supply: Use a stable and noise-free power supply to ensure reliable operation.

Example: Using a Motor Encoder with Arduino UNO

Below is an example of interfacing an incremental motor encoder with an Arduino UNO to measure position and direction.

// Motor Encoder Example with Arduino UNO

// Reads quadrature signals (A and B) to determine position and direction

#define ENCODER_PIN_A 2 // Connect Channel A to digital pin 2

#define ENCODER_PIN_B 3 // Connect Channel B to digital pin 3

volatile int position = 0; // Variable to store encoder position

volatile int direction = 0; // Variable to store rotation direction

void setup() {

pinMode(ENCODER_PIN_A, INPUT); // Set Channel A as input

pinMode(ENCODER_PIN_B, INPUT); // Set Channel B as input

// Attach interrupts to Channel A and B

attachInterrupt(digitalPinToInterrupt(ENCODER_PIN_A), readEncoder, CHANGE);

attachInterrupt(digitalPinToInterrupt(ENCODER_PIN_B), readEncoder, CHANGE);

Serial.begin(9600); // Initialize serial communication

}

void loop() {

// Print position and direction to the Serial Monitor

Serial.print("Position: ");

Serial.print(position);

Serial.print(" | Direction: ");

Serial.println(direction > 0 ? "Clockwise" : "Counterclockwise");

delay(100); // Delay for readability

}

void readEncoder() {

// Read the current state of Channel A and B

int stateA = digitalRead(ENCODER_PIN_A);

int stateB = digitalRead(ENCODER_PIN_B);

// Determine direction based on the state of A and B

if (stateA == stateB) {

position++; // Clockwise rotation

direction = 1;

} else {

position--; // Counterclockwise rotation

direction = -1;

}

}

Troubleshooting and FAQs

Common Issues and Solutions

No Output Signals:

- Check the power supply voltage and ensure proper connections to the VCC and GND pins.

- Verify that the encoder is properly mounted to the motor shaft.

Incorrect Position or Direction:

- Ensure the A and B channels are connected to the correct microcontroller pins.

- Check for loose or noisy connections and use shielded cables if necessary.

Signal Noise or Interference:

- Add pull-up resistors to the signal lines if the encoder uses open-collector outputs.

- Use capacitors or software filters to debounce noisy signals.

Encoder Slippage:

- Verify that the encoder is securely mounted to the motor shaft and aligned properly.

FAQs

Q: What is the difference between incremental and absolute encoders?

A: Incremental encoders provide relative position and speed information using quadrature signals, while absolute encoders provide the exact position of the motor shaft, even after power loss.

Q: Can I use a motor encoder with a stepper motor?

A: Yes, motor encoders can be used with stepper motors to provide feedback for closed-loop control, improving accuracy and reliability.

Q: How do I calculate the motor's speed using an encoder?

A: Measure the time between pulses on the A or B channel and use the encoder's resolution (PPR) to calculate the rotational speed in RPM.

Q: What is the purpose of the Z (index) signal?

A: The Z signal provides a single pulse per revolution, which can be used as a reference point for absolute positioning.